Академический Документы

Профессиональный Документы

Культура Документы

Advanced Metallization For New Holographic Image

Загружено:

CHANDER SHEKHAR JEENAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Advanced Metallization For New Holographic Image

Загружено:

CHANDER SHEKHAR JEENAАвторское право:

Доступные форматы

Technology

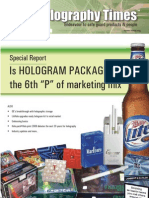

The Holography Times Vol. 8, Issue 23

Advanced metallization for new holographic image

by Professor Nadir A.G.Ahmed Idvac Ltd., Manchester, UK In collaboration with Giriraj Foils, India

dvac Ltd has signed a technology transfer agreement with Giriraj Foils, India to deliver a wide range of novel advanced metalized process know how based on Idvac Ltd. expertise in this ield. Idvac Ltd., Manchester, UK is a leading company in the development of advanced processes for holographic and packaging applications. Founded by Professor Nadir Ahmed in 2004. Giriraj Foils, was founded in 1993 by Mr Shobhit Arora and currently based at Vrindavan, India. It specializes in manufacturing a wide range of speciic coated ilms and foils to the security and packaging markets. Giriraj Foils has ISO 9001:2008 certiication. It is also a member of IHMA (International manufacturers Association) and a member of HOMAI (Hologram Manufactures Association of India).

This collaboration will provide customized solutions that are speciically designed and produced to meet individual customer demand for functional and decorative holograms.

Vacuum metalizing

Vacuum metalizing has been used for a long time to metalize plastic ilms with aluminium for packaging and standard holographic hot stamped foils. Vacuum metalizing is a batch process in which a substrate is coated with speciic material such as aluminium inside a vacuum chamber. For standard holographic applications aluminium is used to give high relectance on the embossed ilm to exhibit the striking interference colours of a hologram. However, the demand for new vacuum metalized functional coatings on holograms has resulted in the development of many products to ight counterfeiting and to meet the environmental challenge. As an example, metalized aluminium has high relectance and minimum transmission. The demand for semi-transparent coating that can be applied on security documents has resulted in the development of high refractive index (HRI) zinc sulphide or titanium oxide to give 40% relectance and about 60% transmission. Zinc sulphide is widely used now on embossed ilms for passports, driving licence, identity cards and other security document which requires semi-transparent hologram for protection against counterfeiting.

CORROSION PROTECTION OF CHROME ALLOY

100 90 80 Acid or Alkaline Solution

Total Corrosion, %

70 60 50 40 Protected Costing 30 20 Aluminium (Control) 10 Silicaon Aluminium 0 Acid Sweat Alkaline Sweat Cr Alloy PCT Al; Silice on AI or Cr Alloy

Disclaimer: This section is received from Giriraj Foils without any involvement of The Holography Times Team. www.homai.org

13

The Holography Times Vol. 8, Issue 23

Technology

Gold colour effect on metallised holographic lm with no inks or dyes

This is a vacuum metallisation process to convert silver metallised lm into golden colour without using inks, dyes or chemicals. Unique shade of gold colour can be applied on the top side of metallised lm. Signicant Features: Bright, Gold colour on embossed, plain metallised lms and metallised paper. Vacuum dry and environmentally friendly process since no chemicals such as inks or dyes are used. Lower production cost than gold colour produced by inks and dyes. It can be done at faster line speed. Also, it offers lower disposal costs. Can be used on moisture sensitive substrates including paper without

introducing extra moisture. It is used for holographic hot stamping foils or plain metallised lms for security and decorative packaging applications. Adhere securely to numerous kinds of reective surfaces. The hologram can contain a range of overt and covert security features. Unique gold shade which is difcult to reproduce by dyes or inks. Different unique gold shades can be applied on the top, back or both sides of aluminium metallised lms or papers. It is carried out inside a standard vacuum web Metalizer at average line speed of 200-300m/min depending on gold shade required.

Unique metalized products

The continuous demand for new holograms with special properties to ight counterfeiting and to have special environmental durability has lead to the development of advanced vacuum metallised coatings. Following this collaboration, Giriraj Foils, India, will provide a new range of customized solutions to meet individual customer demand. The new range of metalized products includes:

c.

d.

e. f.

g.

Chrome alloy

This is a vacuum metallization process to metalize embossed holographic ilms or plain ilms with Chrome Alloy. The bright Chrome Alloy metalized ilm is moisture durable and can be used as outdoor hologram for vehicle registration number plates, licence disc and other outdoor applications. It provides durability against salty humid environment. Chrome Alloy metalized product has the following signiicant features: a. More relective and brighter inish than pure chrome. b. Lower production cost than pure chrome since it can be done at faster line speed.

Durable against salty humid environment than standard metalized aluminium. It is used for hot stamping foils for use on vehicle registration plates. Adhere securely to numerous kinds of relective surfaces. The hologram can contain a range of overt and covert security features. Can help governments, vehicle registration organisations and transport organisations worldwide stay one step ahead of the counterfeiters and tax evaders.

Copper metallization

A copper metallized holographic ilm exhibits an aesthetically appealing copper lustre that cannot be produced by ink. There are two main reasons for the production of copper metallization as an alternative to aluminium. The irst is the bright lustre of copper, which is dificult to be replicated by using standard aluminium metallization with pigments or dyes, and the second is the de-metallization of copper, which is somewhat harder than the de-metalizing of aluminium, In the de-metallization process the metal is partially removed by

www.homai.org

14

Technology

The Holography Times Vol. 8, Issue 23

Copper Metallization

Colour Shift

chemical or physical processes to print text, logos, or patterns within the metalized side. Demetalizing add another feature to the security hologram to ight counterfeiting. The other added advantage is the electrical conductivity of copper, which could be used for other electrical or electronic applications such as RFID.

Gold colour effect

This gold colour effect can be produced on metalized surface without using inks or dyes. This is a vacuum metallization process to convert the silvery metalized ilm into golden colour without using inks or pigments. Unique shade of gold colours can be produced. This is an environmentally friendly process since no wet chemicals are used. This offer lowest disposal costs. This process can be used on moisture sensitive substrates such as paper without introducing extra moisture. The unique gold colour can be used for holographic hot stamping foils or plain metalized ilms for security and decorative packaging applications.

grating structure or embossing. The inal inish is highly bright with aesthetically appealing lustre and can be used for hot stamping foil or lamination. The colour shift effect can be printed on ilms to produce text, logos, patterns and other textured features with quick colour switching from green to red, or red to green. This effect can contain a range of overt and covert security features. It is produced inside a standard vacuum web Metalizer. The collaboration between Idvac Ltd., UK and Giriraj Foils, India, will introduce more advanced metalized products into the holographic and functional markets to meet present and future demands. Professor Ahmed commented that the two companies have the state of art technologies for applying high quality advanced metalized products into foils and labels to provide unique security products with special environmental durability and functional applications. We look forward to working with Giriraj Foils to develop and launch other advanced products that incorporates covert and overt features soon.

Colour shift

The colour shift effect is produced on ilms with quick colour switch from green to red without using

www.homai.org

15

Вам также может понравиться

- The Holography Times, Vol 4, Issue 13Документ20 страницThe Holography Times, Vol 4, Issue 13CHANDER SHEKHAR JEENAОценок пока нет

- Free Ebook On ResinДокумент279 страницFree Ebook On ResinSHRIKANT PRABHAKAR ATHAVALEОценок пока нет

- The Holography Times Issue 22Документ20 страницThe Holography Times Issue 22CHANDER SHEKHAR JEENAОценок пока нет

- DR Fixit Epoxy Floor Screed 90 1Документ4 страницыDR Fixit Epoxy Floor Screed 90 1amit sharmaОценок пока нет

- Hard Rock Tunnelling MethodsДокумент20 страницHard Rock Tunnelling Methodskiranism0% (1)

- By Shrikant Athavale SPA Technical Advisor Pune Cell: +91 7588288204Документ80 страницBy Shrikant Athavale SPA Technical Advisor Pune Cell: +91 7588288204Avi Yusri100% (1)

- Introduction To Metal EtchingДокумент2 страницыIntroduction To Metal EtchingfoobiedotОценок пока нет

- Paints Pigment Handout Class PDFДокумент16 страницPaints Pigment Handout Class PDFAidonОценок пока нет

- Digital Printmaking: Pixels, Dots, and Ink JetsДокумент9 страницDigital Printmaking: Pixels, Dots, and Ink JetssoujanaОценок пока нет

- Electroplating Phosphating Powder Coating and Metal Finishing PDFДокумент149 страницElectroplating Phosphating Powder Coating and Metal Finishing PDFmiguelin9169100% (2)

- Harmonica IntroДокумент5 страницHarmonica Introapi-26593142100% (1)

- The Holography TimesДокумент16 страницThe Holography TimestiuwangОценок пока нет

- The Holography TimesДокумент16 страницThe Holography TimestiuwangОценок пока нет

- Coded Holograms Keeping The Supply Chain SecureДокумент2 страницыCoded Holograms Keeping The Supply Chain SecureCHANDER SHEKHAR JEENAОценок пока нет

- Identity Document Challenges and SolutionsДокумент4 страницыIdentity Document Challenges and SolutionsCHANDER SHEKHAR JEENAОценок пока нет

- Making Holograms Uniting Art and Science.: by Pearl JohnДокумент18 страницMaking Holograms Uniting Art and Science.: by Pearl Johnepuchulu100% (1)

- AI Unlocks Passwords in Minutes - Cybersecurity's New ChallengeДокумент4 страницыAI Unlocks Passwords in Minutes - Cybersecurity's New ChallengeironОценок пока нет

- Dolly Preparation For Pull Out TestДокумент6 страницDolly Preparation For Pull Out TestLaughlikesiao HeheОценок пока нет

- Roll To Roll UV Embossing TechnologyДокумент3 страницыRoll To Roll UV Embossing TechnologyCHANDER SHEKHAR JEENAОценок пока нет

- Seminar Report Sem 4Документ15 страницSeminar Report Sem 4Adith KSОценок пока нет

- Thin Film Technology An Introduction To DepositionДокумент7 страницThin Film Technology An Introduction To DepositionGeetha Sokkian RammanoharОценок пока нет

- The Holography Times, Vol 4, Issue 11Документ20 страницThe Holography Times, Vol 4, Issue 11CHANDER SHEKHAR JEENA100% (1)

- Anti Corrosive PaintsДокумент3 страницыAnti Corrosive PaintsMallinatha PNОценок пока нет

- Introduction To Coil CoatingДокумент10 страницIntroduction To Coil CoatingcuongdcОценок пока нет

- How To Decide Between Anodizing Painting & PVDF CoatingДокумент5 страницHow To Decide Between Anodizing Painting & PVDF CoatingNaveen Karki100% (1)

- Basic DWDM Components.Документ16 страницBasic DWDM Components.Pradeep Kumar SahuОценок пока нет

- 2017-Process Tracing in Social SciencesДокумент28 страниц2017-Process Tracing in Social SciencesTudor CherhatОценок пока нет

- Recruitment of Officers in Grade B' (General) - DR - By-2019Документ2 страницыRecruitment of Officers in Grade B' (General) - DR - By-2019Shalom NaikОценок пока нет

- Cure Kinetics of Epoxy-Based Nanocomposites Analyzed by Avrami Theory of Phase ChangeДокумент9 страницCure Kinetics of Epoxy-Based Nanocomposites Analyzed by Avrami Theory of Phase ChangetutuwhyОценок пока нет

- Poly (Urethane) SДокумент45 страницPoly (Urethane) SCarlotta C.Оценок пока нет

- HolographyДокумент17 страницHolographymanoj kumar rout100% (2)

- UrethaneДокумент14 страницUrethaneMuhammad Yazid TharmiziОценок пока нет

- Etching and Lithography in MicrofabricationДокумент8 страницEtching and Lithography in MicrofabricationWhizzWrОценок пока нет

- 7D Holographic Technology: MR - Rushi R. Durge, MR - Hanumant P. JagtapДокумент4 страницы7D Holographic Technology: MR - Rushi R. Durge, MR - Hanumant P. JagtapOoОценок пока нет

- Physical Vapor DepositionДокумент20 страницPhysical Vapor DepositionPraveen KumarОценок пока нет

- Making PaintДокумент11 страницMaking PaintFeri DewaОценок пока нет

- Paint Pigment Solvent Coating Emulsion Paint Additives and FormulationsДокумент9 страницPaint Pigment Solvent Coating Emulsion Paint Additives and FormulationschayanunОценок пока нет

- Exploration of Reflection Holograms and Their Fringes With A Scanning Electron MicroscopeДокумент10 страницExploration of Reflection Holograms and Their Fringes With A Scanning Electron MicroscopePhilip BrocoumОценок пока нет

- Hans Bjelkhagen New Recording Materials For HolographyДокумент12 страницHans Bjelkhagen New Recording Materials For HolographyAABDAHMEDОценок пока нет

- Principle of HolographyДокумент36 страницPrinciple of HolographySumanth BodduОценок пока нет

- Hologram TechnologyДокумент4 страницыHologram TechnologyZez SamuelОценок пока нет

- Epoxy ResinsДокумент121 страницаEpoxy ResinsKarla CastroОценок пока нет

- Project Brazen - ITO - Nov. 27Документ474 страницыProject Brazen - ITO - Nov. 27Toronto Star100% (1)

- What Is A HologramДокумент4 страницыWhat Is A HologramJezibel MendozaОценок пока нет

- Holography QuestionsДокумент1 страницаHolography QuestionsredОценок пока нет

- Categories of HologramsДокумент2 страницыCategories of HologramsChanОценок пока нет

- Holography HistoryДокумент27 страницHolography HistoryasduraiОценок пока нет

- Child Protection Standards in Ontario 2007Документ86 страницChild Protection Standards in Ontario 2007rob mitchellОценок пока нет

- Physic Holograms PaperДокумент8 страницPhysic Holograms PaperWesley ShippОценок пока нет

- HOLGAGONДокумент8 страницHOLGAGONRisky HidayatОценок пока нет

- Effects of Epoxy Resin and Hardener Type OnДокумент135 страницEffects of Epoxy Resin and Hardener Type OnWALTER KLISSMANОценок пока нет

- SigmarineДокумент4 страницыSigmarineHaresh BhavnaniОценок пока нет

- NRDC Smart CoatingsДокумент2 страницыNRDC Smart CoatingsashishОценок пока нет

- Pub 2010-04 Elements33 WH eДокумент7 страницPub 2010-04 Elements33 WH eSariyyaHeydarovaОценок пока нет

- 1586858195metallization ProcessДокумент2 страницы1586858195metallization ProcessNoah Oluwatoyin AderiyikeОценок пока нет

- Diamant Metal FillerДокумент16 страницDiamant Metal Fillersusu222000Оценок пока нет

- Aliphatic Acrylic Polyurethane Finish CoatДокумент4 страницыAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueОценок пока нет

- FestoДокумент144 страницыFestoDanielОценок пока нет

- EPA Chrom HazardsДокумент5 страницEPA Chrom HazardsLuis Paz Soldán GОценок пока нет

- ArcelorMittal Automotive Product Offer enДокумент131 страницаArcelorMittal Automotive Product Offer enqshaathОценок пока нет

- Grillo Wire BrochureДокумент8 страницGrillo Wire BrochuregersomОценок пока нет

- Colour Coated SteelДокумент6 страницColour Coated SteelakmullickОценок пока нет

- Brochure-Coil-Industry 150 Eng FinalДокумент16 страницBrochure-Coil-Industry 150 Eng Finaltrường phạmОценок пока нет

- Nanostructured Zinc Nickel Coating System For Oil and Gas Industries Designed To Replace Cadmium, PTFE & Ceramic-Metallic CoatingsДокумент4 страницыNanostructured Zinc Nickel Coating System For Oil and Gas Industries Designed To Replace Cadmium, PTFE & Ceramic-Metallic CoatingsPR.comОценок пока нет

- Leaflet Cabinet & Casing ProtectionДокумент4 страницыLeaflet Cabinet & Casing ProtectionMuhammad Javed BhattiОценок пока нет

- Prefabrication Primer Range Prefabrication Primer Range: A PPG BrandДокумент8 страницPrefabrication Primer Range Prefabrication Primer Range: A PPG BrandengindmecОценок пока нет

- Write Up AdditionalДокумент3 страницыWrite Up AdditionalMelody Villa Galano-DuldulaoОценок пока нет

- Keep Your Facility Fully Operational.: Chemetall Maintenance ProductsДокумент8 страницKeep Your Facility Fully Operational.: Chemetall Maintenance Productseggy mushadiОценок пока нет

- Keep Your Facility Fully Operational.: Chemetall Maintenance ProductsДокумент8 страницKeep Your Facility Fully Operational.: Chemetall Maintenance ProductsKumar RamanОценок пока нет

- The Holography Times, Issue 23Документ20 страницThe Holography Times, Issue 23CHANDER SHEKHAR JEENAОценок пока нет

- Combating Counterfeiting Trade Association Become ProactiveДокумент6 страницCombating Counterfeiting Trade Association Become ProactiveCHANDER SHEKHAR JEENAОценок пока нет

- Holographic Excise Adhesive Label, Securing Tax Revenue, Protecting Consumer and Curbing Illicit LiquorДокумент6 страницHolographic Excise Adhesive Label, Securing Tax Revenue, Protecting Consumer and Curbing Illicit LiquorCHANDER SHEKHAR JEENAОценок пока нет

- Fight Against Counterfeiting: World Fastest Growing IndustryДокумент5 страницFight Against Counterfeiting: World Fastest Growing IndustryCHANDER SHEKHAR JEENAОценок пока нет

- The Holography Times, Vol 3, Issue 7Документ16 страницThe Holography Times, Vol 3, Issue 7CHANDER SHEKHAR JEENAОценок пока нет

- Blog As Tools of Public RelationДокумент42 страницыBlog As Tools of Public RelationCHANDER SHEKHAR JEENAОценок пока нет

- Hologram Can Uproot Tobacco CounterfeitingДокумент4 страницыHologram Can Uproot Tobacco CounterfeitingCHANDER SHEKHAR JEENAОценок пока нет

- MMC Production PortfolioДокумент81 страницаMMC Production PortfolioCHANDER SHEKHAR JEENA67% (6)

- Project Report in Public RelationДокумент35 страницProject Report in Public RelationCHANDER SHEKHAR JEENA100% (1)

- Vibration Absorbers: Scan This QR CodeДокумент4 страницыVibration Absorbers: Scan This QR CodeMohamed RaafatОценок пока нет

- Lattner HRT Power Plus Operations ManualДокумент42 страницыLattner HRT Power Plus Operations Manualsabir_munnaОценок пока нет

- Alburg-Caldwell Manor 1784-1826 Draft by Fay YoungДокумент3 страницыAlburg-Caldwell Manor 1784-1826 Draft by Fay YoungNancy Cunningham100% (1)

- Model-Checking: A Tutorial Introduction: January 1999Документ26 страницModel-Checking: A Tutorial Introduction: January 1999Quý Trương QuangОценок пока нет

- Congenital Abnormalities of The Female Reproductive TractДокумент14 страницCongenital Abnormalities of The Female Reproductive TractMary SheshiraОценок пока нет

- 1. Mạch điện đồng hồ santafe 2014-2018Документ5 страниц1. Mạch điện đồng hồ santafe 2014-2018PRO ECUОценок пока нет

- Paper 5Документ4 страницыPaper 5hbyhОценок пока нет

- User Guide: Echolife Hg520C Home GatewayДокумент25 страницUser Guide: Echolife Hg520C Home Gatewayluis PavilaОценок пока нет

- The Little MermaidДокумент6 страницThe Little MermaidBobbie LittleОценок пока нет

- HandwritingДокумент4 страницыHandwritingManujОценок пока нет

- Ekoplastik PPR Catalogue of ProductsДокумент36 страницEkoplastik PPR Catalogue of ProductsFlorin Maria ChirilaОценок пока нет

- Ingles - 1 - Bach - Modulo - 2 (20 - 21)Документ32 страницыIngles - 1 - Bach - Modulo - 2 (20 - 21)John Alex Almeida50% (2)

- Fractal Approach in RoboticsДокумент20 страницFractal Approach in RoboticsSmileyОценок пока нет

- Phyto Pharmacy: Current Concepts and GMP NormsДокумент22 страницыPhyto Pharmacy: Current Concepts and GMP NormsSunitha Katta100% (1)

- IHRM Midterm ASHUVANI 201903040007Документ9 страницIHRM Midterm ASHUVANI 201903040007ashu vaniОценок пока нет

- The Sphere Circumscribing A TetrahedronДокумент4 страницыThe Sphere Circumscribing A TetrahedronRaghuveer ChandraОценок пока нет

- Lecture # 3 Introduction To JqueryДокумент88 страницLecture # 3 Introduction To JqueryDanial AhmadОценок пока нет

- Electronic Waste Essay LessonДокумент7 страницElectronic Waste Essay LessonAna Carnero BuenoОценок пока нет

- Lagundi/Dangla (Vitex Negundo)Документ2 страницыLagundi/Dangla (Vitex Negundo)Derrick Yson (Mangga Han)Оценок пока нет

- BasicsДокумент1 страницаBasicsRishi Raj100% (1)

- Stock Trak AssignmentДокумент4 страницыStock Trak AssignmentPat ParisiОценок пока нет

- Shib Mandir, PO-Kadamtala Dist-Darjeeling WB - 734011 JC 18, 3RD Floor, Sector - III Salt Lake City, Kolkata 700098Документ7 страницShib Mandir, PO-Kadamtala Dist-Darjeeling WB - 734011 JC 18, 3RD Floor, Sector - III Salt Lake City, Kolkata 700098Rohit DhanukaОценок пока нет

- COLUMNA A. Erosion B. Ecosystem C. Conservation D - .DДокумент1 страницаCOLUMNA A. Erosion B. Ecosystem C. Conservation D - .DkerinsaОценок пока нет

- SFA TRAINING MODULE Week 1Документ14 страницSFA TRAINING MODULE Week 1Ivan Perez100% (1)

- Electrochemistry DPP-1Документ2 страницыElectrochemistry DPP-1tarunОценок пока нет