Академический Документы

Профессиональный Документы

Культура Документы

Sae J 343

Загружено:

hartala_20000 оценок0% нашли этот документ полезным (0 голосов)

533 просмотров10 страницe

Оригинальное название

SAE J 343

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документe

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

533 просмотров10 страницSae J 343

Загружено:

hartala_2000e

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 10

SAE J¥343 95 mm 2943725 0547958 2b? Ml

GRAM EF Ihe Engineering Society

SABISES. _ sunrace

Sara

Seana Warnme ce = VEHICLE

STANDARD

‘Submitted for recognition as an American National Standard

Issued 1968-06

Revised 1995-11

‘Superseding 1343 JUNSS

(R) TEST AND TEST PROCEDURES FOR SAE 100R

SERIES HYDRAULIC HOSE AND HOSE ASSEMBLIES

“This document is technically equivalent to ISO 6605 except as noted inthe Foreword.

Foreword—SAE J243 has been revised to be technically equivalent to ISO 6605, except that adkitional tests in

paragraphs 4.9 to 4.14 were included.

1. Scope—This SAE Standard gives methods for testing and evaluating performance of the SAE 100R series of

rnydraulfe hose and hose assemblies (hose and attached end fitings) used in hydraulic fluid power systems.

Speci tests and performance criteria for evaluating hose assemblies used in hydraulic service are in

accordance with the requirements for hose in the respective specifications of SAE J517.

‘This document further establishes a uniform means of testing and evaluating performance of hydraulic hose

assemblies.

2. References

2.1 Applicable Documents—The following publications form a part of thie specication to the extent specified

herein. The latest issue of SAE publications shall apply.

2.1.1 SAE PusticaTions—Available from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

SAE J517—Hydraulic Hose

212 ASTM PusticaTions—Avallable from ASTM, 100 Bart Harbor Drive, West Conshohocken, PA 19428-2959.

ASTM D 380—Standard Methods of Testing Rubber Hose

2.1.3 ISO PusLicATions—Available from ANSI, 11 West 42nd Street, New York, NY 10036-8002.

180 3448—Industrial liquid lubricants—ISO viscosity classification

1SO 6605—Hydraulic fluid power—tlose assemblice—Method of test

The Techical Gundaros board Puls pride that “Tha pantie publched by SAE te aavance the state ol techrical anc engineering

ee Tee The use of tus report sendy voluntary, ands eppesbaty and sutabiy for ey parker use, inci ay Patent

‘itepement ening therefrom tho sole responsi ofthe ser”

‘SAE reviews sac technical por atleast every fv year a which in ay be aime revised, or cancated, SAE vis you ween

‘omments ae supgestons

copyright 1988 Sciy of tomate Engine, ne.

‘nih resend, Pemtedin USA.

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

SAE U#343 95 MM 7943725 0547959 173 mw oe

SAE 343 Revised NOVOS

43. Test Procedures—The test procedures described in the current issue of ASTM D 380 shall be followed.

However, in cases of contlict between the ASTM specifications and those described as follows, the latter shall

take precedence,

4, Standard Tests

WARNING—Water or another liquid suitable for the hose under test shall be used as the test medium.

‘The Use of air and other gaseous materials as testing media should be avoided because of

the risk to operators. in special cases where such media are required for the tests, strict

‘safety measures are imperative. Furthermore, it is stressed that when a liquid is used as the

test medium, it is essential that all air is expelled from the test piece because af the risk of

Injury to the operator due to the sudden expansion of trapped air released when the hose

bursts.

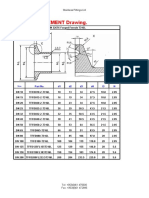

4.1 Dimensional Check Test—The hose shall be i

epplicable specification.

pected for conformity to all dimensions tabulated in the

Determine finished outside diameters and reinforcement diameters, where required, by calculation from

‘measurement of the respective circumference.

Asan alterative, use a flexible tape graduated to read the diameter directly.

Measure the inside diameter by means of a suitable expanding ball or telescoping gage.

Measure concentricity over both the reinforcement and the finished outside diameters using either a dial

indicator gage or a micrometer.

Found the fect of the measuring instrument to conform to the inside diameter of the hose.

Take readings at 90 degree intervals around the nose

NoTE— Acceptability is based on the tolal variation between the high and the low readings.

Take inside and outside diameter measurements at a minimum of 25 mm from the hose ends and concentrcity

‘Measurements at a minimum of 13 mm from the hose ends.

42 Proof Test—Test the hose assemblies hydrostatically to the specified proof pressure for a period of not less

than 20 ¢ nor more than €0 e.

There shall bo no indication of failure or leakage.

4.3 Change in Length Teet—Conduct measurements for the determination of elongation or contraction on a

Previously untested, unaged hose assembly having at least 600 mm length of free hose between hose fittings.

Attach the hose assembly to the pressure source in an unrestricted straight position. if the hose is not straight

due to its natural curvature, it may be fastened laterally to achieve a straight position. Pressurize to the

specified operating pressure for a period of 30 s, then release the pressure.

Place accurate reference marks 500 mm apart on the outer cover of the hose, midway between fitings, after

allowing the hose assembly ta restabilize for a poriod of 20 0 folowing pressure release.

of

Cong by the SAE etrtont

Mn Dee 08 OB-T3:53 2010

SAE J#343 95 MM 7943725 0547960 915 ml saan

Repressurize the hose assembly to the specified operating pressure for a period of 30 s.

Measure the final length while the hose is pressurized. The final length is the distance between reference

marks while the hose is pressurized.

‘Complete the determination of the change in length using Equation 1:

where:

fg Is the distance between the reference marks when the hose was not pressurized following the initial

pressurization;

4; is the distance between the reference marks under pressure;

Aé is the percentage change in length, which will be positive (+) in the case of an increase in length and

negative (-) in the case of a decrease in length.

Burst Test—Subject unaged hose assemblies, on which the end fitings have been attached for net more than

30 days, to a hydrostatic pressure, increased at a constant rate s0 as to attain the specified minimum burst

pressure within a period of not less than 15s nor more than 60 6.

Reject hose assemblies showing leakage, hose burst or indication of failure below the specified minimum burst

pressure.

NoTe—This is a destructive test. Assemblies which have been subjected to this test shalll be destroyed.

Cold Bend Test—Subject hose assemblies to the specified temperature in a straight position for 24 h.

Then, while stil at the specified temperature, the samples shall be evenly and uniformly bent once over a

mandrel having a diameter equel to twice the spocified minimum bend radius. Bending shall be accomplished

within a period of not less than 8 s nor more than 12s.

In the case of hose sizes up to and including 22 mm nominal inside diameter, bend them through 180 degrees

‘over the mandrel; in the ease of hove sizes larger than 22 mm nominal inside diameter. bend them through

90 degrees over the mandrel.

‘After bending, allow the sample to warm to room temperature, visually examine it for cover cracks and subject

ftto the proof test. There shall be no cover cracks or leakage. (In lieu of the bending test, hoses larger than 22

mm nominal inside diameter may be considered acceptable if samples of tube and cover pass the Low

Temperature Test on Tubs and Cover cf ASTM D 380.)

Reject any samples with visible cracks or leakage.

Note—This ic a destructive test. Assemblies which have been subjected to this test shall be destroyed.

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

th,

SAE J*343 95 MM 79543725 054796) 85] Ml ms

46 Impulse Test—Test four unaged hose assemblies with end fitings which have been attached for not more

than 20 days. Where the individual standard requires, also lest aged hose assembles.

Apply a puleating presoure intemally to the hose assemblies al a rale between 0.5 and 1.3 Hz; record the

frequency used. The pressure cycle shall fall within the shaded area of Figure 1 and conform as closely as

Possible to the curve shown.

‘The nominal rate of pressure rice chall be equal to that shown in Equation 2:

R=f(t0p-h)

te of pressure rise in MPa/e

frequency in Hz

1D = nominal impulse test pressure in MPa

MPa

The actual rate of pressure rise shall be determined as shown on Figure 1, and shall be within a tolerance of

£10% of the calculatad nominal value.

Select a test fluid which complies with the roquiremonte of ISO VG 46 4 4.6 at 40 °C per ISO 3449, and

circulate it at a rate sufficient to maintain a uniform fluid temperature within the hose assemblies. Other fluids

may be used as agreed upon between the customer and the manufacturer.

Calculate the free (exposed) length of hose under test, shown on Figure 2, as follows:

'&, Hose sizes up to and including 22 mm nominal inside diameter (see Equation 3):

180 degrees hend free length = x r+ 2d

b. Hose sizes larger than 22 mm nominal inside diameter (see Equation 4):

‘90 degrees bend free length = : reed

where:

F = minimum bend radius

d = hose outside diameter

Connect the test pieces to the apparatus. The test pieces shall be installed according to Figure 2. Test piecas

of hose of nominal inside diameter up to and including 22 mm shall be bent through 180 degrees and hoses of

‘Rominal inside diameter larger than 22 mm shall be bent through 90 degrees.

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

SAE Jx343 95 MM 7943725 O5479b2 798 Ml

‘SAE 343 Revised NOV9S

a

Test Pressure

85% Test Pressure

Tent Proseuresse

Secant Pressure

Rise Rote

Sto 55K

of the Gyele

‘One Impuise cycle

NOTES: 1. Secant pressure rise is the straight line drawn through two points on the pressure rise curve; one

point at 15% of the test pressure and the other at 85% of the test pressure

2. Point’0'is the intersection of the secant pressure rise with 0 pressure.

3. Pressure rise rate is the slope of the secant pressure rise expressed In MPa/s.

4. Cycle rate shall be uniform at 0.5 to 1.3 Hz.

5. The nominal rate of pressure rise shall be equal to:

R=f(10p-k)

where: R= rate of pressure nse in MPa/s

f= frequency in Hz

p =nominal impulse test pressure In MPa

k =5MPa

FIGURE 1_PRESSURE-IMPULSE CYCLE

METHOD OF DETERMINATION OF RATE OF PRESSURE RISE IN IMPULSE TEST

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

SAF Jx343 95 MM 7943725 OS47963 b24

‘SAE J343 Revised NOV95

Minimum bend

d Hose outside

Hose free length = r+ 2d

+ +

ro (2r + 4 )tR% 4

r= Minimum bend radius

d= Hose outside diameter

Hows tos eng = Br 4 2

FIGURE 2—TEST SPECIMEN FOR PRESSURE IMPULSE TEST

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

SAE Ue343 95 MM 7943725 0547964 SO

SAE .1343 Revised NOVOS

Test the hose at the impulse test pressure indicated in the individual specification, The test fluid shall be

circulated through the assemblies at the specified temperature with a tolerance of +3 °C. Cooling or heating of

the test chamber shall not be permitted, except when individual standards require testing with synthetic base

test fluids at a temperature higher than 150 °C. When euch higher temperatures are required, the impulee test

fluid need net be circulated if both the fluid and the assemblies are extemally heated in the test chamber, at the

‘specified temporature with a tolerance of a5 °C.

Determine the duration of the impulse test in total number of cycles by the individual standard for the hose

assemblies. Where aged samples are required, refer to the individual standards.

Itis recommended the test fluid be changed frequently to prevent breakdown.

Note—This is a destructive test. Assemblies which have been subjected to this test shall be destroyed.

Leakage Test—Subject unaged hose assemblies, on which the end fittings have been attached for not more

than 30 days, to a hydrostatic pressure of 70% of the specified minimum burst prossure for a period of botwoen

5.0 to 5.5 min.

Reduce the fluid pressure to 0 MPa.

Re-apply the 70% of minimum burst hydrostatic pressure for another 5.0 to 5.5 min period,

Reject assemblies showing leakage or failure.

NoTe—This is a destructive test. Assemblies which have been subjected to this test shail be destroyed.

48 Visual Examination of Product—All bulk hose shall be visually inspected to see that the hose identification

has been properly applied and all assemblies shail be inspected to determine that the correct fittings are

propery installed.

49 Oil Resistance Test—After 70 h immersion in ASTM Emergency Standard Practice IRM903 oil at the

designated temperature. the volume change of specimens taken from the hose inner tube and cover shall be

within the specified limits.

4.10 Ozone Resistance Test—Hydraulic hose shall be tested for resistance of the cover compound to ozone in

accordance with the latest issue of ASTM D 380, except that the mandrel shall be a diameter twice the

minimum bend radius specified in the individual hose standard, and the cover shall be examined at the

completion of the test under 7X magnification.

4.11 Electrical Conductivity Test (for thermoplastic hose only}—Hose assemblies having a free length of

152 mm + 13 mm without fluid and capped to prevent entry of moisture shall be exposed to a minimum of 85%

relative humidity at 24 °C + 3 °C for a period of 168 h. Surface moisture shall be removed prior to testing.

Conditioned assemblies shall have one end fiting attached to the lead from a source of 60 Hz sinusoidal,

87.5 kV (rms) electricity. This lead shall be suspended by dry fabric strings so that the hose hangs free, at

least 600 mm from any extraneous objects. The lower end of the hose shall be connected to ground through a

1000 to 1 000 000 © resistor, keeping the resistor near the end of the hose. suitable AC voltmeter shall be

‘connected across the resistor, using a fully shielded cable with the shielding well grounded. Thirty-seven and

one-half KV shall be applied to the specimen for § min and a current reading taken. This current shall not

exceed the value specified.

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

SAE J#343 95 MM 7943725 OS479bS 477 Mi =

‘SAE 343 Revised NOV9S

4.12 Electrical Conductivity Test (PTFE hose only}—Test specimen shall be a 330 mm + 10 mm cut length of

hose with fitting attached to one end and the reinforcing braid flared away trom the PTFE tube on the opposite

‘end to prevent contact with the free end of the tube. The inner surface of the tube shall be cleaned, first with

naphtha dry cleaning tiuid or Stoddard solvent, and then with isopropyl alcohol to remove surtace

‘contamination, followed by thorough drying at room temperature,

Relative humidity shall be kept below 70% and room temperature between 16 °C and 32°C.

The specimen shall be mounted in a vertical position as shown in Figure 3. The adapter at the base is simply a

‘convenient means of assuring proper electrical contact ita swivel female fiting is chosen, and may be omitted

if a male fiting is used. In either case, the electrode must be insulated from ground.

conoveror

FLARE RAIO(S)

NONMETTALIC RINGS

TuRe

nose Baio

FIrTINg Boor

FITTING nur

AaPTeR

7 (ansuiaTE evecragoe

ROW GROUND)

FIGURE 3 CONDUCTIVITY TEST DIAGRAM

‘A moreury or salt water solution electrode shall be provided at the upper end as shown, by inserting a

Nonmetallic plug with an O-ring seal to a distance of 75 mm from the end of the tubing, thus providing an

average test length of 255 mm. Mercury or salt water solution shall then be added to a level 25 mm above the

plug. Any suitable conductor to this electrode may be used, including a threaded end attached to the plug if so

desired. Concentration of salt water, if used, shall be 450 9 NaCl per iter of HaO

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

SAE J#343 95 MM 2943725 OS47%bb 333 Ml

‘SAE 343 Revised NOV95

1000 V DC shall be applied between the upper electrode and the lower electrode (adapter or male fitting hex).

‘The current shall be measured with an instrument with a sensitivity of at least 1 wA (1 X 10-6 A).

4.13 Resistance to Vacuum Test—The hose shall not blister nor show any other indication of failure when

subjected to the specified vacuum for a period of 5 min. Where practicable, one end of the hose shall be

‘equipped with a transparent cap and electric light to permit visual examination for failure. Where the length or

size of the hose precludes visual examination, failure shall be determined by inability to pass through the hose

a ball or cylinder 6.5 mm less in diameter than the bore of hoses of 12.5 mm nominal inside diameter and

larger. For hoses under 12.5 mm nominal inside diameter, a ball or cylinder 3.0 mm smaller in diameter than

the bore shall be used.

4.14 Volumetric Expansion Test—Volumetric expansion tests shall be run in accordance with the current issue

of ASTM D 380.

5. Notes

5.1. Marginal Indicia—The (RA) is for the convenience of the user in locating areas where technical revisions have

been made to the previous issue of the report. If the symbol is next to the report tile, it indicates a complete

revision of the report

PREPARED BY THE SAE FLUID CONDUCTORS AND CONNECTORS

TECHNICAL COMMITTEE SC2—HYDRAULIC HOSE AND HOSE FITTINGS

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

SAF #343 95 MM 2943725 OS4?9b? 277 Ml .

+1943 NOVO5

Rationale—Presently SAE Standard J343, ISO 1402, ISO 6605, and ISO 6803 contain tests for hydraulic hoses

and hose assemblies. At a recent ISO/TC45/TC131 joint working group meeting the three ISO Standards were

reviewed for content and mutual standardization. It has been suggested that SAE Standard J343 be rewritten

to be technically equivalent to ISO/DIS 6605, where applicable.

Relationship of SAE Standard to ISO Standard—This document is technically equivalent to ISO/DIS 6605

except that additional tests in paragraphs 4.9 to 4.14 were included.

Application—This SAE Standard is intended to establish uniform methods for the testing and performance

evaluation of the SAE 100R series of hydraulic hose and hose assemblies. The specific tests and performance

criteria applicable to each variety of hose and/or assemblies made therefrom are set forth in the respective

specifications of SAE J517.

Reference Section

SAE J517—Hydraulic Hose

‘ASTM D 380—Standard Methods of Testing Rubber Hose

ASTM D 518—Test Method for Rubber Deterioration—Surface Cracking

‘ASTM D 622—Methods of Testing Rubber Hose for Automotive Air and Vacuum Brake System

ASTMD 1149—Test Method for Rubber Deterioration Surface Ozone Cracking in a Chamber (Flat

Specimens)

1SO 3448—Industrial liquid lubricants—ISO viscosity classification

1SO 6605—Hydraulic fluid power—Hose assemblies—Method of test

Developed by the SAE Fluid Conductors and Connectors Technical Committee SC2—Hydraulic Hose and

Hose Fittings:

‘Sponsored by the SAE Fluid Conductors and Connectors Technical Committee

Copyright by the SE kta

Mn Dee 08 OB-T3:53 2010

Вам также может понравиться

- Iso 6605Документ18 страницIso 6605Fabio StuiОценок пока нет

- Iso 3601 1 2008 en FR PDFДокумент11 страницIso 3601 1 2008 en FR PDFOscar Morello0% (1)

- Sae J518 1993 PDFДокумент14 страницSae J518 1993 PDFdinesh panchal67% (3)

- DTW 1239Документ16 страницDTW 1239GANESH GОценок пока нет

- Iso 19879-2005Документ27 страницIso 19879-2005Márcio Fraga0% (1)

- SAE J518-1993 液压分体法兰 PDFДокумент13 страницSAE J518-1993 液压分体法兰 PDFliu zhao liu zhaoОценок пока нет

- Buttress Threads: BRITISH STANDARD 1657:1950Документ7 страницButtress Threads: BRITISH STANDARD 1657:1950varun salianОценок пока нет

- Sae J343-2010Документ9 страницSae J343-2010Job-AngelОценок пока нет

- Sae J525Документ6 страницSae J525brunoОценок пока нет

- b16 21 PDFДокумент21 страницаb16 21 PDFavinash_k007Оценок пока нет

- Iso 9974-2 Metric Port PDFДокумент3 страницыIso 9974-2 Metric Port PDFJai Bhandari0% (1)

- Iso12151-1 Orfs FittingsДокумент22 страницыIso12151-1 Orfs FittingsGANESH GОценок пока нет

- Din 32676 FerrulesДокумент1 страницаDin 32676 FerruleskrisОценок пока нет

- Classes of ConatminationДокумент36 страницClasses of Conatminationsurfin_bumpkin100% (2)

- Iso 228-1-2000 PDF DownloadДокумент14 страницIso 228-1-2000 PDF DownloadRhdh kldmkОценок пока нет

- BS EN 13765 2010 - Mangueiras Termoplásticas para Transferecia de Hidrocarb, Solventes e QuimicosДокумент28 страницBS EN 13765 2010 - Mangueiras Termoplásticas para Transferecia de Hidrocarb, Solventes e QuimicosJoice100% (3)

- Cummins AEB 24.20 Iss. 2015-06, Hoses and ConnectionsДокумент50 страницCummins AEB 24.20 Iss. 2015-06, Hoses and ConnectionsKrzysztof OkrajekОценок пока нет

- Sae J246 2000 (En)Документ23 страницыSae J246 2000 (En)Oh No PotatoОценок пока нет

- Sae j744 1996 120126105824 Phpapp01Документ7 страницSae j744 1996 120126105824 Phpapp01Nonato100% (1)

- C-Series and D-Series Modular Gear Units Product CatalogueДокумент176 страницC-Series and D-Series Modular Gear Units Product CatalogueCarlos Catalán PinoОценок пока нет

- Lock Nutand Shaft DimensionsДокумент2 страницыLock Nutand Shaft DimensionsLorettaMayОценок пока нет

- Astm A182-A182m-05Документ17 страницAstm A182-A182m-05NadhiraОценок пока нет

- ABNT NBR 11900-5 EnglishДокумент14 страницABNT NBR 11900-5 EnglishCinthia BazethОценок пока нет

- Iso 4411Документ18 страницIso 4411Fabio StuiОценок пока нет

- BS en Iso 10380Документ1 страницаBS en Iso 10380Easun - MR TechnicalОценок пока нет

- Sae 6000 PsiДокумент41 страницаSae 6000 PsiEricОценок пока нет

- Iso 2859 2 2020Документ15 страницIso 2859 2 2020Yakobus Eko KusmardaniОценок пока нет

- Din 444Документ1 страницаDin 444joseocsilvaОценок пока нет

- Sae J514 37Документ1 страницаSae J514 37deepakg9Оценок пока нет

- ASTM Compasse E208 Standart Method Dor Conducting Drop Weight Test To Determinate Nil Ductilly TransitionДокумент13 страницASTM Compasse E208 Standart Method Dor Conducting Drop Weight Test To Determinate Nil Ductilly TransitionAlexandre LaraОценок пока нет

- Manual Kaeser CSDX T Compress TranslateДокумент170 страницManual Kaeser CSDX T Compress Translateverel adamОценок пока нет

- Astm d2000 18 PDFДокумент53 страницыAstm d2000 18 PDFEric Fernandes0% (1)

- DIN 17102 Welded Steel GradesДокумент10 страницDIN 17102 Welded Steel Gradesjulio_rocha_1Оценок пока нет

- Iso 4409 2019Документ12 страницIso 4409 2019Hamza LashinОценок пока нет

- Standards PDFДокумент1 страницаStandards PDFscemanjuОценок пока нет

- Norma FIAT 52631 - Tubo Acero SoldadoДокумент13 страницNorma FIAT 52631 - Tubo Acero SoldadoZAPSE100% (2)

- Catalogo EnerpacДокумент258 страницCatalogo EnerpacAlejandro Zambrano Morales100% (1)

- 5.back StopДокумент44 страницы5.back Stopaiyubi20% (1)

- ASTM A333 Grade 6 Seamless Pipe SupplierДокумент4 страницыASTM A333 Grade 6 Seamless Pipe SupplierRajendra FittingsОценок пока нет

- ASTM A536 - 1984 (2014) - Especificação Padrão para Fundições de Ferro DuctileДокумент6 страницASTM A536 - 1984 (2014) - Especificação Padrão para Fundições de Ferro DuctileFabricio TarulloОценок пока нет

- Standard Metric Bolt Shank Dimensions PDFДокумент2 страницыStandard Metric Bolt Shank Dimensions PDFbcvdocu100% (1)

- Iso 10100Документ16 страницIso 10100jaime jeanpierre bernal olarte100% (1)

- Norma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesДокумент13 страницNorma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesJuan Rivera100% (1)

- International StandardДокумент20 страницInternational StandardGANESH GОценок пока нет

- Din 1705Документ2 страницыDin 1705Anurag Jain50% (2)

- BS - Iso - 6605 Hose Assy Test MethodsДокумент20 страницBS - Iso - 6605 Hose Assy Test MethodsHYDRAULIC POWER SOLUTIONS FBDОценок пока нет

- Sae J200-Epdm-Ts5 - Google SearchДокумент2 страницыSae J200-Epdm-Ts5 - Google SearchJessica ApalinОценок пока нет

- As ISO 1302-2005 Geometrical Product Specifications (GPS) - Indication of Surface Texture in Technical ProducДокумент9 страницAs ISO 1302-2005 Geometrical Product Specifications (GPS) - Indication of Surface Texture in Technical ProducSAI Global - APAC0% (4)

- Iso 1402 2021Документ10 страницIso 1402 2021Thejaswini100% (1)

- Stellite 6Документ3 страницыStellite 6Jessicalba LouОценок пока нет

- Din 17100Документ7 страницDin 17100Marco Antônio Deitos FilhoОценок пока нет

- How Many SweetsДокумент0 страницHow Many SweetsMixhedryanson ReagenОценок пока нет

- Casey Anthony - June 15-20 Cellphone RecordsДокумент11 страницCasey Anthony - June 15-20 Cellphone RecordsTruthTronОценок пока нет

- Mil STD 2110Документ22 страницыMil STD 2110Milorad PavlovicОценок пока нет

- File Ban HangДокумент208 страницFile Ban Hangtrungthanhnguyen_83Оценок пока нет

- Pre History PaperДокумент13 страницPre History PaperAMIT TIWARIОценок пока нет

- Incidents 2010-09-24Документ165 страницIncidents 2010-09-24Ariane Galante PimentaОценок пока нет

- Designer Smiles URL AuditДокумент41 страницаDesigner Smiles URL AuditKhushboo MathurОценок пока нет

- En Defensa de Los Derechos Fundamentales en Internet: Signatures Per Month For All TimeДокумент2 страницыEn Defensa de Los Derechos Fundamentales en Internet: Signatures Per Month For All Timeapi-25961283Оценок пока нет

- مناهج رياض الأطفالДокумент345 страницمناهج رياض الأطفالزهر البنفسج أحمدОценок пока нет

- Progressive Era Reforms of Theodore Roosevelt and Woodrow WilsonДокумент18 страницProgressive Era Reforms of Theodore Roosevelt and Woodrow WilsonbilalОценок пока нет

- Fraser V Mls Write Up-2Документ3 страницыFraser V Mls Write Up-2api-335087999Оценок пока нет

- Lecture Horizontal Merger PDFДокумент59 страницLecture Horizontal Merger PDFGaurav JakhuОценок пока нет

- 4 ProcureДокумент37 страниц4 ProcureeguadarОценок пока нет

- Price Determination Under OligopolyДокумент10 страницPrice Determination Under OligopolyKomala GowdaОценок пока нет

- Market Structures EditДокумент26 страницMarket Structures Editapi-213462480Оценок пока нет

- Is Microsoft A MonopolyДокумент2 страницыIs Microsoft A Monopolymrchiariello0% (1)

- Chapter 10 Notes Principles of MicroeconomicsДокумент2 страницыChapter 10 Notes Principles of MicroeconomicsDerek Ng100% (2)

- State AG's NZFSPA LetterДокумент8 страницState AG's NZFSPA LetterJames LynchОценок пока нет

- Japan Line, Ltd., Kawasaki Kisen Kaisha, Ltd., Mitsui O. S. K. Lines, Ltd., Nippon Yusen Kaisha, Ltd., Yamashita-Shinnihon Steamship Company, Ltd., and Maritime Company of the Philippines v. Sabre Shipping Corporation, 407 F.2d 173, 2d Cir. (1969)Документ5 страницJapan Line, Ltd., Kawasaki Kisen Kaisha, Ltd., Mitsui O. S. K. Lines, Ltd., Nippon Yusen Kaisha, Ltd., Yamashita-Shinnihon Steamship Company, Ltd., and Maritime Company of the Philippines v. Sabre Shipping Corporation, 407 F.2d 173, 2d Cir. (1969)Scribd Government DocsОценок пока нет

- AssignmentДокумент6 страницAssignmentRandz RamosОценок пока нет

- ECO 415 - THEORY OF FIRMs - OligopolyДокумент36 страницECO 415 - THEORY OF FIRMs - Oligopolykimi9090Оценок пока нет

- EconomicsДокумент24 страницыEconomicsArun Koshy Thomas0% (1)

- USA v. Apple Comic BriefДокумент11 страницUSA v. Apple Comic BrieftompirragliaОценок пока нет

- 5th Amended Complaint - Kirk Dahl V Bain Capital PartnersДокумент221 страница5th Amended Complaint - Kirk Dahl V Bain Capital Partnersdarwinbondgraham100% (1)

- NCAA Now Facing Multi-State Lawsuit Amid Tennessee NIL InvestigationДокумент20 страницNCAA Now Facing Multi-State Lawsuit Amid Tennessee NIL InvestigationWVLT NewsОценок пока нет

- Ethics in The MarketplaceДокумент31 страницаEthics in The MarketplaceDONGGU KANGОценок пока нет

- Joseph Anaya v. The Las Cruces Sun News, 455 F.2d 670, 10th Cir. (1972)Документ5 страницJoseph Anaya v. The Las Cruces Sun News, 455 F.2d 670, 10th Cir. (1972)Scribd Government DocsОценок пока нет

- Concept of Tying Bundling and Its Effect On Competition - A Critical Study of It in Various JurisdictionsДокумент43 страницыConcept of Tying Bundling and Its Effect On Competition - A Critical Study of It in Various JurisdictionsBhuvnesh PrakashОценок пока нет

- Compitition LawДокумент22 страницыCompitition LawYamini PatelОценок пока нет

- History of Competition Law AssignmentДокумент2 страницыHistory of Competition Law AssignmentYohanes Baptista Durman SelamunОценок пока нет

- United States District Court For The District of ColumbiaДокумент53 страницыUnited States District Court For The District of ColumbiaZerohedgeОценок пока нет

- Managerial Economics in A Global Economy, 5th Edition by Dominick SalvatoreДокумент22 страницыManagerial Economics in A Global Economy, 5th Edition by Dominick SalvatoreYentl Rose Bico RomeroОценок пока нет

- Competition Policy in Romania After The Eu AccessionДокумент7 страницCompetition Policy in Romania After The Eu AccessionAndreea OancaОценок пока нет

- Monopoly AmJurДокумент8 страницMonopoly AmJurNC BergoniaОценок пока нет

- Affidavit of LossДокумент3 страницыAffidavit of LosslendiibanezОценок пока нет

- Microeconomics Practice TestДокумент9 страницMicroeconomics Practice TestSonataОценок пока нет

- Facebook Motion To Dismiss FTC's Amended Complaint, Filed Oct. 4, 2021Документ55 страницFacebook Motion To Dismiss FTC's Amended Complaint, Filed Oct. 4, 2021jonathan_skillings100% (1)

- Meregers and AquisationДокумент122 страницыMeregers and AquisationAmit GanjiОценок пока нет

- The United States Supreme Court - 1948-1949Документ56 страницThe United States Supreme Court - 1948-1949Tomás AguerreОценок пока нет