Академический Документы

Профессиональный Документы

Культура Документы

Underground Coal Gasification at Hanna, Wyoming

Загружено:

AlexReitu0 оценок0% нашли этот документ полезным (0 голосов)

24 просмотров22 страницыUCG technology research, for commercialization

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документUCG technology research, for commercialization

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

24 просмотров22 страницыUnderground Coal Gasification at Hanna, Wyoming

Загружено:

AlexReituUCG technology research, for commercialization

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 22

-1

UNDERGROUND COAL GASIFICATION AT

HANNA, WYOMING

G. G. CAMPBELL, C. F. BRANDENBURG,

'R. M. BOYD, AND T. E. STERNER

LARAMIE ENERGY RESEARCH CENTER

LARAMIE, WYOMING

PRESENTED AT THERMAL POWER CONFERENCE,

WASHINGTON STATE UNIVERSITY, PULLMAN, WA

OCTOBER 16, 1975

ABSTRACT

UNDERGROUND COAL GASIFICATION AT

HANNA, WYOMING

G. G. Campbell, C. F. Brandenburg,

R. M. Boyd and T. E. Sterner

Laramie Energy Research Center

Laramie, Wyoming

A second underground coal gasification experiment is being conducted at

the Laramie Energy Research Center's field site near Hanna, Wyoming. This

paper preSents the results from the first phase of the Hanna II experiment

in which coal seam permeability was evaluated, pneumatic linking and linking

via reverse combustion were studied, and in which a sustained gasification

process was maintained between the two linked vertical wells. Air injection

alone did not increase permeability to levels which .JOuld allow sustained

gasification. Reverse combustion linking was determined to be a local,

relatively low temperature process which advanced at a rate of 5 ft/day and

produced a high permeability carbonized path. Subsequent gasification was

maintained over a 38 day period. Overall, injection of 1.9 ~ scf/day of

air yielded 2.7 MM scf/day of gas with an average heating value of 152

Btu/scf. Material balance calculations indicate that 1700 tons of coal in

place were utilized.

INTRODUCTION

Underground coal gasification (UCG) has been the subject of investiga-

tions for more than 100 years (1). The process has been shmm to be

technically feasible, but has been economically unattractive in competition

with petroleum resources. The recent shortages of petroleum fuels have

rekindled interest in research on efficient in situ gasification of coals

in the United States. Russian activities in underground gasification of

coal have been the most sustained (1). Electricity has been generated from

low-Btu gas at several large scale plants in the Soviet Union from sub-

bituminous coals and lignites since 1960. Recently, diminished Soviet

utilization of UCG for energy production is believed due to the discovery

of adequate local petroleum fuel sources. In England, UCG was studied

extensively and field experiments produced processes ,vhich were techni-

cally feasible and nearing commercial utilization but were abandoned in

1959 because they were not sufficiently economical at that time (2).

Similarly, investigations were c6nducted in the United states by the Bureau

of from 1946 to 1959 (3-6) and by Gulf Research in 1968 (7). These

studies were also discontinued for lack of immediate need and economic

incentive.

The Bureau of Mines started a reassessment of UCG in 1971 (1). This

study showed that a renewed field effort was appropriate. A field site near

Hanna, Wyoming, was selected and the Hanna I experiment was conducted be-

tween March 1973 and March 1974 (8-10). Tne Hanna I experiment showed that

western subbituminous coals were suited to underground gasification because

they are generally thicker, more permeable and more reactive. Tne Hanna I

experiment also showed that a low Btu gas, 125 Btu/ft

3

; could be produced

for an extended period.

A second field experiment, Hanna II, was designed to answer questions

generated by the. first experiment and to include an expanded instrumentation

effort. The instrumentation was provided by the Sandia Laboratories and

included thermal, acoustic and resistivity measurements.

Hanna II is now being conducted in three phases: Phase 1, an experi-

ment to examine pneumatic and combustion linking of wells to conduct a

limited gasification test, and to evaluate instrumentation; Phase 2, two

two-well burns to gasify coal berween an injection and production well in

preparation for the third phase, a line-drive burn to gasify coal along a

60 foot combustion front.

OPERATION

A basic problem in underground coal gasification is the formation of an

underground reaction vessel before actual gasification of the coal. This is

necessary because the permeability of the virgin coal is too low to allow

gasification by either a forward or a reverse combustion process. Various

approaches to underground gaSification differ mainly in the technique used

to create the necessary permeability. These techniques include mining,

directional drilling, fracturing, electrolinking and combustion (1). The

Hanna experiments use the combustion oriented vertical well technique.

In this concept, the reaction vessel is prepared by generating a permeable

path through the coal seam between adjacent vertical wells by reverse

combustion.

FIELDING DESCRIPTION

The Hanna II experiment is being conducted on a site near Hanna, Wyoming,

at a location approximately 700 ft west of the site of the Hanna I experiment.

The location and geology of the formation have been described previously

(8,9,13). The ceiling of the thirty-foot-thick coal seam lies at a depth

of 275 it compared to a depth of 400 ft in the Hanna I experiment.

The surface layout of the eight wells for Phase I of the Hanna II

experiment is shown in Fig. 1. Wells I, 2, 3, and 4 were cased injection

and production wells. The original experiment plan called for Wells 2, 3,

and 4 to be on a 60 ft radius from Hell 1; however, the original Well 3 was

plugged and abandoned due to a parted casing and cement bonding proble1!lS.

Wells AA, BB, CC, and DD were 'instrumentat,ion wells containing thermocouples,

geophones, resistivity probes, and a gas sampling canister.

Wells 1, 2, and 4 were drilled two-thirds of the way through the coal

seam and 6 in diameter casings were ,set at this level and cemented with high

temperature cement containing 35% silica flour. After cementing, the hole

was reentered and drilled out to the bottom of the coal, seam., The second

Well 3 was drilled out to a level 15 ft below the bottom of the coal seam and

the 61n casing set at this level. After cementing with high temperature

cement, the casing in the bottom third ,of the coal, "as' perforated with 4

perforations per ,foot. This completion method, with access to only the

bottom third of the coal seam, was intended to confine the linkage pathway

in the lower portion of the seam.

The air injection and gas production facilities used for the experiment

are shown schematically in Fig. 2. All static and differential pressure,

and temperature measurements were made with electronic transducers. The

signals from these sensors were recorded with a system built around a mini-

computer. Computer software was developed so that both injection and

production flow measurements were calculated at five minute intervals from

which;,hourly average flow parameters were obtained.

TEMPERATURE INSTRUMENTATION

Phase 1 was planned as a preliminary experiment (11). For this reason,

the temperature sensing array, shown in Fig. 3, was sufficient to provide

only limited spatial resolution in the vertical direction and to observe

typical thermal histories at isolated points. Such a sparse array does not

allow clear definition of the velocity and direction of reaction zone propa-

gation, the horizontal location of linking paths, nor the lateral extent of

the reaction zone at any horizon.

RESULTS

,Phase 1 of the Hanna II experiment was conducted in the following

sequence: (1) air injection tests to determine the permeability and

directional flow characteristics of the coal seam and to attempt to create

a pneumatic link, (2) ignition and formation of a link by reverse combustion,

and (3) sustained gasification in a forward burn mode.

DIRECTIONAL PERHEABILITY AND PNEU.ATIC LINK TESTS

Since the flow of air through the natural fractures in virgin coal is

an important parameter during linkage, the Hanna II experiment was designed

to evaluate not only the directional permeability under seam conditions but

also to evaluate permeability enhancement via continued air injection through

the seam without combustion (pneumatic linking). Based upon directional

permeability measurements and visual analysiS of an oriented core taken from

WeIll, Well 2 was located from WeIll along the major fracture direction of"

the coal, Well 3 was located along the minor fracture direction, and Well 4

o

was located 100 from the major fracture direction. This is shown in Fig. 1.

The measurement of the directional flow of air from WeIll to Wells 2,

3, and 4 was conducted April 7-16, 1975 (Julian days 97 'to 106; reference

January 1, 1975). The injection pressure and injection rate during this

period are shown in Fig. 4. The injection pressure was maintained below the

overburden pressure to prevent pneumatic fracturing. The average air pro-

duction rates of Wells 2, 3, and 4 during this period were 2,30, and 9 scfm,

respectively, clearly indicating preferred flow in the direction towards

Well 3. This coincides with the updip and minor fracture direction of the

coal seam--Fig. 1 (13). This directional flow portion of the experiment was

prematurely halted when Well CC showed signs of leakage. Air injection was

switched to Well 3 in order to reduce the pressure at Well CC.

Air injection was initiated at Well 3 on April 17 (107), and was

continued for 31 days--Fig. 4. Injection pressure was increased progressive-

ly over a five day period, then held steady at approximately 225 psig during

this experiment. At constant pressure, the injection rate increased only

slightly. However, the air recovery rate was approximately 40 to 50 percent.

Two wells are considered to be linked when injection capacity is at least

1000 scfm of air at pressures of less than 50 psig.

IGNITION AND REVERSE COMBUSTION LINKAGE

The slightly enhanced permeability observed during the pneumatic linking

phase was judged inadequate to provide sufficient flows for gasification.

Such permeabilities and resultant flows can be obtained by reverse combustion

as demonstrated in the Hanna I experiment (10).

The coal was ignited in the lower 10 ft of 1-1ell 1 with air injection

into Well 1 and Well 3 open for production--Fig. 5b. A 24 Kw electric heater

was used to achieve ignition. Injection and production flows during this

ignition phase are shown in Fig. 6. The temperature of the heater shell

was maintained between 800 and 10000F from initiation of heating on May 21

(141) until Hay 25 (145). Hithin 12 hours after initiation of heating, an

abrupt increase in C02 content of the gas produced from Well 3 indicated

that combustion had been initiated. As indicated in Fig. 6, injection and

production rates both decreased during this period even though the air

injection pressure increased to 270 psig. This decreasing flow behavior was

typical of prior attempts to effect forward combustion in a coal seam without

preliminary permeability enhancement.

In the second step of combustion linking, flow is reversed to achieve

the reverse combustion mode--Fig. 5c. The flow of the oxidizing air through

the fissure structure toward the ignite,d region progressively reacts with

the coal at the exposed faces near the burning region, thus enlarging the

flow cross-section along local paths.

The downhole heater was removed from Well 1 and air injection into

Well 3 was begun to initiate formation of a link by reverse combustion. The

flow parameters of the system during this period are shown in Fig. 7. The

injection pressure during this period was main.tained between 240 and 270

psig. The initial air injection rate was about 50 scfm; this rate gradually

increased to almost 90 scfm by June.3 (154). The gas production during this

period increased gradually until, on June 1(152), the produced'gas rate

exceeded that of air injection.

A nitrogen balance ratio (nitrogen in the produced gas versus the

nitrogen injected) during ,this period ranged from 40 to 80%. Some nitrogen

loss to the formation was expected due to the high injection pressure. The

oxygen content.of the. produced gas ranged from 1 to 2%; indicating that a

small .amount of inj ected air bypassed thereac tion zone. The overall gas

composition of produced gas during this period was like that of Hanna I and

is shown in Fig. 8.

The'completion of linkage is a sudden and dramatic occurrence. It is

evidenced .by an abrupt increase in inject,ion and production rate and decrease

in injection.pressure as was observed in this work and as reported previously

(12). An hourly plot of inj ection pressure and flow rate is shown in Fig. 9,

and, shows. a drop from 220 to 141 psig ,at 0900 on June 4 (155). The 500 cfm

plateau in the flow rate resulted from the limited flm. capacity of the

single air compressor on line at the time of linking. The addition of another

compressor resulted in the increase in pressure and flow rate at 1400 hours.

The injection pressure continued to decrease over an additional period, but

linkage v,as virtually complete after 15 hours. As shown in Fig. 8, a distinct

change in the product gas composition also occurs upon linkage: CO, H2 and

CHI.! all increase and the concentration of CO exceeds, tha t of ;C02'

This linking process utilized 33 Mscf of air injected pe.r lineal foot

of linkage, the same quantity utilized during the Hanna I experiments. This

is less than the Russian experience for which values of 80-240 Hcf/ft have

been reported ,(14). Haterialba1ance calculations (10, 15) during the

1inkipg.process indicate that a total of 15.1 tons of coal in, place were

affected.

GAS IFICATION

Upon linking, the increased flows were sufficient to sustain gasifica-

tion. The same injection and production wells ,.ere used, and the differences

from the preceding step were only in the flow parameters and changes in the

coal seam produced by combustion linking. The reaction zone proceeded from

Well 3 toward \.Je1l 1 in a forward burn mode with the reaction air flowing

both along the reaction surface and through the reaction: zone into the

unreacted c.oal. The geometry of the burn front' was dictated by the permeable

link and .was affected by the relative flow resistance of the linking path and

the less permeable but larger area of the unreacted coal.

The gasification phase of the experiment was continued for 38 days from

the time of linking. During this period, the air injection rate usually

exceeded 1000 scfm (1.4 MMscf/day) and gas" production rates were generally

greater than 1.4 times the air injection rates. The average daily flow

conditions during that period are shown in Fig. 10. This figure shows that

the injection pressure gradually decreased during the course of this experi-

ment. Occasional variations in the injection rate reflected deliberate or

unavoidable operational changes. Significantly, none of the variations of

flow observed at the surface resulted "from subsurface conditions peculiar

to the in situ oblique forward bu"rn" reactor system, but.were the result of

operational changes in air compressor equipment.

Measured and calculated values for the gas produced are both shm-m in

"Fig. 10. There are inherent difficulties in accurately measuring the flow

rate of a gas containing unknown and variable quantities of water and tar.

It is felt that the flow rate calculated from a nitrogen balance and assuming

zero leakage, as was observed in Hanna I (9), gives a more realistic value of

the gas production rate.

The daily average compositions of the produced gases are shown in Fig. 11.

The daily average gross heating value and product temperature are given in

Fig. 12. The overall average gas composition for the gasification phase is

found in. Table 1. This gas composition is similar in most respects to air-

blown producer gas (16). Table II presents a summary of the average

operational parameters during the gasification phase.

The quantity of affected in place coal was calculated by a material

balance method used previously by Elder (15) and was also used for evalu-

ation of the Hanna I experiments (10). Daily material balance results for

the gasification phase are presented in Fig. 13. The analysis assumes that

the in situ coal reaction occurs in two steps: Carbonization followed by

gasification. The method. is based on the stoichiometric difference between

carbonization and gasification products. Only the carbon, hydrogen, and

oxygen are considered in this calculation and a steady state reaction is

assumed. The calculated amount of "coal-carboni zed-only" includes that

portion of coal from which only the carbonization products have been removed

prior to complete gasification. Although variations of production rate were

experienced, the calculated material balance is considered to offer a good

approximation of the amount of coal utilized. From this analysis, the total

amount of coal affected during gasification \Vas 1000 tons (moisture and ash-

free) which corresponds to about 1700 tons of in situ coal. Of the 1000 tons,

total, 500 tons w-erecarboriized, and 500 tons ","lere gasified completely.

CONCLUSIONS

This first phase of the Harina II experiment utilizing the linked vertical

well technique has again demonstrated the technical feasibility of lli"i.der

ground coal gasification and has been helpful in developing a description

of the basic process parameters involved.

Evidence from this experiment suggests that the dip direction, as well

as the fracture direction, play an important role in determL,ing the

preferred directional flow of air injected into the Hanna I coal seam.

An attempt to create a link between adjacent wells sufficient to sustain

gasification simply by air injection was not feasible. The ability to effect

a linkage by reverse combustion in a reproducible and dependable manner has

been confirmed.

During the 38 day gasification period, injection of 1.9 MMscf/day of

air yielded 2.7 MMsef/day of produced gas with a heating value of 152 Btu/scL

Material balance calculations indicate that 1700 tons of coal in place were

utilized. Two.features distinguished the gas production in this experiment:

the heating value of product gas was both relatively high, 152 Btu/scf, and

relatively uniform over the life of the experiment. Both factors favorably

affect economic

ACKNOWLEDGMENT

The author thanks all personnel of the Laramie Energy Research Center

and Sandia Laboratories associated with various aspects of this field

experiment. Special acknowledgment is given to the Rocky Mountain Energy

Company, a subsidiary of the Union Pacific Railroad, for the use of their

land as the test site at Hanna, Wyoming.

RE:E'ERENCES

.1. A. D. Little, Inc. itA Current Appraisal of Underground Coal Gasifica-

tion." Report No. C-73671, Dec. 1971, 121 pp.

2. Sir Alexander Gibb and Partners, The Underground Gasification of

Coal, Sir Isaac Pitman and Sons, ,London (1964).

3. Dowd, J.J., J.L, Elder, J.P. Cohen.

Gasification of Coal, Gorgas, AL."

62 pp.

"Experiment in Underground

BuMines RI 4164, Aug. 1947,

4. Elder, J.L., M.H. Fies, H.G. Graham, R.C. Montgomery, L.D. Schmidt,

and E.T. Wilkins. "The Second Underground Gasification Experiment

at Gorgas, AL." BuMinesRI 4808, Oct. 1951, 72 pp.

5. Capp, J.P., J.L. Elder, C.D. Pears, R.W. Lowe, K.D. Plants and

M.H. Fies, "Underground Gasification of Coal--Hydraulic Fracturing

as Method of Preparing a Coalbed." BuMines RI 5666, 1960, 50 pp.

6. Capp, J.P., and K.D. Plants, "Underground Gasification of Coal with

Oxygen-Enriched Air." BuMines RI 6042, 1962, 14 pp.

7. Raimondi, P., P.L. Terwilliger, and L.A. Wilson, Jr., "A Field Test

of Underground Combustion of Coal, " SPE4.J13, presented at the

Eastern Regional Meeting of the SPE of AIME, Pittsburgh, Penn.,

Nov. 7-9, 1973, 11 pp.

8. Campbell, G.G., C.F. Brandenburg, and R.M. Boyd, "Preliminary

Evaluation of Underground .Coa1 Gasification at Hanna, Wyoming,"

BuHines TPR 82, Oct. 1974, 14 pp.

9. Schrider, L.A., J.\.[. Jennings, C.F. Brandenburg, and D.D. Fischer,

"An Underground Coal Gasification Experiment, Hanna, Hyoming,"

SPE 4993, presented at the SPE Fall Meeting of AIME, Houston, TX,

Oct. 6-9, 1974, 25 pp.

10. Brandenburg, C.F., D.D. Fischer, G.G; Campbell, R.M. Boyd, and

J.K. Eastlack, "The Underground Gasification of a Subbituminous

Coal," presented at the Div. of Fuel Chem., Am. Chem. Soc. National

Spring Heeting, Philadelphia, PA, Apr. 1975, 11 pp.

11. Brandenburg, C.F., R.P. Reed, R.M. Boyd, D.A. Northrop, and

J.W; Jennings, "Interpretation of Chemical and Physical Measure-

ments From an In Situ Coal Gasification Experiment," SPE 5654,

presented at the SPE Fall Meeting of AIME, Dallas, TX, Sept 28-

Oct. 1, 1975, 28 pp.

12. Kreinin, E.. and M. Revva, "Underground Gasification of Coal"

Kemerovskoe Knizhnoe Izdatel'stvo, 1966, 85 pp.

13. Schrider, L.A., C.F. Brandenburg, D.D. Fischer, R.M. Boyd and

G.G.- Campbell, "The Outlook for Underground Coal Gasification,"

presented at the 1975 Lignite Symposium, Grand Forks, ND, May 1975.

14. Lavrov, N.V., G.O. Nuginov, D.K. Semenenko, "Results of Studies of

Underground Gasification of Brown Coal," Khimiya Tverdogo Top1iva 1

(1968) 113-120.

15. Elder, J.L., M.H. Fies, H.G. Graham, J.P. Capp, and E. Sarapuu,

"Field-Scale Experiments in- Underground Gasification of Coal at

Gorgas, Alabama; Use of Electrolinking-Carbonization as a Means

of Site Preparation," BuMines RI 5367, October 1957, 101 pp.

16. Fischer, D.D., and L.A. Schrider, "Comparison of Results from

Underground Coal Gasification and From a Stirred Bed Producer,"

presented at the National AIChE Heeting, Houston, TX, Har. 16-20,

1975, 34 pp.

"

TABLE I

Overall Average Composition of Product Gas

(volume percent)

Hz

17.3

Nz

51.0

CO 14.7 Ar. 0.6

COz

12.4

~ S

0.1

CHIf

3.3

CZ-CIf

0.6

TABLE II

Average Operational Parameters

Heating Value of Gas (Gross) 152 Btu/sci

Daily Gas Production 2.7 MM scf

Daily Air Injection 1.9 MM scf

Daily Btu Production 420 MM Btu

Ratio: Heat/Air Volume 223 Btu/sci

N60W

FIGURE ~

TRUE

NORTH

1 MN

o 10 20

30 40 feet

H I I

I I

S20W

WELL PATTERN; PHASE OF THE

HANNA II EXPERIMENT

"

",

4

. . ,11--0

,

"

"

.... 4"

"" "" , ,

, ,

4"'" '--1.1---,

, I

~ - - 1 r _ - ,

I

I

I

16

11

I

I

I

I

FLARE

o 10 20 30 40

H E-=J

0 WELL

AI R INJECTION

LINE

GAS PRODUCTiON

LINE

-

GATE VALVE

-1,1- ORIFICE

FIGURE 2, - SCHEMATIC OF SURFACE PIPING

WELL 3 WELL 1

DO SURFACE

CC

GROUTED

INSTRUMENT

WELLS

275' OVER-

BURDEN

3

4

5

6 LEVEL

7

8 30' COAL

SEAM

9

52.5 45 30 15 0

, ,

I I

,

FEET FROM WELL I

FIGURE 3,

- CROSS SECTION OF WELLS 1, CC, DD,

AND 3 SHOWING WELL COMPLETIONS AND

THERMOCOUPLE LOCATIONS

DIRECTIONAL

PERMEABILITY TEST

INJECTION INTO WELL

250

200

0>

(I)

a.

lLJ

~ 1 5 0

(J)

(J)

lLJ

a::

a..

ZIOO

o

H

.....

U

lLJ

J

Z

H 50

PRESSURE

/"'1

_J/ I

/___ I

/ I

/ '

I I

: I

I I

I

I

,

FLOW \

RATE--------'

,

\

\

\

\

\

\

\

\

/_..J

I

/

/

,-

PNEUMATIC LINK TEST

INJECTION INTO WELL 3

PRESSURE

----"""'--/',-.......

- I' ~ "

""" -- \ I ' ...... ""... "

...,/ \ /

/'- _/ \.I--FLOW RATE

/

250

200

E

'+-

o

(I)

lLJ

150 .....

<:(

a::

z

o

H

100 .....

U

50

lLJ

J

Z

H

01 1 I I I I I I I I -.-10

95 100 105 110 115 120 125 130 135 140 145

JULIAN DAY, 1975

FIGURE 4. - DIRECTIONAL PERMEABILITY AND PNEUMATIC LINK TESTS

.,

(A.) Virgin Coal (low

permeability)

HIGH PRESSURE GAS

AIR INJECTION PRODUCTION

(C.) Combustion Linking

Front Proceeds to

Source of Air

P

HIGH PRESSURE

GAS AIR

-ION .l1'4 u t:.l- TION

I

I ~

AIR DO

~ C B E L

'-= .. HE

WN HOLE

ECTRIC

ATER

(B.) Ignition of Coal

LOW PRESSURE

AIR INJECTION

GAS

PRODUCTION

--tl-I ~ I

(D.) Linkage complete

when combustion zone

reaches injection well

(system ready for

gasification)

FIGURE 5. - SEQUENCE OF EVENTS IN LINKAGE BY REVERSE COMBUSTION -.'

I

I

I

!

I

I

70

!

-

l

E !

I If-

I

u

(/)

-60

I

W

!

I

t-

I

<t

I a::: 50

!

Z i

I

0 ,

-

I

t- I

t 040

I

:::>

il

I

Q

f

0

!

g: 30

,

J

Q

Z

<t 20

Z

0

-

t- 10

0

W

J

Z

0

H

INJECTION PRESSURE

INJECTION RATE INTO WELL 1

-0'

w

a:::

:::>

160 C/)

C/)

W

a:::

120 Cl..

Z

o

t-

O

W

J

~ 4 0 ~

PRODUCTION RATE

AT WELL 3

141 142

JULIAN

144

1975

FIGURE 6. - FLOW PARAMETERS DURING 'IGNITION

o

145

"

W

I-

0:: 1000

Z

o

-

I-

o

:::>

Q

o

a::

a..

Q

Z

Z

o

INJECTION PRESSURE

PRODUCTION

RATE

280

240

-0'

w

a::

:::>

160 (f)

(f)

120

W

a::

a..

Z

o

I-

o

W

...,

Z

H

I-

o

W

...,

Z

H

0E-"3 T ~ ; = ~ I -=- Jo

145 150 155

JULIAN DAY, 1975

FIGURE 7, - FLOW PARAMETERS DURING LINKAGE VIA REVERSE COMBUSTION

I-

Z

UJ 60

u

a::

UJ

a.

50

UJ

:E.

;:,

c; 40

I

z .

ri

20t __ L

C02

___ ---- --

u

8 10 ________________________ _____________ ---------------

-------

JULIAN DAY,

W

I-

<t

a::

FIGURE 8. - PRODUCED GAS COMPOSITION DURING LINKING

AND EARLY GASIFICATION

TIME. hours

FLOW RATE

too;

:::J

fJ)

fJ)

w

a::

0...

Z

o

z

o

H

I-

U

w 500

--,

100

U

W

--,

Z

H

PRESSURE

FLOW RATE

OL-__________

156

JULIAN DAY. 1975

FIGURE 9. - FLOW PARAMETERS AS LINKAGE WAS ATTAINED

Z

H

>-

0

"'0

.......

-

0

C/l

~

~

.

w

I-

0::

Z

02

H

I-

U

::>

0

0

a::

0...

0

Z

z

0

H

I-

U

W

J

Z

H

,

,

--.. ~ ...

MEASURED FLOW

CALCULATED FLOW

,',

I' \ ~

,

.

,

,

~ ~ ... ~

I

~

... ~

'\.

,

-- .. \

~ /

,

. '

.... _ .........

/ ........... ... <:...AIR INJECTION RATE

,

, ...........

.... .. "

,

,

,

.... ~ ..... -

". ..

'.

"

~ - -....

t[

60

w

a::

50 ::>

(f)

(f)

40 w

0:::

0...

30

Z

0

20

H

I-

U

10 w

J

Z

OLI ____ -L ________ L _ ________ ________ _L ________ __ . ________ L_ ________ _L ________ __

0 H

152 155 160 165 170 175 180 185 190 192

JULIAN DAY. 1975

FIGURE 10. - AVERAGE FLOW PARAMETERS DURING GASIFICATION TEST c,

I

,

I

I

.-.60

.-

Z

W

u 50

a::

w

n..

w 40

~

:::>

...J

o

> 30

'-'

z

o ~ _

H20/""-

.- '--

--

H2\.... ___ _

-

-

~ IOr ............. .... ...... ..... < ............ .. ........ .

w r CO

2

CH

4

)

~ ~ ............. ..

u

Z

o

U OIL ______ L-____ -L ______ ____ ~ ____ ~ ~ ~ ____ ~

155 160 165 170 175 180 185 190 192

JULIAN DAY, 1975

fIGURE 11. - AVERAGE COMPOSITION Of THE GASES PRODUCED

DURING GASIfICATION TEST

,.

(!)

Z

H

I-

<{

W

I

I

I

I

1

I

I

,

,

I

I

,

,

,

I

I

I

/

,_/

I

I

I

I

".--"\

TEMPERATURE ~ ,-----/ \ ~ /

'---- / \ I

~ . . \ r-../ \ I

".. \ I ""' .....

,,...' ........... _, /' ,/ \ I

/ \/1 I V

r.... ,,/" \1 \ .,/

,_/ >I \ ,/'_- ____ -

\../

HEATING VALUE

W

lY

:::>

I-

300 <{

lY

W

a..

:E

200 w

I-

01 I I I I I I I I 10

152 155 160 165 170 175 180 185 190 192

JULIAN DAY, 1975

FIGURE 12. - AVERAGE HEATING VALUE AND TEMPERATURE OF THE

GASES PRODUCED DURING GASIFICATION TEST

'-,

i

,

I

I

I

I

I

!

....J

<i

o

u

o COAL CARBONIZED ONLY

E223 COAL COMPLETELY GASIFIED

01 ~ ~ 1 r 1 r r 1 r L r r r r r r r r r f L r r r r r i

155 160 165 170 175

JULIAN DAY, 1975

FIGURE 13. - MATERIAL BALANCE CALCULATIONS, DURING GASIFICATION TEST

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Algebra Cheat SheetДокумент2 страницыAlgebra Cheat SheetDino97% (72)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- VALVESДокумент153 страницыVALVESHamood Ahmad100% (1)

- 12 Allowable Pipe Span Formulas and TablesДокумент10 страниц12 Allowable Pipe Span Formulas and TablesSeungmin Paek91% (11)

- Engineering Design Qualilty Control ProcedureДокумент15 страницEngineering Design Qualilty Control ProcedureAlexReituОценок пока нет

- Turbine Fuel SystemДокумент66 страницTurbine Fuel SystemDamon Leong100% (1)

- Boilers NotesДокумент16 страницBoilers Notesjust randomОценок пока нет

- Topsoe Large Scale Hydrogen ProducДокумент20 страницTopsoe Large Scale Hydrogen ProducAnonymous j9s0eQ0uОценок пока нет

- Matlab Finite Element Modeling For Materials Engineers Using MATLABДокумент74 страницыMatlab Finite Element Modeling For Materials Engineers Using MATLABPujara ManishОценок пока нет

- Standard 3Документ28 страницStandard 3Muhammed SulfeekОценок пока нет

- Gas Processing Plants.: Linde EngineeringДокумент4 страницыGas Processing Plants.: Linde EngineeringAlexReituОценок пока нет

- Pressure Changers On Aspen PlusДокумент19 страницPressure Changers On Aspen PlusAlexReituОценок пока нет

- Pressure Changers On Aspen PlusДокумент19 страницPressure Changers On Aspen PlusAlexReituОценок пока нет

- Steam Reforming - Approach To EquilibriumДокумент39 страницSteam Reforming - Approach To EquilibriumAlexReituОценок пока нет

- Air Products Hydrogen Plant CapacitiesДокумент16 страницAir Products Hydrogen Plant CapacitiesAlexReitu100% (1)

- Calorifier Data SheetДокумент4 страницыCalorifier Data SheetgksakthiОценок пока нет

- Fin Heat Transfer With Generations PDFДокумент16 страницFin Heat Transfer With Generations PDFAlexReituОценок пока нет

- China's Involvement in South Africa's Wind and Solar PV IndustriesДокумент29 страницChina's Involvement in South Africa's Wind and Solar PV IndustriesffkefeОценок пока нет

- Nutritional Guide For CyclistДокумент28 страницNutritional Guide For CyclistAlexReituОценок пока нет

- 11-7731 JS Plus FINALДокумент22 страницы11-7731 JS Plus FINALSerdar ArıcanОценок пока нет

- Increased Steam Methane Reformer ThroughputДокумент5 страницIncreased Steam Methane Reformer ThroughputAlexReituОценок пока нет

- The Thermo-Catalytic Decomposition of Methane For Economical and Emission Free Hydrogen Production (Andrews Thesis)Документ207 страницThe Thermo-Catalytic Decomposition of Methane For Economical and Emission Free Hydrogen Production (Andrews Thesis)AlexReituОценок пока нет

- Bed Height and Material Density Effects On Fluidized Bed HydrodynДокумент117 страницBed Height and Material Density Effects On Fluidized Bed HydrodynAlexReituОценок пока нет

- Increased Steam Methane Reformer ThroughputДокумент5 страницIncreased Steam Methane Reformer ThroughputAlexReituОценок пока нет

- Thermodynamic Textbook 1Документ20 страницThermodynamic Textbook 1AlexReituОценок пока нет

- Ethylene 2520oxide Methods 2520of 2520productionДокумент25 страницEthylene 2520oxide Methods 2520of 2520productionmartin_2104Оценок пока нет

- Introduction To Modelling in EgineeringДокумент17 страницIntroduction To Modelling in EgineeringAlexReituОценок пока нет

- Systematic Approach For Developing Dynamical ModelsДокумент14 страницSystematic Approach For Developing Dynamical ModelsAlexReituОценок пока нет

- THE THE: Notes Meter Factor ForДокумент19 страницTHE THE: Notes Meter Factor Forjgarcia388Оценок пока нет

- Miktex 2.9 Manual: Christian SchenkДокумент91 страницаMiktex 2.9 Manual: Christian SchenkIulian DanciuОценок пока нет

- AMS55 SampleДокумент22 страницыAMS55 SampleAlexReituОценок пока нет

- 3 Tables Friction Loss AquacultureДокумент10 страниц3 Tables Friction Loss Aquaculture45saulОценок пока нет

- Coal Based MethanolДокумент9 страницCoal Based MethanolAlexReituОценок пока нет

- Gas Flaring Basic InformationДокумент4 страницыGas Flaring Basic InformationFriday IjokgwungОценок пока нет

- Tutorial 1 GD StudentsДокумент4 страницыTutorial 1 GD Studentsgokuler137Оценок пока нет

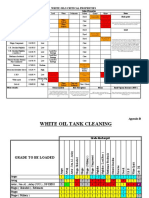

- Oil Tank CleaningДокумент4 страницыOil Tank CleaningMituОценок пока нет

- Reciprocating Air CompressorsДокумент4 страницыReciprocating Air CompressorsAatish ChandrawarОценок пока нет

- How Do You Make LiquidДокумент2 страницыHow Do You Make LiquidjukortaОценок пока нет

- What You Should Know About Flash TanksДокумент4 страницыWhat You Should Know About Flash TanksFrancois HamiauxОценок пока нет

- Assignment 1 Che433 Sem 20224Документ3 страницыAssignment 1 Che433 Sem 20224NUR IRDINAОценок пока нет

- Air Duct Cleanliness TestДокумент8 страницAir Duct Cleanliness TestFahad NaveedОценок пока нет

- Quiz PHASE EQUILIBRIA (Set 2)Документ4 страницыQuiz PHASE EQUILIBRIA (Set 2)Supia NazmaОценок пока нет

- Mec235 - Thermo FluidsДокумент10 страницMec235 - Thermo FluidsManish JainОценок пока нет

- Design and Fabrication of A Ramjet Engine PDFДокумент11 страницDesign and Fabrication of A Ramjet Engine PDFalexОценок пока нет

- Pneumatic Systems: Plastic Injection MoldingДокумент14 страницPneumatic Systems: Plastic Injection MoldingSino Ba To100% (1)

- Active Learning Power Actuated Safety Relief ValveДокумент2 страницыActive Learning Power Actuated Safety Relief ValveNur Syazwani KhalidОценок пока нет

- MPP High Performance Multi Phase Pump E00601Документ6 страницMPP High Performance Multi Phase Pump E00601chijioke ekekeОценок пока нет

- Rev.2 Calculation Tag# HAA10AA201Документ4 страницыRev.2 Calculation Tag# HAA10AA201psaayoОценок пока нет

- Thermodynamic Final Exam ReviewДокумент15 страницThermodynamic Final Exam ReviewvistahpОценок пока нет

- Test 1: Name: ClassДокумент2 страницыTest 1: Name: ClassjohnjabarajОценок пока нет

- SGV Series: Storage Filling PumpДокумент2 страницыSGV Series: Storage Filling PumpAnupam MehraОценок пока нет

- Data Sheet 150x100 FS2KA 5 90Документ5 страницData Sheet 150x100 FS2KA 5 90Andreas B KresnawanОценок пока нет

- Management System Certificate: Boge Kompressoren Otto Boge GMBH & Co. KGДокумент2 страницыManagement System Certificate: Boge Kompressoren Otto Boge GMBH & Co. KGRUN GOОценок пока нет

- Coil Tubing ESP APCДокумент6 страницCoil Tubing ESP APCJhon Doe100% (1)

- R407C PDFДокумент20 страницR407C PDFAllizhita Lorena ProañoОценок пока нет

- Oxygen and Argon SeparationДокумент8 страницOxygen and Argon SeparationazizkhouribgaОценок пока нет

- Tuto Chap 3Документ3 страницыTuto Chap 3Zakiyah Mohamed Razi50% (2)

- Plasma Cleaner: Instructions For UseДокумент18 страницPlasma Cleaner: Instructions For UseOzzyОценок пока нет