Академический Документы

Профессиональный Документы

Культура Документы

7.microbiology of Meats

Загружено:

Mahesh DevasigamaniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

7.microbiology of Meats

Загружено:

Mahesh DevasigamaniАвторское право:

Доступные форматы

7

Microbiology of Meats

DOUGLAS L. MARSHALL and M. FARID A. BALA Mississippi State University, Mississippi State, Mississippi

I. INTRODUCTION II. MEAT CONTAMINATION AND DECONTAMINATION III. MEAT AS A SUBSTRATE FOR MICROBIAL PROLIFERATION IV. MICROBIOLOGY OF FERMENTED AND CURED MEATS V. MEAT-ASSOCIATED FUNGI VI. MEAT-ASSOCIATED PARASITES VII. MICROBIAL MODELING VIII. SUMMARY ACKNOWLEDGMENTS REFERENCES

I. INTRODUCTION Contamination of sterile animal muscle used as food is a direct consequence of slaughtering and dressing of animal carcasses. Wide ranges of microorganisms from different sources are introduced onto moist muscle surfaces that are rich in nutrients. It is argued that only a small portion (10%) of these microorganisms is capable of survival and proliferation during storage, distribution, and retail sales of meats. Additionally, an even a smaller portion will eventually predominate and cause spoilage. Survival and proliferation of microorganisms deposited on meat surfaces depends on their ability to withstand processing and storage conditions and to utilize available nutrients in the muscle through assimilation or proteolysis of complex molecules into readily utilizable substrates. Over the years, efforts to preserve meats have focused on retarding microbial growth or killing selected contaminants by applying chemical, physical, or biological treatments whose net outcome should slow or prevent the growth of spoilers or allow harmless fermentative microorganisms to predominate. In either case, successful treatments extend product shelf life and allow its delivery from farm/processor to remote consumption areas.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

150

Marshall and Bala

Microflora of meat products available to consumers at the retail level is a reflection of the environment in which they were processed and the conditions under which they were stored. From a numerical standpoint, using the per capita meat consumption of 88 kilograms (2,109) and an average microbial load of 10,000 colony forming units (CFU) per gram, a family of four annually brings into their home nearly 1 billion microorganisms associated with raw meat products. The nature and composition of viable microorganisms associated with consumer health risks and associated economic impact on the meat industry vary with the nature of the animal, processing, packaging, storage, and handling conditions. Meats can acquire a large variety of pathogenic and spoilage microorganisms during primary and further processing (Table 1). Pathogens can include Clostridium perfringens, Staphylococcus aureus, Salmonella spp., pathogenic Escherichia coli, Campylobacter spp., Yersinia enterocolitica, Listeria monocytogenes, and Aeromonas hydrophila (44,49,112). Meat pathogens can cause self-limiting human enteric diseases or systemic and fatal infections of the immunocompromised, the elderly, and the young. Spoilage of meats is largely dependent on initial microbiological quality and subsequent storage conditions. Pseudomonas spp. predominate in chilled airstored meats, (38) Enterobacteriaceae in temperature-abused meats, (83) lactic acid bacteria and Micrococcaceae in meats packaged with preservatives (82,88) and Brochothrix thermosphacta in vacuum- and modified atmospherepackaged products (118). Gill (42) reviewed the potential sources of meat contamination during slaughter and butchering of food animals. Animal health, hide, viscera, feces, oral microflora, and carcass handling are all potential sources of cross-contamination of sterile muscle during dressing operations. Ultimately, the microbiological quality of dressed carcasses relies a great deal on the skill level of operators during dressing operations, in particular skinning and evisceration, more so than on physical facilities or the types of stock slaughtered (87). Several decontamination approaches have been proposed to enhance the microbiological quality and safety of dressed carcasses (24). Treatments with organic acids (30), hot water (56), steam pasteurization, and steam carcass vacuuming (122) have been implemented in some processing plants. Bacterial species vary widely in their susceptibility to decontamination treatments, with 2 to 3 log population reductions possible (24,26). Determining the microbiological quality of dressed animal carcasses requires obtaining samples for laboratory analysis. Classical sampling methods have included excising a meat surface portion (16,80) or swabbing a defined surface area delimited by a template (57) to determine microbial loads per unit area. Obtained samples are either suspended and homogenized in a diluent and bacterial counts determined directly by spread plate, pour plates, hydrophobic grid membrane filtration (HGMF), or indirectly by ATP bioluminescence or impedance measurements (51,58). According to Gill and Jones (51), HGMF can enhance detection sensitivity to 1 CFU/100 cm2. For routine microbiological monitoring of hygienic quality of carcasses, USDA-FSIS mandates combining samples obtained from three sites of a given carcass and determining E. coli counts (127). In any event, carcass sampling remains a technique and its usefulness in predicting microbiological quality or microbial profiles depends on obtaining a true representative sample in high volume operations (27,79,119). From a practical standpoint, it is impossible to monitor dressed carcasses for all potential pathogens and spoilage microorganisms they may harbor. This consideration limits meat microbiological monitoring to either total aerobic plate counts or to E. coli counts as an indicator of fecal contamination (127). The latter approach is currently favored in view that total aerobic plate counts bear no indication to the potential presence of pathogens (117). However, the use of E. coli counts, or other potential indicator organisms, shows that no single indicator organism is effective for all types of foods (14).

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats

151

Consumers view quality aspects of meats as being good taste, tender, juicy, fresh, lean, healthy, and nutritious. However, cross-cultural differences exist in what is designated as fresh meat (60). The butcher in most developed countries may no longer be the guarantor of meat freshness, quality, and safety because supermarket chains supplied from major processors dominate the meat processing and retailing business. This chapter will address the microbiology of meat products with emphasis placed on the roles that processing, storage, and retailing exert on the microflora. II. MEAT CONTAMINATION AND DECONTAMINATION The microbiological profile of meat products presented to consumers is the sum total of slaughtered animal health, conditions under which it was reared, quality of slaughtering, processing, packaging, and conditions under which the meat was stored. Table 1 lists the common genera of microorganisms found on fresh, processed, and vacuum-packaged meats. Gill (42) reviewed the potential sources of meat contamination during slaughtering and butchering of food animals. Animal health, hide, viscera, feces, oral microflora, and carcass handling are all potential sources of cross contamination of sterile muscle during dressing operations. With cattle and sheep, the major source of initial meat contamination is the animal hide or fleece (6,7,42,62). These sources are exposed to soil, feces, water, and oral microorganisms during animal rearing. It would seem logical that cleaning the hide or fleece before dressing should reduce the number of potential contaminants; however, several studies have failed to confirm this point (9,10,128). On the other hand, scalding treatments applied to pigs destroys gram-negative bacteria, leaving predominantly gram-positive bacteria as survivors (39). Subsequent pig carcass dehairing reintroduces gram-negative bacteria from accumulated detritus and contaminated recirculated water (12,44,49). Animal hides not only introduce spoilage bacteria such as Pseudomonas, Acinetobacter, and Moraxella but also may introduce potential pathogens such as C. perfringens, S. aureus, Salmonella spp., E. coli, Campylobacter spp., Y. enterocolitica, L. monocytogenes, and A. hydrophila (44,49,112). Foodborne pathogens of animal origin can cause human gastroenteritis, and in high-risk populations they can lead to systemic and sometimes fatal infections (8). Other potential risks of meat contamination involve the potential transfer of antibiotic-resistant microorganisms to dressed meats and their ability to subsequently transfer this resistance to other microorganisms in the human gut (102). Evisceration is another critical step where operator skill is required to avoid spilling fecal matter onto skinned carcasses. It has been shown that bacteria deposited on carcasses during eviscerating operations predominantly originate from the mouth and the anus (50). Ultimately, the microbiological quality of dressed carcasses heavily relies on the skill level of operators during skinning and evisceration, more so than on processing plant physical facilities or the type of animal slaughtered (87,90). Little information exists on the impact of misprocessing events on microbiological quality of dressed carcasses. Gill (42) advocated treating common mishaps, such as spilling of gut contents onto carcasses or contamination introduced by operator handling, as events that necessitate special treatment. Accidentally contaminated carcasses should be flagged and detained for extra trimming and washing to remove visible contamination. Gill and Jones (50) showed that carcass pasteurization combined with a modified dressing process that prevents contamination from animal mouth and viscera can produce dressed pig carcasses with average E. coli counts of 1 per carcass and total counts of 2 CFU/cm2. Enhancing the microbiological quality of

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

152

Marshall and Bala

Table 1 Genera of Microorganisms Commonly Found on Meats

Type of meat Gram Rxn BACTERIA Achromobacter Acinetobacter Aeromonas Alcaligenes Alteromonas Bacillus Brochothrix Campylobacter Carnobacterium Citrobacter Clostridium Corynebacterium Enterobacter Enterococcus Escherichia Flavobacterium Hafnia Janthinobacterium Klebsiella Kluyvera Kocuria Kurthia Lactobacillus Lactococcus Leuconostoc Listeria Microbacterium Micrococcus Moraxella Paenibacillus Pantoea Pediococcus Proteus Providencia Pseudomonas Psychrobacter Salmonella Serratia Shewanella Staphylococcus Vibrio Weissella Yersinia Fresh X XX XX X X X X X X X X X X XX X X X X X X X X X X X X X XX X X X X X XX XX X X X X X X Processed Vacuum packaged

X X X X X

X X

XX XX

X X X

X X XX

X X

X XX X X X X X X X X

X X XX X X X

X X

X X X X

X X X X

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats

153

Table 1 Continued

Type of meat Gram Rxn YEASTS Candida Cryptococcus Debaryomyces Hansenula Pichia Rhodotorula Saccharomyces Torulopsis Trichosporon MOLDS Acremonium Alternaria Aspergillus Aureobasidium Botrytis Chrysosporium Cladosporium Fusarium Geotrichum Monascus Monilia Mucor Neurospora Penicillium Rhizopus Scopulariopsis Sporotrichum Thamnidium Fresh XX X X X X X XX X X X X X X XX X XX X X XX X X XX XX XX Processed X XX Vacuum packaged

X X

X XX X X X X X X XX X X X

X known to occur, XX most frequently isolated. Source: Dillon (25); Garcia-Lopez et al. (35); Jay (78).

dressed carcasses entails recognizing microbial hazards (12,91) and designing strategies to limit their spread to muscle foods during carcass dressing. Following dressing, carcasses are split and knife trimmed to remove visible contamination and bruised tissue (126). Studies of trimming practices have indicated that they are purely of aesthetic value and do not contribute to enhancing microbiological quality of dressed carcasses (42,43,57). Furthermore, trimming causes loss of meat and requires extra operator time and effort without necessarily improving microbiological quality (112). The requirement to meet pathogen reduction performance standards has prompted a number of studies in which antimicrobial intervention strategies have been compared. Washes with chemicals have been most advocated. Considerable literature exists on the antibacterial efficacy of dilute solutions of organic acids, hydrogen peroxide, chlorine, chlorine dioxide, and organic acid salts (63,93,108,110). Overall, such interventions can result in reduction of contaminants by 1 to 2 logs (24). In addition to benefiting meat safety, these

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

154

Marshall and Bala

Figure 1 Time required for spoilage development in frankfurters held at different refrigeration

temperatures. (Data from Ref. 130.)

interventions can also improve meat quality. For example, a reduction in the numbers of psychrotrophs by 4 logs can greatly increase the refrigerated shelf life of frankfurters (Fig. 1). Studies that have addressed meatborne pathogens have shown varying susceptibilities to such treatments. Campylobacter jejuni and Y. enterocolitica are among the most susceptible pathogens to acid treatment (92,94), E. coli O157:H7 and L. monocytogenes are more resistant (13,108,120). Smulders and Greer (123) reviewed other prospects of organic acid decontamination and resultant adverse effects on muscle foods. Using organic acids as a decontaminant in abattoirs has been recommended (127); however, a primary concern to meat exporters is that European Union countries do not allow for product decontamination treatments with anything other than potable water (123). The use of hot water to decontaminate dressed carcasses has been studied with beef (15,23), sheep (28), pork (56), and buffalo (113). A typical outcome of carcass washing was the reduction of microbial loads by 2 logs with hot water treatment (80C for 10 sec) (122). Another possible outcome of all wash operations is the uniform redistribution of contaminants from heavily soiled areas to the whole carcass (42). Hot water washes largely have not been adopted commercially in view that large volumes would be needed to uniformly heat a carcass surface. Moreover, economic reasons would impose recirculating hot treatment water, but sanitary concerns would not entertain such cost reductions (42). Alternatively, steam pasteurization has been advocated as a more viable option (19,29,97); however, to ensure adequate carcass surface heating, supra-atmospheric pressures are needed, which entails the need for specialized containment chambers (19). In commercial applications, steam is applied for 6.5 sec without appreciable sensory degradation and results in 2 log and 1 log reduction in E. coli and total aerobic counts, respectively (29,97,106). Steam pasteurization enriches growth of gram-positive bacteria on meats while reducing the more thermally susceptible gram-negative enteric pathogens (42). A less expensive alternative to steam pasteurization chambers involves the use of hot water or steam vacuum hand-held wands. Selected carcass areas can be treated by this method to remove visible contamination. A favorable report exists on the steam-vacuum approach to treat artificially contaminated meats (29). Use of this method in a commer-

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats

155

cial setting was advocated as an alternative to cleaning soiled carcass areas and to reduce the need for subsequent trimming (29). Following the dressing process, carcasses are transferred to chiller rooms. Rapid cooling before the development of rigor results in toughening of the muscle and subsequent loss of meat quality (125). On the other hand, slow cooling ensures rigor and allows for spoilage and pathogenic bacteria to proliferate (42). Commercial chilling of dressed carcasses use chill tunnels that rely on blasts of cold air (48) or spraying of carcasses with chilled water (55,59). It has been proposed that very fast carcass cooling can ensure muscle tenderness and microbiological quality (81); however, major capital spending would be required to implement fast cooling systems in abattoirs (42). Another consequence that accompanies air chilling is drying of the carcass surface by the reduction of surface moisture. Typically a 0.5 log microbial count reduction is observed as a consequence of surface drying (96). Alternative techniques have desiccated the carcass surface with dry heat (18). The major objection to carcass drying is the accompanying carcass weight loss (39). Accordingly, many abattoirs in North America have adopted intermittent spraying with water during the first hours of cooling to avoid weight loss (42). Gill (42) proposed an explanation for the observed reduction in Gram-negative and E. coli counts on spray-cooled carcasses. His twofold mechanism was that (a) spray cooling washed away surface bacterial loads and (b) surface freezing reduces gram-negative bacteria due to their greater susceptibility to freezing. Offal or organ meats are collected in bulk containers during carcass dressing. The geometry of their storage adversely affects subsequent chilling. Product on the periphery of storage containers cools faster than product in the center of the bulk container (42). Even in freezers of high cooling capacities, product at the centers of large containers will cool more slowly (5), thus providing greater opportunity for microbial proliferation. Offal meat pH is usually 6.0, which implies that the major hurdle in restraining microbial growth would be temperature and potential anaerobic conditions produced at the center of bulk containers (45,47). Enhancing the storage potential of offal can been achieved by vacuum or CO2 packaging to noticeably extend shelf life up to several weeks (46). However, efforts by the meat industry to ensure the microbiological quality of offal will remain proportional to their economic value on the market. Hot boning involves breaking down an animal carcass immediately after dressing as boxed manufacturing meats or for further processing into comminuted, cured, or cooked products. Boxing and stacking of hot boned meats in a cooler suffers similar limitations as the earlier described chilling of offal (111). However, temperature control is possible using ice or liquid carbon dioxide (42). Studies are needed to elucidate the effects of rigor development on the proliferation of microorganisms in hot-boned meats (42). Following chilling, carcasses are either broken down into primal cuts or transported to other processing plants for further processing. In either event, personnel hygiene and proper sanitation of equipment and work surfaces are prerequisites to ensure microbiological quality and safety of processed meat products. Visible cleanliness of equipment and work surfaces although advocated (127) may not be a true reflection of sanitary conditions unless coupled with microbiological or bioluminescent assays to ensure efficacy (34). Important sources of microbial contamination of processed meat products include detritus accumulated in inaccessible parts of equipment that subsequently contaminate products that come in touch with these surfaces (69,70). Under these circumstances, bacterial biofilms flourish due to repeated applications of water and the constant availability of nutrients from accumulated detritus. In cooled work environments, cold-tolerant (psychrotrophic) pathogens such as L. monocytogenes, Y. enterocolitica, and A. hydrophila can flourish

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

156

Marshall and Bala

(49,107). Ensuring the quality of processed meats entails making sure that biofilms do not persist day to day on work surfaces and equipment (131). Processed meats and primal cuts await their distribution in coolers. With raw meats, low storage temperature and low pH (5.5) due to rigor are the only two hurdles to slow bacterial proliferation. At all times, meat temperatures should not exceed 7C to prevent pathogenic mesophiles from proliferating (11). Consequently, storage and transport of meat at chilled temperatures lower than 7C is regarded as safe, although some pathogenic psychrotrophs can proliferate at this temperature (42,103). Limiting psychrotroph growth and further extending shelf life can be achieved by lowering the temperature of boxed meat to 1.5C without obvious ice formation (54). At temperatures of 0, 2, and 5C, chilled meat will have a storage life of 70%, 50%, and 30% of the storage life of meat stored at 1.5C (42). Alternatively, meats can be frozen for extended periods of time; however, the microbiological concern for frozen meats requires that temperatures be maintained below 5C, the minimum growth temperature of yeast and mold fungi (42,84,85). Although chill temperatures inhibit microbial growth, pathogens may survive for prolonged periods in meats even though they do not multiply. The microflora of meats available to consumers is the total sum of microorganisms acquired during processing of animal muscle food. Animal health, dressing skills, personnel hygiene, abattoir cleanliness, and adequate storage and holding temperature during distribution and retail influence the constitution and number of microorganisms present (17,72). It is unlikely that a single intervention can fully enhance quality and safety of meats (42). Rather, consumer education (1) coupled with an integrated approach, which ensures better understanding and optimization of each processing step (41), are more likely to enhance the future quality and safety of meats available to consumers. III. MEAT AS A SUBSTRATE FOR MICROBIAL PROLIFERATION Proliferation of microorganisms in meats is dependent on several factors, which include microflora composition, product temperature, previous product treatments, pH, available nutrients, oxidation-reduction potential, and the atmosphere surrounding the product. Many of these factors are not constant throughout the shelf life of a meat product. Understanding the influence of these factors on microbial growth and survival and the impact on meat spoilage has been greatly aided by the pioneering work of Ingram and Dainty (20,21,74,75). More recently, Nychas et al. (101) reviewed the subject of chemical changes associated with stored meats. Common defects of meats and associated bacteria are shown in Table 2. Microbial proliferation in meats occurs in the aqueous phase surrounding the product. This phase is rich in substrates readily utilizable by almost all microorganisms (98). Frozen (12C) meats prevent the growth of contaminating microorganisms but allow for their abundant survival during storage. Spoilage of thawed meats is due to the number and type of microbes present before freezing and the time/temperature conditions of the product during thawing. Thawed meats are often more perishable than fresh meats because of the abundance of drip containing readily utilizable substrates for microbial metabolism. Although the concentrations of carbohydrates (primarily glucose and glycogen) are low in the aqueous phase in comparison to proteins, available concentrations are sufficient to support massive initial microbial proliferation (40,100). After glucose is depleted, microorganisms start using amino acids for energy and as a result produce volatile compounds that are responsible for spoilage odors (31,32,124). Many bacteria, including pseudomonads, produce ammonia during amino acid metabolism, which is a major cause of pH inCopyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats

157

Table 2 Common Defects of Meats and Causal Bacteria

Defect Slime H2O2 greening H2S greening H2S production Sulfide odor Cabbage odor Potato odor Putrefaction Bone taint Bone taint Pocket taint Internal taint Souring Meat product Meats Meats Vacuum-packaged meats Cured meats Vacuum-packaged meats Bacon Ham Ham Whole meats Bacon Bacon Ham Ham Bacteria Pseudomonas, Lactobacillus, Enterococcus, Weissella, Brochothrix Weisella, Leuconostoc, Enterococcus, Lactobacillus Shewanella Vibrio, Enterobacteriaceae Clostridium, Hafnia Providencia Burkholderia, Pseudomonas Enterobacteriaceae, Proteus Clostridium, Enterococcus Proteus, Vibrio Vibrio, Alcaligenes, Proteus Providencia Lactic acid bacteria, Enterococcus, Micrococcus, Bacillus, Clostridium

Source: Garcia-Lopez et al. (35); Gardner (37); Jay (78).

crease in spoiling meat products (101). Gram-negative bacteria predominate during aerobic spoilage and are generally responsible for the production of putrid and sulfury odors (35). The amino acids cystine, cysteine, and methionine are precursors for hydrogen sulfide, methylsulfide, and dimethylsulfide. Amino acid decarboxylation of lysine yields putrescine. Increasing putrescine levels correlate with increasing pseudomonad counts in meats. Decarboxylation of ornithine or arginine yields cadaverine. Increasing cadaverine levels correlate with increasing Enterobacteriaceae counts (22). It has been noted that pseudomonads preferentially deaminate amino acids, whereas Enterobacteriaceae preferentially decarboxylate (89). Bacteria, other than pseudomonads, responsible for malodorous volatile compounds include Shewanella (Alteromonas) putrefaciens, Proteus, Citrobacter, Hafnia, and Serratia (89). The expression of meat spoilage odors from the degradation of amino acids can be delayed by the addition of glucose to meats. The presence of glucose delays the utilization of amino acids by spoilage bacteria and their subsequent development of sensory spoilage characteristics (4,115). Lactate is another low molecular weight component utilized by meat microflora under both aerobic and anaerobic conditions. Lactate is generally utilized after glucose is depleted and can be used in similar strategies to retard spoilage (116). Indeed, according to Gill (40), as long as readily utilizable low molecular weight substrates are available, meat proteolysis is inhibited. Microbial metabolism in chilled air-stored meats is primarily oxidative (101). Aerobic gram-negative bacteria are the common cause of spoilage of meats stored at 4C, with Pseudomonas species predominating. For example, P. fragi, P. fluorescens, and P. lundensis are the dominant species on beef, lamb, and pork (35). Acinetobacter, Psychrobacter, Moraxella, and psychrotrophic Enterobacteriaceae such as Hafnia alvei, Serratia liquefaciens, and Enterobacter agglomerans also occur but their numbers remain low relative to the dominant pseudomonads. Meats packaged under vacuum or modified atmospheres demonstrate a shift from a diverse flora to one that is predominated by lactic acid bacteria and Brochothrix thermoCopyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

158

Marshall and Bala

Figure 2 Hypothetical development of off-odor and slime in meat due to psychrotrophic bacterial growth during storage under various atmospheres at 1C. (Data from Refs. 3 and 95.) sphacta (68). The impact of this shift in microflora is shown in Fig. 2. As illustrated, the time to develop off odors and slime is greatly extended when oxygen is removed from the headspace of packages. Dairy/cheesy odors of meat stored in gas mixtures with carbon dioxide are primarily due to diacetyl, acetoin, and alcohols produced by B. thermosphacta from glucose fermentation (21). End products of B. thermosphacta metabolism differ with the gaseous atmosphere composition. When oxygen tension is low (2 M oxygen), L-lactate, ethanol, and propanol are the main metabolic end products (101). Accordingly, ethanol and propanol could be used as spoilage indicators of meat stored under vacuum of modified atmosphere (98,101). Future prospects of meat substrate and bacterial metabolite studies could point the way to analytical techniques that could assess meat spoilage without resorting to time-consuming microbiological analysis. According to Jay (77), metabolite-based spoilage detection should ensure that (a) the spoilage indicator is not normally present in the food, (b) the indicator concentration should increase with storage time, and (c) the concentrations of the indicator should reflect the most predominant microorganisms and correlate with sensory quality. IV. MICROBIOLOGY OF FERMENTED AND CURED MEATS Comminuted raw meats fermented into various sausages requires the aid of salt, nitrate/nitrite, and desirable fermentative lactic acidproducing bacteria. When properly fermented, pathogens and spoilage bacteria will be eliminated or greatly reduced in numbers, which yields products with superior shelf-life attributes. In addition, desirable sensory properties are achieved. For example, cured red/pink color, robust flavor, and firm texture are unique to this product type (68). Growth and acid production of lactic acid-forming bacteria are promoted by pH below 6.0, water activity (aw) of 0.96 due to salt (2.5 to 3.0%), 100 ppm sodium nitrite, and 0.3% glucose. When stuffed into casings, the redox potential of the sausage is reduced,

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats

159

which further enhances activity of the lactic acid bacteria (68). Despite the wide variety of fermented meats around the world and various technical differences during processing, the bacteria that tend to dominate in naturally fermented sausages are usually Lactobacillus sake and Lactobacillus curvatus (61,73,114). Predominance of these two species is based on their ability to grow at reduced aw (0.91) and low temperature (4C). Other psychrotrophic lactics (Carnobacterium spp., Leuconostoc spp. and Weissella spp.) are either less halotolerant (except Weissella halotolerans) or grow poorly below 7C (Lactobacillus pentosus, Lactobacillus plantarum, Pediococcus acidilactici, and Pediococcus pentosaceus) (86). Many traditional fermentations use nitrate as the curing agent. As such, the presence of nitrate-reducing micrococci (Micrococcus varians, Staphylococcus carnosus, Staphylococcus xylosus, or Staphylococcus piscifermentans) is necessary to form nitrite, which is needed for proper quality (color) and safety (antibotulinal activity) (67,68,99). Because the reliability of natural fermentations is occasionally less than desired, most industrial processing of fermented sausages use domesticated starter culture bacteria. These starters are either single or mixed strains of homofermentative lactic acid bacteria. When nitrate is used, micrococci also are included (67,86). Commonly used lactics include L. sake, L. curvatus, L. plantarum, L. pentosus, and P. pentosaceus (P. cerevisiae) (33,66,86,129). Strains are selected primarily for their ability to rapidly acidify, accelerate ripening, and improve color intensity and stability at the fermentation temperature desired (Table 3) (64,65). Spoilage microflora in fresh sausages generally are similar to those found in ground meat. Type of meat, presence of preservatives, and storage temperature and atmosphere will determine the predominant microbes (35). Like fresh meats, products in air-permeable packaging will have pseudomonads predominating during low temperature storage and Enterobacteriaceae during higher temperature storage. Presence of these bacteria on fully cooked products is the result of post-heating contamination, usually during casing removal, slicing, and subsequent handling during packaging. Because of the facultatively anaerobic nature of most Enterobacteriaceae, they tend to predominate in vacuum-and modified atmospherepackaged products stored at high temperatures (10C) (35,104). However, this group competes poorly with lactic acid bacteria under proper chill storage conditions (12). Similarly, gram-negative bacteria usually will not spoil fermented sausages, dried meats, and canned meats (35). Bacteria that are resistant to salt and low aw, nitrite, and fermentation and ripening temperatures will be selected for in fermented sausage products. Many of the same microorganisms are found on cured unfermented products such as hams and bacon. For ex-

Table 3 Lactic Acid Bacteria Used as Starter Cultures for Fermented Sausages at Various Processing Temperatures Bacteria type Thermophiles Mesophiles Psychrotrophs

Source: Holzapfel (68).

Process temperature (C) 3038 2025 1520

Bacterial species Pediococcus acidilactici Pediococcus cerevisiae Lactobacillus pentosus Lactobacillus plantarum Lactobacillus sake Lactobacillus curvatus

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

160

Marshall and Bala

ample, Micrococcaceae, lactic acid bacteria (Carnobacterium and Leuconostoc), Vibrio, Enterobacteriaceae, and other gram-negative bacteria (Psychrobacter, Acinetobacter, and Proteus) are the major microbial groups found on cured products (12,35,37). Among the halophilic (salt loving) vibrios, Vibrio costicola is a common slime former (36). V. MEAT-ASSOCIATED FUNGI Carcasses aged at very low temperatures (5C) can have surface defects caused by molds (Table 1). For example black, white, blue-green, and whisker spots may be evident (25). Cladosporium cladosporioides, Cladosporium herbarum, Penicillium hirsutum, and Aureobasidium pullulans were identified as causative agents of black spot (52,53); Chrysosporium pannorum and Acremonium sp. caused white spots (85). Blue-green spots were associated with Penicillium corylophilum and whisker spots were caused by Thamnidium elegans and Mucor racemosus (85). In addition to bacteria, several molds have been responsible for cured meat spoilage. Low aw and presence of oxygen selects for molds from the genera Aspergillus, Alternaria, Fusarium, Mucor, Rhizopus, Botrytis, and Penicillium (25,78). Some dry-cured products, such as European sausages, Italian salami, and country-cured hams, can support prolific growth of aspergilli and penicillia. There is some speculation that the characteristic flavors of these products are due in part to the presence of these fungi (25,78,105). Like many molds and bacteria, psychrotrophic yeasts are capable of growing on meats during refrigerated storage (Table 1). Most yeast-associated meat spoilage occurs when the product has been treated in such a manner to reduce the level and activity of contaminating bacteria. Such treatments usually include low pH by acidification or low aw by salting, drying, or freezing (25). In fresh meats, however, yeasts generally are unable to compete with bacteria because of their slower growth rates. As such, their numbers remain low in proportion to bacterial counts. Candida spp. are the predominate yeast isolated from raw meats (25,71). Spoilage caused by yeasts is typically related to slime formation on products such as dried sausages, wieners, cured hams, and salami. Debaryomyces spp. and Candida spp. are the predominate yeasts found in processed meats (25). VI. MEAT-ASSOCIATED PARASITES Several microscopic animal parasites may be harbored in meats (Table 4). Parasitic protozoa, flatworms, and roundworms associated with meat animals can be infectious to consumers. Unlike bacteria and fungi, the parasites do not grow in foods but are merely transported either intramuscularly or as surface contaminates. Surface contamination can come from contact with feces or more commonly from use of contaminated water supplies. Fortunately, most parasites are easily killed by proper cooking (80C internal temperature) and handling of products. Long-term freezing (10C for 30 days) or salting of meats also has been shown to inactivate many of the parasites (78). Among protozoa, the coccidian Toxoplasma gondii may cause toxoplasmosis in individuals consuming raw or undercooked meats from cattle, pigs, sheep, and goats (76,121). Sarcocystis hominis and Sarcocystis suihominis may be transmitted by consumption of raw beef and pork (78). Cryptosporidium parvum has been linked to ingestion of leftover beef tripe (78). The flatworm Fasciola hepatica is infrequently found in beef livers. Most other flat-

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats Table 4 Parasites Commonly Associated with Meats Parasite Protozoa Genus Toxoplasma Sarcocystis Cryptosporidium Fasciola Taenia Trichinella Meat Beef, pork, sheep, goat Beef Beef Beef liver Beef, pork Pork

161

Flatworms Tapeworms Roundworms

Source: Jay (78).

worms are distributed in fish rather than meat animals (78). The common tapeworms Taenia saginata (Taeniarhynchus saginatus) and Taenia solium can cause mild human illness in consumers eating raw or undercooked beef and pork, respectively. Of more severity is the illness trichinosis, caused by consumption of raw or undercooked pork containing the roundworm Trichinella spiralis. This illness can occasionally be fatal (78). VII. MICROBIAL MODELING

Predictive modeling of microbial growth and survival in meats has become an increasingly important tool in studying the behavior of spoilage and pathogenic microorganisms under different environmental conditions. Predicting the impact of intrinsic (nutrients, pH, salt, nitrite, etc.) and extrinsic (atmosphere, temperature) factors on microorganisms can help processors and regulators determine optimum conditions needed for enhanced quality and safety. Two computer-based modeling programs are available: Food Micromodel (Leatherhead, Surrey, UK) and Pathogen Modeling Program (USDA, Wyndmoor, PA). Example outputs from the USDA model are illustrated in Figs. 3 through 5. Figure 3 shows predicted growth potential of E. coli O157:H7 under specified atmosphere, temperature, pH, salt, and nitrite conditions. Figure 4 demonstrates the predicted amount of time needed to achieve a 3 log or greater reduction in the numbers of L. monocytogenes at pH 3.5, 16.9C, and 0.5% NaCl. Figure 5 illustrates the predicted survival of S. typhimurium at 0C with increasing gamma irradiation doses. VIII. SUMMARY The numbers and types of microorganisms found on meats are determined by the environment under which the animals were raised and processed, and the meat packaged and stored. With current technology it is nearly impossible to produce sterile meats without excessive thermal or irradiation processing. That said, proper animal husbandry, workplace sanitation, and processing will produce edible meats with acceptable microbial numbers and low or no human pathogens. However, it must be expected that raw meats will contain potential human pathogens. In addition, with the possible exception of canned meats, most processed meats will have a limited shelf life that is dictated by the quantity and kinds of spoilage microorganisms on the product. Meat processors have the expectation that farmers and feedlots will provide animals for slaughter that are safe for meat production. Like-

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

162

Marshall and Bala

Figure 3 Predicted aerobic growth of Escherichia coli O157:H7 using the USDA Pathogen Modeling Program.

Figure 4 Predicted low pH inactivation time needed for Listeria monocytogenes using the USDA

Pathogen Modeling Program.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats

163

Figure 5 Predicted irradiation inactivation curve for Salmonella typhimurium using the USDA Pathogen Modeling Program.

wise, consumers have the expectation that meat products available for consumption are safe and wholesome. Failure by the meat industry to meet these expectations frequently leads to microbial problems and ultimately decreased consumer demand. Therefore, understanding the quantity and nature of meatborne microorganisms remains a critical issue for long-term viability of the industry. ACKNOWLEDGMENTS The USDA Pathogen Modeling Program ver. 5.1 was developed by R. L. Buchanan, Ph.D., R. C. Whiting, Ph.D., and A. R. Pickard, Ph.D., at the Microbial Food Safety Research Unit of the USDA/ARS Eastern Regional Research Center in Wyndmoor, PA. REFERENCES

1. 2. 3. 4. 5. 6. 7. Altekruse, S. F., D. A. Street, S. B. Fein, and A. S. Levy. 1996. Consumer knowledge of foodborne microbial hazards and food-handling practices. J Food Prot 59:287294. Anonymous. 1997. U.S. per capita food consumption. Family Econom Nutr Rev 10:3842. Ayres, J. C. 1960. The relationship of organisms of the genus Pseudomonas to the spoilage of meat, poultry and eggs. J Appl Bacteriol 23:471486. Barua, M., and L. A. Shelef. 1980. Growth suppression of pseudomonads by glucose utilization. J Food Sci 45:34951. Baxter, D. C. 1962. The fusion of slabs and cylinders. J Heat Transfer 84:317320. Bell, R. G. 1997. Distribution and sources of microbial contamination on beef carcasses. J Appl Microbiol 82:292300. Bell, R. G., and S. C. Hathaway. 1996. The hygienic efficiency of conventional and inverted lamb dressing systems. J Appl Bacteriol 81:225234.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

164 8. 9.

Marshall and Bala Bishai, W. R., and C. L. Sears. 1993. Food poisoning syndromes. Gastroenterol Clin N Am 22:579608. Biss, M. E., and S. C. Hathaway. 1995. Microbiological and visible contamination of lamb carcasses according to preslaughter presentation status: implications for HACCP. J Food Prot 58:776783. Biss, M. E., and S. C. Hathaway. 1996. Effect of pre-slaughter washing of lambs on the microbiological and visible contamination of the carcases. Vet Rec 138:8286. Bogh-Sorensen, L., and P. Olsson. 1990. The chill chain. In: T.R. Gormley (Ed.) Chilled Foods: The State of the Art. pp. 245267. Elsevier, London. Borch, E., T. Nesbakken, and H. Christensen. 1996. Hazard identification in swine slaughter with respect to foodborne bacteria. Int J Food Microbiol 30:925. Brackett, R. E., Y. Y. Hao, and M. P. Doyle. 1994. Ineffectiveness of hot acid sprays to decontaminate Escherichia coli O157:H7 on beef. J Food Prot 57:198203. Buchanan, R. L., F. J. Shultz, M. H. Golden, K. Bagi, and B. Marmer. 1992. Feasibility of using microbiological indicator assays to detect temperature abuse in refrigerated meat, poultry, and seafood products. Food Microbiol 9:279301. Castillo, A., L. M. Lucia, K. J. Goodson, J. W. Savell, and G. R. Acuff. 1998. Use of hot water for beef carcass decontamination. J Food Prot 61:1925. Charlebois, R., R. Trudel, and S. Messier. 1991. Surface contamination of beef carcasses by fecal coliforms. J Food Prot 54:950956. Collins, J. D. 1995. Animal health and the role of the veterinary food hygienist in the control of meat borne infections. J Food Safety 15:145156. Cutter, C. N., W. J. Dorsa, and G. R. Siragusa. 1997. Rapid desiccation with heat in combination with water washing for reducing bacteria on beef carcass surfaces. Food Microbiol 14:493503. Cygnarowicz-Provost, M., J. C. Craig Jr., and R. C. Whiting. 1995. Computer control of a steam surface pasteurization process. J Food Eng 25:131139. Dainty, R. H. 1982. Biochemistry of undesirable effects attributed to microbial growth on proteinaceous foods stored at chill temperatures. Food Chem 9:103113. Dainty, R. H., and C. M. Hibbard. 1983. Precursors of the major end products of aerobic metabolism of Brochothrix thermosphacta meat-spoilage organisms. J Appl Bacteriol 55:127133. Dainty, R. H., and B. M. Mackey. 1992. The relationship between the phenotypic properties of bacteria from chill-stored meat and spoilage process. J Appl Bacteriol 73:Symp. Suppl. 21:103S114S. Davey, K. R. 1990. A model for the hot water decontamination of sides of beef in a novel cabinet based on laboratory data. Int J Food Sci Technol 25:8897. Dickson, J. S., and M. E. Anderson. 1992. Microbiological decontamination of food animal carcasses by washing and sanitizing systems: a review. J Food Prot 55:133140. Dillon, V. M. 1998. Yeasts and moulds associated with meat and meat products. In: A. Davies and R. Board (Ed.) The Microbiology of Meat and Poultry. pp. 85117. Blackie Academic & Professional, New York. Dorsa, W. J. 1997. New and established carcass decontamination procedures commonly used in the beef-processing industry. J Food Prot 60:11461151. Dorsa, W. J., and G. R. Siragusa. 1998. A representative microbial sampling method for large commercial containers of raw beef based on purge. J Food Prot 61:162165. Dorsa, W. J., C. N. Cutter, and G. R. Siragusa. 1996a. Effectiveness of a steam-vacuum sanitizer for reducing Escherichia coli O157:H7 inoculated to beef carcass surface tissue. Lett Appl Microbiol 23:6163. Dorsa, W. J., C. N. Cutter, G. R. Siragusa, and M. Koohmaraie. 1996b. Microbial decontamination of beef and sheep carcasses by steam, hot water spray washes, and a steam-vacuum sanitizer. J Food Prot 59:127135.

10. 11. 12. 13. 14.

15. 16. 17. 18.

19. 20. 21.

22.

23. 24. 25.

26. 27. 28.

29.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats 30.

165

31. 32.

33. 34.

35.

36. 37.

38.

39. 40. 41. 42.

43. 44. 45. 46. 47. 48. 49. 50.

Dorsa, W. J., C. N. Cutter, and G. R. Siragusa. 1997. Effects of acetic acid, lactic acid and trisodium phosphate on the microflora of refrigerated beef carcass surface tissue inoculated with Escherichia coli O157:H7, Listeria innocua, and Clostridium sporogenes. J Food Prot 60:619624. Edwards, R. A., and R. H. Dainty. 1987. Volatile compounds associated with the spoilage of normal and high pH vacuum-packed pork. J Sci Food Agric 38:5766. Edwards, R. A., R. H. Dainty, and C. M. Hibbard. 1987. Volatile compounds produced by meat pseudomonads and related reference strains during growth on beef stored in air at chill temperatures. J Appl Bacteriol 62:403412. Engesser, D. M., and W. P. Hammes. 1994. Non-heme catalase activity of lactic acid bacteria. System Appl Microbiol 17:1119. Farrell, B. L., A. B. Ronner, and A. C. Wong. 1998. Attachment of Escherichia coli O157:H7 in ground beef to meat grinders and survival after sanitation with chlorine and peroxyacetic acid. J Food Prot 61:81722. Garcia-Lopez, M. L., M. Preito, and A. Otero. 1998. The physiologic attributes of Gram-negative bacteria associated with spoilage of meat and meat products. In: A. Davies and R. Board (Ed.) The Microbiology of Meat and Poultry. pp. 134. Blackie Academic & Professional, New York. Gardner, G. A. 1981. Identification and ecology of salt-requiring Vibrio associated with cured meats. Meat Sci 5:7181. Gardner, G. A. 1983. Microbial spoilage of cured meats. In: T. A. Roberts and F. A. Skinner (Ed.) Food Microbiology: Advances and Prospects. pp. 179202. Academic Press, London. Gennari, M., and F. A. Dragotto. 1992. Study of the incidence of different fluorescent Pseudomonas species and biovars in the microflora of fresh and spoiled meat and fish, raw milk, cheese, soil and water. J Appl Bacteriol 72:281288. Gigiel, A. J., P. Collert, and S. J. James. 1989. Fast and slow beef chilling in a commercial chiller and the effects of operational factors on weight loss. Int J Refrig 12:338349. Gill, C. O. 1976. Substrate limitation of bacterial growth at meat surfaces. J Appl Bacteriol 41:401410. Gill, C. O. 1995. Current and emerging approaches to assuring the hygienic condition of red meats. Can J Anim Sci 75:113. Gill, C. O. 1998. Microbiological contamination of meat during slaughter and butchering of cattle, sheep and pigs. In: A. Davies and R. Board (Ed.) The Microbiology of Meat and Poultry. pp. 118157. Blackie Academic & Professional, New York. Gill, C. O., and L. P. Baker. 1998. Assessment of the hygienic performance of a sheep carcass dressing process. J Food Prot 61:329333. Gill, C. O., and J. Bryant. 1993. The presence of Escherichia coli, Salmonella and Campylobacter in pig carcass dehairing equipment. Food Microbiol 10:337344. Gill, C. O., and K. M. Delacy. 1982. Microbial spoilage of whole sheep livers. Appl Environ Microbiol 43:126266. Gill, C. O., and L. E. Jeremiah. 1991. The storage life of non-muscle offals packaged under vacuum or carbon dioxide. Food Microbiol 8:339353. Gill, C. O., and S. D. M. Jones. 1992a. Efficiency of a commercial process for the storage and distribution of vacuum-packaged beef. J Food Prot 55:880887. Gill, C. O., and T. Jones. 1992b. Assessment of the hygienic efficiencies of two commercial processes for cooling pig carcass. Food Microbiol 9:335343. Gill, C. O., and T. Jones. 1995. The presence of Aeromonas, Listeria and Yersinia in carcass processing equipment at two pig slaughtering plants. Food Microbiol 12:135141. Gill, C. O., and T. Jones. 1997. Assessment of the hygienic characteristics of a process for dressing pasteurized pig carcasses. Food Microbiol 14:8191.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

166 51. 52. 53. 54.

Marshall and Bala Gill, C. O., and T. Jones. 1998. Comparison of methods for sampling and enumerating Escherichia coli on pig carcasses. Food Microbiol 15:617623. Gill, C. O., and P. D. Lowry. 1981. A note on the identities of organisms causing black spot spoilage of meat. J Appl Bacteriol 51:183187. Gill, C. O., and P. D. Lowry. 1982. Growth at sub-zero temperatures of black spot fungi from meat. J Appl Bacteriol 52:245250. Gill, C. O., D. M. Phillips, and J. C. L. Harrison. 1988. Product temperature criteria for shipment of chilled meats to distant markets. In: Refrigeration for Food and People. pp. 4047. Int Inst Refrig, Paris. Gill, C. O., S. D. M. Jones, and A. K. W. Tong. 1991. Application of a temperature function integration technique to assess the hygienic adequacy of a process for spray chilling beef carcasses. J Food Prot 54:731736. Gill, C. O., D. S. McGinnis, J. Bryant, and B. Chabot. 1995. Decontamination of commercial, polished pig carcasses with hot water. Food Microbiol 12:143149. Gill, C. O., M. Badoni, and T. Jones. 1996. Hygienic effects of trimming and washing operations in a beef-carcass-dressing process. J Food Prot 59:666669. Greer, G. G., and B. D. Dilts. 1997. Enumeration of meatborne spoilage bacteria with hydrophobic grid membrane filtration. J Food Prot 60:13881390. Greer, G. G., and S. D. M. Jones. 1997. Quality and bacteriological consequences of beef carcass spray-chilling: effects of spray duration and boxed beef storage temperature. Meat Sci 45:6173. Grunert, K. G. 1997. Whats in a steak? A cross-cultural study on the quality perception of beef. Food Qual Prefer 8:157174. Gurakan, G. C., T. F. Bozoglu, and N. Weiss. 1995. Identification of Lactobacillus strains from Turkish fermented sausages. Lebensm-Wiss u-Technol 28:139144. Hadley, P. J., J. S. Holder, and M. H. Hinton 1997. Effects of fleece soiling and skinning method on the microbiology of sheep carcases. Vet Rec 140:570574. Hamby, P. L., J. W. Savell, G. R. Acuff, C. Vanderzant, and H. R. Cross. 1987. Spray-chilling and carcass decontamination systems using lactic and acetic acid. Meat Sci 21:114. Hammes, W. P. 1993. Zum Reifen von Rohwurst geeignete Mikroorganismen der Art Lactobacillis sake. German Fed Rep Pat DE 42 01 050 C1. Hammes, W. P. 1995. Zum Reifen von Rohwurst geeignete Mikroorganismen vom Stamm Lactobacillis sake. German Fed Rep Pat EP 0 641 857 A1. Hammes, W. P., A. Bantleon, and S. Min. 1990. Lactic acid bacteria in meat fermentation. FEMS Microbiol Rev 87:165174. Hammes, W. P., I. Bosch, and G. Wolf. 1995. Contribution of Staphylococcus carnosus and Staphylococcus piscifermentans to the fermentation of protein foods. J Appl Bacteriol, Symp Suppl 79:76S83S. Holzapfel, W. H. 1998. The Gram-positive bacteria associated with meat and meat products. In: A. Davies and R. Board (Ed.) The Microbiology of Meat and Poultry. pp. 3584. Blackie Academic & Professional, New York. Hood, S. K., and E. A. Zottola. 1997a. Adherence to stainless steel by foodborne microorganisms during growth in model food systems. Int J Food Microbiol 37:145153. Hood, S. K., and E. A. Zottola. 1997b. Isolation and identification of adherent gram-negative microorganisms from four meat-processing facilities. J Food Prot 60:11351138. Hsieh, D. Y., and J. M. Jay. 1984. Characterization and identification of yeasts from fresh and spoiled ground beef. Int J Food Microbiol 1:141147. Hudson, W. R., G. C. Mead, and M. H. Hinton. 1996. Relevance of abattoir hygiene assessment to microbial contamination of British beef carcases. Vet Rec 139:587589. Hugas, M., M. Garriga, M. T. Aymerich, and J. M. Montfort. 1993. Biochemical characterisation of lactobacilli from dry fermented sausages. Int J Food Microbiol 18:107113.

55.

56. 57. 58. 59.

60. 61. 62. 63. 64. 65. 66. 67.

68.

69. 70. 71. 72. 73.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats 74. 75. 76. 77.

167

78. 79. 80. 81. 82.

83.

84. 85. 86.

87. 88. 89. 90. 91. 92. 93. 94.

95. 96.

Ingram, M. 1971. Microbial changes in foodsgeneral considerations. J Appl Bacteriol 34:18. Ingram, M., and R. H. Dainty. 1971. Changes caused by microbes in the spoilage of meats. J Appl Bacteriol 34:2139. Jackson, M. H., and W. M. Hutchison. 1989. The prevalence and source of Toxoplasma infection in the environment. Adv Parasitol 28:55105. Jay, J. M. 1986. Microbial spoilage indicators and metabolites. In: M. D. Pierson and J. N. Stern (Ed.) Foodborne Microorganisms and their Toxins: Developing Methodology. pp. 219240. Marcel Dekker, Basel. Jay, J. M. 1998. Modern Food Microbiology (5th Ed.). Aspen Publishers, Gaithersburg, MD. Jericho, K. W. F., J. A. Bradley, and G. C. Kozub. 1994. Bacteriological variation of groups of beef carcasses before the wash at six Alberta abattoirs. J Appl Bacteriol 77:631634. Jericho, K. W. F., J. A. Bradley, and G. C. Kozub. 1995. Microbiologic evaluation of carcasses before and after washing in a beef slaughter plant. J Am Vet Med Assoc 206:452455. Joseph, R. L. 1996. Very fast chilling of beef and tendernessa report from an EU concerted action. Meat Sci 43:S217S227. Leisner, J. J., G. G. Greer, B. D. Dilts, and M. E. Stiles. 1995. Effect of growth of selected lactic acid bacteria on storage life of beef stored under vacuum and in air. Int J Food Microbiol 26:231243. Lindberg, A. M., A. Ljungh, S. Ahrne, S. Lofdahl, and G. Molin. 1998. Enterobacteriaceae found in high numbers in fish, minced meat and pasteurised milk or cream and the presence of toxin encoding genes. Int J Food Microbiol 39:1117. Lowry, P. D., and C. O. Gill. 1984a. Development of a yeast microflora on frozen lamb stored at 5C. J Food Prot 47:309311. Lowry, P. D., and C. O. Gill. 1984b. Temperature and water activity minima for growth of spoilage molds from meat. J Appl Bacteriol 56:19399. Lucke, F.-K. 1996. Lactic acid bacteria involved in food fermentations and their present and future uses in food industry. In: T. F. Bozoglu and B. Ray (Ed.) Lactic Acid Bacteria: Current Advances in Metabolism, Genetics and Applications, Vol. 98. pp. 8199. NATO ASI Series, Series H: l Biology, Springer Verlag, Berlin. Mackey, B. M., and T. A. Roberts. 1993. Improving slaughtering hygiene using HACCP and monitoring. Fleischwirtsch Int 2:4045. Makela, P. M., H. J. Korkeala, and J. J. Laine. 1992. Ropy slime-producing lactic acid bacteria contamination at meat processing plants. Int J Food Microbiol 17:2735. McMeekin, T. A. 1982. Microbial spoilage of meats. In: R. Davies (Ed.) Developments in Food Microbiology1. pp. 139. Applied Science, London. Mukartini, S., C. Jehne, B. Shay, and C. M. L. Harper. 1995. Microbiological status of beef carcass meat in Indonesia. J Food Safety 15:291303. Nesbakken, T., G. Kapperud, and D. A. Caugant. 1996. Pathways of Listeria monocytogenes contamination in the meat processing industry. Int J Food Microbiol 31:161171. Netten, P. V., and J. H. Huis Int Veld. 1994. The effect of lactic acid decontamination on the microflora on meat. J Food Safety 14:243257. Netten, P. V., D. A. A. Mossel, and J. H. Huis Int Veld. 1995. Lactic acid decontamination of fresh pork carcasses: a pilot plant study. Int. J Food Microbiol 25:19. Netten, P. V., A. Valentijn, D. A. A. Mossel, and J. H. Huis Int Veld. 1997. Fate of low temperature and acid-adapted Yersinia enterocolitica and Listeria monocytogenes that contaminate lactic acid decontaminated meat during chill storage. J Appl Microbiol 82:769779. Newton, K. G., J. C. L. Harison, and K. M. Smith. 1977. The effect of storage in various gaseous atmospheres on the microflora of lamb chops held at 1C. J Appl Bacteriol 43:53 Nottingham, P. M. 1982. Microbiology of carcass meats. In: M. H. Brown (Ed.) Meat Microbiology. pp. 1366. Applied Science, London.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

168 97.

Marshall and Bala Nutsch, A. L., R. K. Phebus, M. J. Riemann, D. E. Schafer, J. E. Boyer, Jr., R. C. Wilson, J. D. Leising, and C. L. Kastner. 1997. Evaluation of a steam pasteurization process in a commercial beef processing facility. J Food Prot 60:485492. Nychas, G. J. E. 1994. Modified atmospheric packaging of meats. In: R. P. Singh and F. A. R. Oliveira (Ed.) Minimal Processing of Foods and Process Optimization. pp. 417435. CRC Press, London. Nychas, G. J. E., and J. S. Arkoudelos. 1990. Staphylococci: their role in fermented sausages. J Appl Bacteriol, Symp Suppl 71:167S188S. Nychas, G. J., V. M. Dillon, and R. G. Board. 1988. Glucose the key substrate in the microbiological changes occurring in meat and certain meat products. Biotechnol Appl Biochem 10:203231. Nychas, G.-J. E., E. H. Drosinos, and R. G. Board. 1998. Chemical changes in stored meat. In: A. Davies and R. Board (Ed.) The Microbiology of Meat and Poultry (1st Ed.). pp. 288326. Blackie Academic & Professional, New York. Okolo, M. I. 1986. Bacterial drug resistance in meat animals: a review. Int J Zoonoses 13:14352. Palumbo, S. A. 1986. Is refrigeration enough to restrain food pathogens? J Food Prot 49:10031009. Penney, N., C. J. Hagyard, and R. G. Bell. 1993. Extension of shelf-life of chilled sliced roast beef by carbon dioxide packaging. Int J Food Sci Technol 28:181191. Pestka, J. J. 1986. Fungi and mycotoxins in meats. In: A. M. Pearson and T. R. Dutson (Ed.) Advances in Meat Research, Meat and Poultry Microbiology. pp. 277309. MacMillan, Basingstoke. Phebus, R. K., A. L. Nutsch, D. E. Schafer, R. C. Wilson, M. J. Riemann, J. D. Leising, C. L. Kastner, J. R. Wolf, and R. K. Prasai. 1997. Comparison of steam pasteurization and other methods for reduction of pathogens on surfaces of freshly slaughtered beef. J Food Prot 60:476484. Pociecha, J. Z., K. R. Smith, and G. J. Manderson. 1991. Incidence of Listeria monocytogenes in meat production environments of a South Island (New Zealand) mutton slaughterhouse. Int J Food Microbiol 13:321327. Prasai, R. K., C. L. Kastner, P. B. Kenney, D. H. Kropf, D. Y. C. Fung, L. E. Mease, L. R. Vogt, and D. E. Johnson. 1997. Microbiological quality of beef subprimals as affected by lactic acid sprays applied at various points during vacuum storage. J Food Prot 60:795798. Putnam, J. J., and L. A. Duewer. 1995. U.S. per capita food consumption: record-high meat and sugars in 1994. Food Rev 18:211. Reagan, J. O., G. R. Acuff, D. R. Buege, M. J. Buyck, J. S. Dickson, C. L. Kastner, J. L. Marsden, J. B. Morgan, R. Nickelson, II, and G. C. Smith. 1996. Trimming and washing of beef carcasses as a method of improving the microbiological quality of meat. J Food Prot 59:751756. Reichel, M. P., D. M. Phillips, R. Jones, and C. O. Gill. 1991. Assessment of the hygienic adequacy of a commercial hot boning process for beef by a temperature function integration technique. Int J Food Microbiol 14:2742. Rogers, S. A., N. W. Hollywood, and G. E. Mitchell. 1992. The microbiological and technological properties of bruised beef. Meat Sci 32:43747. Sachindra, N. M., P. Z. Sakhare, and D. N. Rao. 1998. Reduction in microbial load on buffalo meat by hot water dip treatment. Meat Sci 48:149157. Samelis, J., F. Maurogenakis, and J. Metaxopoulos. 1994. Characterisation of lactic acid bacteria isolated from naturally fermented Greek dry salami. Int J Food Microbiol 23:179196. Shelef, L. A. 1977. Effect of glucose on the bacterial spoilage of beef. J Food Sci 42:11721175. Shelef, L. A. 1994. Antimicrobial effects of lactates: a review. J Food Prot 57:445450.

98.

99. 100.

101.

102. 103. 104. 105.

106.

107.

108.

109. 110.

111.

112. 113. 114. 115. 116.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Microbiology of Meats 117. 118.

169

119. 120. 121. 122. 123.

124.

125. 126. 127. 128.

129. 130. 131.

Sheridan, J. J. 1995. The role of indicator systems in HACCP operations. J Food Safety 15:157180. Sheridan, J. J., A. M. Doherty, P. Allen, D. A. McDowell, I. S. Blair, and D. Harrington. 1997. The effect of vacuum and modified atmosphere packaging on the shelf-life of lamb primals, stored at different temperatures. Meat Sci 45:107117. Siragusa, G. R., and C. N. Cutter. 1995. Microbial ATP bioluminescence as a means to detect contamination on artificially contaminated beef carcass tissue. J Food Prot 58:764769. Siragusa, G. R., and J. S. Dickson. 1992. Inhibition of Listeria monocytogenes on beef tissue by application of organic acids immobilized in a calcium alginate gel. J Food Sci 57:293296. Smith, J. L. 1993. Documented outbreaks of toxoplasmosis: Transmission of Toxoplasma gondii to humans. J Food Prot 630639. Smith, M. G., and K. R. Davey. 1990. Destruction of Escherichia coli on sides of beef by a hot water decontamination process. Food Australia 42:19598. Smulders, F. J. M., and G. C. Greer. 1998. Integrating microbial decontamination with organic acids in HACCP programs for muscle foods: prospects and controversies. Int J Food Microbiol 44:149169. Stanley, G., K. J. Shaw, and A. F. Egan. 1981. Volatile compounds associated with spoilage of vacuum-packaged sliced luncheon meat by Brochothrix thermosphacta. Appl Environ Microbiol 41:816818. Tornberg, E. 1996. Biophysical aspects of meat tenderness. Meat Sci 43:S175S191. USDA. 1993. U.S. Department of Agriculture. Beef carcass trimming versus washing study: Fiscal year 1993. Fed Regist 58:3392533932. USDA. 1996. U.S. Department of Agriculture. Pathogen reduction; hazard analysis and critical control point (HACCP) system; Final rule. Fed Regist 61:3880538989. Van Donkersgoed, J., G. Jewison, M. Mann, B. Cherry, B. Altwasser, R. Lower, K. Wiggins, R. Dejonge, B. Thoriakson, and E. Moss. 1997. Canadian beef quality audit. Can Vet J 38:217225. Wolf, G., and W. P. Hammes. 1988. Effect of hematin on the activities of nitrite reductase and catalase in lactobacilli. Arch Mikrobiol 149:220224. Zottola, E. A. 1972. Introduction to Meat Microbiology. American Meat Institute, Chicago. Zottola, E. A., and K. C. Sasahara. 1994. Microbial biofilms in food processing industry should they be a concern? Int J Food Microbiol 23:12548.

Copyright 2001 by Marcel Dekker, Inc. All Rights Reserved.

Вам также может понравиться

- MSC AdamsДокумент16 страницMSC Adamskuldeepsingh055100% (1)

- Brake System DesignДокумент10 страницBrake System DesignAsif KhanОценок пока нет

- Cellular EnergyДокумент3 страницыCellular Energyapi-224364720Оценок пока нет

- Milk Fermented Products 2013Документ16 страницMilk Fermented Products 2013Miguel RivasОценок пока нет

- Kansas Foodborne Illness ManualДокумент186 страницKansas Foodborne Illness ManualLeo M. Pedro Jr.Оценок пока нет

- Beef Slaughter HACCP Plan: Rosenthal Meat Science and Technology CenterДокумент24 страницыBeef Slaughter HACCP Plan: Rosenthal Meat Science and Technology Centerpopa.janossОценок пока нет

- Model FoodSec Plan ProcessingДокумент23 страницыModel FoodSec Plan ProcessingJorge Gregorio SeguraОценок пока нет

- Dairy Microbiology Handbook: The Microbiology of Milk and Milk ProductsОт EverandDairy Microbiology Handbook: The Microbiology of Milk and Milk ProductsОценок пока нет

- 15.meat and Meat ProductsДокумент19 страниц15.meat and Meat ProductsMahesh DevasigamaniОценок пока нет

- Coleac001 Pip Module 1 Uk PP PDFДокумент342 страницыColeac001 Pip Module 1 Uk PP PDFMonica SinghОценок пока нет

- Tequila PDFДокумент18 страницTequila PDFJulián DíazОценок пока нет

- Hygiene and Sanitary Conditions in A Meat Processing Plant PDFДокумент30 страницHygiene and Sanitary Conditions in A Meat Processing Plant PDFsureshОценок пока нет

- Free Radicals and Reactive Oxygen SpeciesДокумент17 страницFree Radicals and Reactive Oxygen SpeciesSyncOrSwim100% (2)

- BAM Chapter 10 Detection of Listeria Monocytogenes in Foods and Environmental Samples, and Enumeration of Listeria Monocytogenes in Foods FDAДокумент26 страницBAM Chapter 10 Detection of Listeria Monocytogenes in Foods and Environmental Samples, and Enumeration of Listeria Monocytogenes in Foods FDAIwan RidwantoОценок пока нет

- Introduction HaccpДокумент28 страницIntroduction HaccprumpailautОценок пока нет

- HACCP in DairyДокумент5 страницHACCP in DairyPrashant TripathiОценок пока нет

- The Evaluation of Microbiological Criteria For Food Products of AnimalДокумент44 страницыThe Evaluation of Microbiological Criteria For Food Products of AnimalAchara MatiyaОценок пока нет

- NAACPДокумент18 страницNAACPMonishaОценок пока нет

- Food Safety Management ProceeduresДокумент4 страницыFood Safety Management ProceeduresRulment DardaneiОценок пока нет

- Control of Salmonella and Other Bacterial Pathogens in Low-Moisture FoodsОт EverandControl of Salmonella and Other Bacterial Pathogens in Low-Moisture FoodsRichard PodolakОценок пока нет

- USDA Meat Inspection and The Humane Methods of Slaughter ActДокумент6 страницUSDA Meat Inspection and The Humane Methods of Slaughter ActMd. Naim KhanОценок пока нет

- Bread and Pastry Production NC IIДокумент88 страницBread and Pastry Production NC IIjhessica ibal50% (2)

- Food Hygiene - Importance of Food Hygiene/safety PracticesДокумент11 страницFood Hygiene - Importance of Food Hygiene/safety PracticespmmlyОценок пока нет

- Pathogen Guidance - FINALДокумент100 страницPathogen Guidance - FINALmigОценок пока нет

- SAFE-PELLETS Final Part A B C PDFДокумент165 страницSAFE-PELLETS Final Part A B C PDFSHEIKH MD. ARIF SIDDIQUIОценок пока нет

- 1 s2.0 S0956713520300682 Main PDFДокумент11 страниц1 s2.0 S0956713520300682 Main PDFJosilene OliveiraОценок пока нет

- Meat Hygiene Assessment 2nd EdДокумент131 страницаMeat Hygiene Assessment 2nd EddoctorraslanОценок пока нет

- 2073 2005 For Manufacturers FINALДокумент6 страниц2073 2005 For Manufacturers FINALjercherwinОценок пока нет

- Senior 12 Biology 1 Q2 - M7Документ18 страницSenior 12 Biology 1 Q2 - M7Grandpa ZhongliОценок пока нет

- The Microbiology of Meat and PoultryДокумент332 страницыThe Microbiology of Meat and PoultryArham MboОценок пока нет

- Beef SlaughterДокумент62 страницыBeef SlaughterPrasanna KumarОценок пока нет

- Learner Guide For Cambridge Igcse Biology 0610 PDFДокумент102 страницыLearner Guide For Cambridge Igcse Biology 0610 PDFLesterОценок пока нет

- Listeria Monocytogenes TOCbvДокумент301 страницаListeria Monocytogenes TOCbvrubenorozkoОценок пока нет

- Food AllergiesДокумент19 страницFood Allergiesjacky786100% (1)

- Shelf Life of Australian Red Meat 2nd EditionДокумент182 страницыShelf Life of Australian Red Meat 2nd EditionLinhPhạm100% (1)

- Salami: - Mee) Is A Cured Sausage Consisting ofДокумент11 страницSalami: - Mee) Is A Cured Sausage Consisting ofbooks razaОценок пока нет

- Gso 1016 2015Документ26 страницGso 1016 2015Anil Yadav100% (1)

- Quality Control On Dairy Farms With Emphasis On Public HealthДокумент9 страницQuality Control On Dairy Farms With Emphasis On Public HealthDušica Ostojić AndrićОценок пока нет

- Food Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationОт EverandFood Safety in the Seafood Industry: A Practical Guide for ISO 22000 and FSSC 22000 ImplementationОценок пока нет

- Food and Feed Law Guide July 2020Документ29 страницFood and Feed Law Guide July 2020Isa C Freire100% (1)

- A Review of Milk Production in Pakistan With Particular Emphasis On Small-Scale ProducersДокумент44 страницыA Review of Milk Production in Pakistan With Particular Emphasis On Small-Scale ProducersAli AdnanОценок пока нет

- Pork SlaughterДокумент54 страницыPork SlaughterDima Fitria FebrianiОценок пока нет

- AbattoirsPlantConstructEquipOperation PDFДокумент15 страницAbattoirsPlantConstructEquipOperation PDFAnonymous 49VJOeViAОценок пока нет

- Quick Guide For Global StandardsДокумент8 страницQuick Guide For Global StandardsMônica Miyuki Ito ScognamilloОценок пока нет

- As 1162-2000 Cleaning and Sanitizing Dairy Factory EquipmentДокумент8 страницAs 1162-2000 Cleaning and Sanitizing Dairy Factory EquipmentSAI Global - APACОценок пока нет

- HACCP Study 3Документ7 страницHACCP Study 3Karissa Evangelista33% (3)

- CXC - 054 - 2004e - Code of Practice On Good Animal FeedingДокумент12 страницCXC - 054 - 2004e - Code of Practice On Good Animal FeedingIvan PopovicОценок пока нет

- Code of Hygienic PracticeДокумент29 страницCode of Hygienic Practicenitu_gОценок пока нет

- Clostridium Botulinum in Vacuum Packed (VP) FoodДокумент225 страницClostridium Botulinum in Vacuum Packed (VP) FoodRemya PillaiОценок пока нет

- Codex HACCP and Hazard Analysis For Risk Based Measures White Paper 11 July 2018Документ26 страницCodex HACCP and Hazard Analysis For Risk Based Measures White Paper 11 July 2018Alvaro MontañoОценок пока нет

- Adulteration Detection in Milk and Milk ProductsДокумент10 страницAdulteration Detection in Milk and Milk Productscrneetesh0% (1)

- USDA TraceabilityДокумент56 страницUSDA TraceabilityengpontelliОценок пока нет

- Shelf Life Testing of Fresh MeatДокумент4 страницыShelf Life Testing of Fresh Meatlinpok100% (1)

- Topic 5 Food SafetyДокумент23 страницыTopic 5 Food Safetyifa_saimiОценок пока нет

- Hygicult Guide To Monitoring CleanlinessДокумент36 страницHygicult Guide To Monitoring Cleanlinessroem1104100% (1)

- Case Study Meat ProcessingДокумент2 страницыCase Study Meat ProcessingChirag GoelОценок пока нет

- Chemical Safety of Meat and Meat Products PDFДокумент11 страницChemical Safety of Meat and Meat Products PDFekosaputrobbppbatuОценок пока нет

- AnnotatedbibliographyДокумент2 страницыAnnotatedbibliographyapi-340792231Оценок пока нет

- Forms - HACCP Implementation ManualДокумент18 страницForms - HACCP Implementation ManualShree PunekarОценок пока нет

- A Review in Reuse of Water in Dairy Companies Possible SolutionsДокумент21 страницаA Review in Reuse of Water in Dairy Companies Possible SolutionsWendyОценок пока нет

- FDA Handbook On Defect ActionДокумент21 страницаFDA Handbook On Defect ActionTim Alvaran100% (1)

- Biosafety - FH - Guidance - Artisanal Cheese and Dairy Products PDFДокумент98 страницBiosafety - FH - Guidance - Artisanal Cheese and Dairy Products PDFGian NiotisОценок пока нет

- Food Security in JapanДокумент13 страницFood Security in JapanPun Punnie100% (1)

- Microbiological Criteria Fishery ProductsДокумент65 страницMicrobiological Criteria Fishery Productsvladyda04687Оценок пока нет

- GFSI Food Safety Culture Position PaperДокумент54 страницыGFSI Food Safety Culture Position Paper1 FOOD SCIENCE S.A.SОценок пока нет

- China GB4789.40 2010 Food Microbiological Examination Enterobacter Sakazakii PDFДокумент13 страницChina GB4789.40 2010 Food Microbiological Examination Enterobacter Sakazakii PDFmmoradi55Оценок пока нет

- BAM Chapter 18 - Yeasts, Molds and Mycotoxins - FDAДокумент13 страницBAM Chapter 18 - Yeasts, Molds and Mycotoxins - FDAsunnysatwОценок пока нет

- Determination of PH and Water Holding Capacity of BeefДокумент6 страницDetermination of PH and Water Holding Capacity of BeefmichabcdeОценок пока нет

- Hypobaric Storage in Food Industry: Advances in Application and TheoryОт EverandHypobaric Storage in Food Industry: Advances in Application and TheoryОценок пока нет

- Production of Single Cell Protein From Grape Peel and Custard Apple RindДокумент22 страницыProduction of Single Cell Protein From Grape Peel and Custard Apple RindMahesh Devasigamani100% (1)

- Conveyor Catalog A 30Документ155 страницConveyor Catalog A 30Mahesh Devasigamani100% (2)

- Mould StorageДокумент1 страницаMould StorageMahesh DevasigamaniОценок пока нет

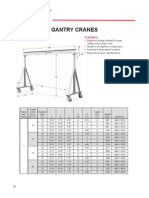

- Gantry Cranes: Fixed Steel (H90)Документ6 страницGantry Cranes: Fixed Steel (H90)Mahesh DevasigamaniОценок пока нет

- Tranzbelt: Features IncludeДокумент1 страницаTranzbelt: Features IncludeMahesh DevasigamaniОценок пока нет

- History of BiochemДокумент1 страницаHistory of BiochemAngelОценок пока нет

- C-Bacterial Metabolism-Springer-Verlag New York (1986)Документ370 страницC-Bacterial Metabolism-Springer-Verlag New York (1986)xuantra100% (1)

- Termossonicação Nondairy ResultadosДокумент9 страницTermossonicação Nondairy ResultadosBruna VieiraОценок пока нет

- Fusel Oil ProjectДокумент29 страницFusel Oil ProjectMorgen MukamwiОценок пока нет

- Bakteri Dan KapangДокумент6 страницBakteri Dan KapangedОценок пока нет

- Lecture Notes Preservation Technologies Methods of Preservation of Fruits and VegetablesДокумент17 страницLecture Notes Preservation Technologies Methods of Preservation of Fruits and VegetablesJasvir MannОценок пока нет

- AlcoholДокумент3 страницыAlcoholvyastrupti1Оценок пока нет

- X Cbse Science Unit Test - Solutions: Life Processes-Nutrition & Respiration Marks: 30 Test Code: 10SUT103 Duration: 1 HRДокумент4 страницыX Cbse Science Unit Test - Solutions: Life Processes-Nutrition & Respiration Marks: 30 Test Code: 10SUT103 Duration: 1 HRdayanandan1Оценок пока нет

- Dry Salt Cucumber (Preserving Method and Principle)Документ16 страницDry Salt Cucumber (Preserving Method and Principle)Mohamad Arif NasaruddinОценок пока нет

- IEA Rapport Biobased Chemicals TotaalДокумент36 страницIEA Rapport Biobased Chemicals Totaalduannidejean100% (1)

- Oooxidation and Fermentation QuizДокумент5 страницOooxidation and Fermentation QuiztoppleОценок пока нет

- CHE323-Biochemical Engineering 1 - PresentationДокумент30 страницCHE323-Biochemical Engineering 1 - PresentationPreciousОценок пока нет

- GadenДокумент7 страницGadenBenjamin HonorioОценок пока нет

- Experiment Lab 6Документ8 страницExperiment Lab 6exo kaiОценок пока нет

- Class 11 - Biology - Respiration in PlantsДокумент13 страницClass 11 - Biology - Respiration in PlantsDivyansheeОценок пока нет

- Bioresource TechnologyДокумент12 страницBioresource TechnologyThayna CandidoОценок пока нет

- How Cells Harvest Chemical Energy: Chapter ObjectivesДокумент12 страницHow Cells Harvest Chemical Energy: Chapter Objectivesirene9tan9ailianОценок пока нет

- KarДокумент15 страницKartrendzz youtuberОценок пока нет

- Difference Between Batch & Continuous Fermentation - EasybiologyclassДокумент9 страницDifference Between Batch & Continuous Fermentation - EasybiologyclassrajdeepjaswalОценок пока нет

- Harrison 2009Документ11 страницHarrison 2009JUAN DAVID DAZA BURGOSОценок пока нет

- Fermenter Systems and AssemblyДокумент5 страницFermenter Systems and AssemblyaleenaОценок пока нет

- Pruebas Bioquimicas de LactobacillusДокумент8 страницPruebas Bioquimicas de LactobacillusSergio Contreras ReinosaОценок пока нет

- Pla PDFДокумент11 страницPla PDFbhavesh moorjaniОценок пока нет