Академический Документы

Профессиональный Документы

Культура Документы

The Handling Unit

Загружено:

Mirela NastaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The Handling Unit

Загружено:

Mirela NastaАвторское право:

Доступные форматы

Papers

M aterial H andling C lassics

in the classics series have appeared in previous publications

the

of

Material Handling Institute and are at least ten years old.

Nonetheless, their value

in contributing to the evolution of the industry and to current practice is viewed to be timeless, even though in many cases the authors and companies credited are no longer in the industry.

THE HANDLING UNIT

1982 NATIONAL MATERIAL HANDLING FORUM APRIL 19-21, 1982

STERLING ANTHONY, JR. STERLING ANTHONY INC. The Handling Unit is defined, for purposes of this presentation, as packaged or unitized material or product. The objective of this presentation is to promote a better understanding and appreciation of the handling unit by addressing three interrelated positions: 1) The handling unit is the focal point of the material handling/packaging interface. 2) The handling unit affects the costs and efficiencyand therefore, productivityof material flows. 3) The handling unit, then, is a building block for productivity, and should be systematically planned and managed. The Material Handling/Packaging Interface

We have a Society of Packaging and Handling Engineers. The editors of the upcoming Material Handling Handbook have devoted a section of the volume to the subject of packaging. So the suggestions are strong and explicit that there is a relationship between the material handling and packaging functions. What is the material/handling interface? It is the systems view that both material handling and packaging are components of a larger system; namely, the material flow system, and that:

8720 Red Oak Boulevard Suite 201 Charlotte, North Carolina 28217-3992

Material Handling Classics Page 1 of 6

Packaging decisions influence material handling decisions and vice versa. The objective of the interface between packaging and material handling is not the optimization of either function, or the cost minimization of either function. The objective is the net improvement of the overall material flow system through the interactions and trade-off between packaging and material handling.

Having thus defined the material handling/packaging interface, why do I insist that the handling unit is its focus? Quite simply, it represents the area where packaging and material handling literally and physically meet. Isnt it, after all, the package or unit, along with its contents, that is handled? Reflect for but a moment on the interrelationship, if not interchangeability of such concerns as: How do we package and unitize the product for best handling. How do we handle the packaged or unitized product for least damage, and best utilization of labor, equipment, and space? How do we package/unitize and handle for best interaction with other flow systems functions (i.e. transportation, warehousing, inventory control etc.) for best overall system performance.

Now, if imaginative, aggressive, and effective answers to such inquiries are not a sure path to reduced costs and greater productivity, I for one, remain to be convinced. The Handling Unit Affects Material Flows

The material flow concept instructs us that industry can be regarded as a series of pipelines (flows) of materials. Starting with the retrieval of the basic raw materials from the mines, forests, fields, and sea, converters and manufacturers produce a variety of materials and products, distributed to a variety of customers, through a variety of channels. The concept also embraces the possibility for reverse flows (disposal, recycling, recalls, etc.). While the material flow concept has been around and accepted for some time, its translation into managerial concepts of material management, physical distribution, and logistics has a shorter history. But, the basic concept of flow remains. Follow this simple logic: flows require movement; movement is achieved, in large part, through material handling; and material handling requires efficient packaging and unitizing methods for best performance. When it comes to material handling, you cant read a book, or attend a conference on the subject without being reminded that material handling is pervasive throughout the flow system. Adding no value to the material, while definitely adding cost, material handling should be the constant object of control efforts. So lets learn to better utilize on e of the most potent versatile tools. So lets learn to better utilize on eof the most potent and versatile tools at our disposal for achieving better flows and handling-- packaging!

8720 Red Oak Boulevard Suite 201 Charlotte, North Carolina 28217-3992

Material Handling Classics Page 2 of 6

I stated earlier that packaging methods affects productivity of material flows. Here are some of the key areas in which greater productivity can be promoted: Even as advances in automation become commonplace, and the prospects for the automated factory loom a distinct possibility, the task of moving material throughout the flow or made more efficient when: 1. Packaging allows the movement of a given quantity of material through a minimum number of individual moves. In other words, its more efficient to move caseloads and unit loads 2. order picking, and inventory control activities. When the packaging is communicative and functional, there is less opportunities for mistaken identity, the wrong goods shipped, 3. minimize the chances of injured people, lawsuits, and negative publicity stemming from packages that topple, strain the workers physical strength limits, or fail to protest the worker

Equipment Often mistakenly thought of as the opposite of labor, equipment is an adjunct to chosen and acquired can affect a companys liquidity, profitability and competitive position for a long time. The equipment issue, therefore, deserves careful analysis of many factors, not the

Lets examine some basic relationships between packaging and the three major equipment categories: trucks, conveyors and cranes/hoists. Trucks The fork truck, the workhorse of industry, is inseparably associated with the for either case. But such an argument would be pointless if it fails to realize that the pallets identify crisis underscores the close interface between packaging and material

There are many opportunities to improve the utilization of trucks with packaging and unitizing that better challenges the lift capacity of the trucks.

of packaged loads handled, and affects equipment utilization, operator skill requirements, and the costs for equipment acquisition, operation and maintenance. Conveyors Infeed, outfeed, integrating and linking of operations: these are the major unit loads. Packaging, in order to run efficiently on conveyors, must be conscientiously designed to do so. A package too small or too large for the conveyor

8720 Red Oak Boulevard Suite 201 Charlotte, North Carolina 28217-3992

Material H andling Classics 3 of

and declines that a conveyor route may take through a facility; or one too heavy for the drive mechanism which powers the conveyor. And. Of course, conveyorized movement imparts shocks, vibrations, and impacts to the packaging; hazards which should be considered in determining the packagings strength requirements. Cranes and hoists packaging handled by cranes and hoists must be suitable by providing the means for attaching the slings, for instance. Just as basic, is the recognition that acceleration, declaration, and gravitational forces act upon a package as its lifted, held suspended, and lowered. Careful analysis is called for here, for if a load becomes unhitched, or the bottom of, say, a crate falls out, product damage is a certainty, and personnel injury is real possibility. Space Packages and unit loads occupy space in storage and in transportation vessels. That truth should be reflected in the determination of what the packaging should be in terms of shape, size and weight. Simply put, packaging and unitizing should be designed for the efficient use of cube. It is difficult to overstress that need in these times of transportation deregulation, and the trend toward consolidation of warehousing facilities. Technology Some of the newer technologies upon which industry is spearheading its productivity drive are directly related to the packaging and material handling interface. Specifically: automated storage and retrieval, optical scanners, automatic guided vehicle systems, and robotics. As an example, unit loads in order to be compatible with automated storage/ retrieval systems must conform to the weight and cubic limitations of the storage addresses. Optical scanners, in addition to relying upon the package to carry the machine decipherable code, are influenced by the printing quality and contrast of the code, as well as the orientation of the package as it passes the code reader. Automatic guided vehicle systems transport unitized loads. Those loads should be secure, stable, and within stated dimensional limitations, so that they dont tilt over, come apart, or otherwise prove incompatible with the method of handling. And, robots can be programmed to palletize, load and unload shipping containers, and even perform package testing. This generalization will tend to hold true: automation is basically inflexible. Standardized or modular packaging can permit a greater degree of automation than is possible under conditions of greater variability of packaging.

8720 Red Oak Boulevard Suite 201 Charlotte, North Carolina 28217-3992

Material Handling Classics Page 4 of 6

An additional challenge to packaging takes the form of the need to be more exacting in holding automation.

Planning and Managing the Handling Unit

By now, its hoped that we are in accord that the handling unit deserves description as a building and managing the many factors that influence the nature of the handling unit. There is but one way to achieve that, and it is to approach the handling unit decision from a systems approach. Know to the fullest detail possible the entire system suppliers, your manufacturing about your own operations. How is the handling unit concept used or underused at your company? To what degree does the handling units for raw material received from your suppliers machinery, materials, and space used in assembling the handling unit. To what degree does the handling unit of the finished product facilitate storage, order picking, loading into transport carrier, and low transportation damage rates. To what degree does the handling unit of the finished product facilitate your or production. To what degree does captive-handling units, i.e. pallets, bins, trays, racks, and hoppers facilitate in-process storage, inventory control, and production line feeding and out-

The flow of raw materials from supply sources into the manufacturing location, the flow of inprocess materials through the manufacturing location, the flow of finished goods from the and recalls back through the system: all can be made more efficient and productive by better design and use of the handling unit.

rule, not the exception. For instance, there have been quite recent innovations in the entire major means unitizing pallets, slip-sheets, durable containers, stretch wrapping, shrink wrapping, packaging system, which integrates well with material handling and other material flow

Material Handling

lassics Page 5 6

functions. On the contrary, the path toward such packaging must be charted with systematic analysis and decision making. My concluding advice is that as industry plans layouts for new facilities and flow systems, and revises existing facilities and flow systems in its pursuit of greater productivity, reduced costs, better customer service, and improved sales and profited, it should look to the handling unit - the packaging/material handling interface as an indispensable building block towards those aims.

8720 Red Oak Boulevard Suite 201 Charlotte, North Carolina 28217-3992

Material Handling Classics Page 6 of 6

Вам также может понравиться

- Reducing Capital Expenditures Through Effective Material HandlingДокумент9 страницReducing Capital Expenditures Through Effective Material HandlingMirela NastaОценок пока нет

- Storage Systems Carousels and Other Storage OptionsДокумент9 страницStorage Systems Carousels and Other Storage OptionsMirela NastaОценок пока нет

- The Use of Scanners in Computer-Based Materials Handling SystemsДокумент18 страницThe Use of Scanners in Computer-Based Materials Handling SystemsMirela NastaОценок пока нет

- Utilizing Equipment, Lift Trucks, Racks and ShelvingДокумент8 страницUtilizing Equipment, Lift Trucks, Racks and ShelvingMirela NastaОценок пока нет

- The Basis For An Economical Storage SystemДокумент12 страницThe Basis For An Economical Storage SystemMirela NastaОценок пока нет

- Five (5) Step Packaging DevelopmentДокумент16 страницFive (5) Step Packaging DevelopmentMirela NastaОценок пока нет

- The Fundamentals of Traditional Small Item StorageДокумент8 страницThe Fundamentals of Traditional Small Item StorageMirela NastaОценок пока нет

- Training Supervisory Personnel and Equipment Operators For Material Handling OperationsДокумент5 страницTraining Supervisory Personnel and Equipment Operators For Material Handling OperationsMirela NastaОценок пока нет

- Audit Your Material HandlingДокумент5 страницAudit Your Material HandlingMirela NastaОценок пока нет

- Bid Evaluating Process and Final Supplier SelectionДокумент5 страницBid Evaluating Process and Final Supplier SelectionMirela NastaОценок пока нет

- Successful Maintenance Practices at Abhalt LaboratoriesДокумент9 страницSuccessful Maintenance Practices at Abhalt LaboratoriesMirela NastaОценок пока нет

- Successful Maintenance Practices at Abhalt LaboratoriesДокумент9 страницSuccessful Maintenance Practices at Abhalt LaboratoriesMirela NastaОценок пока нет

- New Manager'S To-Do List: Marty Williamson Joann Hackos Imci Technologies Comtech Services, IncДокумент16 страницNew Manager'S To-Do List: Marty Williamson Joann Hackos Imci Technologies Comtech Services, IncMirela NastaОценок пока нет

- New Manager Onboarding GuideДокумент14 страницNew Manager Onboarding GuideMirela Nasta100% (10)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFДокумент8 страницCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- 7155 - 7 Inspection & MaintenanceДокумент5 страниц7155 - 7 Inspection & MaintenanceMann GurpreetОценок пока нет

- Hakki Pilke 38 ManualДокумент36 страницHakki Pilke 38 ManualautobritaiОценок пока нет

- TS1 Catalog v3Документ80 страницTS1 Catalog v3geo12345Оценок пока нет

- Striker SQR2062 20x6 Mobile Scalping ScreenДокумент2 страницыStriker SQR2062 20x6 Mobile Scalping ScreenBenjamin MurphyОценок пока нет

- Business Plan For Plastic in Ethiopia Un Modified.Документ37 страницBusiness Plan For Plastic in Ethiopia Un Modified.Yeruksew Fetene100% (1)

- Cement Machinery Process EquipmentДокумент46 страницCement Machinery Process EquipmentArul Chinnapillai100% (1)

- Guidelines for Wet Mix Macadam (WMMДокумент21 страницаGuidelines for Wet Mix Macadam (WMMsathish puramОценок пока нет

- Tunkers CatalougeДокумент390 страницTunkers CatalougevenkatselvakumarОценок пока нет

- Plant Engineering September 2016 MagazineДокумент68 страницPlant Engineering September 2016 MagazineMariver LlorenteОценок пока нет

- Automated Material Handling SystemsДокумент19 страницAutomated Material Handling Systemssiva_karthidpmОценок пока нет

- Case Study 0151-Foundry Material HandlingДокумент2 страницыCase Study 0151-Foundry Material HandlingBala SasiОценок пока нет

- Mining 01 00011Документ13 страницMining 01 00011bernardОценок пока нет

- English - VOLKMANN - PDF Catalogs - Technical Documentation - Brochure PDFДокумент12 страницEnglish - VOLKMANN - PDF Catalogs - Technical Documentation - Brochure PDFSvetlana VujovićОценок пока нет

- An Introduction To Material Handling Equipment SelectionДокумент39 страницAn Introduction To Material Handling Equipment Selectioncancer24Оценок пока нет

- Unit I: Plant Layout and Material Handling Objective Type Questions & AnswersДокумент16 страницUnit I: Plant Layout and Material Handling Objective Type Questions & AnswersSenthilsuja KumarОценок пока нет

- Extra Exercise Pneumatics Sequence CircuitДокумент1 страницаExtra Exercise Pneumatics Sequence CircuitJ.m.MoraОценок пока нет

- Failure Analysis of Conveyor System in Thermal Powerplant PDFДокумент6 страницFailure Analysis of Conveyor System in Thermal Powerplant PDFSiddharth PantОценок пока нет

- Ultraplast Chainbelts Private LimitedДокумент8 страницUltraplast Chainbelts Private LimitedSatendra SaraswatОценок пока нет

- Folder ApplicationsSolutions EN 03 19-WebДокумент32 страницыFolder ApplicationsSolutions EN 03 19-WebbalakrishnaОценок пока нет

- Part Presentation Playbook PDFДокумент87 страницPart Presentation Playbook PDFDuvan TamayoОценок пока нет

- Catalogo Transportador Helicoidal PDFДокумент48 страницCatalogo Transportador Helicoidal PDFLucero LlantoyОценок пока нет

- TSДокумент25 страницTSanindya.basu859217Оценок пока нет

- Mechanical StandardsДокумент81 страницаMechanical StandardsDineshОценок пока нет

- Idler EngrDimДокумент64 страницыIdler EngrDimJosé Eduardo Gaete DuarteОценок пока нет

- 1012TSДокумент87 страниц1012TSסטניסלב טלשבסקיОценок пока нет

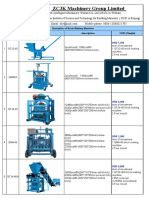

- ZCJK Brick Machine Price List - LilyДокумент4 страницыZCJK Brick Machine Price List - LilyTimothy Ndeleva100% (1)

- 2945 Emco Pug Mill 500MM - 20 - 2 - 2018 PDFДокумент25 страниц2945 Emco Pug Mill 500MM - 20 - 2 - 2018 PDFsamar209Оценок пока нет

- PPTДокумент86 страницPPTAjeet Sony100% (1)

- MINE REGULATION RETURNS AND ADDRESSESДокумент72 страницыMINE REGULATION RETURNS AND ADDRESSESsuraj46453100% (1)