Академический Документы

Профессиональный Документы

Культура Документы

WPS 856110.016 Rev 3

Загружено:

laz_kИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WPS 856110.016 Rev 3

Загружено:

laz_kАвторское право:

Доступные форматы

Intermare Sarda

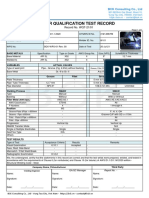

SUPPORTING Verbale di procedura di saldatura: WELDING PROCESS(ES) AND TYPE:

Procedimento di saldatura e tipo

WELDING PROCEDURE SPECIFICATION

SPECIFICA PROCEDIMENTO SALDATURA

WPS 856110.016

Project: Usan TA&BA Sheet 1/1

According to AWS D1.1:2006 + TOTAL GS EP STR 301 rev. 5 WPQR 91-2009 GTAW + FCAW

Manual + Semiautomatic

BASE MATERIAL Materiale Item A / Item B Spec. & type: EN 10225 S 355G15+N / ASTM A694 F52

AWS D1.1:2006

Gr. No. 2 / Gr. No. 2

Structural steel work All NDT classes

JOINTS Smussi Groove design: See sketch

Tipo

Backing: YES for FCAW

Supporto

Steel Mill & Delivery condition:ITEM A:Vallourec&Mannesmann / Normalized ITEM B: Icarus / Forged + Q&T Impact Test Quality: KL-40 & KT -50 / KL-29 & KT-29

Thickness mm: 9.53 28.58

Spessore

POSITION Posizione Groove position: ALL

Posizione di cianfrino

Deposited metal:

Mat. Depositato

Backing mat: Weld metal (FCAW)

Mat. Supporto

Diameter mm: 60.3 323.8

Diametro

Weld progr.: UPHILL FOR Avanzamento VERTICAL Fillet position: N.A.

Posizione d angolo

ITEM A: C0,15% ITEM B: C0,11%

GAS Shielding gas: Argon for GTAW;

Gas di protezione

Ceq0,45% Ceq0,41%

PREHEAT Preriscaldo Temp. C

Mantenimento

Pcm0,25% Pcm0,21% HEAT TREATMENTS Trattamenti termici NO Type/ Tipo :

Holding temp.C

Temperatura

Mixture Ar-CO2 for FCAW

47

Composition: 99.99% Argon for GTAW; Composizione 80% Ar 20%CO2 (2%nom) for FCAW Flow rate (l/min.): 1014 for GTAW

Consumo Gas di supporto

Maintenance: UP TO WELD COMPLETION Method: PROPANE BURNERS

/ / / /

/ / / /

Holding time h

Mantenimento

1820 for FCAW

Gas Backing: N.A. Trailing shielding gas compos.: N.A.

Interpass C: 242

Heating rate C/h

Gradiente di Salita

Cooling rate C/h

Gradiente di Discesa

TECNIQUE Tecnica String or weave bead: STRING Passata larga o stretta Oscillation: N.A. Oscillazione Initial interpass cleaning: BRUSHING / GRINDING Pulizia Method of back gouging: N.A. Metodo di ripresa Orifice or gas cup size: 10 mm for GTAW; 1420 mm for FCAW Contact tube to work distance: 1525 mm for FCAW Multipass or single: MULTIPASS Single or multiple electrode: SINGLE

FILLER METALS AND WELDING PARAMETERS Materiali d'apporto e parametri di saldatura Process

Procedimento

GTAW (1) OK 13.23 ESAB 2.4 / 5.28 ER 80S Ni1 6 10 DIRECT 130 140 11.6 12.5 N.A. 6.3 7 1.29 1.67 STRAIGHT N.A.

GTAW (2) OK 13.23 ESAB 2.4 / 5.28 ER 80S Ni1 6 10 DIRECT 142 154 12.5 13.5 N.A. 6.8 7.3 1.46 1.83 STRAIGHT N.A.

FCAW (1) OK 15.17 ESAB 1.2 / 5.29 E81T1-Ni1 / / DIRECT 170 210 22 25.4 N.A. 24 26.3 0.85 1.33 REVERSE N.A.

FCAW(2) OK 15.17 ESAB 1.2 / 5.29 E81T1-Ni1 / / DIRECT 182 205 23.5 26 N.A. 23 26.5 0.97 1.39 REVERSE N.A.

Filler type

Mat. d'apporto

Supplier

Fornitore

Size mm

Diametro mm

EN Class. SFA N AWS Class. F N A N Current

Corrente

Power Source: CV output for FCAW

NOTE :

Consumable control procedure: 856110-7006-INS-WI-QUAL-015 Welding Repair: according to WPS 856110.016R

Amps Volts ROL cm Speed cm/min

Velocit

Maximum thickness of buttering shall be 12 mm Heat input Buttering is allowed to correct root openings not greater than twice the thk of KJ/mm thinner part or 20mm, whichever is less Polarity

Polarit

Arc time

Sec.

SKETCH: (Schizzo)

+5 -0

WELDING SEQUENCE (Sequenza di saldatura) Single Side and Buttering layers on ITEM A or B

Root pass by GTAW(1); Hot pass by GTAW(2); Fill by FCAW(1); Cap by FCAW(2)

Double Side

15

37, -0 5

+5

Root pass by GTAW(1); Hot pass by GTAW(2); Fill by FCAW(1); Cap by FCAW(2) Backgoug up to sound metal;Back passes (min 2) by GTAW(2)

ITEM A

0.7-1.5

ITEM B 3

+1 -0

3 2 Rev.

15/12/2010 01/07/2010 Date

S. Musso O. Fois / S. Musso

M. Mihai Reviewed by Saipem Third Party Certification Approval by Total

IMS, welding eng

Вам также может понравиться

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989От EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookОценок пока нет

- Welding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Документ2 страницыWelding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Erick HoganОценок пока нет

- Welding Book Revised 2012 07 14Документ15 страницWelding Book Revised 2012 07 14surya1960Оценок пока нет

- d1.1 Fcaw Unlimited Test Plate ConfigurationДокумент77 страницd1.1 Fcaw Unlimited Test Plate ConfigurationJuan Martinez100% (1)

- Defectology NDT Final Edit PDFДокумент132 страницыDefectology NDT Final Edit PDFIdjzulz Zulkifli100% (1)

- DR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07Документ13 страницDR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07SasaОценок пока нет

- Visual Examination Procedure: 1 - PurposeДокумент4 страницыVisual Examination Procedure: 1 - PurposeElvin MenlibaiОценок пока нет

- AWS Guide To Abbreviations Certified WelderДокумент1 страницаAWS Guide To Abbreviations Certified Weldersigurdur hannessonОценок пока нет

- Welder Qualification Manual Revision 5Документ20 страницWelder Qualification Manual Revision 5Hugo RodriguezОценок пока нет

- Welding Procedure For BOXNR Wagon (WPS)Документ8 страницWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateДокумент3 страницыWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaОценок пока нет

- Welding Procedure Specification (WPS) : Supporting PQR 01Документ2 страницыWelding Procedure Specification (WPS) : Supporting PQR 01duyanhОценок пока нет

- Is 7310 RequirementsДокумент4 страницыIs 7310 RequirementsRavichandran Tirupattur SubramaniamОценок пока нет

- 1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016Документ64 страницы1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016ivan sulistianОценок пока нет

- Carefully Evaluate Code RequirementsДокумент3 страницыCarefully Evaluate Code Requirementsmayav1Оценок пока нет

- QW 482 WPSДокумент2 страницыQW 482 WPSsmit patelОценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKAnonymous Ij6VfaОценок пока нет

- PreheatДокумент2 страницыPreheatScott TrainorОценок пока нет

- Gta+sma PQRДокумент3 страницыGta+sma PQRRahul MoottolikandyОценок пока нет

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeДокумент1 страницаWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- RTCC Manual WPS Approval WE-WPS-001Документ7 страницRTCC Manual WPS Approval WE-WPS-001Akansha SharmaОценок пока нет

- WPS Format For AWS D1.1 - WPS - FCAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityОценок пока нет

- WPQ WeldCanada PDFДокумент1 страницаWPQ WeldCanada PDFAhmad DanielОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesdhasdjОценок пока нет

- Blank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Документ1 страницаBlank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)GMОценок пока нет

- CIGWELDДокумент244 страницыCIGWELDrodastrid5653100% (1)

- Sample Forms AWS, ASME and APIДокумент14 страницSample Forms AWS, ASME and APIaamirtec301Оценок пока нет

- 05-Welder Certification PDFДокумент11 страниц05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- Template BUTTДокумент1 страницаTemplate BUTTDylan TriggОценок пока нет

- WQT Aws D1.1Документ1 страницаWQT Aws D1.1Ali HammoudaОценок пока нет

- Linde Rates For Welding Test Services-2018Документ2 страницыLinde Rates For Welding Test Services-2018Hoque AnamulОценок пока нет

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Документ60 страниц3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmОценок пока нет

- Welding QualificationДокумент45 страницWelding QualificationeswarОценок пока нет

- General Format For Girder Fabrication Check ListДокумент4 страницыGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryОценок пока нет

- PQR - 152Документ3 страницыPQR - 152MAT-LIONОценок пока нет

- En 15085-2020-What Has ChangedДокумент2 страницыEn 15085-2020-What Has ChangedBoran YelkenciogluОценок пока нет

- Annex Form J1 D1.1 D1.1M 2020 PDFДокумент4 страницыAnnex Form J1 D1.1 D1.1M 2020 PDFDarioОценок пока нет

- Visual Inspection - AWS & BS PDFДокумент22 страницыVisual Inspection - AWS & BS PDFSelvakpm06Оценок пока нет

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFДокумент1 страницаPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraОценок пока нет

- Mechanical Testing 01B: Part 2 Charpy Impact TestingДокумент25 страницMechanical Testing 01B: Part 2 Charpy Impact Testingsamurai7_77100% (1)

- AWS D1.1 Welder Quallification RequirementsДокумент3 страницыAWS D1.1 Welder Quallification RequirementsKrishna VachaОценок пока нет

- Welding Procedure Qualification Record: Shipyard LogoДокумент4 страницыWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Fillet Weid Break and Macroetch Test PlateДокумент1 страницаFillet Weid Break and Macroetch Test PlatewijiestОценок пока нет

- BPVC Ix Qw-484aДокумент1 страницаBPVC Ix Qw-484aTC Capulcu Mustafa MОценок пока нет

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Документ3 страницыWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielОценок пока нет

- PQRДокумент2 страницыPQRHoangОценок пока нет

- Differences Between AC Welding and DC WeldingДокумент2 страницыDifferences Between AC Welding and DC WeldingDevarakonda KondayyaОценок пока нет

- Magnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Документ5 страницMagnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Dinesh GuptaОценок пока нет

- WOPQ Form English1Документ2 страницыWOPQ Form English1oaperuchenaОценок пока нет

- Norma CWB Cambios en W47.1-2009Документ6 страницNorma CWB Cambios en W47.1-2009Jose ManuelОценок пока нет

- WPS, PQR, WQT, WPQ: BBW30103 Teknologi Kimpalan BerautomasiДокумент12 страницWPS, PQR, WQT, WPQ: BBW30103 Teknologi Kimpalan BerautomasiNazrin GLОценок пока нет

- 6082 T6 Aluminum Plate SuppliersДокумент9 страниц6082 T6 Aluminum Plate Supplierssanghvi overseas incОценок пока нет

- Astm E350-95Документ1 страницаAstm E350-95ippon_osotoОценок пока нет

- Fabricatin Inspection Testing of Structural ProductДокумент44 страницыFabricatin Inspection Testing of Structural ProductwalitedisonОценок пока нет

- Manual Joints (QW - 402) : Page 1 of 12Документ12 страницManual Joints (QW - 402) : Page 1 of 12miteshpatel191Оценок пока нет

- PQR Editable SampleДокумент2 страницыPQR Editable SampleKoya ThangalОценок пока нет

- SF188 Rev 1 - Welder Qualification Test CertificateДокумент1 страницаSF188 Rev 1 - Welder Qualification Test CertificateMike BoyesОценок пока нет

- Wps 316L SMAW+GTAW R00Документ2 страницыWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Документ48 страницQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Manual Structural WeldingДокумент12 страницManual Structural WeldingwalitedisonОценок пока нет

- Datasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1Документ3 страницыDatasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1laz_kОценок пока нет

- Trade of Vehicle Body Repair: MIG - Welding FabricationДокумент149 страницTrade of Vehicle Body Repair: MIG - Welding Fabricationlaz_kОценок пока нет

- PWHT Responsibility Assignment Matrix: SR Topic Tasks DetailsДокумент6 страницPWHT Responsibility Assignment Matrix: SR Topic Tasks Detailslaz_kОценок пока нет

- Chem Iii-Amines-P255 JOB DescriptionДокумент1 страницаChem Iii-Amines-P255 JOB Descriptionlaz_kОценок пока нет

- Datasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1Документ3 страницыDatasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1laz_kОценок пока нет

- Socket Weld LeakДокумент5 страницSocket Weld Leaklaz_k100% (1)

- Carber Service CatalogДокумент32 страницыCarber Service Cataloglaz_kОценок пока нет

- Personnel, Consumable & ToolsДокумент3 страницыPersonnel, Consumable & Toolslaz_kОценок пока нет

- Asset Integrity EngineerДокумент4 страницыAsset Integrity Engineerlaz_kОценок пока нет

- Metrode ConsumablesДокумент309 страницMetrode Consumablesrodofgod100% (1)

- Weld Filler WireДокумент37 страницWeld Filler WireSiva Raman MurugesanОценок пока нет

- Bonney Forge BrochureДокумент22 страницыBonney Forge BrochureAnonymous dvrhf5Оценок пока нет

- Electrical Maintenance TechniciancvДокумент3 страницыElectrical Maintenance Techniciancvlaz_k100% (1)

- Pipe LineДокумент62 страницыPipe LineBahtiar Anak LaNang100% (1)

- EN 1090 White Paper17 119019 PDFДокумент24 страницыEN 1090 White Paper17 119019 PDFZaza PokumbaОценок пока нет

- Portfolio Storage&Drying Control ProcedureДокумент4 страницыPortfolio Storage&Drying Control Procedurelaz_kОценок пока нет

- Welded Steel Pipe Design ManualДокумент93 страницыWelded Steel Pipe Design ManualfileseekerОценок пока нет

- AIChE Wilhelm April 08 Process SafetyДокумент16 страницAIChE Wilhelm April 08 Process Safetymostafa_1000Оценок пока нет

- Offshore ProtectionДокумент334 страницыOffshore ProtectionSumit PardeshiОценок пока нет

- Electrical Maintenance Supervisor CVДокумент3 страницыElectrical Maintenance Supervisor CVlaz_k100% (1)

- Stainless Steel Dissimilar Welding ChartДокумент1 страницаStainless Steel Dissimilar Welding Chartlaz_kОценок пока нет

- Bicine - AmineДокумент14 страницBicine - Aminelaz_kОценок пока нет

- RBI Corrosion Calculation Day2Документ7 страницRBI Corrosion Calculation Day2laz_kОценок пока нет

- Stainless Steels and Their PropertiesДокумент45 страницStainless Steels and Their PropertiesSH1961Оценок пока нет

- Valve SizingДокумент1 страницаValve SizingdlescribdОценок пока нет

- Water Treatment CatalogueДокумент12 страницWater Treatment CatalogueJim TsikasОценок пока нет

- Mantenimiento 6466 PDFДокумент3 страницыMantenimiento 6466 PDFmarcosluna680% (3)

- TEM Sample PreparationДокумент4 страницыTEM Sample PreparationMythily VedhagiriОценок пока нет

- Clesse, Comap, NovacometДокумент60 страницClesse, Comap, NovacometVivek RajanОценок пока нет

- Radioactivity 1 QPДокумент9 страницRadioactivity 1 QPAnonymous N3VvjVSTATОценок пока нет

- CHE100 - Sample ExamДокумент13 страницCHE100 - Sample Examshaduni deenaОценок пока нет

- Positive Displacement Pump PDFДокумент345 страницPositive Displacement Pump PDFTapas Chaudhuri100% (3)

- Magnasoft JSSДокумент5 страницMagnasoft JSSLe LocОценок пока нет

- TR0006 Extinction CoefficientsДокумент3 страницыTR0006 Extinction CoefficientsRizmahardian Ashari KurniawanОценок пока нет

- UNIT V - Ceramics-Composites-Nano MaterialsДокумент59 страницUNIT V - Ceramics-Composites-Nano MaterialsHarsha MallaОценок пока нет

- SABAДокумент13 страницSABAJp GuittapОценок пока нет

- 1 s2.0 S2590048X22001030 MainДокумент17 страниц1 s2.0 S2590048X22001030 MainJeff DatinguinooОценок пока нет

- 4.04 IsophoroneДокумент2 страницы4.04 Isophoronekhizer iqbalОценок пока нет

- Polymer Blends and AlloysДокумент15 страницPolymer Blends and AlloysSurenderMalanОценок пока нет

- EOCQ - Ans - 6 BiologyДокумент2 страницыEOCQ - Ans - 6 BiologySabQilah100% (4)

- Lab Report Emulsion PolymerizationДокумент7 страницLab Report Emulsion PolymerizationNUR AMNI QHAIRUNNAJWA BINTI ARIFFIN STUDENTОценок пока нет

- MS Fragmentation Functional Groups (Compatibility Mode)Документ68 страницMS Fragmentation Functional Groups (Compatibility Mode)Adriana Estefanía HPОценок пока нет

- Eh PHДокумент22 страницыEh PHGörkem Efe100% (1)

- Tana Gseries Ho C110304enДокумент65 страницTana Gseries Ho C110304enNguyen Ngoc100% (1)

- Titanium Literature ReviewДокумент39 страницTitanium Literature Reviewapi-570207350Оценок пока нет

- Global Pharma StrategyДокумент15 страницGlobal Pharma StrategyDr Amit RangnekarОценок пока нет

- Chemistry Signature Assignment PDFДокумент3 страницыChemistry Signature Assignment PDFapi-302384998Оценок пока нет

- Hy-Tuf - AMS 6425 PDFДокумент2 страницыHy-Tuf - AMS 6425 PDFapurv bhartiОценок пока нет

- Ammo 67Документ22 страницыAmmo 67Eric Mak100% (1)

- Opio Faith K 201301 PHD PDFДокумент266 страницOpio Faith K 201301 PHD PDFMiguel FrezОценок пока нет

- High Rise Buildings Basement Construction PDFДокумент82 страницыHigh Rise Buildings Basement Construction PDFVineetha Alfred100% (1)

- I Am Sharing 'Industrial Hygiene 1' With YouДокумент27 страницI Am Sharing 'Industrial Hygiene 1' With YouFAISAL DESHPANDEОценок пока нет

- Roselle Seed As A Potential New Source of Healthy Edible OilДокумент12 страницRoselle Seed As A Potential New Source of Healthy Edible OilAminul IslamОценок пока нет