Академический Документы

Профессиональный Документы

Культура Документы

Checklist For Fireextinguisher As Per Is

Загружено:

Qhsef Karmaveer Jyoteendra VaishnavИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Checklist For Fireextinguisher As Per Is

Загружено:

Qhsef Karmaveer Jyoteendra VaishnavАвторское право:

Доступные форматы

ANNEX C [Clause 11.

5 (e)] MAINTENANCE CHECK LIST FOR FIRE EXTINGUISHERS (For routine check and monthly maintenance) SODA ACID FIRE EXTINGUISHER (IS 934, IS 5506) a) Open the extinguisher, withdraw the case and remove the acid bottle and examine it for cracks. Check the main liquid level and empty main liquid charge into a clean container. b) Remove acid bottle if cracked and replace with a new one. Renew the main liquid charge if level is appreciably reduced. c) Examine the extinguisher body externally and internally using illuminating probe. d) Examine nozzle, strainer, vent holes, internal discharge tube, snifter valve and clean them properly. Examine hose assembly; wheel carriage in case of 50 litre soda acid extinguishers. e) Check the operating mechanism for free movements and sealing washers for correctness and replace, if necessary. f) Check the nozzle and see that it is not clogged and clean it. g) Clean the extinguisher externally and internally and return the original charge to the extinguisher and make up the level with water if slightly less. Otherwise use a new charge. FIRE EXTINGUISHER, WATER TYPE GAS CARTRIDGE (IS 940) a) Open the extinguisher, see the water level, throw away the water charge. b) Examine the extinguisher body internally and externally for corrosion and damaged conditions with illuminating probe. Damaged and corroded extinguishers should be removed from service. Corroded gas cartridge should also be replaced. c) Examine the gas cartridge for mass. If there is loss of more than 10 percent of original mass, the cartridge should be sent for re-charging after being replaced by a charged one. For re-charging, procedure given in 12.4 should be followed. d) Examine nozzle, strainer, vent holes, internal discharge tube, sealing washer, replace them if not in good condition. Otherwise clean them thoroughly. e) Check the operating mechanism for free movement and piercing mechanism if working properly. f) Refill the fire extinguisher with clean water. FIRE EXTINGUISHER, WATER TYPE STORED PRESSURE (IS 6234) a) Examine and verify that the pressure gauge or any other pressure indicating device fitted in is indicating the internal pressure correctly, if the extinguisher shows a loss of pressure of more than 10 percent, refer to the manufacturers instructions for appropriate action. b) Examine the extinguisher body externally for corrosion or damage. c) Weigh the extinguisher (with or without the operating mechanism according to the manufacturers instructions) or use suitable alternate means to check that it contains the correct mass of liquid. Check the mass against the mass recorded when it was first put into service. d) Examine the nozzle and hose and clean if necessary. e) Examine the hose for wear and replace if not in good condition. f) Where the extinguishers are designed to have the operating mechanism removed, check the operating mechanism and discharge control (where fitted) for free movement, clean, rectify or replace, if necessary. g) Replace safety clip/wire seal or equivalent device as originally fitted. h) Refill the fire extinguisher with clean water. FIRE EXTINGUISHER, FOAM TYPE MECHANICAL (IS 10204) a) Open the extinguisher, check the liquid level. Pour liquid in separate clean receptacle to see if there is any sediment at the bottom of the cylinder. Reject the charge if there is sufficient sludge formation. b) Examine the extinguisher externally and internally for any corrosion or damage. Damaged and corroded extinguisher should be removed from service. Corroded gas cartridge should also be replaced. c) Examine the gas cartridge of mass. If there is loss of more than 10 percent of original mass, replace it with fully charged one.

d) Examine the foam generating nozzle, strainer, vent holes, internal discharge tube ceilng washer, etc. Replace them, if not in good condition. Otherwise clean them thoroughly. e) Check the operating mechanism for free movement and piercing mechanism for proper working. f) Clean the hose assembly and check it for any dust/sediment at either shank ends. FIRE EXTINGUISHER, DRY POWDER TYPE GAS CARTRIDGE (IS 2171, IS 10658, IS 11833) All dry powder extinguishers should be inspected and maintained in accordance with the following. The dry powder extinguishers should be opened in a dry room and for a minimum possible time to avoid effect to atmospheric moisture on powder. a) Dry powder extinguisher, where discharge control is fitted on the nozzle, should be operated before opening the extinguisher to ensure that there is no pressure in the extinguisher. b) Weigh the extinguisher to check the correct mass of powder filled in it which should be marked on the body of extinguisher and record book when it was first put into service. c) Open the extinguisher and remove gas cartridge and see that sealing disc is intact. Weigh and compare its mass with full mass of cartridge marked on it. In case, loss of mass is more than 10 percent, it should be replaced by new cartridge. d) Check the operating mechanism, discharge control for free movement and closing. Examine nozzle, hose, vent holes, piercing mechanism of cap cartridge holder, grease and wipe clean. e) Remove the inner shell (if any) and clean port holes. f) Empty the dry powder in a dry container and examine for caking, lumps and foreign matter, in which case replace it with new dry powder charge. g) Examine the extinguisher body internally for any damage or corrosion and replace corroded or damaged extinguisher. h) Clean the extinguisher using dry air. j) Return the original charge to the extinguisher and fit the cartridge and other fittings. k) In case of higher capacity dry powder fire extinguisher as per IS 10658, remove the carbon dioxide cylinder and check the weight marked on the cylinder to ensure that the size conforms to that stipulated in the specification. On weighing, if the loss of mass is more than 10 percent it should be sent for recharging. Also examine the wheel carriage and discharge hose assembly with control nozzle for free flow and test it with dry air. m) In case of dry powder extinguisher for metal fires as per IS 11833, in addition to item 10 above, examine the applicator pipe and the discharge shower head for freedom from clogging and clean it with dry air. Sample of the dry powder for metal fire may be tested on a small fire of magnesium turning or chips to ensure that the powder is suitable for metallic fire risks. n) The safety valves and pressure gauges fitted on higher capacity extinguishers should be calibrated once in 3 years and recorded in the register. FIRE EXTINGUISHER, CARBON DIOXIDE TYPE (IS 2878) a) Examine extinguisher body externally. Damaged or corroded extinguisher should be replaced. b) Weigh the extinguisher, compare mass against the mass marked on it for fully, charged extinguisher. It should be sent for refilling if the loss is more than 10 percent of mass. Clean and polish externally. c) Examine hose, horn and assembly and clean. In case of trolley mounted extinguisher, examine the wheel carriage for free movement.

Вам также может понравиться

- Microeconomics Test Bank and Solutions ManualДокумент7 страницMicroeconomics Test Bank and Solutions ManualTestBank0% (13)

- Multi-Format Assessment 2Документ11 страницMulti-Format Assessment 2Hassan AlawamiОценок пока нет

- Aftercooler - Test PDFДокумент6 страницAftercooler - Test PDFDaniel Castillo Peña100% (1)

- Scope of Work Gas TurbineДокумент13 страницScope of Work Gas TurbinePhong le100% (1)

- Method Statement of Chiller Preventive MaintenanceДокумент5 страницMethod Statement of Chiller Preventive MaintenanceBalajiОценок пока нет

- Lsa Ffa Monthly ChecksДокумент11 страницLsa Ffa Monthly ChecksakashОценок пока нет

- Ek GeneralДокумент24 страницыEk GeneralPRASHANT SAWANTОценок пока нет

- Imai Ek General Q AДокумент88 страницImai Ek General Q APranjyoti SaikiaОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Vortec 1.6L I-4 IndustrialДокумент3 страницыVortec 1.6L I-4 IndustrialSantiago UrgilesОценок пока нет

- FLSmidth CrossBar Cooler v2 PDFДокумент8 страницFLSmidth CrossBar Cooler v2 PDFgrameshkreddy2013Оценок пока нет

- Audit ChecklistДокумент3 страницыAudit Checklistlbss22008Оценок пока нет

- P8000 Series SM PDFДокумент444 страницыP8000 Series SM PDFKamil OwsianieckiОценок пока нет

- Kruti Amc - 7Документ2 страницыKruti Amc - 7rvsharma100Оценок пока нет

- Halogenated Agent Fire Extinguishers Annual Maintenance ProcedureДокумент1 страницаHalogenated Agent Fire Extinguishers Annual Maintenance ProcedureEazy DigitalОценок пока нет

- SOP For XL Grade Cylinder FillingДокумент3 страницыSOP For XL Grade Cylinder Fillingtejcd1234Оценок пока нет

- 75 KG DCP ExtinguisherДокумент3 страницы75 KG DCP Extinguishervivekvpsfe100% (1)

- DownloadДокумент6 страницDownloadrasullareyas82Оценок пока нет

- 25 KG DCP Extinguisher: A) DescriptionДокумент4 страницы25 KG DCP Extinguisher: A) DescriptionvivekvpsfeОценок пока нет

- Britannia Powder CartridgeДокумент5 страницBritannia Powder Cartridgealfred.mathewsОценок пока нет

- Operator Questions - Docx Version 1Документ5 страницOperator Questions - Docx Version 1MOHIT TIWARIОценок пока нет

- 10 Kg DCP extinguisher operation and maintenanceДокумент3 страницы10 Kg DCP extinguisher operation and maintenancevivekvpsfeОценок пока нет

- Accumulator and Bop Test ProceduresДокумент7 страницAccumulator and Bop Test Proceduresyefersson morales lopezОценок пока нет

- 16 K SMP of Ajax 2803 Non LeДокумент5 страниц16 K SMP of Ajax 2803 Non LeAbhishek NayakОценок пока нет

- Fire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Документ3 страницыFire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Nego1975Оценок пока нет

- Cleaning Blender GemcoДокумент3 страницыCleaning Blender GemcoImran AsgharОценок пока нет

- Preventative Maintenance ManualДокумент7 страницPreventative Maintenance ManualSebastián Isaías Soto FernándezОценок пока нет

- Ajax Preventative Maintenance ManualДокумент7 страницAjax Preventative Maintenance ManualJavier PalaciosОценок пока нет

- Standard Operating Procedure (Sop) A. TankДокумент9 страницStandard Operating Procedure (Sop) A. TankRESYОценок пока нет

- Maintenance Operations: Engine Cold Engine OperationsДокумент18 страницMaintenance Operations: Engine Cold Engine OperationsJorgeAlbuquerqueОценок пока нет

- Boiler Do's & Don'tsДокумент7 страницBoiler Do's & Don'tsMithilesh YadavОценок пока нет

- Fire Extinguisher NFPA 10 Annual Inspection GuideanceДокумент1 страницаFire Extinguisher NFPA 10 Annual Inspection Guideancehani_shdОценок пока нет

- Gmi 404470935806Документ5 страницGmi 404470935806b8505887Оценок пока нет

- Api 576Документ2 страницыApi 576Babar Manzoor GhauriОценок пока нет

- For BSДокумент23 страницыFor BSFrancis Mark AriraoОценок пока нет

- P A S S ++extinguisherДокумент30 страницP A S S ++extinguisherJudy Ann GallegoОценок пока нет

- Hydrojetting Daily InspectionДокумент6 страницHydrojetting Daily InspectionUnknownОценок пока нет

- (A) Scope of Work in Maintenance of Fire Fighting EquipmentДокумент6 страниц(A) Scope of Work in Maintenance of Fire Fighting Equipmentsunilarora9999Оценок пока нет

- SpectraAA Flame Pre Analysis Maintenance ChecklistДокумент2 страницыSpectraAA Flame Pre Analysis Maintenance ChecklistlynxxОценок пока нет

- Servicing & Maintenance ProceduresДокумент5 страницServicing & Maintenance ProceduresjoshОценок пока нет

- Maintenance Working Hours Flow For Gas TurbineДокумент7 страницMaintenance Working Hours Flow For Gas TurbineHilmi HanoinОценок пока нет

- Flushing Air Conditioner ProcedureДокумент3 страницыFlushing Air Conditioner Proceduredimchien100% (1)

- PM ScheduleДокумент2 страницыPM ScheduleEdmund YoongОценок пока нет

- Mls Instruction Manual 02 04 2019Документ6 страницMls Instruction Manual 02 04 2019Prakash VasudevanОценок пока нет

- Instruction Manual Vacuum CondenserДокумент12 страницInstruction Manual Vacuum CondenserGarry BernzОценок пока нет

- Mep March 2023Документ17 страницMep March 2023Subham SamantarayОценок пока нет

- Smi 292Документ28 страницSmi 292Sourav NandiОценок пока нет

- Fluid Pump Maintenance ProcedureДокумент8 страницFluid Pump Maintenance ProcedureTrue StoryОценок пока нет

- Man Entry Method StatementДокумент4 страницыMan Entry Method Statementsuresh kumarОценок пока нет

- BIT-EnD 8E4198 - Caterpillar D10TДокумент2 страницыBIT-EnD 8E4198 - Caterpillar D10Tgraha networkОценок пока нет

- Appendixc Well Drilling ProcedureДокумент7 страницAppendixc Well Drilling Proceduremartahan manurungОценок пока нет

- Notice To Surveyors, Shipowners, Managers and Classification SocietiesДокумент36 страницNotice To Surveyors, Shipowners, Managers and Classification SocietieskdimosОценок пока нет

- Void Content Apparatus For Coarse Aggregate: Product ManualДокумент4 страницыVoid Content Apparatus For Coarse Aggregate: Product ManualAmir OnsoriОценок пока нет

- CARTRIDGE EXTINGUISHER SERVICEДокумент9 страницCARTRIDGE EXTINGUISHER SERVICEArty BatizОценок пока нет

- Overhaul Procedure for Coal MillДокумент5 страницOverhaul Procedure for Coal MillJenal Tampubolon100% (1)

- Ek GeneralДокумент24 страницыEk GeneralCadet ABDUL REHMANОценок пока нет

- PreparationForOpeningATankAndTankEntry Tank DrillingДокумент4 страницыPreparationForOpeningATankAndTankEntry Tank DrillingargaegargvagrОценок пока нет

- Compresor Tuflo 550Документ6 страницCompresor Tuflo 550Ramón José Aponte FrancoОценок пока нет

- MaintenanceInformation 4CylVeradoДокумент27 страницMaintenanceInformation 4CylVeradocombaheeОценок пока нет

- Testing of Engines - 0Документ12 страницTesting of Engines - 0S lenkaОценок пока нет

- Generic Drill Stem Test ProcedureДокумент6 страницGeneric Drill Stem Test Procedureadi nugrohoОценок пока нет

- GCTroubleshooting Part One NotesДокумент5 страницGCTroubleshooting Part One NotesSoheil MoghadamОценок пока нет

- List of Methods For Well TestingДокумент6 страницList of Methods For Well TestingRizwan FaridОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- MPW Training ModuleДокумент48 страницMPW Training ModuleQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- 112Документ60 страниц112Qhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Pledge - 11 07 2023 09 30 49Документ1 страницаPledge - 11 07 2023 09 30 49Qhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- 7Документ48 страниц7Babu SОценок пока нет

- 6qfiny8w 1654533493154Документ1 страница6qfiny8w 1654533493154Qhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Reliability Improvement of Coker Charge PumpДокумент18 страницReliability Improvement of Coker Charge Pumprachmadi adyОценок пока нет

- CAME Receipt-007 - 2023Документ3 страницыCAME Receipt-007 - 2023Qhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- New Zealand Job Placement for Construction Workers and Truck DriversДокумент5 страницNew Zealand Job Placement for Construction Workers and Truck DriversQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- P F E & R: Assion or Mpowerment EcognitionДокумент40 страницP F E & R: Assion or Mpowerment EcognitionQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- CQS After July 2021 Powerpoint Presentation PPT With Effects JPEGДокумент14 страницCQS After July 2021 Powerpoint Presentation PPT With Effects JPEGQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Meraya Certificates (Without Stemp)Документ15 страницMeraya Certificates (Without Stemp)Qhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Vol Registration Form SetДокумент8 страницVol Registration Form SetQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Certificate CourseДокумент4 страницыCertificate CourseQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Chinmay Academy For Multipurpose EducationДокумент3 страницыChinmay Academy For Multipurpose EducationQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Karmaveer Vaishnav Certificate of Multimedia ResourcesДокумент1 страницаKarmaveer Vaishnav Certificate of Multimedia ResourcesQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Covering Letter-Quo-Shine Pharmaceaticals Pvt. LTD PDFДокумент1 страницаCovering Letter-Quo-Shine Pharmaceaticals Pvt. LTD PDFQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Digit Two-Wheeler Package Policy: Go Digit General Insurance LTDДокумент2 страницыDigit Two-Wheeler Package Policy: Go Digit General Insurance LTDQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Karmaveer Vaishnav-Work Place-Backside-SmartSign PDFДокумент1 страницаKarmaveer Vaishnav-Work Place-Backside-SmartSign PDFQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Leading Suppliers of Automotive & Industrial Batteries Battery Charger Ups & InvertersДокумент1 страницаLeading Suppliers of Automotive & Industrial Batteries Battery Charger Ups & InvertersQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Congratulations On Your Completion: Karmaveer VaishnavДокумент2 страницыCongratulations On Your Completion: Karmaveer VaishnavQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Record of Achievement in Waste ManagementДокумент1 страницаRecord of Achievement in Waste ManagementQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Chinmay Education TrustLock Out Tag Out Safety-SmartSign PDFДокумент1 страницаChinmay Education TrustLock Out Tag Out Safety-SmartSign PDFQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Specimen Exam Paper - SP9 - IFoA - 2019 - Final PDFДокумент7 страницSpecimen Exam Paper - SP9 - IFoA - 2019 - Final PDFQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Fire Alarm Panel Quotation For Shine Pharmaceaticals Pvt. LTD PDFДокумент1 страницаFire Alarm Panel Quotation For Shine Pharmaceaticals Pvt. LTD PDFQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- TP042374 Desktop Assessment Report Status Deemed Not ReadyДокумент7 страницTP042374 Desktop Assessment Report Status Deemed Not ReadyQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- COVID-19-occupational-health & Safety-Karmaveer VaishnavДокумент1 страницаCOVID-19-occupational-health & Safety-Karmaveer VaishnavQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Guidelines For Educstional InstitutesДокумент2 страницыGuidelines For Educstional InstitutesQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Karmaveer Vaishnav-Work Place-Backside-SmartSign PDFДокумент1 страницаKarmaveer Vaishnav-Work Place-Backside-SmartSign PDFQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Guidelines For Educstional InstitutesДокумент2 страницыGuidelines For Educstional InstitutesQhsef Karmaveer Jyoteendra VaishnavОценок пока нет

- Data Baru ValidДокумент56 страницData Baru ValidNullОценок пока нет

- CVD Icon LibraryДокумент5 страницCVD Icon LibraryAnonymous SR0AF3Оценок пока нет

- Eusebi Pesaola IWMC 2013 On CEN 14972Документ31 страницаEusebi Pesaola IWMC 2013 On CEN 14972kdsessionsОценок пока нет

- Kaizen & Kanban Production SystemДокумент17 страницKaizen & Kanban Production SystemNishit ShauryaОценок пока нет

- Installation Guide - Tecnomen NGM 5.1.3 - IG - 6000700 - 11Документ110 страницInstallation Guide - Tecnomen NGM 5.1.3 - IG - 6000700 - 11fahad01Оценок пока нет

- 7 XcucsagpdfДокумент428 страниц7 XcucsagpdfCristea CalinОценок пока нет

- Application Programming Interface: Oracle Order CaptureДокумент62 страницыApplication Programming Interface: Oracle Order Capturesurapaneni4uОценок пока нет

- IQTC IntroductionДокумент19 страницIQTC IntroductionVijayan Munuswamy100% (1)

- PAM-4 January2017 FinalДокумент75 страницPAM-4 January2017 Finaljose300Оценок пока нет

- Modutech Catalog 2021 2Документ206 страницModutech Catalog 2021 2ercanmusaОценок пока нет

- 20 Step7 Basic v10.5 Quick Start en v11Документ36 страниц20 Step7 Basic v10.5 Quick Start en v11QuangThắngОценок пока нет

- Ap7600 PDFДокумент12 страницAp7600 PDFArief ArdiyuandaОценок пока нет

- Lab 8.4.2Документ8 страницLab 8.4.2Luis David López TelloОценок пока нет

- I9100 Electrical Part List PDFДокумент9 страницI9100 Electrical Part List PDFDaniel CekulОценок пока нет

- HeliCoil Primer Free II ApplicationsДокумент2 страницыHeliCoil Primer Free II ApplicationsAce Industrial SuppliesОценок пока нет

- 600 Series BrochureДокумент54 страницы600 Series BrochureEmolNZ100% (1)

- XLG3 OverviewДокумент44 страницыXLG3 OverviewVALDEMIRОценок пока нет

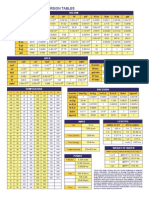

- Conversion TablesДокумент1 страницаConversion TablesSeherzada Kadric-RibicОценок пока нет

- AFL Fiber Cable Accessories PDFДокумент160 страницAFL Fiber Cable Accessories PDFMilagros Mercedes Olmos CervantesОценок пока нет

- Pipistrel VirusSWiS Information Pack PDFДокумент14 страницPipistrel VirusSWiS Information Pack PDFDany AndresОценок пока нет

- GRCA Specification PDFДокумент15 страницGRCA Specification PDFrencydОценок пока нет

- Record Plus Catalogue en Export Ed09-14Документ252 страницыRecord Plus Catalogue en Export Ed09-14ohoboho79100% (1)

- RAN Feature Documentation RAN22.1 - 07 20221201150622Документ236 страницRAN Feature Documentation RAN22.1 - 07 20221201150622myososОценок пока нет

- Bulletin 2707 - DTAM Plus Operator InterfaceДокумент20 страницBulletin 2707 - DTAM Plus Operator InterfaceahilsergeyОценок пока нет