Академический Документы

Профессиональный Документы

Культура Документы

Kuliah 1 Cair

Загружено:

kolasasa0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров50 страницteknologi farmasi

Оригинальное название

Kuliah 1 Cair (1)

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документteknologi farmasi

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров50 страницKuliah 1 Cair

Загружено:

kolasasateknologi farmasi

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 50

Teknologi Farmasi I

Cair dan Semi Padat

Najma Annuria Fithri

Ganjil 2013

Self Introduction

Najma Annuria Fithri

Education

- SMP Al-Kautsar, Bandar Lampung

- SMA Al-Kautsar , Bandar Lampung

- S1 Farmasi Sains dan Industri UGM 2006

- Apt Fak. Farmasi UGM 2010

- S2 Ilmu Farmasi Sains dan Teknologi UGM 2011

CP

- email: empith@gmail.com

- HP : 081931769304 / 082325780787

Syllabus

Liquid excipients

Semi solid excipients

Tools and equipments in manufacture

Methods of manufacture liquid

Methods of manufacture semi solid

Quality control and evaluations

Quality control and evaluations (Task)

Scoring system

Final test (50%

Quizes (20%)

Tasks (20%)

Involvement in class (10%)

Types of LDF

Solutions

- Aqueous solutions + Sugar Syrup

- Hydroalcoholic Elixir

- Aromatic alcoholic solutions Spirit

- Aromatic aqueous solutions Aromatic water

- Extracted liquids from crude products Tincture

Emulsions

Suspensions

Type of excipients

Solvents/Co-solvents

Buffering agents

Anti microbial preservatives

Anti oxidants

Sequestering agents

Wetting agents

Anti foaming agents

Thickening agents

Sweetening agents

Colouring agents

Flavouring agents

Humectant

Solvents/Co-Solvents

Water is the solvent most widely used as a vehicle due to:

Lack of toxicity, physiological compatibility, and good solubilising power (high

dielectric constant), but

Likely to cause instability of hydrolytically unstable drugs

Good vehicle for microbial growth

Sorbitol, dextrose, etc. are often added as solubilisers, as

well as base sweeteners

Similar pros and cons to water alone

Water-miscible co-solvents are used to:

Enhance solubility, taste, anti-microbial effectiveness or stability

Reduce dose volume (e.g. oral, injections)

Or, conversely, optimise insolubility (if taste of API is an issue)

Examples: propylene glycol, glycerol, ethanol, low molecular weight PEGs

Water-immiscible co-solvents, e.g.

Emulsions / microemulsions using fractionated coconut oils

Some solvents for liquid preparations

Alcohol, Ethyl alcohol (ethanol)C

2

H

5

OH

1. Next to water, alcohol is the most useful solvent in pharmacy. It is used as a primary

solvent for many organic compounds.

2. It forms hydroalcoholic mixture with water that dissolves both alcohol-soluble and

water-soluble substances

3. Alcohol has been well recognized as a solvent and excipient in the formulation of oral

pharmaceutical products. Alcohol is often preferred because of its miscibility with

water and its ability to dissolve many water-insoluble ingredients, including drug

substances, flavorants, and antimicrobial preservatives.

4. It is also used in liquid products as an antimicrobial preservative alone or with

parabens, benzoates, sorbates, and other agents.

5. Toxicity of ingested alcohol particularly for children. For OTC oral products intended

for children under 6 years of age, the recommended alcohol content limit is 0.5%, for

products intended for children 6 to 12 years old, the recommended limit is 5% and for

children over 12 years and adults, the recommended limit is 10%.

Diluted alcohol

- Is prepared by mixing equal volumes of alcohol and purified water (50%).

- Diluted alcohol is a useful hydroalcoholic solvent in various pharmaceutical processes

and preparations.

Alcohol, Rubbing (alcohol rubbing compound)

- It contains about 70% ethyl alcohol by volume.

- It is employed as a rubefacient externally and as soothing rub for bedridden patients, a

germicide for instruments

- As vehicle for topical preparation

- As skin cleanser before injection

Isopropyl rubbing alcohol

- It has the advantage over ethyl alcohol in that the commonly available product contains

not over 1% of water, while ethyl alcohol contains about 5% water, which often a

disadvantages.

-Is about 70% by volume isopropyl alcohol, with or without colour additives, stabilizers and

perfume oils

- It is used externally as a rubefacient and soothing rub and for topical products

- The commercially available 91% isopropyl alcohol solution are commonly employed by

diabetic patients in preparing needles and syringes for hypodermic injections of insulin

and for disinfecting the skin.

Glycerin, Glycerol

- It is a clear syrupy liquid with sweet taste

- It is miscible with water and alcohol

- As solvent it is comparable with alcohol, but because of

its viscosity, solutes are slowly soluble in it unless it is

rendered less viscous by heating.

- It is used as a stabilizer and as auxiliary solvent in

conjunction with water or alcohol.

- It has preservative qualities

- It is used in internal preparations

- It dissolves the fixed alkalies, a large number of salts

and vegetable acids, pepsin, tannin, some active

principals of plants, etc.

- It also dissolves gum, starch, etc.

Propylene glycol

- A viscous liquid, miscible with water, with acetone and with chloroform in all

proportions.

- It is soluble in ether and will dissolve many essential oils but is immiscible with

fixed oils.

- It is a useful solvent with wide range of application

- It is substituted for glycerol in modern pharmaceutical preparations

- It is used for formulation of digoxin, diazepam, phenobarbital injection

- As diluent for ear drops

Polyethyleneglycol, PEG 400

- It is miscible with water, acetone, alcohol and other glycols.

- It dissolves many water-soluble organic compounds as well as certain water

insoluble substances such as acetylsalicylic acid and theophyllin.

- Is used as a solvent in topical solution

- Used as co-solvent with alcohol and water

- Can be used for extraction processes

- In the formulation of veterinary solutions

Role of co-solvency

Weak electrolytes and non-polar molecules frequently have poor

water solubility

Their solubility usually can be increased by the addition of a water-

miscible solvent in

which the drug has good solubility.

This process is known as co-solvency, and the solvents

used in combination to

increase the solubility of the solute are known as co-

solvent

Co-solvents are employed not only to affect solubility of the

drug, but also to improve the solubility of volatile constituents

used to impart a desirable flavor and odour to the product.

Types of pharmaceutical water

Purified water, USP

Water for injection

Aromatic water

Physiological compatibility

Lack of toxicity

Possesses a high dielectric constant

ensuring the dissolution of a wide range of ionizable

materials

Lack of selectivity

Water is used both as vehicle and as a solvent for the desired

flavoring or medicinal ingredients.

Advantages: Tasteless, odourless, lack of pharmacological

activity, neutral and very cheap

Tap Water

It is not permitted to use tap water for the dispensing of

pharmaceutical dosage forms due to its possible bacterial

contamination and the presence of dissolved salts that destroy

the active ingredients or enhance their decomposition.

Freshly Boiled and Cooled Water

Boiling is seldom used to destroy vegetative bacteria. But, on

storage for long time spores may yield vegetative

microorganism.

Purified Water

Must be used for most pharmaceutical operations and in all the

tests and assays.

Such water is prepared by distillation, deionization (ion

exchange method) or reverse osmosis.

"Hard" waters are those that contain the Ca and Mg cations.

Alkaline" waters are those that contain bicarbonates as the

major impurity.

Ultraviolet energy, heat or filtration (Millipore filtration) can be

used to remove or kill the microorganisms present in the water.

Water for injection

Must be used for the formulation of parental solutions.

It is obtained by sterilizing pyrogen-free distilled water.

Aromatic Waters

Aromatic waters (medicated waters) are clear, saturated aqueous

solution of volatile oils or other aromatic or volatile substances.

They are used principally as flavored or perfumed vehicles.

Volatile oils solutions represent an incompatibility problem of

salting out. This occurs after the incorporation of a very soluble

salt in their solution.

Aromatic water will deteriorate with time therefore:

- should be made in small quantities

- protected from intense light and excessive heat by storing in air

tight, light resistant containers.

- If they become cloudy or otherwise deteriorate; they should be

discarded. Deterioration may be due to volatilization,

decomposition or mould growth.

The strengths of pharmaceutical preparations are usually expressed in terms of percent

strength, although for very dilute preparations, expressions of ratio strength may be

used.

Percentage (%)

% w/v (e.g., 1%w/v =1g constituent in 100 mL preparation)

%v/v (e.g., 1%v/v = 1mL constituent in 100 mL preparation)

% w/w (e.g.,1%w/w=1 g constituent in 100 g preparation)

Ratio strength

weight in volume (e.g., 1:1000 w/v= 1g constituent in 1000 mL

preparation)

volume in volume (e.g., 1:1000 v/v = 1ml constituent in 1000

mL preparation)

weight in weight (e.g., 1:1000 w/w = 1 g constituent in 1000 g

preparation)

Buffering Agents

Can be necessary to maintain pH of the formulation to:

Ensure physiological compatibility

Maintaining/optimising chemical stability

Maintaining/optimising anti-microbial effectiveness

Optimise solubility (or insolubility if taste is an issue)

But, optimum pH for chemical stability, preservative

effectiveness and solubility (or insolubility) may not be

the same

Compromises need to be made

Ex: carbonates, citrates, phosphate, lactates,

gluconates, tartarates, borates (external). Its

presence in solution resists any changes in pH

upon dilution or addition of small quantities of

acid or base. The usual buffering agents used in

oral liquid preparations are acetate and

phosphate buffer. The buffer increase

Anti-microbial Preservatives

Preservatives are used in multi-use cosmetic/pharmaceutical

products (including paediatric formulations)

Prevents an increased risk of contamination and proliferation by opportunistic

microbes (from excipients or introduced externally), that would result in potential

health issues

Avoid use wherever possible, especially in products aimed at younger paediatric

patients

e.g. not required for sterile, single-dose products (as recommended for neonates)

Ideally targeted for microbial cells - showing no toxicity/irritancy

towards mammalian cells

Challenge is that the active groups involved are usually harmful to all living tissue

There are a limited number of approved preservatives available for

multi-use oral products, and options are even more limited for other

routes of administration

Should not use in parenteral infusions

Must avoid access to cerebrospinal fluid and retro-ocular administration

This restricted number can be further reduced by consideration of

factors such as levels required (dose), pH-solubility profiles, API &

excipient incompatibilities, adsorption, irritancy and toxicity.

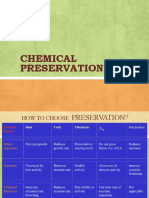

Choice of Preservative

The preservative selected should have the following

properties :

1. It should be effective against a wide range of

microorganisms.

2. It should be compatible with other ingredients of the

formulation.

3. It should be soluble in aqueous phase when used in

emulsions.

4. It should be nontoxic.

5. It should be free from odour and taste.

6. It should preserve the preparations and remain stable

for the shelf life of the product.

No singly preservative possesses all the qualities

therefore it becomes necessary to use a combination of

preservatives to prevent the growth of microorganisms.

The most commonly used preservatives are as follows:

1. Benzoic acid and sodium benzoate 0.1 to 0.2%.

2. Salicylic acid 0.1%.

3. Phenol 0.2 to 0.5%.

4. Chlorocresol 0.05 to 0.1%.

5. Alcohol 15 t 20%.

6. Chlorbutanol 0.5%.

7. Phenylmercuric nitrate 0.002 to 0.005%.

8. Sorbic cid and its salts 0.05 to 0.2%.

9. Benzalkoniumchloride 0.004 to 0.02 %.

10. Methyl paraben and propyl paraben 0.1% to

0.2%.

Anti-Oxidants

Used to control oxidation of:

API

Preservative, e.g. potassium sorbate

Vehicle, e.g. oils or fats susceptible to -oxidation (rancidification)

Colourants (ageing discolouration)

Sacrificial (more oxidisable than API, preservative, etc). Levels

will reduce with time. need to be monitored by specific assay

Light exposure and metal ion impurities can accelerate oxidative degradation and

hence depletion of antioxidant

Need to assess regulatory acceptability (differs in different

countries)

Efficacy can be affected by:

Compatibility with other excipients

Partitioning into micelles (from surfactants)

Adsorption onto surfaces (container, thickening agent and suspended particles)

Incompatibilities, e.g. with metal ions

Sequestering/Chelating agents

Chelating agent excipients are used in chelation therapy to

detoxify poisonous metal agents such as mercury [Hg],

arsenic [As], and lead [Pb] by converting them to a

chemically inert form that can be excreted without further

interaction with the body.

Chelating agents inhibits auto oxidations by metal ions

Metal ions are a catalyst to auto oxidation process

Wetting Agents

To aid wetting and dispersion of a hydrophobic API,

preservative or antioxidant

Reduce interfacial tension between solid and liquid during manufacture or

reconstitution of a suspension

Not all are suitable for oral administration

Examples include:

Surface active agents, e.g.

Oral: polysorbates (Tweens), sorbitan esters (Spans)

Parenteral: polysorbates, poloxamers, lecithin

External: sodium lauryl sulphate

.but these can cause excessive foaming (see anti-foaming agents) and can

lead to deflocculation and undesirable physical instability (sedimentation) if

levels too high

Hydrophilic colloids that coat hydrophobic particles, e.g. bentonite, tragacanth,

alginates, cellulose derivatives. Also used as suspending agents, these can

encourage deflocculation if levels are too low.

Anti-Foaming Agents

The formation of foams during manufacturing processes or

when reconstituting liquid dosage forms can be undesirable

and disruptive.

Anti-foaming agents are effective at discouraging the

formation of stable foams by lowering surface tension and

cohesive binding of the liquid phase.

A typical example is Simethicone (polydimethylsiloxane-

silicon dioxide), which is used at levels of 1-50ppm.

Of course, a foam is also a very valid dosage form option for

certain situations, e.g. for topical administration and in

wound dressings.

In addition, wet granulation using a foam rather than aqueous

granulation fluid is gaining popularity.

Thickening Agents

Suspension stabilisers: prevent settling/sedimentation

(particularly if a wetting agent present)

They usually modify viscosity and are often thixotropic (where

viscosity is dependent on applied shear and exhibits shear

thinning)

Easily poured when shaken

Must permit accurate dosing with chosen method (e.g. graduated

syringe, spoon)

Quickly reforms gel-like structure

They can impact on flocculation at low levels

Work by entrapment of solid particles, e.g. API, in a viscous or

even

gel-like structure

Can be either water-soluble, e.g. methylcellulose or

hydroxyethylcellulose

Or water-insoluble, e.g. microcrystalline cellulose

Example:

semi-synthetic: thickening agents-methyl

cellulose, carboxy methyl cellulose,

hydroxypropyl cellulose, synthetic polymers and

gelatin. Sodium carboxy methyl cellulose (3.5%)

is used in injectable suspensions.

Clays: hydrated aluminiumsilicate or

magnesium silicate

Non-ionic: sorbitol, glycerin, sugar or

polycthylene glycols

Sweetening Agents

Natural sweeteners

Sucrose; soluble in water (vehicle), colourless, stable (pH 4-8), increases viscosity;

Arguably the best taste/mouthfeel overall but cariogenic & calorific avoid in

paediatrics?

Sorbitol (non-cariogenic, non-calorific - appropriate for paediatric formulations),

but lower sweetness intensity than sucrose (so you need more) & can cause

diarrhoea

Artificial sweeteners

Regulatory review required often restricted territories

Much more intense sweeteners compared with sucrose

As a consequence the levels are much lower (<0.2%) but still need to refer to

WHO Acceptable Daily Intakes (ADIs)

Can impart a bitter or metallic after-taste (hence used in combination with natural

sweeteners), e.g.

Saccharin, and its salts

Aspartame

Acesulfame K

Sucralose excellent sweetness, non-cariogenic, low calorie, wide & growing

regulatory acceptability but relatively expensive

Flavouring Agents

Supplement and complement a sweetening agent

Ensures patient compliance (especially in paediatric formulations a big issue)

Can be natural, e.g. peppermint, lemon oils,

Or artificial e.g. butterscotch, tutti-frutti flavour

Instability can be an issue combinations can be used to cover intended product

shelf-life

Taste appreciation is not globally consistent

Genetic element: one persons acceptable taste is anothers unacceptable taste

Territorial (cultural?) differences in preference; e.g. US vs. Japan vs. Europe

Affected by age (paediatric perception and preferences are different from adult)

Can be affected by certain disease states, e.g. during cancer chemotherapy

Regulatory acceptability of flavours needs to be checked

Different sources, different compositions, different flavour, e.g. there are >30

different strawberry flavours!

Usually complex of composition (so refer to internationally recognised standards)

Colouring agents

Colouring agents may be defined as the substances used to

impart colour to foods, drugs and cosmetics to increase their

organoleptic properties. In pharmaceutical preparations

they may be used to increase their acceptability by the

patients, to give warning, or to produce standard

preparations.

The examples of mineral colours are ferric oxide (yellow

and red), carbon black, titanium dioxide and ultramarine.

Only the permitted colours are used in food and

pharmaceutical preparations. Caramel or burnt sugar, an

artificial colour is used to produce brown colour in cough

syrups. elixirs and other oral liquid preparation.

Certified color additives are classified according to

their approved use: (a) FD&C color additives,

which may be used in foods, drugs, and cosmetics;

(b) D&C color additives, some of which are

approved for use in drugs, some in cosmetics, and

some in medical devices; and (c) external D&C

color additives, the use of which is restricted to

external parts of the body, not including the lips

or any other body surface covered by mucous

membrane

Humectants

Hygroscopic excipients used at ~5% in aqueous

suspensions and emulsions for external application.

Their function is to retard evaporation of aqueous

vehicle of dosage form:

To prevent drying of the product after application to the skin

To prevent drying of product from the container after first opening

To prevent cap-locking caused by condensation onto neck of

container-closure of a container after first opening

Examples include:

propylene glycol

glycerol

PEG

Overview thoughts for paediatric dosage forms

So..

A quite wide range of excipients and dosage forms

needs to be considered

Key considerations for paediatric formulations are

to

minimize the use of excipients, understand the

limitations of those types of excipient that can and

are used and be able to justify their use at the dose

levels involved.

General philosophy regarding excipients for

liquid dosage forms

Choose the appropriate dosage formfor the target

population(s)

Avoid health hazards apply a benefit vs. risk balance

assessment:

Minimum age of target population

Maximum duration of therapy

Double-check age-related safety of established (adult dosage form?) excipients

Novel excipients need comprehensive safety testing

Justify inclusion and minimise number of excipients and

quantity to

be used:

Especially younger age groups

Choose dosage forms that achieve this

Not for aesthetic or cosmetic purposes

Avoid sugar for long-term use

Can any taste issue be reduced without resorting to the use of additives? e.g. through

dilution, pH control, API version selection (does reduced API solubility resolve the issue?)

Avoid biologically active excipients e.g. preservatives, anti-oxidants, unless dosage

flexibility warrants inclusion. Use lowest feasible levels.

Compliance with relevant regulations and be alert to the latest guidance

Solvents/Preservatives

Propylene Glycol Toxicity

Propylene glycol (PG) is a general solvent with anti-

microbial properties used in a wide range of

pharmaceutical preparations including oral liquids,

topicals and parenteral preparations

However, its use in large volumes in children is

very much discouraged:

PG has been associated with cardiovascular, hepatic, respiratory and

CNS adverse events, especially in neonates where the biological half-

life is prolonged (~17h) compared with adults (5h).

I.V. parenterals containing PG must be infused slowly

PG also has a laxative action at high oral doses through high osmotic

pressure effects.

Solvents

Ethanol Toxicity

Widely used as a co-solvent to aid solubility

In US, maximum permitted quantities in OTC products:

<0.5% for children under 6-years

<5% for children 6-12-years

<10% for children over 12-years

Acute (overdose) or chronic (long-term use) toxicity is possible

May cause adverse symptoms of intoxication, lethargy, stupor, coma,

respiratory depression and cardiovascular collapse

Peanut Oil Toxicity

Peanut oil is used as a food additive and as a solvent in intra-muscular

injections

It has been suggested that the use of peanut oil in childhood (infant

formula and topical preparations) can lead to later episodes of

hypersensitivity, and therefore should be discontinued

Sweeteners

Saccharin

Restricted regulatory acceptability

Poor aftertaste

Hypersensitivity reactions; mainly dermatologic

Paediatrics with allergy to sulphonamides should avoid saccharin

Aspartame Toxicity

Source of phenylalanine possibly an issue for phenylketoneurics

Aspartame has been blamed for hyperactivity in children but as yet

unproven

Sorbitol

Can induce diarrhoea

Solvents/Solvent sweeteners

Need for oral liquid preparations (that children

typically find easier to swallow) often

necessitates:

Taste-masking; which often relies on sweeteners

Addition of co-solvents to improve drug solubility if a solution is wanted

(elegance/mouth feel vs. taste)

Most commonly used solvent sweeteners are

Propylene glycol

Glycerine (Glycerol)

Anti-microbial Preservatives

Benzyl Alcohol toxicity in neonates

Widely used as a preservative in cosmetics, foods and pharmaceuticals

(including injectables and oral liquids)

Toxic syndrome observed in neonates it was attributed to the practice

of flushing out umbilical catheters with solutions containing benzyl

alcohol (BA), because of trace levels of benzaldehyde that were present

Dilution of nebulisation solutions with BA-preserved saline led to

severe respiratory complications and even death in neonates.

Attributed to accumulation of BA due to an immature metabolic

capability.

Only dilute inhaled solutions with non-preserved, sterile diluents

Anti-microbial Preservatives

Sodium Benzoate toxicity

Widely used as a preservative in cosmetics, foods and pharmaceuticals

(including injectables and oral liquids)

Injectable combinations of Na Benzoate and Caffeine should not be

used in neonates; found to elicit non-immunological contact reactions,

including urticaria and atopic dermatitis

Limitation on dosing of NA benzoate to neonates - 10mg/kg/day

due to immature metabolic capability

Thimerosal toxicity

Formerly widely used as a preservative in cosmetics, in soft contact lens

solutions and pharmaceuticals (primarily vaccines)

Being phased out from most paediatric vaccines as better options

emerge

Possible links with toxicity in paediatric vaccines, e.g. linked with

childhood autism but not proven

Diluents/Fillers

Lactose toxicity (immature metabolism)

Lactose occurs widely in dairy products and is used in infant feed formulae.

In pharmaceutical preparations it is widely used as a diluent in tablets and

capsules, in lyophilised powders, as a sweetener in liquid formulations and

as a carrier in dry powder inhalation products.

Lactose intolerance occurs when there is a deficiency in the intestinal

enzyme lactase, leading to GIT build-up of lactose. There is then the risk of

abdominal bloating and cramps.

Lactase is normally present at high levels at birth, declining rapidly in early

childhood (4-8 years) . Hypolactasia (malabsorption of lactose) can thus

occur at an early age and, furthermore, this varies among different ethic

groups.

Significant lactose intolerance can also occur in adults but this is rare.

E numberAdditives

(Colourants, preservatives, stabilisers, anti-

oxidants, etc.)

Current high profile concerns...

Some opinion that additives in processed foods are linked to children's

allergies.

Particular attention has been paid to infants and children's products

because their immature organs are less efficient at removing such

toxins from their systems.

Certain combinations of the following artificial food colours: sunset

yellow (E110), quinoline yellow (E104), carmoisine (E122), allura red

(E129), tartrazine (E102) and ponceau 4R (E124) have been linked to a

negative effect on childrens behaviour.

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Pizza Hut IngredientsДокумент18 страницPizza Hut Ingredientsnital001Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Phle Reviewer Module 5 PharmaceuticsДокумент97 страницPhle Reviewer Module 5 PharmaceuticsCarlstine Ileto100% (3)

- Listening and Speaking 4 Q: Skills For Success Unit 5 Student Book Answer KeyДокумент4 страницыListening and Speaking 4 Q: Skills For Success Unit 5 Student Book Answer KeyNgoc Thanh100% (1)

- Food AdditivesДокумент21 страницаFood AdditivesHarish Srinivasan100% (1)

- Calcium PropionateДокумент8 страницCalcium PropionateGaganpreet KaurОценок пока нет

- Consumer Chemistry Q2 M3Документ22 страницыConsumer Chemistry Q2 M3Garcia Family Vlog57% (7)

- Chapter 5 Curing Fish and Other Marine ProductsДокумент9 страницChapter 5 Curing Fish and Other Marine ProductsGraceCayabyabNiduaza100% (1)

- Finalization: (Banana Peelings As An Alternative Substitute To Vinegar)Документ6 страницFinalization: (Banana Peelings As An Alternative Substitute To Vinegar)Myka Gomez OtnamОценок пока нет

- FOOD INGREDIENTS NUMBERS (E-Numbers) - WorldOfIslam - Halal & Haram FoodДокумент13 страницFOOD INGREDIENTS NUMBERS (E-Numbers) - WorldOfIslam - Halal & Haram FoodMatthew BrownОценок пока нет

- Unit 5. Food Processing and Preservation TechniquesДокумент30 страницUnit 5. Food Processing and Preservation Techniquesfeyisa100% (1)

- Deterioration of FishДокумент12 страницDeterioration of FishZeenat MoambarОценок пока нет

- Meets BC Regulatory Requirements: Sample Food Safety PlanДокумент9 страницMeets BC Regulatory Requirements: Sample Food Safety PlanPSAОценок пока нет

- CBCS PDFДокумент227 страницCBCS PDFali skОценок пока нет

- PreservativeДокумент40 страницPreservativeKrishnan vijayОценок пока нет

- Novel Natural Food Preservatives and Applications in Seafood Preservation A ReviewДокумент11 страницNovel Natural Food Preservatives and Applications in Seafood Preservation A ReviewAbe LimОценок пока нет

- Use of Natural Preservatives in Seafood PDFДокумент17 страницUse of Natural Preservatives in Seafood PDFAnonymous SKlyU5sJ5AОценок пока нет

- 8 Science MicroorganismsДокумент6 страниц8 Science MicroorganismsAjay AnandОценок пока нет

- CITATION Mas19 /L 1033Документ3 страницыCITATION Mas19 /L 1033Fadhlin SakinahОценок пока нет

- CosmeticsДокумент4 страницыCosmeticsMadhu Kiran DhondalayОценок пока нет

- Chemistry (Yang Ini)Документ45 страницChemistry (Yang Ini)Nabil MuhammadОценок пока нет

- 2 - 1 Chemical PreservationДокумент18 страниц2 - 1 Chemical PreservationAn FakeihahОценок пока нет

- ProClin® Preservatives For in Vitro Diagnostic Materials: Efficacy vs. Thimerosal and Sodium AzideДокумент2 страницыProClin® Preservatives For in Vitro Diagnostic Materials: Efficacy vs. Thimerosal and Sodium AzideSAFC-Global100% (1)

- Effect of Water ActivityДокумент2 страницыEffect of Water ActivityMariel GeleraОценок пока нет

- Summative Test 4 Tle 6Документ4 страницыSummative Test 4 Tle 6Jovanni Bendulo LegaspinaОценок пока нет

- Hyperspectral Imaging Technique For Evaluating Food Quality AndsafetyДокумент11 страницHyperspectral Imaging Technique For Evaluating Food Quality AndsafetyRaluca Alexandra NeculaОценок пока нет

- COMMON METHODS of PROCESSING and PRESERVING of FOODS 3rd QuarterДокумент13 страницCOMMON METHODS of PROCESSING and PRESERVING of FOODS 3rd QuarterMaymay AuauОценок пока нет

- Pengembangan Farmasetik Bentuk Sediaan Cair (Larutan)Документ40 страницPengembangan Farmasetik Bentuk Sediaan Cair (Larutan)niantri laiaОценок пока нет

- Application of Ftir For The Characterisation of Sustainable Cosmetics and Ingredients With Antioxidant PotentialДокумент9 страницApplication of Ftir For The Characterisation of Sustainable Cosmetics and Ingredients With Antioxidant PotentialChiper Zaharia DanielaОценок пока нет

- Q2 Week 2 Con ChemДокумент18 страницQ2 Week 2 Con ChemB05 - SAMAN GERARD JOHN ALBERTОценок пока нет

- Methods of Dairy Milk PreservationДокумент5 страницMethods of Dairy Milk PreservationAbdy ShahОценок пока нет