Академический Документы

Профессиональный Документы

Культура Документы

Naxtra-Xabo 2010 GB

Загружено:

josel213Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Naxtra-Xabo 2010 GB

Загружено:

josel213Авторское право:

Доступные форматы

N-A-XTRA

and XABO

high-strength steels

For lighter living

ThyssenKrupp Steel Europe

Thinking the future of steel

Quenched and tempered N-A-XTRA

and XABO

steels

for lighter living

Different quenched and tempered steels

for different applications

The most common quenched and tempered

structural steel is N-A-XTRA

700, which

meets customer requirements for high

strength and easy processing. N-A-XTRA

700 combines a high yield strength of at

least 700 MPa with outstanding toughness

even at temperatures down to 60C. Its

lean chemical composition makes it ideal

for cold forming and all common weld-

ing methods. N-A-XTRA

800 combines

elevated strength with good cutting and

welding properties similar to those of

N-A-XTRA

700 thanks to the same lean

analysis concept.

The XABO

890 and 960 steels are used if

higher yield strengths of 890 or 960 MPa

are required. These steels are best welded

under shield gas. XABO

1100 represents

the current peak of high-strength structural

steel development. This steel offers a

minimum yield strength of 1100 MPa

combined with good toughness and weld-

ability. Despite its outstanding strength, this

steel can also be easily processed by cold

forming.

The high-strength quenched and

tempered N-A-XTRA

and XABO

steels from

ThyssenKrupp Steel Europe make living

lighter and easier. In highly stressed struc-

tures they allow a reduction of the plate

thickness and thus lighter buildings. Sub-

stituting N-A-XTRA

700 for the general

structural steel S355 (St 52-3) allows a

50% reduction in plate thickness, and using

XABO

960 an even greater reduction of

70%. Further advantages of high-strength

steels are lower consumption of welding

fillers and reduced welding costs. Light-

weighting is particularly important in com-

mercial vehicle and mobile crane construc-

tion, where dimensions, axle loads and total

weight of the vehicle are restricted by legal

regulations. The development of mobile

cranes for loads of up to 1200 tons was only

made possible by the advent of high-strength

steels.

These steels, known worldwide under

the brand names N-A-XTRA

and XABO

,

were developed in the Heavy Plate Unit of

ThyssenKrupp Steel Europe, one of the

worlds leading producers of flat-rolled steel.

The first high-strength quenched and tem-

pered heavy plates in Europe were produced

there more than 40 years ago. Advancements

since then have been remarkable, and

nowadays various grades are available with

minimum yield strengths up to 1100 MPa

in plate thicknesses from 3 to 100 mm.

These steels have proven highly successful

not only in the construction of commercial

vehicles and mobile cranes but also when

used for mining equipment and in the con-

struction of pressure vessels and pipelines.

N-A-XTRA

ThyssenKrupp

high strength

XABO

ThyssenKrupp

high strength

N-A-XTRA

700 for S355 (St 52-3) allows

costs for preheating prior to welding to be

reduced. Depending on welding method,

plate thicknesses up to 20 mm (or com-

bined thicknesses up to 40 mm) can be

welded without preheating. Furthermore,

N-A-XTRA

700 displays good cold form-

ing properties allowing tight bending radii.

Plates up to 6 mm thick can be bent with

radii as low as r/t 2.5 (> 6 mm to 16 mm

thick plates with r/t 3).

N-A-XTRA

and XABO

steels

for different applications

Balanced alloying concepts for simple

processing and high strength

The special chemical composition and the

quenching and tempering heat treatment

of N-A-XTRA

and XABO

steels give them

excellent toughness properties for reliable

performance even at extremely low tem-

peratures. The N-A-XTRA

700 grade in

particular displays outstanding toughness

and can therefore be welded with higher

heat input and longer cooling times t

8/5

. A

further characteristic feature of N-A-XTRA

steels is their low carbon equivalent. Due

to the reduced plate thickness, substituting

Mechanical properties

1)

for thickness 65 mm

4)

grades N-A-XTRA

M: 40 C

2)

for thickness 50 mm

5)

bending line parallel to rolling direction

3)

for thickness 40 mm

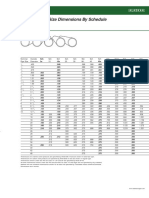

Steel grade Yield strength Tensile strength Elongation Impact energy Bending radii

5)

R

e

[MPa] R

m

[MPa] A [%] A

v

27 J at r (t 6 mm)

N-A-XTRA

550 550

1)

640 820

1)

16 60 C

4)

2.0 t

N-A-XTRA

620 620

1)

700 890

1)

15 60 C

4)

2.5 t

N-A-XTRA

700 700

1)

770 940

1)

14 60 C

4)

2.5 t

N-A-XTRA

800 800

1)

840 1000

1)

11 60 C

4)

3.0 t

XABO

890 890

2)

940 1100

2)

11 40 C 3.5 t

XABO

960 960

2)

980 1150

2)

10 40 C 3.5 t

XABO

1100 1100

3)

1200 1500

2)

8 40 C 3.5 t

A further important requirement for the use

of XABO

was that the high toughness

requirements of the parent metal are also

met in the heat affected zone of the weld

and the weld metal. When using the metal

active gas method to weld XABO

890 and

960, matching welding fillers are available.

For XABO

1100 the welds are usually

located in lower stressed parts of the struc-

ture, as the strength of the weld metal using

common welding filler metals does not

match the strength of the parent metal.

Up to 6 mm thick XABO

plates can be bent

with a minimum radius r/t 3.5 (> 6 mm to

16 mm thick plates with r/t 4).

In addition to static loading, steel struc-

tures can also be exposed to dynamic loads.

XABO

1100 displays the same good

fatigue properties as the proven XABO

960

grade. However, it must be considered that

the fatigue strength of weld joints is virtually

the same on both normal and high-strength

steels. Post-weld treatment, e.g. shot peening

or TIG dressing, is needed to take advantage

of the high fatigue strength of the parent

metal.

Hot strip plates for weight

optimized constructions

Weight plays an important role in many struc-

tures. Therefore, restricted thickness toler-

ances are often required. ThyssenKrupp

Steel Europe can produce N-A-XTRA

and

XABO

steels via two different routes. Hot

strip mill production offers the advantage of

very close thickness tolerances of 0.2 mm

which are lower than the usual thickness

tolerances off our-high mill plates and also

lower than the tolerances usually required by

customers. In addition to weightsaving poten-

tial, the extremely uniform plate thickness of

plates cut from hot strip also offers advan-

tages with regard to cold forming.

minimum requirement

I

m

p

a

c

t

e

n

e

r

g

y

[

J

]

a

t

4

0

C

100

200

27

N-A-XTRA

700

XABO

960

XABO

1100

Typical toughness of quenched an tempered structural steels

Total thickness tolerance [mm]

R

e

l

a

t

i

v

e

f

r

e

q

u

e

n

c

y

0.2

Hot strip

plates

Crane

specs.

0.7 1.5

EN 10029

Statistical thickness tolerance distribution for hot strip plates

Modern shot blasting and priming line

offers high surface quality

Plates are delivered shot blasted and primed

to meet the highest surface quality require-

ments. Shot blasting and priming is carried

out on a modern line at ThyssenKrupp Steel

Europe. A low-zinc silicate primer is usually

applied with an even coat 1218 m thick.

Investigations have shown that plates with

this primer can be cut by laser without any

problems. The inorganic content means

that the primer can be welded over, making

removal of the primer before welding gener-

ally unnecessary.

ThyssenKrupp Steel Europe

more than just a material supplier

ThyssenKrupp Steel Europe is more than

a reliable material supplier. The expansion

of our worldwide distribution network is

aimed not just at guaranteeing the avail-

ability and just-in-time delivery of N-A-XTRA

and XABO

steels to consumers. The close

cooperation with first-class steel service

centers also makes it possible to offer

components which are prefabricated by

means of cutting, cold forming or welding.

In this way ThyssenKrupp Steel Europe

meets the steadily growing demands of its

customers for quality, service and delivery

performance.

The ThyssenKrupp Steel Europe

world of special structural steels on CD

Optimized processing and application of

N-A-XTRA

and XABO

steels requires close

contact between supplier and customer.

A comprehensive technical customer service

has therefore been established to provide

support in all material processing and design

questions. A multilingual compact disc

containing information about our special

structural steels, including data sheets,

processing recommendations and ProWeld,

General note

All statements as to the prop erties or

utilization of the materials and products

men tioned in this brochure are for the

purpose of description only. Guarantees in

respect of the existence of certain proper-

ties or utilization of the material mentioned

are only valid if agreed upon in writing.

Subject to technical changes without notice.

Reprints, even extracts, only with permission

of ThyssenKrupp Steel Europe AG,

Heavy Plate Unit.

Images made available with the kind

support of the following companies:

Fahrzeugwerk Bernard Krone GmbH,

Gronemeyer & Banck GmbH & Co. KG,

Liebherr-Werk Ehingen GmbH and

Putzmeister Concrete Pumps GmbH

(amongst others).

a computer software developed by

ThyssenKrupp Steel Europe for calculating

welding parameters, is available free of

charge from ThyssenKrupp Steel Europe.

All the information is naturally also avail-

able in printed brochures. Customers can

see the very latest developments on the

internet homepage only a click away from

ThyssenKrupp Steel Europe.

O

r

d

e

r

N

o

.

1

0

9

7

E

d

i

t

i

o

n

0

9

/

2

0

1

0

Please contact:

Heavy Plate Unit

Sales

Domestic Market Export

Mario Klatt Roland Riesbeck

Telephone +49 (0)203 52-75617 Telephone +49 (0)203 52-75604

Telefax +49 (0)203 52-75653 Telefax +49 (0)203 52-75653

E-mail: mario.klatt@thyssenkrupp.com E-mail: roland.riesbeck@thyssenkrupp.com

Technical Customer Service

Dr. Hans-Jrgen Kaiser

Telephone +49 (0)203 52-75114

Telefax +49 (0)203 52-75654

E-mail: juergen.kaiser@thyssenkrupp.com

The latest information can be found on the internet

www.thyssenkrupp-steel-europe.com/plate

ThyssenKrupp Steel Europe AG

Kaiser-Wilhelm-Strasse 100 47166 Duisburg Germany

Postal address: 47161 Duisburg Germany

Telephone +49 (0)203 52-0 Telefax +49 (0)203 52-25102

www.thyssenkrupp-steel-europe.com info.steel-europe@thyssenkrupp.com

Вам также может понравиться

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Welding Duplex Stainless SteelДокумент44 страницыWelding Duplex Stainless SteelTran Thanh HaoОценок пока нет

- Cold Rolled Steel StripДокумент40 страницCold Rolled Steel StripshelarsanjayОценок пока нет

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopОт EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopРейтинг: 4.5 из 5 звезд4.5/5 (2)

- ASME B16.48-2010 Line BlanksДокумент56 страницASME B16.48-2010 Line Blanksjosel213Оценок пока нет

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingОт EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingРейтинг: 5 из 5 звезд5/5 (1)

- STAINLESS Filler Selector Guide PDFДокумент1 страницаSTAINLESS Filler Selector Guide PDFArul Edwin VijayОценок пока нет

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsДокумент1 страницаTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014Оценок пока нет

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsДокумент1 страницаTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014Оценок пока нет

- Creusabro 4800Документ8 страницCreusabro 4800ravigurajapuОценок пока нет

- Materials Properties Handbook Titanium Alloys CompressДокумент788 страницMaterials Properties Handbook Titanium Alloys CompressJordan PowellОценок пока нет

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОт EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОценок пока нет

- Plastering PDFДокумент6 страницPlastering PDFAlexi MilanОценок пока нет

- Arc Welding of Specific Steels and Cast Irons: Fourth EditionДокумент170 страницArc Welding of Specific Steels and Cast Irons: Fourth EditionJose Luis ChapasОценок пока нет

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicОт EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicОценок пока нет

- Carbon Structural Steel: Standardspecification ForДокумент4 страницыCarbon Structural Steel: Standardspecification ForlinaОценок пока нет

- 2001 Drawworks EuroRig 5 0027 Sub Supplier GB Rev0Документ668 страниц2001 Drawworks EuroRig 5 0027 Sub Supplier GB Rev0Florin Stoica100% (4)

- Plasma Coated Piston RingsДокумент4 страницыPlasma Coated Piston RingsThomas JoseОценок пока нет

- Steels For Oil - Gas - ExplorationДокумент16 страницSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىОценок пока нет

- Concertina CoilДокумент4 страницыConcertina CoilvklsОценок пока нет

- PetroSync - API 571 Damage Mechanism Affecting Fixed Equipment in The Refining Industry 2017Документ9 страницPetroSync - API 571 Damage Mechanism Affecting Fixed Equipment in The Refining Industry 2017Gonzalo TelleríaОценок пока нет

- Sample Leak Testing Report For Ast TankДокумент1 страницаSample Leak Testing Report For Ast TankArimoro Cyril Obuse43% (7)

- DP Test ProcedureДокумент8 страницDP Test ProcedureAjith KumarОценок пока нет

- MITSUBOSHI - Timing BeltДокумент142 страницыMITSUBOSHI - Timing BeltAnonymous jW9BkgbQmE67% (3)

- 2011specific Kobelco BookДокумент169 страниц2011specific Kobelco Bookmas_munir7174Оценок пока нет

- WaterfordДокумент12 страницWaterfordCamilo MorenoОценок пока нет

- TPN8C30 M&E Inspection FormДокумент32 страницыTPN8C30 M&E Inspection FormWunNaОценок пока нет

- Steel Guide To SelectionДокумент7 страницSteel Guide To Selectionsinetron88Оценок пока нет

- 24UTP Railway GBДокумент8 страниц24UTP Railway GBwpsssamsungОценок пока нет

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingОт EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingРейтинг: 1 из 5 звезд1/5 (1)

- Application - Cast Iron RepairДокумент16 страницApplication - Cast Iron RepairAnonymous L0ChmPGОценок пока нет

- Tutorial Chapter 02 - AnswerДокумент8 страницTutorial Chapter 02 - AnswerFateh Hakeem100% (4)

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsОт EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsОценок пока нет

- ISO 10816 - Severidad en Vibracion PDFДокумент2 страницыISO 10816 - Severidad en Vibracion PDFJuan Carlos Bonifacio BricenoОценок пока нет

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОт EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОценок пока нет

- Finite Element Analysis of Heat Flow inДокумент5 страницFinite Element Analysis of Heat Flow inWilly Villa SalsavilcaОценок пока нет

- S690QLДокумент4 страницыS690QLReginaldo Matias NunesОценок пока нет

- Alform-Plate High-Strength Rev3 EnglДокумент12 страницAlform-Plate High-Strength Rev3 EnglTomáš BrtníkОценок пока нет

- Comparing Steel Plate Grades Ebook PDFДокумент5 страницComparing Steel Plate Grades Ebook PDFJayaseelan GОценок пока нет

- GB235 MetalsДокумент12 страницGB235 MetalsAhmet HamamcıoğluОценок пока нет

- Aspac Royalloy enДокумент7 страницAspac Royalloy enNugroho Faris SudrajatОценок пока нет

- Technical Data: ApplicationsДокумент3 страницыTechnical Data: ApplicationssushmaxОценок пока нет

- ThyssenKrupp - XAR PLUSДокумент3 страницыThyssenKrupp - XAR PLUSParametric EngineeringОценок пока нет

- Wear Plate PDFДокумент19 страницWear Plate PDFNorma SalazarОценок пока нет

- Advance StructuresДокумент6 страницAdvance StructuresManju NishaОценок пока нет

- WS Hws Hss Asp CPMДокумент12 страницWS Hws Hss Asp CPMGross Meltiade AlexanderОценок пока нет

- PB Alumec EnglishДокумент12 страницPB Alumec EnglishByron RodriguezОценок пока нет

- Raex 500Документ4 страницыRaex 500chara459254Оценок пока нет

- XAR 400 (WB 703) EnglischДокумент3 страницыXAR 400 (WB 703) Englischgheoda8926Оценок пока нет

- 421 - Domex 700 MCДокумент2 страницы421 - Domex 700 MClalamed21Оценок пока нет

- Aws Weldingmarketplace 201401 PDFДокумент16 страницAws Weldingmarketplace 201401 PDFSivalingam SubashОценок пока нет

- Essar Steel Galvanised BrochureДокумент9 страницEssar Steel Galvanised BrochureSukanya Sen DuttaОценок пока нет

- HX900 Brochure LowresДокумент8 страницHX900 Brochure LowresMathew VargheseОценок пока нет

- Roll-Bonded Clad Plates: Our Cost-Efficient Answer To CorrosionДокумент40 страницRoll-Bonded Clad Plates: Our Cost-Efficient Answer To CorrosionRoyster CabralОценок пока нет

- Strenx 700 PDFДокумент3 страницыStrenx 700 PDFMarcelo Losekann0% (1)

- Plates PDFДокумент10 страницPlates PDFkarthiksaadhanaОценок пока нет

- LR Tata Steel Plates BrochureДокумент8 страницLR Tata Steel Plates BrochureAGОценок пока нет

- Steel Products Today: (Https://steelknowledge - Ca/)Документ3 страницыSteel Products Today: (Https://steelknowledge - Ca/)Samia H. BhuiyanОценок пока нет

- HighPerformance Steel (ForBridgeConstrunction) enДокумент38 страницHighPerformance Steel (ForBridgeConstrunction) enDavid CrownОценок пока нет

- ThyssenKrupp - PASДокумент3 страницыThyssenKrupp - PASWalter AcostaОценок пока нет

- Recom. de Soldadura XARДокумент4 страницыRecom. de Soldadura XARelias667Оценок пока нет

- Forging Parts Catalog EngДокумент22 страницыForging Parts Catalog EngCeausu Razvan DanutОценок пока нет

- 173 Armox 440t Uk Data SheetДокумент2 страницы173 Armox 440t Uk Data SheetErnestoОценок пока нет

- P 1554452Документ4 страницыP 1554452GusmoОценок пока нет

- "RBT" Steel Billet Connecting RodsДокумент6 страниц"RBT" Steel Billet Connecting Rodscrower_scribdОценок пока нет

- Alform 700 MCДокумент9 страницAlform 700 MCCarlos Nombela PalaciosОценок пока нет

- 9ni Cryogenic Materials PDFДокумент5 страниц9ni Cryogenic Materials PDFyogie4061100% (1)

- Designing With Ductile IronДокумент4 страницыDesigning With Ductile IronCarlos LaoОценок пока нет

- Aluminium Alloy - Commercial Alloy - 6063 - T6 ExtrusionsДокумент4 страницыAluminium Alloy - Commercial Alloy - 6063 - T6 ExtrusionsOgulcan CafОценок пока нет

- Stainless Steel ReinforcementДокумент8 страницStainless Steel Reinforcementsattar12345Оценок пока нет

- 09-Hardox Tool Recommendations For Hardox Wear PlateДокумент4 страницы09-Hardox Tool Recommendations For Hardox Wear PlateAnonymous c8uPXQW7Оценок пока нет

- Guide To Selection: Hot Rolled Carbon Steel BarsДокумент4 страницыGuide To Selection: Hot Rolled Carbon Steel BarsJess OrtonОценок пока нет

- Aluminum Tooling Study-Aluminum Mold PlateДокумент20 страницAluminum Tooling Study-Aluminum Mold PlatemauricefjohnsonОценок пока нет

- Ruukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCДокумент9 страницRuukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCM R PatraputraОценок пока нет

- 113 14Документ8 страниц113 14rahul srivastavaОценок пока нет

- Offshore Plates SteelДокумент3 страницыOffshore Plates SteelmarinaksmgmailcomОценок пока нет

- TurningДокумент64 страницыTurningSerhat DoğandemirОценок пока нет

- Summary ISO TR 15608 Metallic Materials Grouping SystemДокумент3 страницыSummary ISO TR 15608 Metallic Materials Grouping SystemharikrishnanОценок пока нет

- P Number Soldadores (Welder)Документ1 страницаP Number Soldadores (Welder)josel213Оценок пока нет

- Nominal Pipe Size Dimensions by Schedule: AlaskanДокумент1 страницаNominal Pipe Size Dimensions by Schedule: Alaskanjosel213Оценок пока нет

- F Number ER70S 6Документ1 страницаF Number ER70S 6josel213Оценок пока нет

- Concept Shot BlastingДокумент16 страницConcept Shot Blastingjosel213Оценок пока нет

- Welding StainlessSteel LincolnДокумент40 страницWelding StainlessSteel Lincolnjosel213Оценок пока нет

- F Number ER70S 6Документ1 страницаF Number ER70S 6josel213Оценок пока нет

- 1169 2014-BOK Rev-071014Документ9 страниц1169 2014-BOK Rev-071014Siva KumarОценок пока нет

- Al Flhakj Halhfakg Lkahf LKJHG Agas GaДокумент1 страницаAl Flhakj Halhfakg Lkahf LKJHG Agas Gaabidaliabid1Оценок пока нет

- Test TensileДокумент31 страницаTest Tensilejosel213Оценок пока нет

- Test TensileДокумент31 страницаTest Tensilejosel213Оценок пока нет

- A572 15056-1Документ1 страницаA572 15056-1josel213Оценок пока нет

- A36 23793-1 PDFДокумент1 страницаA36 23793-1 PDFjosel213Оценок пока нет

- A36 23793-1 PDFДокумент1 страницаA36 23793-1 PDFjosel213Оценок пока нет

- b31.4 Contenido PDFДокумент6 страницb31.4 Contenido PDFEliezerlunaОценок пока нет

- M1 121 221 2011Документ1 страницаM1 121 221 2011josel213Оценок пока нет

- XAR 400 (WB 703) EnglischДокумент3 страницыXAR 400 (WB 703) Englischgheoda8926Оценок пока нет

- Usg Gypsum Board Arc Spec en 09260 092116Документ27 страницUsg Gypsum Board Arc Spec en 09260 092116mariutza_luciaОценок пока нет

- CountryProfile ProductMetadataforSectorДокумент232 страницыCountryProfile ProductMetadataforSectorMeenakshi JaikrishnanОценок пока нет

- ExerciseДокумент4 страницыExerciseariefnur19Оценок пока нет

- Danfoss DML Filter DriersДокумент16 страницDanfoss DML Filter DrierswidhiantoОценок пока нет

- Residual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamageДокумент69 страницResidual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamagemilindshettiОценок пока нет

- Schaeffler Kolloquium 2014 02 enДокумент9 страницSchaeffler Kolloquium 2014 02 enNazif MisnanОценок пока нет

- t5 BrochureДокумент8 страницt5 Brochureesteve.griОценок пока нет

- BD80 Instructions PDFДокумент24 страницыBD80 Instructions PDFPipe CastilloОценок пока нет

- Compostable PackagingДокумент2 страницыCompostable PackagingLAVANYA KOTHAОценок пока нет

- Miniature Lamp GuideДокумент3 страницыMiniature Lamp GuideKAZIMALI25Оценок пока нет

- Windsor Steampac WT Boiler Brochure 2019Документ2 страницыWindsor Steampac WT Boiler Brochure 2019AnthonyОценок пока нет

- ParthsarthiДокумент423 страницыParthsarthiMahatab HasanОценок пока нет

- Materials Notes Sem 2Документ161 страницаMaterials Notes Sem 2rishigoel284Оценок пока нет

- Cleasby Conveyors MaintenanceДокумент2 страницыCleasby Conveyors MaintenanceRino AdityaОценок пока нет

- Exercise 4.3Документ3 страницыExercise 4.3Anonymous w7ujq3cH2FОценок пока нет

- New Text DocumentДокумент6 страницNew Text DocumentsadsdОценок пока нет

- Sheet Metal Forming PDFДокумент8 страницSheet Metal Forming PDFAlpha WolfОценок пока нет

- C Compact EUROMOLDДокумент40 страницC Compact EUROMOLDWalter CahuanaОценок пока нет

- Valves and Fittings AssДокумент45 страницValves and Fittings AssGkou DojkuОценок пока нет