Академический Документы

Профессиональный Документы

Культура Документы

Process Costing

Загружено:

pablopaul56Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Process Costing

Загружено:

pablopaul56Авторское право:

Доступные форматы

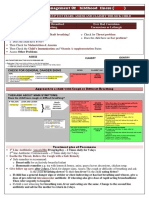

4. Process Costing.

doc

UNIVERSITY OF THE CORDILLERAS

College of Accountancy

Accounting 24c MAS

___________________________________________________________________

Process Costng

Prepared by: Siegfried M. Erorita, cpa, mba c!"#

___________________________________________________________________

Re$e% O&'ect$es

1. Record the flow of materials, labor, and overhead through a process costing

system.

2. Compute the equivalent units of production using the weighted-average

method.

. !repare a quantity schedule using the weighted-average method.

". Compute the costs per equivalent unit using the weighted-average method.

#. !repare a cost reconciliation using the weighted-average method.

$. Compute the equivalent units of production using the %&%' method.

(. !repare a quantity schedule using the %&%' method.

). Compute the costs per equivalent unit using the %&%' method.

*. !repare a cost reconciliation using the %&%' method.

To(c Su))ary

A* +o&,Or-er Costng $s* Process Costng* !rocess costing is used in industries

that produce homogenous products such as bric+s, flour, and cement on a

continuous basis.

.* S)lartes &et%een 'o&,or-er an- (rocess costng* ,ob-order and

process costing systems share some characteristics-

a. .oth systems have the same basic purpose/to assign material, labor, and

overhead cost to products.

b. .oth systems use the same basic manufacturing accounts- 0anufacturing

'verhead, Raw 0aterials, 1or+ &n !rocess, and %inished 2oods.

c. 3he flow of costs through the manufacturing accounts is basically the same.

/* Dfferences &et%een 'o&,or-er an- (rocess costng* 3he differences

between 4ob-order and process costing occur because the flow of units in a

process costing system is more or less continuous and the units are essentially

indistinguishable from one another. 5nder process costing-

a. 6 single homogenous product is produced on a continuous basis over a long

period of time. 3his differs from 4ob-order costing in which many different

products may be produced in a single period.

b. Costs in process costing are accumulated by department, rather than by

individual 4ob.

c. 3he department production report is the +ey document in process costing,

showing the accumulation and disposition of cost. &n 4ob-order costing, the

4ob-cost sheet is the +ey document.

0* O$er$e% of Process Costng* 0anufacturing costs are accumulated in

processing departments in a process costing system. 6 processing department is

any location in the organi7ation where wor+ is performed on a product and where

materials, labor, and overhead costs are added to the product. !rocessing

departments should also have two other features. %irst, the activity performed in

the processing department should be essentially the same for all units that pass

through the department. 8econd, the output of the department should be

7iggy9crac+attac+:treme.com;6cctg2"c;mas;yahoogroups;html;<*211*()

1

4. Process Costing.doc

homogeneous. &n process costing, the average cost of processing units for a period

is assigned to each unit passing through the department.

3wo process costing methods are illustrated in the te=t/the weighted-average

method and the %&%' method. 1hile the %&%' method provides more current cost

data for decision-ma+ing and performance evaluation purposes, it is more difficult

for students to grasp. %or that reason, the %&%' method is covered in an appendi=.

C* E1u$alent Unts of Pro-uct* &n order to calculate the average cost per unit,

the total number of units must be determined. !artially completed units pose a

difficulty that is overcome using the concept of equivalent units. >quivalent units are

the equivalent, in terms of completed units, of partially completed units. 3he

formula for computing equivalent units is-

Number of

Equivalent Percentage

partially completed

units completion

units

=

>quivalent units are the number of complete, whole units one could obtain from the

materials and effort contained in partially completed units.

5nder the weighted-average method, the equivalent units for a particular cost

category ?e.g., materials or conversion cost@ is computed by adding together the

number of units completed and transferred out to the ne=t department during the

period and the equivalent units in the ending wor+ in process inventory in the

department.

Units transferred to Equivalent Equivalent units

units of the next department in ending work in

or to finished goods process inventory production

= +

D* Pro-ucton Re(ort* 3he purpose of a production report is to summari7e all of

the activity that ta+es place in a departmentAs wor+ in process account for a period.

6 production report consists of three parts-

B 6 quantity schedule and a computation of equivalent units.

B 6 computation of costs per equivalent unit.

B 6 reconciliation of all cost flows into and out of the department during the

period.

E* Pro-ucton Re(ort2 3eg4te-,A$erage 5et4o-* >mphasi7e that the

weighted-average method does not attempt to separate units in the beginning

inventory from units started during the current period. Costs and units from

beginning inventory are blended together with costs and units from the current

period.

.* 6uantty Sc4e-ule an- E1u$alent Unts* 3he first step in preparing a

production report is to prepare a quantity schedule, which shows the physical

flow of units through the department. 3his schedule allows managers to see at

glance how many units moved through the department during the period. 5sing

the quantity schedule, the equivalent units can be easily computed.

/* Costs (er E1u$alent Unt* 3he second step in preparing a production report

is to calculate the costs per equivalent unit. 3he cost per equivalent unit is

computed for a particular cost category ?i.e., materials, labor, overhead, or

conversion@ by dividing its total cost by its total equivalent units. Cote that

under the weighted-average method the costs include both the costs already in

beginning inventory as well as the costs added by the department during the

current period.

7* Cost Reconclaton* 3he third step in preparing a production report is to

prepare a cost reconciliation. 3he purpose of a cost reconciliation is to show

how the costs from beginning wor+ in process inventory and costs that have

been added during the period are accounted for.

7iggy9crac+attac+:treme.com;6cctg2"c;mas;yahoogroups;html;<*211*()

2

4. Process Costing.doc

a. Costs come into the department from units in beginning inventory, from

material, labor, and overhead costs that are added during the period, and

from any units that might have been transferred in from a prior

department.

b. 6 departmentAs costs are accounted for by showing the costs that are

transferred out to the ne=t department ?or to finished goods@ and by

specifying the costs that remain in the ending wor+ in process inventory.

F* O(eraton Costng* 3he costing systems discussed in Chapters and "

represent the two ends of a continuum. 'n one end is 4ob-order costing and on the

other is process costing. .etween the two e=tremes, there are many DhybridE

systems. 'peration costing is an e=ample of such a hybrid system. &t is used in

situations where products have some common as well as individual characteristics.

3Fs, for e=ample, have some common characteristics in that all models must be

assembled and tested following the same basic steps. Gowever, each model has

different components with different costs. 3he costs of the components ?materials@

would be charged to a batch of a particular model individually, as in 4ob-order

costing, but the conversion costs may be assigned using process costing.

8* FIFO 5et4o-* 3he %&%' method segregates the units and costs in the

beginning inventory from the units and costs of the current period.

.* 6uantty Sc4e-ule* 3he quantity schedule prepared under the %&%' method is

identical to that prepared under the weighted-average method, e=cept that the

Dunits transferred outE are separated into those units that came from beginning

inventory and those units that were started and completed this period.

/* E1u$alent Unts* 3he %&%' method differs from the weighted-average method

for computation of equivalent units in two ways.

a. %irst, under the %&%' method the Dunits transferred outE figure is split

between units completed from the beginning inventory and units started

and completed during the current period.

b. 8econd, the equivalent units refers to 4ust the equivalent units for the wor+

performed during the current period. 3he equivalent units under the %&%'

method consist of three amounts- the wor+ needed to complete the units in

the beginning inventoryH the wor+ e=pended on the units started and

completed during the current periodH and the wor+ e=pended on partially

completed units in the ending inventory.

c. 3his method is called the %&%' method because it assumes that the units in

beginning inventory are completed and transferred out before any new units

are started. 3he costs of beginning inventory are segregated from costs

added during the period.

d. 3he only difference in the equivalent unit calculations between the two

methods is that the equivalent units in beginning inventory are included in

the weighted-average method. 5nder the weighted-average method the

costs already in beginning inventory will be added to the costs incurred

during the period to arrive at unit costs. 3o be consistent we must add the

equivalent units already in beginning inventory to the equivalent units for

the wor+ performed during the current period.

7* Costs (er E1u$alent Unt* &n computing costs per equivalent unit, costs

associated with the beginning wor+ in process inventory are ignored. &t is

assumed that the units in beginning inventory are completed and transferred to

the ne=t department before any new units are wor+ed on. !roviding that more

units are transferred out than were in beginning inventory, all of the costs

associated with beginning inventory will be transferred to the ne=t department.

9* Cost Reconclaton* 6s with the weighted-average method, the purpose of a

cost reconciliation is to show how the costs have been charged to a department

during a period and to show how these costs are accounted for.

7iggy9crac+attac+:treme.com;6cctg2"c;mas;yahoogroups;html;<*211*()

4. Process Costing.doc

a. 3he DCosts to be accounted forE section of the report is the same as for the

weighted-average method.

b. 3he DCost accounted forE section differs from the weighted-average method

in that four layers of cost are involved. 3hese layers are ?1@ the cost in the

beginning inventory, ?2@ the cost required to complete the units in the

beginning inventory, ?@ the cost of units started and completed during the

current period, and ?"@ the cost of the ending wor+ in process inventory.

H* E$aluaton of 3eg4te-,A$erage an- FIFO * 3he weighted-average method

is simpler to learn and apply than the %&%' method, but the %&%' method is

generally considered to be superior for cost control. 3he reason is that the %&%'

method helps to isolate current performance by segregating current costs from prior

period costs. 3he weighted-average method mi=es the costs of the current period

with the costs of prior periods.

7iggy9crac+attac+:treme.com;6cctg2"c;mas;yahoogroups;html;<*211*()

!

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Bomber JacketДокумент3 страницыBomber JacketLaura Carrascosa FusterОценок пока нет

- Pitman SolutionДокумент190 страницPitman SolutionBon Siranart50% (2)

- 114 The Letter S: M 'TafontДокумент9 страниц114 The Letter S: M 'TafontHarry TLОценок пока нет

- Pertanyaan TK PDBДокумент4 страницыPertanyaan TK PDBHardenОценок пока нет

- 3rd Stage ComplicationsДокумент84 страницы3rd Stage ComplicationsDream100% (1)

- ADC ManualДокумент47 страницADC ManualRavi ShuklaОценок пока нет

- Presentation 1Документ7 страницPresentation 1Abdillah StrhanОценок пока нет

- MAP V6.3: Reference ManualДокумент106 страницMAP V6.3: Reference ManualGkou DojkuОценок пока нет

- Practical 3.1 Determining The Specific Heat CapacityДокумент3 страницыPractical 3.1 Determining The Specific Heat CapacityiAlex11Оценок пока нет

- Penetration Test & Softening PointДокумент7 страницPenetration Test & Softening PointAli M. Chehadeh100% (4)

- BCSL 058 Previous Year Question Papers by IgnouassignmentguruДокумент45 страницBCSL 058 Previous Year Question Papers by IgnouassignmentguruSHIKHA JAINОценок пока нет

- Section 08630 Metal-Framed SkylightДокумент4 страницыSection 08630 Metal-Framed SkylightMØhãmmed ØwięsОценок пока нет

- DEAD STARS by Paz Marquez BenitezДокумент17 страницDEAD STARS by Paz Marquez BenitezArmiethazen Khea Page PalarcaОценок пока нет

- PANCREATITISДокумент38 страницPANCREATITISVEDHIKAVIJAYANОценок пока нет

- Inverse Curve Trip Time Calculation: Enter Values in White CellДокумент3 страницыInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxОценок пока нет

- IMCI UpdatedДокумент5 страницIMCI UpdatedMalak RagehОценок пока нет

- Osce05ans 110918053819 Phpapp01Документ20 страницOsce05ans 110918053819 Phpapp01masood alamОценок пока нет

- Annie Ovenden Exibition 2017Документ19 страницAnnie Ovenden Exibition 2017Vitaliy ChuenkoОценок пока нет

- Campa Cola - WikipediaДокумент10 страницCampa Cola - WikipediaPradeep KumarОценок пока нет

- Boyle's Law 2023Документ6 страницBoyle's Law 2023Justin HuynhОценок пока нет

- Chapter 9 Material ChangesДокумент6 страницChapter 9 Material ChangesFitria Istikomah DewiОценок пока нет

- Battery Installation ProcedureДокумент5 страницBattery Installation ProceduresantoshkumarОценок пока нет

- Ae 2 PerformanceДокумент4 страницыAe 2 PerformanceankitОценок пока нет

- HACH LANGE Amino Acid F Reagent Powder (2353255)Документ6 страницHACH LANGE Amino Acid F Reagent Powder (2353255)kerem__22Оценок пока нет

- Bsi MD Ivdr Conformity Assessment Routes Booklet Uk enДокумент15 страницBsi MD Ivdr Conformity Assessment Routes Booklet Uk enGuillaumeОценок пока нет

- Spina 2002Документ10 страницSpina 2002hasantapОценок пока нет

- Types of WinesДокумент91 страницаTypes of Winesrajanrld19880% (1)

- Nitofloor NДокумент3 страницыNitofloor Nkiranmisale7Оценок пока нет

- 2019 - High Levels of Polypharmacy in RheumatoidДокумент7 страниц2019 - High Levels of Polypharmacy in RheumatoidGustavo ResendeОценок пока нет