Академический Документы

Профессиональный Документы

Культура Документы

PDF 630

Загружено:

memo_gh89Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PDF 630

Загружено:

memo_gh89Авторское право:

Доступные форматы

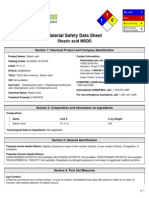

Determining an Efficient Solvent Extraction Parameters for Re-Refining of Waste Lubricating Oils

HASSAN ALI DURRANI,* MUHAMMED IBRAHIM PANHWAR*, AND RAFIQUE AKTHAR KAZI** RECEIVED ON 16.03.2011ACCEPTED ON 15.03.2012

ABSTRACT

Re-refining of vehicle waste lubricating oil by solvent extraction is one of the efficient and cheapest methods. Three extracting solvents MEK ((Methyl-Ethyl-Ketone), 1-butanol, 2-propanol were determined experimentally for their performance based on the parameters i.e. solvent type, solvent oil ratio and extraction temperature. From the experimental results it was observed the MEK performance was highest based on the lowest oil percent losses and highest sludge removal. Further, when temperature of extraction increased the oil losses percent also decreased. This is due to the solvent ability that dissolves the base oil in waste lubricating oil and determines the best SOR (Solvent Oil Ratio) and extraction temperatures. Key Words: Waste Lubricating Oil Recycling, Solvent Extraction Parameters.

1.

INTRODUCTION

equal to impurities and addictiveness in the waste lubricating oil [11]. Fig. 1 shows schematic diagram solvent extraction experimental setups for re-refining of waste lubricating oil. The designing step is more difficult for development of suitable solvent extraction technique consists of solvent(s) type, extraction factors (SOR, pressure, temperature, etc). This process has capability of removing sludge particles from waste lubricating oil in maximum capacity and losing base oil amount minimum in sludge phase. For an optimum extraction, many processes have been demonstrated for hydrocarbons as solvents, ketones and alcohols [12]. Theses methods were used for solvent performance for optimization extraction that depend on solvent ability to remove sludge from waste lubricating oil and use physical properties, experimental data (polymer in waste lubricating oil additives and solubility of solvent) as indicator. Solvent's solubility

n re-refining waste lubricating oils, different methods have been used. In recent years the solvent extraction processes have been proposed as an alternative process being a simple process [1-6]. The usual acid-clay treatment successfully generates poisonous acidic sludge [7-8]; the solvent extraction replaces the common acidclay treatment successfully [9-10]. In this process solvent has to mix with waste lubricant oil in proper proportion and fully miscible with the base oil and reject impurities (carbonaceous and additives) generally found in waste oils that flocculates and settled down due to gravity action, then recover the used solvent for recycle purpose during distillation. Among the alternative processes, solvent extraction re-refining remained efficient way for separating sludge particles from waste oil received considerable attention. It also reduces base oil losses from sludge phase around 10-14% quantity approximately that is more or less

* **

Professor, Department of Mechanical Engineering, Mehran University of Engineering & Technology, Jamshoro. Professor, Institute of Petroleum & Natural Gas Engineering, Mehran University of Engineering & Technology, Jamshoro. Mehran University Research Journal of Engineering & Technology, Volume 31, No. 2, April, 2012 [ISSN 0254-7821] 265

Determining an Efficient Solvent Extraction Parameters for Re-Refining of Waste Lubricating Oils

parameters difference depend on the sludge removal in percent from waste lubricating oil and the polymer found normally in waste oils additives, Concluded that as difference in the solubility parameters increase, the solvent capability increases to remove the impurities and additives from the waste lubricating oil [13]. In the experimental work effective parameters of solvent extraction has been studied i.e. solvent type, solvent to oil ratio and temperature of extraction, based on the experimental results of oil losses and sludge removal aim to know about different in solubility among oil and solvent that decreases in the light of well-known hypothesis of Elias that oil decreases due to increases in miscibility of solvent in oil, as a result oil losses decreases experimentally determined at various extraction conditions [14].

areas from Hyderabad and Karachi, mixed in a container to represent a mix feed stock to a re-refinery plant for recycling, it was kept in a closed drum to homogenize before to any testing. Used oil 30gm (Woil) mixed with the commercial grade solvent (Wsol) of commercial grade solvents, MEK, 1-Butanol, 2- Propanol at a specified ratios in conical flask to evaluate the extraction performance at extraction temperatures, 20, 30 and 50oC. The sample was stirred at 275-300 rpm for 30 min in the flask with no oil losses and ensured sufficient mixing. The temperature of bath was maintained and for gravity settlement it was left for 24 hours where in the bottom of the flask, sludge particles in black color were clearly observed and from the experiment work, following parameters were studied.

2.1 2. EXPERIMENTAL WORK

Percent Sludge Removal

A laboratory scale (glassware) setup was made in the Petroleum Refinery Laboratory, Institute of Petroleum & Natural Gas Engineering, MUET (Mehran University of Engineering & Technology), Jamshoro, Pakistan as shown in Fig. 1. The waste oil samples of different crankcase lubricating oil from internal combustion engines were collected from service stations and garages of different

The PSR (Percent Sludge Removal) indicates the weight of dry sludge (Wdry) in gram/kilogram separated from the wet sludge washed with n-hexane and 2-propanol as suggested by [15]. This process was used to remove oil content in the wet sludge expected about 95%. It was soaked in an oven at 100oC for 10 min just to evaporate excess solvent then it was reported as dry sludge (Wdry) and the PSR was calculated in Equation (1):

FIG. 1. FLOW DIAGRAM OF WASTE OIL RE-REFINING PROCESS BY SOLVENT EXTRACTION Mehran University Research Journal of Engineering & Technology, Volume 31, No. 2, April, 2012 [ISSN 0254-7821] 266

Determining an Efficient Solvent Extraction Parameters for Re-Refining of Waste Lubricating Oils

F Wdry I 100% PSR = G H woil JK

2.2 Percentage Oil Loss

(1)

POL (Percentage Oil Loss) is defined as the loss of oil to the sludge during SEP process, in mass. Thus, POL was calculated by Equation (2):

F Wwet Wdry I POL = G GH Woil JJK 100%

3. RESULTS AND DISCUSSION

This sector shows the optimum SOL (Solvent Oil Loss) at specified extraction temperature where to get the oil losses minimum in the sludge, the curve shows a retreating effect in the POL instead of further increase in the SOR. This is because of the fact that increasing SOR, oil losses in sludge phase getting reduction and for the other solvents at different extraction temperature, the same trends were found. The curves shown in the Figs. 2-3 for percent oil losses of 1- butanol - oil system, that the oil losses decreases as the extraction temperature increases, so for (SOR) 3:1 at temperature 20oC the maximum oil losses found 12%, at temperature 30oC was 10.8% weight and at temperature 50oC was observed 10.5% and similar trend found at higher temperature. The effect of SOR on the PSR (Percent Sludge Removals) for same solvent at temperature 20, 30, and 50oC is shown in Fig. 4. The rapid sludge removal percent weight found at waste oil ratio (1:1-2:1) and then gradually increasing the sludge removal percent was 15.5 using waste oil ratios (6:1).

(2)

The performance of commercial grade hydrocarbon solvents, i.e. 1-Butanol, 2-Propanol, and MEK were investigated, determining the best solvent: oil ratio and temperature of extraction based on the solvents capability to dissolve base oil in waste oil. Figs. 2-3 show the result of solvent: oil ratio on the oil losses percent and sludge removal for solvent 1butanol at extraction temperatures of 20, 30 and 50oC. It was observed that at extraction temperature 20 o C solvent: oil ratio increases but POL decreased and quick drop in POL amount was found at SOR (1.1 -1. 8) i.e. lower ratio and at SOR (2.0-2.6) oil losses POL found decreases.

FIG. 3. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF OIL LOSSES FOR 1-BUTANOL AT 20,30 AND 50OC

FIG. 2. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF OIL LOSSES FOR 1-BUTANOL AT 20OC

FIG. 4. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF SLUDGE REMOVAL FOR 1-BUTANOL AT 20,30 AND 50OC

Mehran University Research Journal of Engineering & Technology, Volume 31, No. 2, April, 2012 [ISSN 0254-7821] 267

Determining an Efficient Solvent Extraction Parameters for Re-Refining of Waste Lubricating Oils

The oil losses curve for the 2-propanol solvents at temperature 20, 30 and 50oC is shown in Fig. 5. It was observed that due to the effect of SOR, POL was found as decreasing because of decreasing extraction temperature, the maximum oil losses found 11.3 with SOR 4:1 gave almost similar trends for PSR shown in Fig. 6. These results are in close agreement with the PSR result reported by [8].This optimum value does not necessary correspond to maximum PSR because an increase of the SOR beyond the optimum point can still lead to an increase in percent sludge removal and minimum oil losses. Nimir, et. al. [16] have also worked on the solvent 2-propanol and concluded that an increase in the SOR leads to an increase of PSR but a decrease in POL. MEK offers the lowest POL and sludge removal shown in Figs. 7-8, when compare to solvents 1-butanol and 2-propanol as shown in Figs. 9-11. As per Elias hypothesis [12], a solvent having

solubility difference minimum from that of oil will have higher miscibility in oil hence lower oil losses percent and among the above solvents the lowest solubility difference i.e. (4(J/cm3)1/2) has been found in MEK then by 1-butanol (6(J/cm3)1/2) and 2-propanol (7(J/cm3)1/2) Elbashir, et. al. [17] and Mutalib, et. al. [18] reported the measuring method for solubility parameters at different extraction temperature.

FIG. 7. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF OIL LOSSES FOR MEK AT 20, 30 AND 50OC

FIG. 5. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF OIL LOSSES FOR 2-PROPANOLAT 20, 30 AND 50OC

FIG. 8. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF SLUDGE REMOVAL FOR MEK AT 20, 30 AND 50OC

FIG. 6. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF SLUDGE REMOVAL FOR 2-PROPANOLAT 20, 30 AND 50OC

FIG. 9. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF OIL LOSSES FOR 1-BUTANOL, 2-PROPANOL AND MEK AT 20OC

Mehran University Research Journal of Engineering & Technology, Volume 31, No. 2, April, 2012 [ISSN 0254-7821] 268

Determining an Efficient Solvent Extraction Parameters for Re-Refining of Waste Lubricating Oils

Pakistan, for granting permission to carry out an experimental work in Petroleum Refinery Laboratory of the Institute.

REFERENCES

[1] El-Din, O.I.S., Hassan, S.I., Taman, A.R., Farog, A.S., "Recovery of Waste Lubricating Oil by Solvent Extraction", Hungarian Journal of Industrial Chemical No. 15, pp. 357-364, 1987. FIG. 10. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THE PERCENT OF OIL LOSSES FOR 1-BUTANOL, 2-PROPANOL AND MEK AT 30 OC [2] Reis, M.A., Jeronimo, M.S., "Waste Lubricating Oil ReRefining by Solvent Extraction Flocculation", A Scientific Basis to Design Efficient Solvents, Industrial Engineering. Chemical Research, Volume 27, pp. 1222-1228, 1988. [3] Saunders, J., "Used Oil Refining Revolution?", Lubricants World, pp. 20-24., 1996. [4] Chementator, "Solvent Extraction Process Recycles Waste Oil", Chemical Engineering, Volume 103, pp. 8-19, 1996. [5] FIG. 11. EFFECT OF SOLVENT: OIL RATIO ON THE EXTRACTION MEASURED BY THEM PERCENT OF OIL LOSSES FOR 1-BUTANOL, 2-PROPANOL AND MEK AT 50OC [6] Lai, H.H., "Minimization of Waste Oil in Oily Sludge by Solvent Extraction", M.Sc Dissertation, Lamar University, 1989. Dang, G.S., "Rerefining of Used Oils: A Review of Commercial Process", Journal of Wiley Inter Science, Volume 3, No. 4, pp. 445-447, March, 2006.

4.

CONCLUSIONS

The main objective of the study was to determine the efficient solvent extraction parameters i.e. SOR and extraction temperature based on the experimental results (i.e. SRP and POL). The principle investigation shows that the solvent Methyl-Ethyl- Keton gave the best results from that of oil. This research work is the guidance that before to carry out any extensive experimental work, initial determination of the best extraction conditions for particular solvent can be used.

[8] Siddiquee, R.M.M., Samdani, T.A., and Kabir, K.B., "Effect of Operating Variables on Regeneration of Base Oil from Waste Oil by Conventional Acid-Clay Method", Chemical Engineering Research Bulletin, Volume 12, pp. 24-27, 2008. [9] Elbashir, N.O., Al-Zahrani, S.M., Abdul Mutalib, M.I., and Adnan, "Recycling of Used Lubricating Oil by Solvent Extraction", A Guideline for Single Solvent Design, Proceedings of RSCE97, Volume 1, pp. 420-427, Johar, Malaysia, 1997. [7] Khelifi, O., Giovnna, F.D., Vranes, S., Lodolo, A., and Miertus, S., "Decision Support Tool for Oil Re-Generation Technologies Assesment and Selection", Journal of Hazardous Materials, Volume 137, pp. 437-442, 2006.

ACKNOWLEDGEMENTS

I the author (First Author) would like to thank to the Institute of Petroleum & Natural Gas Engineering, Mehran University of Engineering &Technology, Jamshoro,

Mehran University Research Journal of Engineering & Technology, Volume 31, No. 2, April, 2012 [ISSN 0254-7821] 269

Determining an Efficient Solvent Extraction Parameters for Re-Refining of Waste Lubricating Oils [10] Rincon, J., Canizares, P., and Maria, T.G., "Regeneration of Used Lubricant Oil by Ethane Extraction", Journal of Super Critical Fluids, Volume 39, pp. 7854-7859, 2005. [11] Sherman, J.H., "Removal of Transition Metals from Motor Oil Using Ion Exchange Resins", Environmental Technology, Volume 14, No. 11, pp. 1097-1100, 1993. [12] Elbashir, N.O., The Effect of Design Parameters on the Solvent Extraction Performance for Recycling of Used Oil, M.E. Thesis, University of Technology Malaysia, 1998. [13] Reis, M.A., and Jeronimo, M.S., "Waste Lubricating Oil Re-refining by Extraction-Flocculation 2A Method to Formulate Efficient Composite Solvents", Industrial Engineering Chemical Research, Volume 29, [18] [17] Elbashir, N.O., Al-Zahrani, S.M., Abdul Mutalib, M.I., and Abasaeed, A.E., "A Method of Predicting Effective Solvent Extraction Parameters for Recycling of Used Lubricating Oils", Journal of Chemical Engineering and Processing, Volume 41, pp. 765-769, 2002. Abdul Mutalib, M.I., Elbashir, N.O., Sahriff, M., and Adnan, R., "Practical Use of the Solubility Parameters in Determining Effective Solvent Extraction Parameters [14] Elias, H.G., "Macromolecules, Polenum", First Edition, Volume 1, pp. 205-210, New York, 1997. for Recycling Used Lubricating Oil, Proceeding of RSC, pp. 110-117, Manila, Philippines, 1998. [16] [15] Reis, M.A., and Jeronimo, M.S., "Waste Lubricating Oil Re-Refining by Solvent Extraction Flocculation", A Scientific Basis to Design Efficient Solvents, Industrial Engineering Chemical Research, Volume 27,

pp. 1222-1228, 1988. Nimir, O.M., Abdul Mutalib, M.I., and Adnan, R., "Recycling of Used Lubrication Oil by Solvent ExtractionA Guide for Single Solvent Design", Institute of Technology PETRONAS, 31750 Tronoh, Perak, Malaysia, 1997.

pp. 432-436, 1990.

Mehran University Research Journal of Engineering & Technology, Volume 31, No. 2, April, 2012 [ISSN 0254-7821] 270

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- E-COMPANY PROFILE KMR 2020-NewДокумент10 страницE-COMPANY PROFILE KMR 2020-NewLeonardoОценок пока нет

- Cleaning of Equipment For Oxygen ServiceДокумент6 страницCleaning of Equipment For Oxygen ServiceSolada Naksiri100% (1)

- Determination of Sulfur Compound in Natural GasДокумент7 страницDetermination of Sulfur Compound in Natural Gasnimasina100% (1)

- A - General IndexДокумент24 страницыA - General IndexzargeenaОценок пока нет

- Preliminary Study On Optimization of PH, Oxidant and Catalyst Dose For High COD Content: Solar Parabolic Trough CollectorДокумент10 страницPreliminary Study On Optimization of PH, Oxidant and Catalyst Dose For High COD Content: Solar Parabolic Trough Collectormemo_gh89Оценок пока нет

- The Modified Fenton Process For Decolorization of Dye WastewaterДокумент5 страницThe Modified Fenton Process For Decolorization of Dye Wastewatermemo_gh89Оценок пока нет

- Photo-Fenton Treatment of Water Containing Natural Phenolic PollutantsДокумент8 страницPhoto-Fenton Treatment of Water Containing Natural Phenolic Pollutantsmemo_gh89Оценок пока нет

- 12 (629 633) IcgseeДокумент5 страниц12 (629 633) Icgseememo_gh89Оценок пока нет

- Analysis of Lue Oil - Part Two: Ground RulesДокумент6 страницAnalysis of Lue Oil - Part Two: Ground Rulesmemo_gh89Оценок пока нет

- PS 020 PFO Final Feb 2010 1Документ4 страницыPS 020 PFO Final Feb 2010 1memo_gh89Оценок пока нет

- Subject: Chemistry Class: JC Chapter: Periodic Table Teacher: Arbab MazharДокумент8 страницSubject: Chemistry Class: JC Chapter: Periodic Table Teacher: Arbab MazharArbab MazharОценок пока нет

- Lime StabilizationДокумент9 страницLime StabilizationKarthikeyan Rajamanickam0% (1)

- Elements Project - CobaltДокумент7 страницElements Project - CobaltXoom JbОценок пока нет

- Urriculum: A2 Level ChemistryДокумент15 страницUrriculum: A2 Level ChemistrySiddhant DuggalОценок пока нет

- Hair OilДокумент5 страницHair OilSairam KogantiОценок пока нет

- Product and Process Information: As Of: June 2003Документ9 страницProduct and Process Information: As Of: June 2003avinashchauhan2695Оценок пока нет

- Pipeline Colour CodeДокумент25 страницPipeline Colour CodeRahul KadamОценок пока нет

- Stearic Acid MsdsДокумент5 страницStearic Acid Msdsapi-263411629Оценок пока нет

- Production of Perfumes .Документ13 страницProduction of Perfumes .tariq fareedОценок пока нет

- The Engineer's Companion - Fastener Design Manual, Part OneДокумент8 страницThe Engineer's Companion - Fastener Design Manual, Part OneSebastián Castillo MorenoОценок пока нет

- Nozzle Clogging Behavior of Ti-Bearing Al-Killed ULC SteelДокумент8 страницNozzle Clogging Behavior of Ti-Bearing Al-Killed ULC SteelEstéfano Aparecido VieiraОценок пока нет

- Conceptual Improvement of Isomerism Final DPP-372Документ69 страницConceptual Improvement of Isomerism Final DPP-372Himanshu Kejriwal82% (17)

- Composites CommunicationsДокумент6 страницComposites CommunicationsNicolle Paredes ReyesОценок пока нет

- Appendix 1 2017Документ34 страницыAppendix 1 2017Sohrab FarmanОценок пока нет

- Decalcification: Mark Lester B. Cauan, RMTДокумент59 страницDecalcification: Mark Lester B. Cauan, RMTMarissa Cordova100% (2)

- Atoms and MoleculesДокумент17 страницAtoms and MoleculesJai KumarОценок пока нет

- Reviewing The Operation of Gold ElectrowДокумент35 страницReviewing The Operation of Gold ElectrowAnonymous FfIxH2o9100% (1)

- He Ravi 2007Документ4 страницыHe Ravi 2007Vivek ShewaleОценок пока нет

- Preparation of Poly Acrylic Acid - Starch Hydrogel and Cadmium Ion RemovalДокумент8 страницPreparation of Poly Acrylic Acid - Starch Hydrogel and Cadmium Ion RemovalMd. Asifur RahmanОценок пока нет

- Naming Aromatic CompoundsДокумент14 страницNaming Aromatic Compoundssantosmaangelica16100% (1)

- 2423 e 3Документ21 страница2423 e 3Abdel Rahman MohamedОценок пока нет

- MatterДокумент25 страницMatterMarvin De JonggoyОценок пока нет

- 2021 NYJC H2 Chemistry 9729 P4 (QP)Документ20 страниц2021 NYJC H2 Chemistry 9729 P4 (QP)Allison KhooОценок пока нет

- Blabla ChemДокумент5 страницBlabla Chemfatima hahsmiОценок пока нет

- 08 Chapter 12Документ26 страниц08 Chapter 12M Zia DogarОценок пока нет

- Hasan Sayginel: Edexcel A Level Organic ChemistryДокумент41 страницаHasan Sayginel: Edexcel A Level Organic ChemistryDEEBANОценок пока нет