Академический Документы

Профессиональный Документы

Культура Документы

Distribution Generation With Fuzzy

Загружено:

Tariq KhanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Distribution Generation With Fuzzy

Загружено:

Tariq KhanАвторское право:

Доступные форматы

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.

3, July 2012

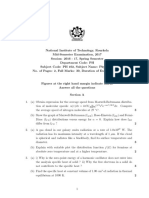

PERFORMANCE OF FUZZY LOGIC BASED MICROTURBINE GENERATION SYSTEM CONNECTED TO GRID/ISLANDED MODE

Sanjeev K Nayak1 and D N Gaonkar2

1&2

Department of Electrical and Electronics Engineering, National Institute of Technology Karnataka, Surathkal Mangalore, INDIA

nayaksanjeev82@gmail.com dngaonkar@gmail.com

ABSTRACT

The microturbine generation (MTG) system are becoming the popular source of distributed generation (DG) due to their fuel flexibility, reliability and power quality. The MTG system is a complicated thermodynamic electromechanical system with high speed of rotation, frequency conversion and its control strategy. In spite of several techniques to control high speed of microturbine is not accurate and reliable due to their anti-interference problem. This paper presents a fuzzy logic controlled MTG system for grid connected and islanded mode of operation. The development of fuzzy logic based speed governor includes input and output membership function with their respective members. The load variation on MTG system is performed using conventional PI controller and fuzzy logic controller are implemented in Matlab/Simulink and their results are compared with each other. The simulation result of MTG system shows the performance improvement of fuzzy logic governor over a conventional governor.

KEYWORDS

Distributed Generation, Microturbine PMSM, Power Converter, and Fuzzy logic.

1. INTRODUCTION

Distributed Generation (DG) is predicted to play an increasing attention in the electric power system of the near future. DG is limited size of generation (25kW to 1MW) and interconnected at the substation, distribution feeders or consumer load levels [1]. The microturbine generation (MTG) system is a typical and practical system of DG source, because of its small scale generation with fuel flexibility, reliability and power quality. It has been applied in various fields, such as peak power saving, co-generation, remote and premium power applications [2]. The MTG system composed of microturbine as a prime mover, permanent magnet synchronous machine (PMSM), power interfacing circuit for frequency conversion between generation and load. A microturbine is thermodynamically complex mechanical system cannot be modelled accurately and it is difficult to control the speed [2]. A microturbine is integrated with PMSM produces high frequency AC power, where the operating speed ranges generally between 50,000 to 120,000 rpm. The power produced at the generator is around 1 k to 2 kHz of frequency, this high frequency AC power is convertedto DC then inverted back to 50 or 60Hz AC power using suitable converter and inverter [3]. The nonlinear controlled methods based on model cannot solve the various control problems on MTG system, some advance control method as have been applied such as incremental fuzzy PI controller, fuzzy PID controller and neural network controllers. Controlled algorithm based on fuzzy logic have been implemented in many processes the application of such control techniques has been motivated by the following reasons, 1) it improves the robustness over a conventional linear control algorithm, 2) Simplified control design for difficult system model 3) Simplified implementation[4]. This paper presents a fuzzy

DOI : 10.5121/ijfls.2012.2304 41

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

logic controlled speed governor and conventional transfer function governor for a microturbine to predict the performance of fuzzy logic controller. The microturbine is used as MTG system once it is compared with nominal controller connected to the grid and isolated mode of DG system. The simulation result shows the performance of fuzzy logic controller for different load on MTG system.

2. MICROTURBINE GENERATION (MTG) SYSTEM

Microturbines are smaller version of heavy duty gas turbines compact in size and components like compressor, heat exchanger, burner and turbine. Basically there are two types of microturbines, classified based on construction and location of its components. One is a high speed single shaft design with compressor and the turbines are mounted on the same shaft usually the PMSM is use to generate the electrical power. Another is split shaft design that uses a power turbine rotating at 3600 rpm and a conventional generator (usually induction generator or synchronous generator) connected via a gearbox [6]. The microturbine system presented in this paper is based on gas turbine model presented by W I Rowen[5] which was successfully adopter as microturbine generation(MTG) system by Huang Wei[6] connected in parallel to the microgrid, and used as DG system by Gaonkar[7] and Guda S R[8] in isolated mode. The turbine model was proposed by W I Rowen[5] is to be adopted as single shaft microturbine with fuzzy logic speed governor implemented in MATLAB/Simulink is shown in Figure.1, and the same is used as prime mover for the MTG with PMSM and power electronics circuit interfacing system shown in Figure.2.

Tempreture controller +

3.3s+1 0.5s

Tr

+ G4 1+sT4

G5 1+sT5

Reference Temp f1(u) Exhaust system

+

Ref Speed(pu) du dt

K1

0.8

f2(u)

e-sT

0.23

Fuel & Combustion

G1 1+sT1 G2 1+sT2

e-sT

+ -

L O W

100 s

K3

K2

Speed Governor 0.01 +

+ Acceleration controller du dt 1 JT

Rotor Inertia

f3(u)

G3 1+sT3

Turbine dynamics +

f4(u)

Rotor Speed

Figure.1. Fuzzy logic controlled microturbine

Ref, Speed

PLL Fuel Fuzzy Logic Valve Speed Controller Burner

L Compressor Turbine Rectifier C Inverter

Rt

Lt

PMSM Load Ambient air

GRID

Exhaust air

Heat exchanger

Figure.2 Fuzzy logic controlled MTG system 42

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

The linear pattern is utilizes as generator model applicable for transient analysis and the model comprises temperature controller, fuel control, turbine dynamics, speed governor and acceleration controller blocks [7]. The speed governor for a microturbine can be divided into droop regulation and non-drop regulation, which is utilized and designed for the purpose of adopting the requirement of different load characteristics. Speed controller is usually modelled using lead-lag transfer function or by PID controller. In this work a fuzzy logic based governor has been used as speed and change in speed are input member ship function, regulated speed as output membership function. The membership function can adjusted so that the governor can act with droop or as isochronous governor [7][8]. The fuel flow is controlled as a function of Vce are shown in a series of blocks including the valve position and flow dynamics, the output of low value selector (represented by Min in MATLAB/Simulink) is the lowest of the three inputs and results in the amount of fuel to the compressor-turbine, and Vce represents the final amount of fuel demand for that particular operating point and is an input to the fuel system [6][8]. The slow dynamics performance of the MTG system is focused here based on the simplified model is built in with an assumption, i.e. MTG system is operating under normal condition by neglecting the fast dynamics of microturbine (start up, shut down, internal faults, sudden loss of power etc). In addition to that the proposed model employees per unit system to represents the microturbine as its control system with expectation of temperature, each important control block is discussed as subsection in[7] [8]. The model presented in this paper is concentrates on slow dynamics of MTG system.

3. FUZZY LOGIC

Fuzzy logic controller is rule based controller where a set of rules represents a control decision mechanism to correct the effect of certain cause used for generation systems. In fuzzy logic, the linguistic variables are expressed by fuzzy sets defined on their respective universe discourse, to overcome the difficulties of soft controlling fuzzy logic found to be effective alternating to conventional control techniques[9]-[10]. The configuration of fuzzy logic based system into four parts they are, Fuzzification, Knowledge Base, Interface Mechanism and Defuzzification. The lead lag transfer function compensator is replaced by the equivalent fuzzy logic based speed governor, the design of PI-like fuzzy knowledge base controller works on the area control error (ACE) and change in area control error (ACE) is considered as input to the fuzzy logic controller. For the automatic generation control problem the input to fuzzy controller for ith area at a particular instant are ACEi(t) and linguistic variables as VHS: Very High Speed, HS: High Speed, NC: No Change, NS: Normal Speed, LS: Low Speed, VLS: Very Low Speed, LN: Large Negative, N: Negative, P: Positive, LP: Large Positive, VL: Very Low, L: Low, Z: Zero, H: High, VH: Very High- respectively. All the variables of ACE, ACE and U are considered in a symmetrical triangular membership function. The membership function of ACE over the operating range of minimum and maximum values of ACE is shown in Figure.3 (a) (b) and (c). The membership function would perform a mapping from the crisp values to a fuzzified value, One such particular crisp input ACE is converted to fuzzified value i.e. 0.8/VHS + 0.2/HS where 0.8 and 0.2 are membership grade membership function.

VHS HS NS LS VLS 1 0.8

1 VL L Z H VH

LN N NC

LP

0.5 0.2 0

0.5

0.5

Figure.3 a) Speed b) Change in speed c) Reg, speed 43

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

Corresponding to the linguistics variables VHS and HS in fuzzy system a membership grades are zero for all other linguistic values except VHS and HS. Here the crisp value input to the system will be converted to fuzzified value considering several membership grades corresponding to each linguistic variable. Same way the other input of ACE and U are fuzzified. The output of the inference mechanism is a fuzzy value, and hence it is necessary to convert the fuzzy value to (crisp) real value sine, the physical process cant deal with fuzzy value s. This operation which is inversely fuzzified is known as defuzzification. The well known centre of defuzzification method has been used for its simplicity. The major drawback of Mean of Maximum (MOM) method is that it does not use all the information converted by the fuzzy command and hence it becomes difficult in generating commands that run the system smoothly.

U =

U = j * Uj j

I ( Membership P * Output correspond ( Membership of I P )

ing

(1)

U is determined using the centre of gravity method j is the membership value of the lingivustic variables recommending the fuzzy control action, Uj is the precise numerical value corresponding to the fuzzy control action. The U obtained from (9) is added with the existing previous signal to obtain the actual output signal U which is given to the microturbine [11].

Table. 1 Fuzzy logic tables

Speed

Speed

VL LN LN LN N NC

L LN LN N NC P

Z LN N NC P LP

H N NC P LP LP

VH NC P LP LP LP

VLS LS NS HS VHS

3. MODELLING OF PMSM

Based on the d-q reference frame, the stator voltage equitation of PMSM can be described as [12].

d ud = dt d u = q dt

d

q + rs i d d + rs i q

(2)

Where, ud, & dq are d and q components of the stator winding voltage, d & q are d and q components of stator flux, id ,iq are d q component of stator winding current, is

44

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

the angular speed, rs is the stator resistance. The flux linkage of PMSM can be expressed as, d = L d i d + PM q = L q i q

(3)

Where, Ld, Lq are d and q axis inductances, PM is the permanent magnet rotor flux linkage, The electromagnetic torque equation of the PMSM is given as [12],

Te = 3 p ( d i q q i d 2

(4)

Where p is the number of pole pairs, the motion equation is expressed as,

Te = J d + B + TL dt

= p

(5) (6)

Where, PM is the rotor flux linkage, J is the moment of inertia, B is the damping torque and TL is the motor load.

3. POWER ELECTRONICS CONVERTER

The power electronics interfacing is a critical component in the single shaft microturbine design and represents significant design challenge, especially in matching turbine output power to the connected load or grid. There are different configurations available to interface the MTG power to load. One possible is to use a three phase diode rectifier, voltage source invert and filter. This requires a separate start-up arrangement for the microturbine. The configuration used in this paper is assumed to be brought to rated speed for the isolated mode of operation and bidirectional power converter has been used for the grid connected mode of operation. For a single shaft microturbine the power interfacing circuit is used to convert high frequency AC power produced by the PMSM into usable electrical power. The power conditioning circuit is one of the critical components in a single shaft microturbine design and represents significant challenge in design. Especially in matching turbine output to required load. The control structure for grid connected mode of operation is shown in Figure 4. The grid side converter operates as a controlled power source. The standard PI controller is used to regulate the grid current in the dq synchronous frame in the inner control loops and the DC voltage regulator in the outer loop. It is seen that a PI controller regulates the DC bus voltage by imposing an id current component. Id represents the active power component of the injected current into the grid and iq is it reactive component. In order to obtain only a transfer of active power only a transfer of active power, the id current reference set to zero. The decoupling terms are used to obtain independent control of id and iq in. A PLL is used to synchronize the converter with the grid. The philosophy of the PLL is that the difference between the grid phase and inverter phase angel can be reduced to zero using PI controller and locking the line side inverter phase to grid [8].

45

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

Figure 4: Line side converter control for grid connected mode

For the isolated mode of operation the power conditioning unit consist of a three phase diode rectifier, a voltage source inverter (VSI) and LC filter are used. The control system for a voltage source inverter is shown in Figure 5. A 166 Hz, voltage source feeds a 50Hz, 50kW load through an AC/DC/AC converter. The 480V, 166Hz AC power is first rectified by six pulse diode bridge rectifier and filtered. DC link voltage is given to an IGBT two level inverter generating 50Hz. The IGBT inverter uses Pulse Width Modulation (PWM) with 2 kHz carrier frequency. The voltage is regulated at 1p.u.(480 Vrms) by a PI voltage regulator using abc to dq and dq to abc transformation. The first output voltage regulator is a vector containing the three modulation signals used by the PWM generator to generate six IGBT pulses [8].

Figure 5: Line side converter control for isolated mode

3. SIMULATION RESULTS

Before connection the MTG system to an electrical load, the performance of microturbine controller is verified by the fuzzy logic and nominal PI controller in Matlab/simulink. Form the performance test of microturbine it is ascertained that, the fuzzy logic based controller settling time is less than nominal PI controller and also the oscillation are eliminated in fuzzy logic controller. The comparison study of fuzzy logic and nominal PI controller are considered for the fuel demand, turbine torque, speed and power. The simulation is performed for a total duration of time t=80 second. The turbine is loaded in steps of half load and full load respectively. The variation of fuel demand and turbine torque with fuzzy logic and nominal PI controller are shown in Figures 6 and 7 respectively. From the reported Figures 6 and 7 it is observed that, the settling

46

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

time of fuzzy logic controller is less then PI controller. With respect to fuel flow, the variation of turbine speed and power are shown in Figures 6 and 7.

1.4

0.8 0.6 0.4 0.2 19 20 21 22 23 24 25 26

Fuel demand (p.u)

1.2 1 0.8 0.6

Fuzzy logic controler PI contrller

0.4 0.2 0 0 10 20 30

0.8 0.6 0.4 60 61 62 63 64 65 66

Time (s)

40

50

60

70

80

Figure.6 Fuel demand

1.2 1 0.8 0.6 0.4 0.2 0 -0.2 -0.4 0 10 20

0.6 0.4 0.2 0 21 22 23 24 0.9 0.8 0.7 0.6 0.5 0.4 62 64 66

Turbine torque (p.u)

Fuzzy logic controller PI controller

30

Time (s)

40

50

60

70

80

Figure.7 Turbine torque

1.01 1 0.99 0.98 0.97

0.98 0.985 0.98 0.975 0.97 0.965 62 63 64 65

Fuzzy controller PI controller

Turbine speed(p.u.)

0.96 0.95 0

0.97 0.96 40 41 42 43 44 45

10

20

30

Time (s)

40

50

60

70

80

Figure 8. Turbine speed

1 0.8

Turbine power (p.u)

0.6 0.4

0.9

0.2 0 -0.2 -0.4 0 10 20

0.6 0.4 0.2 0 18 20 22 24 26

0.8 0.7 0.6 0.5 0.4 61 62 63 64 65 66 67

Fuzzy logic controller PI controller 30

Time (s)

40

50

60

70

80

Figure 9. Turbine power

3.1 GRID CONNECTED MODE

The MTG system in connected to the grid is supplying a power to the grid is predicted on the basis of active and reactive power. The active and reactive power supplied by the fuzzy logic controlled MTG system is shown in Figure.10. From the reported Figure.10 it is observed that, the active power is 50kW and reactive power is almost zero. Hence it is ascertained that the PMSM supplies only active power. The DC link voltage and turbine torque are shown in Figures 11 and 12 respectively. From the reported Figure12 it is observed that the turbine torque is

47

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

negative in per unit, it means that, the PMSM is running as generator. To generate the turbine toque the proportional fuel demand and speed are shown in Figures 14 and 15. The inverter output voltage and load voltage are shown in Figures 16 and 17 respectively. From the Figures 16 and 17 it is observed that, the MTG system is supplying quality power to the grid.

1 x 10

4

1.015 1.01

Active & reactive power

0.5

Turbine speed (p.u)

1.005 1 0.995 0.99 0.985 0.98 0.975 0 1 2 3 4 5 6 7 8

0 -0.5 -1 -1.5 0 Active power in watts Reactve power in Var 1 2 3

Time (s)

Time(s)

Figure.10 Actvie and reactive power

700 600

0.6 0.4 0.2 0 -0.2 -0.4 0

Figure.14 Turbine speed

DC link voltage (V)

500 400 300 200 100 0 0 1 2 3 4 5 6 7 8

Turbine torque(p.u)

Time (s)

Time (s)

Figure.11 DC link voltage

0.5

500 400 300 200 100 0 -100 -200 -300 -400 -500

Figure.15 Turbine torque

Inverter voltage (V)

600 400 200 0 -200 -400 -600 2.55 2.6 2.65 2.7 2.75 2.8

Troque (p.u)

-0.5

-1 0

Time (s)

Time (s)

Figure.12 Turbine torque

0.7

Figure.16 Inverter voltage

1.5 1 0.5 0 -0.5 -1 -1.5 0 1 1 0 -1 2.045 2.05 2.055 2.06 2.065 2.07 2.075 2.08 2.085

0.5

Fuel flow (p.u)

0.4 0.3 0.2 0.1 0 -0.1 0 1 2 3 4 5 6 7 8

Load voltage (p.u.)

0.6

Time (s)

Time (s)

Figure.13 Fuel flow

Figure.17 Load voltage

3.2 Isolated mode

The fuzzy logic controlled MTG system is connected to an isolated mode and it performance is simulated for the total duration of 30sec. The variation of turbine fuel flow and torque are shown in Figure.18 and 19 respectively. From the reported Figures 18 and 19 it is observed that, the fuel demand and turbine torque increase with increase in load and decreases with decrease in load.

48

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

The variation of turbine speed due to the increase and decrease of load on the MTG system is shown in Figure. 20. The active and reactive power is one of the important parameters of MTG system in connected to the load. Since the MTG system power generation by PMSM, it can supply only the active power. it is observed from the reported Figure.22. It has been measured between phase to ground voltage and current. The variation of load voltage and current between phases to ground is shown in Figures 23 and 24 respectively. From the reported Figures 23 and 24 it is observed that, the variation of load voltage and current maintains the power quality.

0.7 0.6

14000 12000

Active power in kW Reactive power in Var

Active & reactive power

2 4 6 8 10 12 14 16 18 20

Fuel demand (p.u)

0.5 0.4 0.3 0.2 0.1 0 0

10000 8000 6000 4000 2000 0 -2000 0 2 4 6 8 10 12 14 16 18 20

Time (s)

Time (s)

Figure.18 Fuel demand

0.6 0.4

Figure.22 Active and reactive power

300 200

Turbine torque (p.u)

Load voltage (V)

0.2 0 -0.2 -0.4 0

100 0 -100 -200

300 200 100 0 -100 -200 4.97 4.98 4.99 5 5.01 5.02 5.03 200 100 0 -100 -200 -300 14.96 14.97 14.98 14.99 15 15.01 15.02 15.03 15.04

Time (s)

10

12

14

16

18

20

Figure.19 Turbine torque

1.005 1 0.995 0.99 0.985 0.98 0.975 0 2 4 6 8 10 12 14 16 18 20

-300 0

Time (s)

10

12

14

16

18

20

Figure.23 Load voltage

40 30

Turbine speed (p.u)

Load current (A)

20 10 0 -10 -20 -30

50 40 20 0 0 -20 -40 -50 9.98 9.99 10 10.01 10.02 10.03 14.98 14.99 15 15.01 15.02

Time (s)

Figure.20 Turbine speed

-40 0

Time (s)

10

12

14

16

18

20

Figure.24 Load current

4. CONCLUSIONS

The Fuzzy logic controlled MTG system connected to the grid and isolated load has been implemented and simulated using Matlab/Simulink. Initially the microturbine controller verified by the both nominal PI controller and fuzzy logic controller. Form the simulation study, the fuzzy logic controller is preferred over a nominal PI controller due to minimum oscillation and steeling time. The fuzzy logic based verified microturbine is used for the MTG system in connected to the grid and isolated model of operation. The developed model of MTG system includes microturbine, PMSM and power electronics interfacing circuit. From the simulation study of the MTG system is supplying power to the grid and the performance of load fallowing character is ascertained. The fuzzy logic controlled MTG system will maintain the quality power and fewer harmonic. From the simulation study it is observed that, the active and reactive power injected by the MTG system for grid connected as well as isolated mode of operation.

49

International Journal of Fuzzy Logic Systems (IJFLS) Vol.2, No.3, July 2012

REFERENCES

[1] P. P. Barker, and R. W. de Mello, 2000, Determining the impact of distributed generation on power systems: Part 1- Radial Distribution systems, in Proc. IEEE Power Eng. Society. Summer Meeting, vol. 3, pp.1645-1656. [2] Shijie Yan and Xu Wang Fuzzy Controlled with Tracking Differentiator for Microturbine Sixth international conference on fuzzy systems and Knowledge Discovery,FSKD-2009 Tianjin,14th -16th August 2009, pp. 97101. [3] A. Al-Hinai and A. Feliachi, Dynamic model of microturbine used as a distributed generation in Proc 34th South Eastern Symposiums on system theory, Huntsville, Alabama, 2002,pp.209-213. [4] Jenica Ileana Corcau and Eleonor Stoenescu Fuzzy logic controlled as power system stabilizer International Journal of Circuits, System and Signal Processing, Vol.1, Issue.3, 2007, pp.266-273. [5] W. I. Rowen, Simplified Mathematical Representations of Heavy Duty Gas Turbines, Journal of Engineering for Power, Trans. ASME, vol. 105, no. 4, pp. 865-869, Oct, 1983. [6] Hung Wei, Wu Ziping, Niu Ming, Zhang Jianhua, Guo Yuanbo and Wu Chong Dynamic Modelling and Simulation of Microturbine Generation System for the parallel operation of microgrid International Conference on Sustainable Power Generation and Supply,2009 SUPERGEN-09, Nanjing, 6th -7th April 2009, pp.1-8. [7] D. N. Gaonkar and R N Patel Modeling and Simulation of Microturbine Based Distributed Generation System IEEE Power India Conference 2006, New Delhi, 5th June 2006. pp.05. [8] S. R. Guda. C .Wang and M H. Neherir, Modeling of Microturbine Power Generation Systems Electric Power Components and systems,1532-5016, Vol.34, Issue.9,pp.1027-1041,2006. [9] U. Yolac and T Yalcinoz Comparison of fuzzy logic and PID controller for TCSC using MatLab 39th IEEE International Conference on Power Engineering, Vol.1,2004,pp.438-442. [10] B Anand and Ebenezer Jeyakumar Fuzzy logic based load frequency control of hydro thermal system with non-linearity International Journals of Electrical and Power Engineering, Vol.3,Issue.2,2009,pp.112-118. [11] Shijie Yan and Xu Wang Active Disturbance Rejection Fuzzy Control of MTG Fuel pressure IEEE International Conference on Mechatronics and automation, 9th -12th August 2009 Changchum, China. [12] J. B Ahn, Y. H. jeong, D.H. Kang and J.H.Park Developmen t of High Speed PMSM for Distributed Generation Using Microturbine 30th IEEE Annual Conference on Industrial Electronics Society, November 2-6,2004,Busan, Korea.

Authors

Sanjeev K Nayak received his (M Tech degree from UBDT College of Engineering Davengere, Kuvempu University Shimoga Karnataka, INDIA in the year 2007, He worked as a faculty in the Department of Electrical and Electronics Engineering, at Nitte Meensakashi Institute of Technology, Bangalore for a duration of three years. Currently he is pursuing his Ph.D research in the Department of Electrical and Electronics Engineering at National Institute of Technology Karnataka Surathkal. His areas of research interests are Distributed Generation-Microturbine, Fuel cell and Power Quality. He published paper in national and international conference, in INDIA, Saudi Arabia and Thailand. D. N. Gaonkar (M2008) has received his Ph.D. degree from the Indian Institute of Technology Roorkee, India; in the year 2008. He was a visiting research scholar at the University of Saskatchewan Canada in the year 2008. He has edited and written a chapter in the book titled DISTRIBUTED GENERATION, which is published by INTECH publication Austria. He has published many papers in international journals and conferences. Presently he is working as an Assistant Professor in the Department of Electrical Engineering, National Institute of Technology Karnataka, Surathkal, Mangalore, INDIA. His research areas of interest are Power System Operation and Control, Power Electronics and Distributed Generation Systems.

50

Вам также может понравиться

- Buck Boost Converter Small Signal Model Dynamic Analysis Under System Uncertainties PDFДокумент13 страницBuck Boost Converter Small Signal Model Dynamic Analysis Under System Uncertainties PDFTariq KhanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Content of Book Titled Advanced Control and Optimization Paradigms For Wind Energy SystemsДокумент6 страницContent of Book Titled Advanced Control and Optimization Paradigms For Wind Energy SystemsTariq KhanОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- A Neural-Network-Based Model Predictive Control of Three-Phase Inverter With An Output FilterДокумент11 страницA Neural-Network-Based Model Predictive Control of Three-Phase Inverter With An Output FilterTariq KhanОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Slides Ch1 PDFДокумент45 страницSlides Ch1 PDFTariq KhanОценок пока нет

- WRITING TASK 1: Band Descriptors (Public Version)Документ2 страницыWRITING TASK 1: Band Descriptors (Public Version)Tariq KhanОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 1 s2.0 S0968089607002568 MainДокумент18 страниц1 s2.0 S0968089607002568 MainTariq KhanОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- PHP Lecture by Tariq Kamal UET Abbottabad CampusДокумент14 страницPHP Lecture by Tariq Kamal UET Abbottabad CampusTariq KhanОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Lab On Open Circuit TestДокумент14 страницLab On Open Circuit TestTariq KhanОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Microturbine FuzzyДокумент7 страницMicroturbine FuzzyTariq KhanОценок пока нет

- Drive Test ProcedureДокумент14 страницDrive Test ProcedureTariq Khan100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Lab On Short CKT TestДокумент12 страницLab On Short CKT TestTariq KhanОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Engineering Electromagnetic Fields and Waves: Carl T. A. JohnkДокумент5 страницEngineering Electromagnetic Fields and Waves: Carl T. A. JohnkMarce MatosОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Stem - Physics 1 CGДокумент13 страницStem - Physics 1 CGVictoria MabiniОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- PH102Документ2 страницыPH102Shobhit ParkiОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- b2 Symmetry and RelativityДокумент70 страницb2 Symmetry and RelativityAndrew OrrОценок пока нет

- 250 Service Manual PDFДокумент47 страниц250 Service Manual PDFSnejana Stoianov100% (2)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Max Seal Fluid Loss Control AdditiveДокумент2 страницыMax Seal Fluid Loss Control AdditiveadrianitoalaОценок пока нет

- ALI AFNAN - S Instruction Manual Usui Reki Level-1 & 2 Combined, With Detailed SymbolsДокумент13 страницALI AFNAN - S Instruction Manual Usui Reki Level-1 & 2 Combined, With Detailed Symbolskrasivaad100% (1)

- Adina CFD FsiДокумент481 страницаAdina CFD FsiDaniel GasparinОценок пока нет

- Development of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldДокумент14 страницDevelopment of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldTaiwo Adenike BashorunОценок пока нет

- Principles and Practices of Reverse OsmosisДокумент9 страницPrinciples and Practices of Reverse OsmosisMohamadОценок пока нет

- From Newton To Mandelbrot-A Primer in Theoretical PhysicsДокумент277 страницFrom Newton To Mandelbrot-A Primer in Theoretical PhysicsΠΑΝΑΓΙΩΤΗΣ ΨΥΧΑΣ100% (1)

- Dinli ATV Electrical System ManualДокумент15 страницDinli ATV Electrical System ManualgryzzlyОценок пока нет

- A Proactive 2-Stage Indoor CO2-based Demand-Controlled Ventilation Method Considering CoДокумент18 страницA Proactive 2-Stage Indoor CO2-based Demand-Controlled Ventilation Method Considering CoMariaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Climate Change: Frequently Asked QuestionsДокумент8 страницClimate Change: Frequently Asked QuestionsAdriano Racho MelendresОценок пока нет

- Chemistry: Long Exam 1Документ4 страницыChemistry: Long Exam 1Barbara BananaОценок пока нет

- Flow Testing BrochureДокумент12 страницFlow Testing BrochureImadОценок пока нет

- Design and Fabrication of Stair Climber TrolleyДокумент21 страницаDesign and Fabrication of Stair Climber TrolleyAnonymous 1mMOyt9zОценок пока нет

- GROHE Pricelist-2020 en GB PDFДокумент1 020 страницGROHE Pricelist-2020 en GB PDFNikhil AggarwalОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Answer Key - CWT 1Документ2 страницыAnswer Key - CWT 1Areeb AbbaxiОценок пока нет

- Working and Maintenance of Crushing EquipmentДокумент53 страницыWorking and Maintenance of Crushing EquipmentKeshav ChhawchhariaОценок пока нет

- AV65WP74Документ19 страницAV65WP74ElectroCenterОценок пока нет

- Smpling - Storage - Transportation - Installation ProcedureДокумент75 страницSmpling - Storage - Transportation - Installation ProcedurePaddyОценок пока нет

- Project EvsДокумент8 страницProject Evsnaveenkmr04550% (2)

- S 1514Документ4 страницыS 1514bacuoc.nguyen356Оценок пока нет

- KKT Chillers PI ECO EngДокумент2 страницыKKT Chillers PI ECO EngjltenorioОценок пока нет

- Como Sobreviver A Um Apocalipse ZumbiДокумент30 страницComo Sobreviver A Um Apocalipse ZumbirejaneОценок пока нет

- Four Bar Linkage Knee Analysis: by Michael P. Greene, B.S., M.E., C.P.OДокумент10 страницFour Bar Linkage Knee Analysis: by Michael P. Greene, B.S., M.E., C.P.ObaksoОценок пока нет

- Yamaha Outboard Carburetor KitsДокумент4 страницыYamaha Outboard Carburetor KitsMarine Parts ChinaОценок пока нет

- Selected Bibliography On Brickmaking in Developing CountriesДокумент4 страницыSelected Bibliography On Brickmaking in Developing CountriesRobert PetrutОценок пока нет