Академический Документы

Профессиональный Документы

Культура Документы

4.2 Design of The Pump According To The Installation Baseplated Pumps Advantages

Загружено:

Sandi AslanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

4.2 Design of The Pump According To The Installation Baseplated Pumps Advantages

Загружено:

Sandi AslanАвторское право:

Доступные форматы

4.

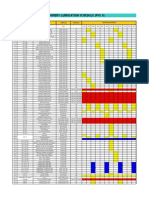

Design of the pump according to the installation Advantages: adaptable to a selection of drivers and drive methods Disadvantages: space requirement precise alignment of driver and pump is necessary cost of baseplate, coupling and guard

Baseplated pumps

Close coupled pumps

Advantages: reduced space construction requirement due to compact

no alignment of pump and driver is necessary no baseplate, coupling or guard is necessary Disadvantages: limited to drive by electric motor, up to a power of approx. 45 kW Inline Pumps Advantages: direct installation in the pipeline is possible, so minimal space requirement no alignment of pump and driver is necessary no baseplate, coupling or guard is necessary Disadvantages: limited to drive by electric motor, up to a power of approx. 45 kW Multistage Pumps Advantages: installation with piping from almost all directions secondary discharge from one of the stages possible accessories such as instrumentation, lubrication and seal flushing on the base plate possible special high temperature installations with feet in plane of axis

107

Vertical pumps (multi)

Advantages: minimum space requirement for multistage pumps no alignment of pump and driver is necessary no baseplate, coupling or guard is necessary Disadvantages: limited to drive by electric motor, up to a power of approx. 55 kW

Vertical pumps

Advantages: direct installation in the container or sump is possible , so minimal space requirement suction and delivery line not necessary easy installation ready for operation Disadvantages: given adequate submersion its immediaetly ready for operation driver must be above flood height

Submersible pumps

Advantages: direct installation in the sump is possible suction and delivery line not necessary given adequate submersion its immediately ready for operation special pump house not required Disadvantages: special submersible driver is required operating temperature limited to 40 to 50 C

108

Underwater pumps

Advantages: installation in narrow and deep boreholes possible without special drive arrangement can be installed directly in pipeline as a booster pump Disadvantages: limited applications

Sump pumps

Advantages: direct installation in the container or sump is possible connections in the base of the container are not necessary removing safety problems for certain fluids suction and delivery line not necessary given adequate submersion its immediately ready for operation Disadvantages: limited installation length fluids with abrasive solids content require a special construction (cantilever) due to the inner bearing design

Canned pumps

Advantages: by varying the can length and therefore the pump length, the suction head is varied increasing the value of (NPSHA) even with poor suction conditions, no booster pump is nessary, increasing realiability Disadvantages: higher capital and installation costs

109

Вам также может понравиться

- Eugenics in The United StatesДокумент14 страницEugenics in The United StatesSnark Jacobs100% (1)

- M96SC05 Oleo StrutДокумент6 страницM96SC05 Oleo Strutchaumont12345Оценок пока нет

- Pressure GaugeДокумент22 страницыPressure GaugeSandi Aslan100% (2)

- Artificial Lift System LДокумент106 страницArtificial Lift System LG Inba MalarОценок пока нет

- 5 (Jeremy Stranks) Health and Safety Pocket BookДокумент10 страниц5 (Jeremy Stranks) Health and Safety Pocket BookTuralОценок пока нет

- Surge Tank Design for Water Hammer Pressure ReliefДокумент26 страницSurge Tank Design for Water Hammer Pressure ReliefAmar WadoodОценок пока нет

- Drainage Culverts 07Документ17 страницDrainage Culverts 07Avish GunnuckОценок пока нет

- Port Works Design Manual Part 2 PDFДокумент124 страницыPort Works Design Manual Part 2 PDFhessian123Оценок пока нет

- Structure Dismantling JSAДокумент2 страницыStructure Dismantling JSAtnssbhaskar69% (13)

- Westfalia in Palm Oil MillДокумент24 страницыWestfalia in Palm Oil MillSupatmono NAIОценок пока нет

- Town Water Supply - Pump, Pumping Main: Delivery PipeДокумент2 страницыTown Water Supply - Pump, Pumping Main: Delivery PipeJohn BandaОценок пока нет

- 1 6Документ58 страниц1 6Emiliano.Armando Aguilera.Vázquez100% (1)

- Sps and Wetwell NTLДокумент3 страницыSps and Wetwell NTLProject ManagerStructuresОценок пока нет

- RO Water Treatment Process OptimizationДокумент30 страницRO Water Treatment Process Optimizationmiths_0087100% (1)

- Pipeline profile and reservoir water levelsДокумент7 страницPipeline profile and reservoir water levelsPhyu Mar Thein KyawОценок пока нет

- Precast Concrete PDFДокумент160 страницPrecast Concrete PDFSandi AslanОценок пока нет

- Pressure/vacuum valves and flame arresters for petroleum storage tanksДокумент14 страницPressure/vacuum valves and flame arresters for petroleum storage tanksSandi AslanОценок пока нет

- Pipe Sizing V0.4Документ17 страницPipe Sizing V0.4Ibrahim A. Hameed100% (1)

- NetafimДокумент67 страницNetafimxtianОценок пока нет

- TUTORIAL3 Series-Paralel-Branched Pipe SystemДокумент5 страницTUTORIAL3 Series-Paralel-Branched Pipe SystemNurul QurratuОценок пока нет

- Calculating Pressure LossДокумент2 страницыCalculating Pressure LossAhmed MoustafaОценок пока нет

- Condensate Recovery Pump SystemsДокумент8 страницCondensate Recovery Pump SystemsSandi AslanОценок пока нет

- Activated Sludge Waste Water Treatment Calculations - S.I. UnitsДокумент2 страницыActivated Sludge Waste Water Treatment Calculations - S.I. Unitsnsr2t100% (1)

- Coca Cola Primary Activities: 1. Inbound Logistics Include Functions Like Receiving, Warehousing, and Managing InventoryДокумент5 страницCoca Cola Primary Activities: 1. Inbound Logistics Include Functions Like Receiving, Warehousing, and Managing InventoryJaene L.Оценок пока нет

- Hydraulic Jump Length Calculator 111205Документ2 страницыHydraulic Jump Length Calculator 111205abhishek5810Оценок пока нет

- Electrical Load Data Sheet Site PlanДокумент1 страницаElectrical Load Data Sheet Site Plangag aaОценок пока нет

- Residential and Commercial High StrengthДокумент36 страницResidential and Commercial High StrengthNiong DavidОценок пока нет

- Projectile MotionДокумент11 страницProjectile MotionRamachandran VenkateshОценок пока нет

- Design Criteria 2019 PDFДокумент64 страницыDesign Criteria 2019 PDFngronau124545Оценок пока нет

- Design of Vertical Drop Fall: Surface FlowДокумент3 страницыDesign of Vertical Drop Fall: Surface FlowMohammedОценок пока нет

- AWDM 10 CH04 Water - Consumption PDFДокумент49 страницAWDM 10 CH04 Water - Consumption PDFEdward BeleñoОценок пока нет

- Hdpe - Weight Chart 80Документ1 страницаHdpe - Weight Chart 80vishnumani3011Оценок пока нет

- Is Reinforcement Needed in Precast Concrete Manhole UnitsДокумент1 страницаIs Reinforcement Needed in Precast Concrete Manhole UnitsPanji Ginaya TaufikОценок пока нет

- Growth and Capacity Evaluation Warrenton 05072015Документ16 страницGrowth and Capacity Evaluation Warrenton 05072015Fauquier NowОценок пока нет

- Super Elevation CalculationДокумент1 страницаSuper Elevation CalculationUmesh KumarОценок пока нет

- Min Pattern: Icrc/Wathab Demand Analysis 10/19/2017Документ3 страницыMin Pattern: Icrc/Wathab Demand Analysis 10/19/2017GJ CCОценок пока нет

- Permeate Line Pressure Drop CalculationsДокумент2 страницыPermeate Line Pressure Drop Calculationsask.kulkarni KulkarniОценок пока нет

- PE Pipe Wall Thickness Chart for Various Sizes and Pressure RatingsДокумент10 страницPE Pipe Wall Thickness Chart for Various Sizes and Pressure RatingsSreenubabu KandruОценок пока нет

- Population Equivalance and WSPДокумент5 страницPopulation Equivalance and WSPWong Kuan SengОценок пока нет

- Design of Outlets - JaboriДокумент7 страницDesign of Outlets - JaboriHaji Ahmad BhattiОценок пока нет

- Peak Factor For Hourly Design Demands AnДокумент7 страницPeak Factor For Hourly Design Demands AnAnilduth BaldanОценок пока нет

- Water DemandДокумент9 страницWater Demandraveena athiОценок пока нет

- GRP & Hdpe MtoДокумент11 страницGRP & Hdpe Mtonice guyОценок пока нет

- UPVC Pipe SizeДокумент2 страницыUPVC Pipe Sizeahmedomar_953724702Оценок пока нет

- Water Demand CalculationДокумент6 страницWater Demand CalculationValium MorphineОценок пока нет

- Water Tank Crack WidthДокумент1 страницаWater Tank Crack WidthPurnima ArkalgudОценок пока нет

- Stormwater Design CriteriaДокумент15 страницStormwater Design CriteriaSyazwan AbhОценок пока нет

- Sewer Pipes and Flows in SewersДокумент28 страницSewer Pipes and Flows in SewersBalanlan PenalesОценок пока нет

- Muhammad Jazil L13-5775 B: LPCD Liters Per Capita in One DayДокумент5 страницMuhammad Jazil L13-5775 B: LPCD Liters Per Capita in One DaySikandar MalikОценок пока нет

- Analysis of RateДокумент18 страницAnalysis of RateRaja Usman AhmedОценок пока нет

- BNC - Dana Gas PipelineДокумент4 страницыBNC - Dana Gas PipelinesebincherianОценок пока нет

- HMWSSB Godavari Pipe Line ProjectДокумент110 страницHMWSSB Godavari Pipe Line ProjectSasidhar KatariОценок пока нет

- Piping and Pipelines Network DesignДокумент3 страницыPiping and Pipelines Network DesignOmar EzzatОценок пока нет

- Lube Oil Plan PVC2Документ10 страницLube Oil Plan PVC2daxОценок пока нет

- Pipe LineДокумент24 страницыPipe Linesamer8saifОценок пока нет

- UPVC Pipe SizeДокумент2 страницыUPVC Pipe SizefebousОценок пока нет

- Stoplog DatasheetДокумент2 страницыStoplog DatasheetjayusmanОценок пока нет

- Pumpstation Input Data: Zone M1Документ95 страницPumpstation Input Data: Zone M1TahirJabbar50% (2)

- Minimum Design Criteria For The Permitting of Gravity SewersДокумент2 страницыMinimum Design Criteria For The Permitting of Gravity SewerslaikienfuiОценок пока нет

- Pressure Loss in Schedule 40 Steel PipesДокумент11 страницPressure Loss in Schedule 40 Steel PipesAnonymous qrSsYuxyoYОценок пока нет

- Equipment List Inquire 1Документ1 страницаEquipment List Inquire 1Agung Eko PurnomoОценок пока нет

- Storm Z2 Rev4Документ20 страницStorm Z2 Rev4TahirJabbarОценок пока нет

- Assignment Stepped April20thДокумент1 748 страницAssignment Stepped April20thMegh Raj KCОценок пока нет

- Flow Duration CurveДокумент4 страницыFlow Duration CurvesunnytouchОценок пока нет

- D. Design Load D.1. Loading DataДокумент14 страницD. Design Load D.1. Loading DataEdОценок пока нет

- Drip Design at SolДокумент13 страницDrip Design at SolVan BGОценок пока нет

- Hazen WilliamsДокумент2 страницыHazen WilliamssushilkumarОценок пока нет

- Irrigation Scheduling by Book Keeping MethodДокумент13 страницIrrigation Scheduling by Book Keeping MethodShekh Muhsen Uddin AhmedОценок пока нет

- Public Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inДокумент10 страницPublic Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inSanthosh BabuОценок пока нет

- Pumps DefinitionsДокумент31 страницаPumps DefinitionsFortuna JohnОценок пока нет

- 5 A Surface Irrigation System PDFДокумент65 страниц5 A Surface Irrigation System PDFsewmehon amareОценок пока нет

- Horizontal vs Vertical Pump DesignДокумент2 страницыHorizontal vs Vertical Pump DesignBill GuОценок пока нет

- Westin Premier Electric MotorДокумент4 страницыWestin Premier Electric MotorSandi AslanОценок пока нет

- Convenient & Powerful Smart Valve PositionerДокумент8 страницConvenient & Powerful Smart Valve PositionerSandi AslanОценок пока нет

- Beaver Industrial ValveДокумент6 страницBeaver Industrial ValveSandi Aslan100% (1)

- Deflo MSDДокумент5 страницDeflo MSDSandi AslanОценок пока нет

- Flexible HoseДокумент3 страницыFlexible HoseSandi AslanОценок пока нет

- Sentinel Chart RecorderДокумент4 страницыSentinel Chart RecorderSandi AslanОценок пока нет

- Meca Inox-01-Ball 1pcs BodyДокумент3 страницыMeca Inox-01-Ball 1pcs BodySandi AslanОценок пока нет

- Actuator SunYehДокумент10 страницActuator SunYehSandi AslanОценок пока нет

- Beaver Industrial ValveДокумент6 страницBeaver Industrial ValveSandi Aslan100% (1)

- Rupture Disc Holders - DescriptionДокумент1 страницаRupture Disc Holders - DescriptionSandi AslanОценок пока нет

- Butterlfy TSVДокумент2 страницыButterlfy TSVSandi AslanОценок пока нет

- Pressure GaugesДокумент1 страницаPressure GaugesSandi AslanОценок пока нет

- Pneumatic ActuatorДокумент14 страницPneumatic ActuatorSandi AslanОценок пока нет

- Unicom ValveДокумент27 страницUnicom ValveSandi AslanОценок пока нет

- Ari Faba-Ansi LonglifeДокумент8 страницAri Faba-Ansi LonglifeSandi AslanОценок пока нет

- Solenoid ValveДокумент2 страницыSolenoid ValveSandi AslanОценок пока нет

- Ari - Temperature ControllerДокумент12 страницAri - Temperature ControllerSandi AslanОценок пока нет

- Pipes and Pipe Sizing PDFДокумент22 страницыPipes and Pipe Sizing PDFSandi AslanОценок пока нет

- MSEP DatasheetДокумент2 страницыMSEP DatasheetSandi AslanОценок пока нет

- Goldpro BrochuresДокумент20 страницGoldpro BrochuresSandi AslanОценок пока нет

- Temperature Regulator With Two Temperature SensorsДокумент2 страницыTemperature Regulator With Two Temperature SensorsSandi AslanОценок пока нет

- Budidaya Cengkeh PDFДокумент38 страницBudidaya Cengkeh PDFNoval Gibran SОценок пока нет

- Back Pressure Safety ValveДокумент12 страницBack Pressure Safety ValveSandi AslanОценок пока нет

- TD-W8951ND User Guide PDFДокумент79 страницTD-W8951ND User Guide PDFSandi AslanОценок пока нет

- Design of Palm Kernel PDFДокумент9 страницDesign of Palm Kernel PDFSandi AslanОценок пока нет

- Osteo Book Final 2014Документ51 страницаOsteo Book Final 2014hyanandОценок пока нет

- Two-day workshop budgetДокумент2 страницыTwo-day workshop budgetVishwanath BaliОценок пока нет

- Computed Tomography (CT) - BodyДокумент7 страницComputed Tomography (CT) - Bodyfery oktoraОценок пока нет

- Insulation MBMA-NAIMA Acousticical Performance Guide Noise SoundДокумент26 страницInsulation MBMA-NAIMA Acousticical Performance Guide Noise SoundDianna LambertОценок пока нет

- AC7101.1 Rev G 2Документ37 страницAC7101.1 Rev G 2Namelezz ShadowwОценок пока нет

- A Text Book On Nursing Management AccordДокумент790 страницA Text Book On Nursing Management AccordMohammed AfzalОценок пока нет

- Sodium Chloride MSDSДокумент5 страницSodium Chloride MSDSIbaharmovic LpuОценок пока нет

- PE1 q1 Mod6 ProperEtiquetteand-Safetyinthe-UseofFacilitiesEquip v1-ADMДокумент12 страницPE1 q1 Mod6 ProperEtiquetteand-Safetyinthe-UseofFacilitiesEquip v1-ADMelvira.raagas2Оценок пока нет

- EMAAR HOUSING HVAC SYSTEM SPECIFICATIONSДокумент91 страницаEMAAR HOUSING HVAC SYSTEM SPECIFICATIONSBhuvan BajajОценок пока нет

- Review of Literature Review of LiteratureДокумент31 страницаReview of Literature Review of LiteratureeswariОценок пока нет

- Interest RatesДокумент207 страницInterest RatesBenjamin RogersОценок пока нет

- Horlicks: Cooking Tips For HorlicksДокумент4 страницыHorlicks: Cooking Tips For HorlickschhandacОценок пока нет

- Statistics of Design Error in The Process IndustriesДокумент13 страницStatistics of Design Error in The Process IndustriesEmmanuel Osorno CaroОценок пока нет

- Unit Test-Unit 5-Basic TestДокумент2 страницыUnit Test-Unit 5-Basic Testphamleyenchi.6a8txОценок пока нет

- Examiner's report on F6 Taxation (UK) December 2010 paperДокумент3 страницыExaminer's report on F6 Taxation (UK) December 2010 paperyorcpl200Оценок пока нет

- Carbohidratos - Determinación - Use of The Alditol Acetate Derivatisation For The Analysis of Reducing Sugars in Potato TubersДокумент5 страницCarbohidratos - Determinación - Use of The Alditol Acetate Derivatisation For The Analysis of Reducing Sugars in Potato TubersHernán AstudilloОценок пока нет

- Single Inlet Centrifugal FanДокумент43 страницыSingle Inlet Centrifugal Fan4uengineerОценок пока нет

- Annex C Olp On The RoadДокумент7 страницAnnex C Olp On The RoadCabanglasanfs OLPОценок пока нет

- Narrative Poetry 6305Документ14 страницNarrative Poetry 6305Siti AisyahОценок пока нет

- Weld Procedure Specification (WPS) : Joint Design Welding SequenceДокумент1 страницаWeld Procedure Specification (WPS) : Joint Design Welding SequenceRicardo SoaresОценок пока нет

- c19 Standard Operating ProceduresДокумент36 страницc19 Standard Operating ProceduresahsОценок пока нет

- Lesson 1:: Introduction To Science, Technology and SocietyДокумент17 страницLesson 1:: Introduction To Science, Technology and SocietyAlexis A. AguilarОценок пока нет

- Rorschach y SuicidioДокумент17 страницRorschach y SuicidioLaura SierraОценок пока нет