Академический Документы

Профессиональный Документы

Культура Документы

GD&T Glossary

Загружено:

AmolPagdalИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GD&T Glossary

Загружено:

AmolPagdalАвторское право:

Доступные форматы

GEOMETRIC TOLERANCING

Actual Local Size - The value of any individual distance at any cross section of a FOS. Actual Mating Envelope (AME) of an External eature of Size - A similar perfect feature counterpart of the smallest size that can be circumscribed about the feature so that it just contacts the surfaces at the highest points. Actual Mating Envelope (AME) of an Internal eature of Size - A similar perfect feature counterpart of the largest size that can be inscribed within the feature so that it just contacts the surfaces at their highest points. All!Aroun" S#$%ol - A circle placed on the bend of the leader line of a profile control. Angularit# - The condition of a surface centerplane or a!is being e!actly at a specified angle Angularit# Control - A geometric tolerance that limits the amount a surface a!is or centerplane is permitted to vary from its specified angle. ASME &'()*M!'++( - The national standard for dimensioning and tolerancing in the "nited States. AS#$ stands for American Society of #echanical $ngineers. The %&'.( is the standard number. )#) is to indicate the standard is metric and &**' is the date the standard was officially approved. Axi, T-eor# - The a!is +or centerplane, of a FOS must be within the tolerance zone. .a,ic /i$en,ion - A numerical value used to describe the theoretically e!act size true profile orientation or location of a feature or datum target. .et0een S#$%ol - A double ended arrow that indicates the tolerance zone e!tends to include multiple surfaces. .i!"irectional Control - -here the location of a hole is controlled to a different tolerance value in two directions. .ilateral Tolerance - A tolerance that allows the dimension to vary in both the plus and minus directions. .onu, Tolerance - An additional tolerance for a geometric control. -henever a geometric tolerance is applied to a FOS and it contains an ##. +or /#., modifier in the tolerance portion of the feature control frame a bonus tolerance is permissible. .oun"ar# - The word )0O"12A3%) is placed beneath the feature control frames to invo4e a boundary control. Cartoon Gage - A s4etch of a functional gage. A cartoon gage defines the same part limits that a functional gage would but it does not represent the actual gage construction of a functional gage. Circularit# - A condition where all points of a surface of revolution at any section perpendicular to a common a!is are e5uidistant from that a!is. Circularit# Control - A geometric tolerance that limits the amount of circularity on a part surface. Circular Runout - A composite control that affects the form orientation and location of circular elements of a part feature relative to a datum a!is. Circular Runout Control - A geometric tolerance that limits the amount of circular runout of a part surface. Coaxial /atu$ eature, - -hen coa!ial diameters are used to establish a datum a!is.

Coaxial /ia$eter, - Two +or more, diameters that are shown on the drawing as being on the same centerline +a!is,. Co$po,ite Control - .ontrols the form location and orientation of a part feature simultaneously +in a single gage reading,. Concentricit# - The condition where the median points of all diametrically opposed elements of a cylinder +or a surface of revolution, are congruent with the a!is of a datum feature. Concentricit# Control - A geometric tolerance that limits the concentricity error of a part feature. Controlle" Ra"iu, - A radius with no flats or reversals allowed. The symbol for a controlled radius is ).3.) Coor"inate Tolerancing - A dimensioning system where a part feature is located +or defined, by means of rectangular dimensions with given tolerances. Coplanar /atu$ eature, - Two or more datum features that are on the same plane. Coplanar Surface, - Two or more surfaces that are on the same plane. C#lin"rical OS - .ontains one feature6 the cylindrical surface. C#lin"ricit# - A condition of a surface of revolution in which all points of the surface are e5uidistant from a common a!is. C#lin"ricit# Control - A geometric tolerance that limits the amount of cylindricity error permitted on a part surface. /atu$ - A theoretically e!act plane point or a!is from which a dimensional measurement is made. /atu$ eature - A part feature that contacts a datum. /atu$ eature Si$ulator - The inspection e5uipment +or gage surfaces, used to establish a datum. /atu$ Reference ra$e - A set of three mutually perpendicular datum planes. /atu$ S-ift - The allowable movement or looseness between the part datum feature and the gage. /atu$ S#,te$ - A set of symbols and rules that communicate to the drawing user how dimensional measurements are to be made. /atu$ Target - A symbol that describes the shape size and location of gage elements that are used to establish datum planes or a!es. /i$en,ion - A numerical value e!pressed in appropriate units of measure and used to define the size location orientation form or other geometric characteristics of a part. Engineering /ra0ing - A document that communicates a precise description of a part. This description consists of pictures words numbers and symbols. E1ual .ilateral Tolerance - A tolerance where the allowable variation from the nominal value is the same in both directions. eature - A general term applied to a physical portion of a part such as a surface hole or slot. eature Control ra$e - A rectangular bo! that is divided into compartments within which the geometric characteristic symbol tolerance value modifiers and datum references are placed.

eature of Size ( OS) - One cylindrical or spherical surface or a set of two opposed elements or opposed parallel surfaces associated with a size dimension. eature of Size /i$en,ion - A dimension that is associated with a feature of size. ixe" a,tener A,,e$%l# - -here the fastener is held in place +restrained, into one of the components of the assembly. ixe" a,tener or$ula - 7 8 F 9 :T or T 8 -here6 T 8 position tolerance diameter 7 8 ##. of the clearance hole F 8 ##. of the fastener latne,, - The condition of a surface having all of its elements in one plane. latne,, Control - A geometric tolerance that limits the amount of flatness error a surface is allowed. loating a,tener A,,e$%l# - -here two +or more, components are held together with fasteners +such as bolts and nuts, and both components have clearance holes for the fasteners. loating a,tener or$ula - T 8 7 - F -here6 T 8 position tolerance diameter +for each part, 7 8 ##. of the clearance hole F8 ##. of the fastener unctional /i$en,ioning - A dimensioning philosophy that defines a part based on how it functions in the final product. unctional Gage - A gage that verifies functional re5uirements of part features as defined by the geometric tolerances. un"a$ental /i$en,ioning Rule, - A set of general rules defined by AS#$ for dimensioning and interpreting drawings. Geo$etric C-aracteri,tic S#$%ol, ('() - The symbols are divided into five categories6 form profile orientation location and runout. Geo$etric /i$en,ioning an" Tolerancing (G/2T) - A set of fourteen symbols used in the language of ;2<T. =t consists of well-defined of symbols rules definitions and conventions used on engineering drawings to accurately describe a part. ;2<T is a precise mathematical language that can be used to describe the size form orientation and location of part features. ;2<T is also a design philosophy on how to design and dimension parts. Go Gage - A gage that is intended to fit into +for an internal FOS, or fit over +for an e!ternal FOS, the FOS. Great M#t- of G/2T - The misconception that geometric tolerancing raises product costs. I$plie" .a,ic +34 Angle, -A *>? basic angle applies where centerlines of features in a pattern +or surfaces shown at right angles on a drawing, are located and defined by basic dimensions and no angle is specified. I$plie" .a,ic 5ero /i$en,ion - -here a centerline or centerplane of a FOS is shown in line with a datum a!is or centerplane the distance between the centerlines or centerplanes is an implied basic zero. I$plie" /atu$ - An assumed plane a!is or point from which a dimensional measurement is made. Incline" /atu$ eature - A datum feature that is at an angle other than *>o relative to the other datum features.

Inner .oun"ar# (I.) - A worst-case boundary generated by the smallest feature of size minus the stated geometric tolerance +and any additional tolerance if applicable,. International Stan"ar", Organization (ISO) - The organization that published an associated series of standards on dimensioning and tolerancing. Lea,t Material Con"ition - The condition in which a feature of size contains the least amount of material everywhere within the stated limits of size. Li$it Tolerance - -hen a dimension has its high and low limits stated. =n a limit tolerance the high value is placed on top and the low value is placed on the bottom. Maxi$u$ Material Con"ition - The condition in which a feature of size contains the ma!imum amount of material everywhere within the stated limits of size Me"ian 6oint - The mid-point of a two-point measurement. Mo"ifier, (7) - .ommunicate additional information about the drawing or tolerancing of a part. Multiple Single!Seg$ent 6rofile Control - -hen two or more profile controls are tolerancing a surface relative to different datums. Multiple Single!Seg$ent TO6 Control - -hen two +or more, single segment TO@ callouts are used to define the location spacing and orientation of a pattern of FOS. No!Go Gage - A gage that is not intended to fit into or over a FOS. A 1o-;o gage is made to the /#. limit of the FOS. Non! eature of Size /i$en,ion - A dimension that is not associated with a FOS. Outer .oun"ar# (O.) - A worst-case boundary generated by the largest feature of size plus the stated geometric tolerance +and any additional tolerance if applicable,. 6aralleli,$ - The condition that results when a surface a!is or centerplane is e!actly parallel to a datum. 6aralleli,$ Control - A geometric tolerance that limits the amount a surface a!is or centerplane is permitted to vary from being parallel to the datum. 6erpen"icularit# - The condition that results when a surface a!is or centerplane is e!actly *>? to a datum. 6erpen"icularit# Control - A geometric tolerance that limits the amount a surface a!is or centerplane is permitted to vary from being perpendicular to the datum. 6lanar /atu$ - The true geometric counterpart of a planar datum feature. 6lanar OS - A FOS that contains two features6 the two parallel plane surfaces. 6lu,!$inu, Tolerance - The nominal or target value of the dimension is given first followed by a plusminus e!pression of a tolerance. 6ri$ar# /atu$ - The first datum plane that the part contacts in a dimensional measurement. 6rofile- The outline of a part feature in a given plane. 6rofile Control - A geometric tolerance that specifies a uniform boundary along the true profile that the elements of the surface must lie within. 6rofile of a Line Control - A geometric tolerance that limits the amount of error for line elements relative to their true profile.

6rofile of a Surface Control - A geometric tolerance that limits the amount of error a surface can have relative to its true profile. 6ro8ecte" Tolerance 5one - A tolerance zone that is projected above the part surface. Ra"iu, - A straight line e!tending from the center of an arc or circle to its surface. Regar"le,, of eature Size - The term that indicates a geometric tolerance applies at any increment of size of the feature within its size tolerance. Rule 9' - -here only a tolerance of size is specified the limits of size of an individual feature prescribe the e!tent to which variations in its form--as well as in its size--are allowed. Rule 9: - 3FS applies with respect to the individual tolerance datum reference or both where no modifying symbol is specified. Secon"ar# /atu$ - The second datum plane that the part contacts in a dimensional measurement Si$ulate" /atu$ - The plane +or a!is, established by the datum feature simulator. Si$ultaneou, Engineering - A process where design is a result of input from mar4eting engineering manufacturing inspection assembly and service. Special!Ca,e OS /atu$ - -hen a FOS datum feature is referenced at ##. but simulated in the gage at a boundary other than ##.. Straig-tne,, (Axi, or Centerplane) - The condition where an a!is is a straight line +or in the case of a centerplane each line element is a straight line,. S#$$etr# - The condition where the median points of all opposed elements of two or more feature surfaces are congruent with the a!is or centerplane of a datum feature. S#$$etr# Control - A geometric tolerance that limits the symmetry error of a part feature. Tertiar# /atu$ - The third datum plane that the part contacts in a dimensional measurement. ;!:!' Rule - 2efines the minimum number of points of contact re5uired for a part datum feature with its primary secondary and tertiary datum planes. Tolerance - The total amount that features of the part are permitted to vary from the specified dimension. Tolerance Anal#,i, C-art - A means of graphically displaying the limits of a part as defined by the print specifications Tolerance of 6o,ition (TO6) Control - A geometric tolerance that defines the location tolerance of a FOS from its true position. Tolerance Stac< - A calculation used to find the e!treme ma!. or min. distance on a part. Total Runout - A composite control affecting the form orientation and location of all surface elements of a diameter +or surface, relative to a datum a!is. Total Runout Control - A geometric tolerance that limits the amount of total runout of a surface. True Geo$etric Counterpart - The theoretical perfect boundary or best fit tangent plane of a specified datum feature. True 6o,ition - The theoretically e!act location of a FOS as defined by basic dimensions.

True 6rofile - The e!act profile of a part feature as described by basic dimensions. =ne1ual .ilateral Tolerance - A tolerance where the allowable variation is from the target value and the variation is not the same in both directions. =nilateral Tolerance - A tolerance where the allowable variation from the target value is all in one direction and zero in the other direction. >aria%le Gage - A gage capable of providing a numerical reading of a part parameter. >irtual Con"ition (>C) - A worst-case boundary generated by the collective effects of a feature of size specified at ##. or at /#. and the geometric tolerance for that material condition. >irtual Con"ition .oun"ar# T-eor# - A theoretical boundary limits the location of the surfaces of a FOS. ?or,t!ca,e .oun"ar# (?C.) - A general term to refer to the e!treme boundary of a FOS that is the worstcase for assembly. 2epending upon the part dimensioning a worst-case boundary can be a virtual condition inner boundary or outer boundary. 5ero Tolerance at MMC - A method of tolerancing part features that includes the tolerance geometric value with the FOS tolerance and states a zero at ##. in the feature control frame.

Вам также может понравиться

- 23856411-fe5b-4518-b333-2f0062013752Документ9 страниц23856411-fe5b-4518-b333-2f0062013752Arun VermaОценок пока нет

- Advances in Vehicle DesignДокумент187 страницAdvances in Vehicle Designsayed92% (13)

- Catia Tip No - Inc 006Документ3 страницыCatia Tip No - Inc 006AmolPagdalОценок пока нет

- Creating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFДокумент7 750 страницCreating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFAmolPagdal10% (10)

- Celebrity QuotesДокумент7 страницCelebrity QuotesAmolPagdalОценок пока нет

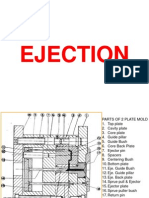

- Basic Mold Concept PDFДокумент68 страницBasic Mold Concept PDFAmolPagdalОценок пока нет

- Wireframe and Surface Catia TutorialДокумент105 страницWireframe and Surface Catia TutorialSunita SinghОценок пока нет

- BIW Design PDFДокумент17 страницBIW Design PDFAmolPagdalОценок пока нет

- Racing Sports Car Chassis Design - 0837602963Документ167 страницRacing Sports Car Chassis Design - 0837602963dineshtej7768100% (23)

- Links in CatiaДокумент8 страницLinks in CatiaAmolPagdalОценок пока нет

- Catia SymbolsДокумент9 страницCatia SymbolsAmolPagdalОценок пока нет

- Catia Tip No - Inc 0005Документ3 страницыCatia Tip No - Inc 0005AmolPagdalОценок пока нет

- Pa12 PDFДокумент2 страницыPa12 PDFAmolPagdalОценок пока нет

- Basic Mold ConceptДокумент30 страницBasic Mold ConceptAmolPagdalОценок пока нет

- Concept Testing & Product Architecture PDFДокумент37 страницConcept Testing & Product Architecture PDFcadcam010% (1)

- Brian Tracy The Power of ClarityДокумент72 страницыBrian Tracy The Power of ClarityBiblioteca_Virtual100% (3)

- Automotive Interior Solutions Optimised Performance and Surface AestheticsДокумент16 страницAutomotive Interior Solutions Optimised Performance and Surface AestheticsAmolPagdal100% (1)

- PBT - The Plastic MaterialДокумент2 страницыPBT - The Plastic MaterialAmolPagdalОценок пока нет

- Johnson Controls Casestudy en LRДокумент2 страницыJohnson Controls Casestudy en LRAmolPagdalОценок пока нет

- Volvo ApqpДокумент30 страницVolvo ApqpAmolPagdalОценок пока нет

- My 12th Biology Project 2015-16Документ12 страницMy 12th Biology Project 2015-16AmolPagdalОценок пока нет

- Intro ToAPQP WebinarДокумент130 страницIntro ToAPQP Webinaraorto3919Оценок пока нет

- BASF Snap Fit Design GuideДокумент24 страницыBASF Snap Fit Design GuidewantamanualОценок пока нет

- Eaton ApqpДокумент142 страницыEaton ApqpAmolPagdalОценок пока нет

- Bubble SensingДокумент16 страницBubble SensingAmolPagdalОценок пока нет

- Brain Bee Info BookletДокумент60 страницBrain Bee Info Bookletjon1262Оценок пока нет

- Design Process For PlasticДокумент43 страницыDesign Process For PlasticAmolPagdalОценок пока нет

- Green Planet Store ManagementДокумент2 страницыGreen Planet Store ManagementAmolPagdalОценок пока нет

- K EjectionДокумент21 страницаK EjectionAmolPagdalОценок пока нет

- Dont Know What To Say PDFДокумент6 страницDont Know What To Say PDFAmolPagdalОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Graduation Commencement Speech You Will Never HearДокумент4 страницыThe Graduation Commencement Speech You Will Never HearBernie Lutchman Jr.Оценок пока нет

- The Invisible Hero Final TNДокумент8 страницThe Invisible Hero Final TNKatherine ShenОценок пока нет

- Estwani ISO CodesДокумент9 страницEstwani ISO Codesनिपुण कुमारОценок пока нет

- 01 Design of Flexible Pavement Using Coir GeotextilesДокумент126 страниц01 Design of Flexible Pavement Using Coir GeotextilesSreeja Sadanandan100% (1)

- Brooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFДокумент36 страницBrooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFlois.guzman538100% (12)

- Practical LPM-122Документ31 страницаPractical LPM-122anon_251667476Оценок пока нет

- Obat LasaДокумент3 страницыObat Lasaibnunanda29Оценок пока нет

- Ilham Bahasa InggrisДокумент12 страницIlham Bahasa Inggrisilhamwicaksono835Оценок пока нет

- Brochure - Truemax Concrete Pump Truck Mounted TP25M4Документ16 страницBrochure - Truemax Concrete Pump Truck Mounted TP25M4RizkiRamadhanОценок пока нет

- Oracle Fusion Financials Book Set Home Page SummaryДокумент274 страницыOracle Fusion Financials Book Set Home Page SummaryAbhishek Agrawal100% (1)

- Intec Waste PresiДокумент8 страницIntec Waste Presiapi-369931794Оценок пока нет

- EG-45-105 Material Information Sheet (Textura) V2Документ4 страницыEG-45-105 Material Information Sheet (Textura) V2GPRОценок пока нет

- Long Run Average Cost (LRAC) : Economies of ScaleДокумент3 страницыLong Run Average Cost (LRAC) : Economies of ScaleA PОценок пока нет

- Module 4-Answer KeyДокумент100 страницModule 4-Answer KeyAna Marie Suganob82% (22)

- Rakpoxy 150 HB PrimerДокумент1 страницаRakpoxy 150 HB Primernate anantathatОценок пока нет

- Tupperware India's Perception StudyДокумент10 страницTupperware India's Perception StudyAnmol RahangdaleОценок пока нет

- 3.2 Probability DistributionДокумент38 страниц3.2 Probability Distributionyouservezeropurpose113Оценок пока нет

- Maximizing modular learning opportunities through innovation and collaborationДокумент2 страницыMaximizing modular learning opportunities through innovation and collaborationNIMFA SEPARAОценок пока нет

- MKT-case StudyДокумент7 страницMKT-case StudyJoe Thampi KuruppumadhomОценок пока нет

- Linguistics: Chapter 1 - 10Документ41 страницаLinguistics: Chapter 1 - 10Ahmad A. JawadОценок пока нет

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Документ28 страницMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palОценок пока нет

- Euro4 vehicle diesel engines 199 - 397 kW (270 - 540 hpДокумент6 страницEuro4 vehicle diesel engines 199 - 397 kW (270 - 540 hpBranislava Savic63% (16)

- Legal Principles and The Limits of The Law Raz PDFДокумент33 страницыLegal Principles and The Limits of The Law Raz PDFlpakgpwj100% (2)

- Universal Robina Co. & Bdo Unibank Inc.: Research PaperДокумент25 страницUniversal Robina Co. & Bdo Unibank Inc.: Research PaperSariephine Grace ArasОценок пока нет

- Exam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023Документ285 страницExam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023maniОценок пока нет

- Write 10 Lines On My Favourite Subject EnglishДокумент1 страницаWrite 10 Lines On My Favourite Subject EnglishIrene ThebestОценок пока нет

- Ogl422 Milestone Three Team 11 Intro Training Session For Evergreen MGT Audion Recording Due 2022apr18 8 30 PM PST 11 30pm EstДокумент14 страницOgl422 Milestone Three Team 11 Intro Training Session For Evergreen MGT Audion Recording Due 2022apr18 8 30 PM PST 11 30pm Estapi-624721629Оценок пока нет

- AIATS 2021 (OYMCF) Test 01 Offline - Code A - SolutionsДокумент34 страницыAIATS 2021 (OYMCF) Test 01 Offline - Code A - Solutionsbhavyakavya mehta100% (1)

- Electrophoresis and Fractionation of Wheat GlutenДокумент14 страницElectrophoresis and Fractionation of Wheat GlutensecucaОценок пока нет