Академический Документы

Профессиональный Документы

Культура Документы

Presentation Lundi02122013

Загружено:

Jose UrendaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Presentation Lundi02122013

Загружено:

Jose UrendaАвторское право:

Доступные форматы

Presentation

Controls and hygiene associated with yoghurt Today we will talk about stages of the process for the production of yogurt. I'm going to talk about Controls and hygiene associated with yoghurt, i'm going to divide this talk into 3 parts; in the first part we'll talk about -livestock nutrition- this by submitting a video, in the second part we'll take of the factory, in this part we will explain step by step process and in the last part we'll sepeak to quality control tests. During this talk, do not hesitate to stop me for answer your questions, also tell them that your table will find a folder with blank pages and a pen, as it is very important to take note of this talk. Well, let's begin! To start this presentation is very important that hygiene instruction are followed, in order to enter the production area. Let's begin with a video that shows the care taken in the diet of the cows. As you can see, there are veterinarians specialized in livestock nutrition. Now let's begin our journey, for it is very important that your safety boots are put, because it is an area of control. Let's go! As you can see it's the first stage MILK RECEPTION. In this area the product is received directly from the cows

and the milk is alamcenada in these tanks that are regulated at a temperature of 4 C. Here we proceed to perform the first tests of quality, we help define whether the product can be processed. The quality tests performed are: acidity, fat, protein and alcohol testing. Once the results are in accordance with European standards, we continue with the next step of the process. Do you have any questions? The following process is PASTEURIZATION. This process is carried out on this machine, as you can see it is very large and can pasteurize 500 liters per minute. Here is very important to microbiological quality tests to see if we have done the process correctly, and it is also very important to control temperature, flow and time. To next is Skimming, In this process, two products are obtained: skimmed milk and cream. Then proceed to homogenize these two products with milk protein, thereby standardizing the fat content. We now turn to pasteurize the mixture obtained, Note that the cooling in this step is 45 C, as the next step requires that temperature. Do you have any questions?... Do not hesitate to let me know your questions! Continuing the process, we have the next step which is seeding fermants,

In this step, the bacteria were inoculated, in order to acidify the product. Here one of the most important quality testing is acidic, because we must reach 90 Dornic acidity. The next step is the maturation tank, here we come every 30 minutes to measure the acidity of the product, we stop to measure once you have reached 90 D. We now turn to the next step which is: brewing and cooling, in this step is stirred and cooled to stop bacterial growth and continue with the following process which is conditioning. In this step we add fruit, which will give it flavor, once this is done, was the packaging and labeling of the final product, as you can see on this machine, packaged 1500 containers per minute. Do you have any questions?... Now we move to the next area, where we will see the last two stages of the process This is the stage of cooling and storage of the final product, the product is kept at a temperature of 4 , for better conservation. Now we go to the last stage: And here is the last stage: shipping yogurt... as you can see, we have delivery trucks, with them deliver product in over 5000 stores in the country. Here ends the tour of the production process, we now turn to the audience to discuss our last topic "quality testing".

Well, sit down please! The quality tests are very important from the beginning of the process until the end, because they depend upon for the satisfaction of consumers. The quality tests can be divided into: rapid tests and specific tests. Rapid tests are those that help to accept or reject the product, as tests of fat, acidity, protein and alcohol testing and specific tests, help me to determine the bacterial growth, the description of the final product, etcetera. If you would like me to elaborate on any point I've made today, please ask. It just remains for me to say, thank you very much for coming and I hope you have found this presentation useful .

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Bba ProjectДокумент66 страницBba ProjectRakesh AОценок пока нет

- MBCT PresentationДокумент55 страницMBCT Presentationapi-548853432Оценок пока нет

- Pulpectomy ProceduresДокумент3 страницыPulpectomy ProceduresITS DENTAL COLLEGE Greater NoidaОценок пока нет

- Whohgnwg85 10 PDFДокумент34 страницыWhohgnwg85 10 PDFbabyОценок пока нет

- Coach Others in Job SkillsДокумент18 страницCoach Others in Job SkillsmeleseОценок пока нет

- Daily Report JuneДокумент116 страницDaily Report JuneEka RahmayantiОценок пока нет

- Rad UnitsДокумент1 страницаRad Unitsmuayad73Оценок пока нет

- FORMS Reseta and All Forms 2022 PDFДокумент16 страницFORMS Reseta and All Forms 2022 PDFJessa MaeОценок пока нет

- Sousa Chapter 8Документ2 страницыSousa Chapter 8api-458167181Оценок пока нет

- Shahad 4Документ15 страницShahad 4Mohammed OmarОценок пока нет

- TIKTOKДокумент10 страницTIKTOKLenny FebryanaОценок пока нет

- Oils and FatsДокумент3 страницыOils and FatstanuОценок пока нет

- Latihan Soal Bahasa Inggris Sma HortatorДокумент6 страницLatihan Soal Bahasa Inggris Sma HortatorErna TemkonОценок пока нет

- Sleep Paralysis Reading ComprehensionДокумент4 страницыSleep Paralysis Reading ComprehensionAssylbek SyssenovОценок пока нет

- 22954017: Clinical Practice Guidelines For Hypothyroidism in Adults Cosponsored by The American Association of Clinical Endocrinologists and The American Thyroid AssociationДокумент54 страницы22954017: Clinical Practice Guidelines For Hypothyroidism in Adults Cosponsored by The American Association of Clinical Endocrinologists and The American Thyroid AssociationUpendra PoudelОценок пока нет

- GRASPSДокумент3 страницыGRASPSESTRELLA RAGAYОценок пока нет

- Dentistry Journal: Adhesion of Two New Glass Fiber Post Systems Cemented With Self-Adhesive Resin CementsДокумент8 страницDentistry Journal: Adhesion of Two New Glass Fiber Post Systems Cemented With Self-Adhesive Resin CementsDeisy Angarita FlorezОценок пока нет

- RP - Training Volume LandmarksДокумент6 страницRP - Training Volume LandmarksКонстантин Иванов100% (1)

- The Arts Refers To The Theory, Human Application and PhysicalДокумент2 страницыThe Arts Refers To The Theory, Human Application and PhysicalLyle PaduaОценок пока нет

- UTS English Script S1 KEP 3BДокумент17 страницUTS English Script S1 KEP 3BNadia ASОценок пока нет

- Paper - Agricultural Research, Technology and Nutrition in Sub-Saharan Africa (Gaiha, 2018)Документ64 страницыPaper - Agricultural Research, Technology and Nutrition in Sub-Saharan Africa (Gaiha, 2018)handoutОценок пока нет

- PR 3Документ23 страницыPR 3Jaylanie MabagaОценок пока нет

- Unit 1 Life Skills: 1.0 ObjectivesДокумент30 страницUnit 1 Life Skills: 1.0 ObjectivesSenaieTibebuОценок пока нет

- Material Safety Data Sheet: Hayem's SolutionДокумент7 страницMaterial Safety Data Sheet: Hayem's SolutionCherie DenielleОценок пока нет

- Learning Feedback Diary: Name of Student Year and Section Name of Instructor Date SubmittedДокумент2 страницыLearning Feedback Diary: Name of Student Year and Section Name of Instructor Date SubmittedSheima Ainie Juripae100% (1)

- Dentist Motivational LetterДокумент2 страницыDentist Motivational Letteranesu mabviraОценок пока нет

- How It Is Done?: Prepared By: Prof. MARIA LUISA ELMA-BARRETTOДокумент21 страницаHow It Is Done?: Prepared By: Prof. MARIA LUISA ELMA-BARRETTOPaul Gabriel CasquejoОценок пока нет

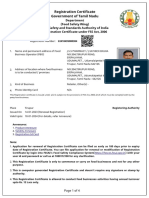

- Registration Certificate Government of Tamil NaduДокумент4 страницыRegistration Certificate Government of Tamil NaduSanthosh DHAYANITHIОценок пока нет

- OSCE Revision Session: Jacob Watts and Maha KashifДокумент41 страницаOSCE Revision Session: Jacob Watts and Maha KashifSweeta GОценок пока нет

- FSSAI Recruitment 2021: 500+ Junior Assistant, Assistant, AM and Other PostsДокумент1 страницаFSSAI Recruitment 2021: 500+ Junior Assistant, Assistant, AM and Other PostsRajesh K KumarОценок пока нет