Академический Документы

Профессиональный Документы

Культура Документы

Annexure 1

Загружено:

RussiaLeaksИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Annexure 1

Загружено:

RussiaLeaksАвторское право:

Доступные форматы

ANNEXURE-1 Page 1 of 3

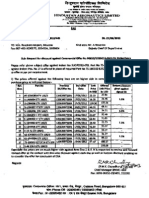

Preliminary observations on Failure of parts of cooling Turbine of Su30MKI aircraft

Recently, SU30 MKI aircraft has developed engine problem due to failure of cooling turbines (Part nos. 3314). These cooling turbines have been sent to HAL, Lucknow for defect investigation. The investigation has revealed the damage of bearings, shaft and Fan (Ventilator) blades of cooling turbines. Subsequent investigation at Air Force base has revealed not only the damage of compressor blades of LH engines caused by the broken blades of fan of cooling turbine but also rupture of oil charging pipe at charging plug of the cooling turbine (Part no. 3314). The damaged parts such as fans, bearings, shafts, charging pipe of the turbo coolers have been received at DMRL for detailed failure investigation to identify causes of failure of these parts. The results of failure investigation of turbo cooler fan (Part no. 3314) are presented in this report. Ventlator/fan: The photograph of the damaged turbo cooler fan/ventilator is shown in Fig.1. It can be seen from Fig. 1 that all the five blades of the fan have broken at the root and blade pieces are found missing. It has been informed that the fan along with its five blades was fabricated from the same block of the alloy by machining. Fracture surfaces of the blade roots on the fan base were marked with numbers 1 to 5 for identification (Fig. 1). The magnified view of the region of the fan base between the blades, as illustrated in Fig. 2, reveal a pattern of deep markings almost parallel to fan blades.

Blade route 1 Blade route 2

Deep markings

Blade root

Fig. 1

Blade route 5

Fig. 2

Blade route 3

Blade route 4

Fracture surface of all five blade roots were examined using scanning electron microscopy. The five blade roots are henceforth referred to as BR1, BR2, BR3, BR4 and BR5. Figures 3 and 4 show fracture features recorded in case of blade rootsBR1

ANNEXURE-1 Page 2 of 3

and BR2, respectively. Figure 3a and 4a show the cracks along deep marks on the fan base next to blade roots. Thumb nail as well as beach marks, typical of fatigue fracture, observed on one side of the fracture surface of blade roots BR1 and BR2 are shown in Fig. 3 (b) and 4 (b), respectively. Fig.5 shows fatigue striations confirming that crack has propagated by Fatigue.

3a

4a

Fig. 3

Fig. 4

4b 3b

Fig. 5

ANNEXURE-1 Page 3 of 3

The fracture surfaces of BR3, BR4 and BR5 have shown over load fracture features. Microstrctural examination essentially showing colony structure of transformed with coarse prior grain size as well as coarse colony size. SEM micrographs revealed that the transformed structure consists of alternate lamellae (grey in contrast) and (white in contrast) phase. Also, laths are very coarse. The fracture of blades BR1 and BR2 has occurred by initiation and propagation of fatigue cracks. The fracture features such as thumb nail and beach marks at lower magnification and striations at higher magnification clearly indicate this proposition. In these two blades, after propagation of fatigue crack to a considerable extent the remaining ligament failed by overload. Also, multiple fatigue cracks have been found to initiate and propagate in these cases. The important observation is that these fatigue cracks have been found to initiate from the deep markings existing on the fan base.. On the other hand, the predominant overload fracture features in case blade BR3, BR4 and BR5 suggest that both these blades failed essentially by overload.

Oil changing pipe: The rupture of oil charging pipe at charging plug of the cooling turbine has shown overload fracture features and the features are covered by oxide layer. Based on these preliminary investigation and thus obtained metallurgical observations, it may be stated that the series of events that lead to failure of turbo cooler components and in turn the damage of compressor blades are as follows. First, the premature fatigue failure of a few fan blades has occurred due to deep surface marks (probably machine marks) combined with coarse microstructure features of the fan alloy (i.e., transformed structure as well as coarse grain size and colony size ). The fracture of these two blades might have created fracture of the remaining 3 blades which might have resulted in dynamic imbalance in the turbo cooler section leading to the failure of the oil changing pipe and bearings and the shaft.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- DMA December 09, 2013Документ52 страницыDMA December 09, 2013RussiaLeaksОценок пока нет

- DMA December 12, 2013Документ44 страницыDMA December 12, 2013RussiaLeaksОценок пока нет

- DMA December 12, 2013Документ44 страницыDMA December 12, 2013RussiaLeaksОценок пока нет

- DMA December 12, 2013Документ44 страницыDMA December 12, 2013RussiaLeaksОценок пока нет

- DMA December 09, 2013Документ52 страницыDMA December 09, 2013RussiaLeaksОценок пока нет

- Dispatch Contract 1261Документ1 страницаDispatch Contract 1261RussiaLeaksОценок пока нет

- DMA December 09, 2013Документ52 страницыDMA December 09, 2013RussiaLeaksОценок пока нет

- Department - 3907Документ8 страницDepartment - 3907RussiaLeaksОценок пока нет

- Critical Issues 27.01.14Документ6 страницCritical Issues 27.01.14RussiaLeaksОценок пока нет

- Details of ReceiptsДокумент4 страницыDetails of ReceiptsRussiaLeaksОценок пока нет

- Department 1125Документ4 страницыDepartment 1125RussiaLeaksОценок пока нет

- Department 3907Документ12 страницDepartment 3907RussiaLeaksОценок пока нет

- Digambar Adhar BagulДокумент3 страницыDigambar Adhar BagulRussiaLeaksОценок пока нет

- Sukhoi Engine Division, Koraput 31 IRSA - DEPARTMENT: 0630/0631/0632/0633Документ3 страницыSukhoi Engine Division, Koraput 31 IRSA - DEPARTMENT: 0630/0631/0632/0633RussiaLeaksОценок пока нет

- Department 1124Документ3 страницыDepartment 1124RussiaLeaksОценок пока нет

- Ê Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷Документ3 страницыÊ Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷RussiaLeaksОценок пока нет

- Deepak Budha SuryawanshiiДокумент3 страницыDeepak Budha SuryawanshiiRussiaLeaksОценок пока нет

- Critical Issues-1 30.12.13Документ5 страницCritical Issues-1 30.12.13RussiaLeaksОценок пока нет

- Critical PartsДокумент6 страницCritical PartsRussiaLeaksОценок пока нет

- Covering LetterДокумент1 страницаCovering LetterRussiaLeaksОценок пока нет

- Critical IssuesДокумент6 страницCritical IssuesRussiaLeaksОценок пока нет

- Ê Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷Документ3 страницыÊ Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷RussiaLeaksОценок пока нет

- Critical Issues As On 17th Dec 2013Документ2 страницыCritical Issues As On 17th Dec 2013RussiaLeaksОценок пока нет

- Comments On CO of JSC ROEДокумент1 страницаComments On CO of JSC ROERussiaLeaksОценок пока нет

- Comments On CO of JSC ROEДокумент1 страницаComments On CO of JSC ROERussiaLeaksОценок пока нет

- Coorrected - Consent Letter From JV PartnersДокумент1 страницаCoorrected - Consent Letter From JV PartnersRussiaLeaksОценок пока нет

- Corst JensДокумент2 страницыCorst JensRussiaLeaksОценок пока нет

- Contract 67 CorrectДокумент1 страницаContract 67 CorrectRussiaLeaksОценок пока нет

- Comments On CO of JSC ROEДокумент1 страницаComments On CO of JSC ROERussiaLeaksОценок пока нет

- Comments On CO of JSC ROEДокумент1 страницаComments On CO of JSC ROERussiaLeaksОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Chilled Water Systems Rev2 PDFДокумент31 страницаChilled Water Systems Rev2 PDF123john123100% (1)

- Catalogo Bray 1Документ16 страницCatalogo Bray 1Luciano CarvalhoОценок пока нет

- Plate 2 Lecture 2Документ4 страницыPlate 2 Lecture 2Hunter BravoОценок пока нет

- Limit State Design of Steel Members To AS4100Документ20 страницLimit State Design of Steel Members To AS4100Sam ThomasОценок пока нет

- Highway SpecificationДокумент85 страницHighway SpecificationAkaninyeneОценок пока нет

- LN 9 FormworkДокумент26 страницLN 9 FormworkFaiz HarisОценок пока нет

- Ale Part 2 Answer KeyДокумент27 страницAle Part 2 Answer KeyTimothy Ryan Wang100% (2)

- BS en 13391 2004Документ24 страницыBS en 13391 2004Ronaldo AlmeidaОценок пока нет

- L-1, T-2, IPE, 2018-2019 (Online)Документ14 страницL-1, T-2, IPE, 2018-2019 (Online)Nazmus Sakib TntОценок пока нет

- Impact of Glass Facades On Internal Environment of Buildings in Hot Arid ZoneДокумент13 страницImpact of Glass Facades On Internal Environment of Buildings in Hot Arid ZoneMohamed FajarОценок пока нет

- Elastic Properties of Materials Elastic Properties of MaterialsДокумент32 страницыElastic Properties of Materials Elastic Properties of MaterialsCHRISTOPHER TEBIT SEMBIОценок пока нет

- Presentation On Summer InternshipДокумент19 страницPresentation On Summer InternshipBadal NayakОценок пока нет

- Masonry Blocks: ProductsДокумент5 страницMasonry Blocks: ProductsErnest NavarroОценок пока нет

- STW Stilling WellДокумент2 страницыSTW Stilling WellROGELIO QUIJANOОценок пока нет

- HW #7Документ8 страницHW #7Jigoku KuroakaОценок пока нет

- Truss BridgeДокумент23 страницыTruss BridgeEdi YantoОценок пока нет

- STUD ADHESIVE BONDED M10x50mm PDFДокумент61 страницаSTUD ADHESIVE BONDED M10x50mm PDFEd2sverissimoОценок пока нет

- Astm E716-94 PDFДокумент5 страницAstm E716-94 PDFRaúl100% (1)

- Bam F-Hvac - 001Документ117 страницBam F-Hvac - 001Claudino Gonçalves100% (1)

- 675 - Alcat Rfi 12597429Документ6 страниц675 - Alcat Rfi 12597429AntonОценок пока нет

- Microstructure and Mechanical Properties of A 5754 Aluminum Alloy Modified by SC and ZR AdditionsДокумент9 страницMicrostructure and Mechanical Properties of A 5754 Aluminum Alloy Modified by SC and ZR Additionshamdast64Оценок пока нет

- AgriculturalДокумент16 страницAgriculturalkafi1234Оценок пока нет

- Wa0082 PDFДокумент34 страницыWa0082 PDFmiteshОценок пока нет

- APT Catalogo 2018Документ48 страницAPT Catalogo 2018Vesna NikolicОценок пока нет

- West Beverly Homes-BoqДокумент6 страницWest Beverly Homes-BoqERICОценок пока нет

- Viscoplastic Model LS-DynaДокумент14 страницViscoplastic Model LS-DynaJoe SatchОценок пока нет

- Refrigerated Gas Plant Hysys SimulationДокумент6 страницRefrigerated Gas Plant Hysys SimulationOsas UwoghirenОценок пока нет

- LIGHTNING PROTECTION - Specification PDFДокумент5 страницLIGHTNING PROTECTION - Specification PDFRamadan El-FakahanyОценок пока нет

- Pipes and Tubes - Recommended Insulation Thickness PDFДокумент4 страницыPipes and Tubes - Recommended Insulation Thickness PDFSandi ApriandiОценок пока нет

- IndexДокумент49 страницIndexImelda SitumorangОценок пока нет