Академический Документы

Профессиональный Документы

Культура Документы

Thermal Analysis

Загружено:

Mathew JohnАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Thermal Analysis

Загружено:

Mathew JohnАвторское право:

Доступные форматы

International Journal of Advanced Engineering Research and Studies

E-ISSN22498974

Research Paper

THERMAL ANALYSIS OF A PISTON OF RECIPROCATING AIR COMPRESSOR

Bhaumik Patel1, Ashwin Bhabhor2

PG Student, ME Thermal,2Asst. Prof, Mechanical Engg.L.D.R.P Institute of Technology and Research, Gandhinagar, Gujarat Technological University, Ahmedabad India ABSTRACT

In this study, the wok is carried out to measure the distribution of the temperature on the top surface of the piston. which predicts that due to temperature weather the top surface of the piston may be going to damaged or broken during the operating conditions because damaged or broken parts are so expensive to replace and generally are not easily available. So it is possible to recover the damage or broken parts due to thermal analysis before taking into operations. It can be seen from that the prescribed operating temperature inside the cylinder penetrates the piston crown through nearly 75 % of its thickness before piston ring dissipates some of heat. KEYWORDS Piston, Boundary conditions, Thermal analysis, ANSYS.

Address for Correspondence

1. INTRODUCTION: It is important to calculate the piston temperature distribution in order to reduce the thermal stresses and deformations within acceptable levels. The temperature distribution enables us to optimize the thermal aspects of the piston design at lower cost, before the first prototype is constructed. As much as 60% of the total engine mechanical power lost is generated by piston ring assembly. Most of the pistons are made of an aluminum alloy which has thermal expansion coefficient, 80% higher than the cylinder bore material made of cast iron. This leads to some differences between running and the design clearances. Therefore, analysis of the piston thermal behavior is extremely crucial in designing more efficient compressor.[5] Damage and broken parts are so expensive to replace and generally are not easily available. So to avoid this problem it needs design of a new part, copy of an existing part, recovery of a damaged or broken part, improvement of model precision and inspection of numerical model.[2] The main requirement of a piston is a good sealing of the cylinder. The Second is that the weight of the piston and the entire crank mechanism is a minimum, particularly for high speed machines, in order to reduce the inertia force and to improve the mechanical efficiency. In horizontal machines a small piston weight reduces the risk of its seizing. To allow for thermal expansion, the diameter of the piston must be smaller than that of the cylinder. The necessary clearance is calculated by estimating the temperature difference between piston and cylinder and considering the coefficient of thermal expansion of piston.[3] 2. TEMPERATURES IN PISTON: The strong periodic fluctuations of temperature in a cylinder cause temperatures to vary in the upper most layer of the piston crown. A large part of the heat absorbed by the piston crown during the expansion stroke is released to the coolant by the piston ring zone and by the cylinder wall. The amplitudes of these fluctuations have magnitude of about 10-400 C on the surface and subside inwardly within a few millimeters according to exponential function. [4] A large part of the heat absorbed by the piston crown during the expansion stroke is released to the coolant by the piston ring zone and by the cylinder wall. IJAERS/Vol. I/ Issue III/April-June, 2012/73-75

Depending on the design of the engine and the piston and influenced by the operating mode and the piston velocity, between 20 and 60% of the amount of heat that accumulates in a piston crown is primarily released by the piston rings. A small portion of the heat is transferred to the fresh gas during gas exchange. The lubricating and cooling oil that reaches a pistons inner wall absorbs the rest of the dissipated heat. 3. MATERIAL OF PISTON: Piston should be made of a material with good friction properties, of high strength, and capable of producing good casting having good machining properties. The requirement of small thermal expansion is also important for high gas temperature, where good thermal conductivity is also desirable. The advantage of aluminum alloy piston is that they do not damage the cylinder in case of jamming. [3] Piston aluminum alloys are a special group of industrial aluminum alloys, which have high mechanical properties at elevated temperatures (approximately up to 3500C). Simultaneously, these alloys are resistant to sudden temperature changes. Due to this, in the design of this type of alloys, their mechanical and thermal strains have to be critically considered without ignoring their environment aggressiveness during exploitation. [1] 4. PISTON DESIGN Main Piston Dimensions A Pistons functional elements include the piston crown, ring zone, piston land, piston pin and skirt. The main piston dimensions are closely interrelated to the main engine dimensions and the dimensions of the other components. The compression height which i.e. the distance between the center of the pin and the upper edge of the piston top land which is the main piston dimension other than cylinder diameter. Also mass of piston plays a major role in high speed compressor. 5. DESIGN DATA OF COMPRESSOR: Power Capacity : 5 H.P Speed : 1440 R.P.M Piston Displacement : 500 LPM Atmospheric Pressure : 1.01325 bar Working Pressure : 10 bar Temperature on top surface of Piston : 81.970 C

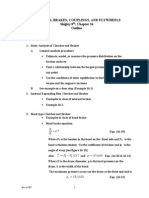

International Journal of Advanced Engineering Research and Studies The above data is taken for the design of piston through which various geometries of the piston can be found out which are mentioned below. The material of the piston is Aluminum alloy 6061. Total Length of Piston : 77.91 mm Diameter of Piston : 100 mm Thickness of Head or Crown : 6 mm Axial thickness of Piston Ring : 6 mm Width of other ring land : 4.5mm Length of Skirt : 31.41mm Length of Ring Section : 32 mm Fig.1 shows the solid model of the piston under study. This model is generated by Creo Elements which is the new version of PRO-E WILDFIRE 5.0.

E-ISSN22498974

piston thermal deformation has an important role in piston skirt design which has a potential to reduce friction and piston slap [5]. It is generally assumed for the piston temperature to remain constant throughout a working cycle and not dependent on operating states. In this design the thermal stresses must be considered indicating the importance of piston thermal analysis. Fig.3 and Fig. 4 shows the heat transfer coefficient for the piston at different positions.

Fig.3 Thermal boundary condition for Piston Head Fig.1 Piston solid model generated by CreoElements The above model is meshed using standard mechancial shape cheking in ANSYS workbench using 78058 nodes and 45534 elements. A mesh convergence analysis showed that this level of mesh refinement is adequate to perform both the static and thermal analysis of the model.

Fig.2 Meshing in ANSYS of the Piston Advantages of Thermal analysis It gives prediction of Components characteristics such as dynamics and friction It predicts the defects in the components in the particular area. It gives capacity to resists the temperature. Amount of heat transfer can be find out. It is also used to measure temperature distibution. Development cost can be reduced. Distortions of the shape can also be minimized. 7. Boundary Conditions for thermal analysis The thermal analysis of piston is important from different perspectives. First, the highest temperature of any point in piston must not exceed more than 66% of the melting point temperature of the alloy. This limit temperature for the current engine piston alloy is about 640 K. Temperature distribution leads to thermal deformations and thermal stresses. The 6. IJAERS/Vol. I/ Issue III/April-June, 2012/73-75

Fig.4 Thermal Boundary Condition for Piston Length 8. RESULTS AND DISCUSSIONS Fig. 5 shows the temperature distribution within piston below. It can be seen from Fig.5 that the prescribed operating temperature inside the cylinder penetrates the piston crown through nearly 75 % of its thickness before piston ring dissipates some of heat. The average piston temperature beneath the piston ring is about 650C.

Fig. 5 Temperature Profile Distribution of the Piston. Fig. 6 shows the total heat flux flows on the top surface of the piston as well as from side of the piston length. It can be seen from the Fig. 6 that from the top surface of the piston 0.33223 to 0.41528 W/mm2 amount of heat transfer.

International Journal of Advanced Engineering Research and Studies

E-ISSN22498974

Fig. 6 Total Heat Flux Transfer Fig. 7 shows that the material of the piston will work well under the prescribed operating conditions and the design is safe to resist the pressure of 10 bar or 10 Mpa.

Fig. 7 Shear Stress Distribution 9. CONCLUSION The results of this study show that the stresses which are produced during the operations are less than the design stress. Also the distribution of the temperature is in prescribed limit. The average piston temperature beneath the piston ring is about 650C. so the design is safe to resists specified temperature and pressure. REFERENCES:

1. Srecko Manasijevic, Radomir Radisa, Srdjan Markovic, Zagorka Acimovic-Pavlovic , Karlo Raic, Thermal analysis and microscopic characterization of the piston alloy AlSi13Cu4Ni2Mg, Intermetallics 19 (2011) 486 492. 2. Gudimetal P, Gopinath C.V, Finite Element analysis of Reverse Engineered Internal Combustion Engine Piston, AIJSTPME (2009) 2(4): 85-92. 3. Vladimir Chlumsky, Reciprocating and Rotary Compressor. 4. Klaus Mollenhauer, Helmut Tschoeke, Handbook of Diesel Engines. 5. Esfahanian, A. Javaheri, M. Ghaffarpour, Thermal analysis of an SI engine piston using different combustion boundary condition treatments, Applied Thermal Engineering 26 (2006) 277287.

IJAERS/Vol. I/ Issue III/April-June, 2012/73-75

Вам также может понравиться

- Multiphase Flow in Polymer ProcessingОт EverandMultiphase Flow in Polymer ProcessingChang HanРейтинг: 1 из 5 звезд1/5 (1)

- Theoretical Analysis of Stress and Design of Piston Head Using CATIA & ANSYSДокумент10 страницTheoretical Analysis of Stress and Design of Piston Head Using CATIA & ANSYSinventionjournalsОценок пока нет

- Impact of Fixture Design On Sheet Metal Assembly VariationДокумент12 страницImpact of Fixture Design On Sheet Metal Assembly VariationSaran CoolОценок пока нет

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationОт EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationОценок пока нет

- International Status of Thermal Error Research (1990) : Ca/UsaДокумент12 страницInternational Status of Thermal Error Research (1990) : Ca/UsaNITHIN REDDYОценок пока нет

- Thermo Coupled Stress Analysis of Exhaust Manifold Assemblage Using ABAQUSДокумент6 страницThermo Coupled Stress Analysis of Exhaust Manifold Assemblage Using ABAQUSInfogain publicationОценок пока нет

- Connecting RodДокумент57 страницConnecting RodNaveenprakashОценок пока нет

- Guide to Anodizing Aluminum and Dyeing ProcessДокумент11 страницGuide to Anodizing Aluminum and Dyeing ProcessG Sathesh KumarОценок пока нет

- Sheet Lamination Additive ManufacturingДокумент2 страницыSheet Lamination Additive ManufacturingYeabsraОценок пока нет

- Study For Design of Magneto Rheological DamperДокумент8 страницStudy For Design of Magneto Rheological DamperAnonymous lPvvgiQjRОценок пока нет

- PISTONДокумент53 страницыPISTONJPPL CHENNAIОценок пока нет

- Introduction To Thermal Analysis Using MSC - ThermalДокумент356 страницIntroduction To Thermal Analysis Using MSC - ThermalSimulation CAEОценок пока нет

- Convection Heat Transfer Coefficient PDFДокумент40 страницConvection Heat Transfer Coefficient PDFzeeshanОценок пока нет

- A Method To Simulate The MR Fluid in ANSYSДокумент19 страницA Method To Simulate The MR Fluid in ANSYSshreedharkolekarОценок пока нет

- Effects of Geometry and Processing On The Blow Molding Pinch-OffДокумент9 страницEffects of Geometry and Processing On The Blow Molding Pinch-OffmanuelОценок пока нет

- 2007 Final ExamДокумент10 страниц2007 Final ExamnikobelookОценок пока нет

- Design and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With IsopolymerДокумент30 страницDesign and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With Isopolymershakeel100% (1)

- Modelling and Analysis of IC Engine Pistons Using FEMДокумент93 страницыModelling and Analysis of IC Engine Pistons Using FEMSuresh Yadav100% (2)

- Manufacturing LectureДокумент44 страницыManufacturing Lecturemohtram1037Оценок пока нет

- 1 Selection of Heat Treatment and Aluminizing Sequence For Rene 77 SuperalloyДокумент4 страницы1 Selection of Heat Treatment and Aluminizing Sequence For Rene 77 SuperalloyEnary SalernoОценок пока нет

- New Microsoft Office Word DocumentДокумент55 страницNew Microsoft Office Word Documentkarnabalu100% (2)

- Dynamic Load Analysis and Optimization of A Fracture-Split Connecting RodДокумент11 страницDynamic Load Analysis and Optimization of A Fracture-Split Connecting RodRahul BadgujarОценок пока нет

- A Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Документ20 страницA Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Ankur SemleОценок пока нет

- 0913HPC Lowres PDFДокумент84 страницы0913HPC Lowres PDFkazzam41Оценок пока нет

- 0011 Structural Design of A Composite Wind Turbine Blade Using FiniteДокумент8 страниц0011 Structural Design of A Composite Wind Turbine Blade Using FiniteKhalil DeghoumОценок пока нет

- Selecting a Material for an Aircraft WingДокумент4 страницыSelecting a Material for an Aircraft WingSabiha Karahasanović0% (1)

- IJERT-2015 Special Issue Structural Thermal Analysis Exhaust ManifoldДокумент4 страницыIJERT-2015 Special Issue Structural Thermal Analysis Exhaust ManifoldKarthikОценок пока нет

- Low Cycle Fatigue Analysis of Gas Turbine BladeДокумент6 страницLow Cycle Fatigue Analysis of Gas Turbine BladeKaushikОценок пока нет

- Thermal and Fluid Characteristics of Three-Layer Microchannels Heat SinksДокумент10 страницThermal and Fluid Characteristics of Three-Layer Microchannels Heat SinksjournalОценок пока нет

- 2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFДокумент14 страниц2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFCaio PaimОценок пока нет

- Magnetorheological Fluids and Its Application in Industrial Shock AbsorbersДокумент31 страницаMagnetorheological Fluids and Its Application in Industrial Shock AbsorbersNabeel AhamedОценок пока нет

- Design For Manufacturing and Assembly of A Connecting Rod 1362031980Документ7 страницDesign For Manufacturing and Assembly of A Connecting Rod 1362031980addayesudasОценок пока нет

- Fracture Analysis of Compact Tension SpecimenДокумент7 страницFracture Analysis of Compact Tension SpecimenIJORAT100% (1)

- Design and Analysis of Thick Walled Cylinders With HolesДокумент47 страницDesign and Analysis of Thick Walled Cylinders With HolesKeryn Pelled-FeldmanОценок пока нет

- Alternative Energy Emerging Technologies - Material Matters v5n4Документ32 страницыAlternative Energy Emerging Technologies - Material Matters v5n4Sigma-AldrichОценок пока нет

- Your Source For GD&T Training and MaterialsДокумент26 страницYour Source For GD&T Training and MaterialsGiridharPogalaGiridharPogalaОценок пока нет

- Automobile Noise and Vibration ReviewДокумент5 страницAutomobile Noise and Vibration ReviewIbrahim LotfyОценок пока нет

- Seminar on Friction Stir Welding: FSW Process, Parameters, ApplicationsДокумент26 страницSeminar on Friction Stir Welding: FSW Process, Parameters, ApplicationsDeepak Kaushal0% (1)

- Uncertainty Analysis of Thermocouple MeasurementsДокумент82 страницыUncertainty Analysis of Thermocouple MeasurementsgardenergardenerОценок пока нет

- Materials Selection For A Carbon Fibre FrameДокумент11 страницMaterials Selection For A Carbon Fibre FramePablo Jaramillo100% (1)

- Brittle Coatings PDFДокумент4 страницыBrittle Coatings PDFJagadeeswari SОценок пока нет

- Mechanical Engineering Subjects Full ListДокумент21 страницаMechanical Engineering Subjects Full Listabhigoyal1989Оценок пока нет

- Clutches and Brakes IntroДокумент42 страницыClutches and Brakes IntroJohnpaul VikyОценок пока нет

- Fabrication Hollow Fiber MembraneДокумент5 страницFabrication Hollow Fiber MembraneDodi AfandiОценок пока нет

- ADVANCED CARBON COMPOSITE MATERIALДокумент22 страницыADVANCED CARBON COMPOSITE MATERIALVince Carlo C GarciaОценок пока нет

- 1492Документ15 страниц1492_Anggyaa_Оценок пока нет

- Training Report For AltairДокумент4 страницыTraining Report For AltairRavi Teja KondetiОценок пока нет

- Finite Element Analysis Project ReportДокумент22 страницыFinite Element Analysis Project ReportsaurabhОценок пока нет

- Finite Element AnalysisДокумент219 страницFinite Element AnalysisRubenОценок пока нет

- Plastics: by Dr. V Phanindra Bogu Dept. of Mech. EnggДокумент18 страницPlastics: by Dr. V Phanindra Bogu Dept. of Mech. EnggV Phanindra BoguОценок пока нет

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenДокумент16 страницFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenОценок пока нет

- Technical Seminar ReportДокумент21 страницаTechnical Seminar ReportManoj MОценок пока нет

- Carbon Fibre Reinforced PlasticДокумент6 страницCarbon Fibre Reinforced PlasticMateus SpinelliОценок пока нет

- Friction Stir Welding GuideДокумент20 страницFriction Stir Welding GuideCebrac ItatibaОценок пока нет

- Unit 10 Properties and Applications of Engineering MaterialsДокумент12 страницUnit 10 Properties and Applications of Engineering MaterialsRavishanker Baliga0% (1)

- Piston - Hce First ReviewДокумент23 страницыPiston - Hce First ReviewLAKKANABOINA LAKSHMANARAOОценок пока нет

- 2007 - Thermal Analysis of A CeramicДокумент5 страниц2007 - Thermal Analysis of A CeramicekremОценок пока нет

- IJRPR6657Документ6 страницIJRPR6657edyОценок пока нет

- Optimizing IC Engine Exhaust Valve Design Using Finite Element AnalysisДокумент5 страницOptimizing IC Engine Exhaust Valve Design Using Finite Element AnalysisIJMERОценок пока нет

- AnSys MechanicalДокумент2 страницыAnSys MechanicalMathew JohnОценок пока нет

- Bird Strike Simulations On Composite Aircraft 2011 FДокумент14 страницBird Strike Simulations On Composite Aircraft 2011 FAntonio MateosОценок пока нет

- Cllutches BrakeДокумент4 страницыCllutches BrakeMathew JohnОценок пока нет

- Cllutches BrakeДокумент4 страницыCllutches BrakeMathew JohnОценок пока нет

- A Distributed Data Storage Protocol For Heterogeneous WirelessДокумент15 страницA Distributed Data Storage Protocol For Heterogeneous WirelessMathew JohnОценок пока нет

- Thermal AnalysisДокумент3 страницыThermal AnalysisMathew JohnОценок пока нет

- Bird Strike Simulations On Composite Aircraft 2011 FДокумент14 страницBird Strike Simulations On Composite Aircraft 2011 FAntonio MateosОценок пока нет

- Engine Controls (Powertrain Management) - ALLDATA RepairДокумент5 страницEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminОценок пока нет

- Valve Seat Recession April 2015Документ2 страницыValve Seat Recession April 2015Moslem KhanlarpourОценок пока нет

- Kater Turbo Povyshennay Moshnost 2kontura 103730Документ43 страницыKater Turbo Povyshennay Moshnost 2kontura 103730TRОценок пока нет

- Troubleshooting Perkins PJ EngineДокумент220 страницTroubleshooting Perkins PJ EngineAhmed100% (1)

- 3515 Chevrolet Sprint L3-61-1.0 ManualДокумент916 страниц3515 Chevrolet Sprint L3-61-1.0 ManualOctavio Ramirez100% (2)

- Geely Manual Parts Engine Mr479q A 1 5Документ3 страницыGeely Manual Parts Engine Mr479q A 1 5leon100% (27)

- MeasuringДокумент4 страницыMeasuringlilikОценок пока нет

- Spesifikasi CompressorДокумент2 страницыSpesifikasi CompressorJevhon TadiusОценок пока нет

- Generating Set Installation ManualДокумент33 страницыGenerating Set Installation Manualmartin.rubenОценок пока нет

- Crankshaft Main BearingsДокумент13 страницCrankshaft Main BearingsYudi setiawanОценок пока нет

- Fundamentals of Aircraft and Rocket Propulsion (2016) PDFДокумент1 025 страницFundamentals of Aircraft and Rocket Propulsion (2016) PDFJose Omar Perez100% (1)

- Ejector Type Nozzle & Thrust ReversalДокумент9 страницEjector Type Nozzle & Thrust ReversalAnonymous VKv75qe98Оценок пока нет

- Design and Analysis of Connecting Rod Using Forged Steel PDFДокумент10 страницDesign and Analysis of Connecting Rod Using Forged Steel PDFavcschaudhariОценок пока нет

- Tourer 125 - Workshop Manual PDFДокумент293 страницыTourer 125 - Workshop Manual PDFjo100% (1)

- ISUZU DIESEL ENGINE 4LE1 DA07 PARTS CATALOGДокумент62 страницыISUZU DIESEL ENGINE 4LE1 DA07 PARTS CATALOGpaulo100% (1)

- MS22045 - 00E 12V 16V 2000 M84 M94 Instructions For Exchange of AssembliesДокумент298 страницMS22045 - 00E 12V 16V 2000 M84 M94 Instructions For Exchange of Assembliesmar100% (16)

- Porsche - US Cayman - 2012 PDFДокумент65 страницPorsche - US Cayman - 2012 PDFSculatorОценок пока нет

- A6 AFN Wiring DiagramДокумент10 страницA6 AFN Wiring DiagramDardan HusiОценок пока нет

- YanmarДокумент2 страницыYanmarRicardo Barbosa100% (2)

- 5.7L Engine Parts BookДокумент37 страниц5.7L Engine Parts Bookbapsi01100% (1)

- Status of System: Log Sheet For Fire Protection SystemДокумент2 страницыStatus of System: Log Sheet For Fire Protection SystemLUTHRASAGAR5927Оценок пока нет

- 5 Diagnostic Trouble Codes and DeratingДокумент4 страницы5 Diagnostic Trouble Codes and DeratingjulianoОценок пока нет

- Summar Training Report HRTC TRAINING REPORTДокумент43 страницыSummar Training Report HRTC TRAINING REPORTPankaj ChauhanОценок пока нет

- r05220304 Thermal Engineering IДокумент8 страницr05220304 Thermal Engineering ISRINIVASA RAO GANTAОценок пока нет

- M1200 PinoutДокумент2 страницыM1200 PinoutRaviVelugulaОценок пока нет

- Teikin Catalog Vol 18-Automotive SubaruДокумент4 страницыTeikin Catalog Vol 18-Automotive SubaruBolívar FuentesОценок пока нет

- 2013 Jupiter-Z1 1n1dy460e1Документ65 страниц2013 Jupiter-Z1 1n1dy460e1Rio Wawo58% (12)

- Compressor Handbook AricelДокумент32 страницыCompressor Handbook Aricelrahilshah100Оценок пока нет

- Performance Curve V158TIH 2010-04-29Документ1 страницаPerformance Curve V158TIH 2010-04-29ramsi17Оценок пока нет

- MEO Class 1 ProjectДокумент2 страницыMEO Class 1 ProjectAshish Ranjan0% (1)

- Design of Foundations for Offshore Wind TurbinesОт EverandDesign of Foundations for Offshore Wind TurbinesРейтинг: 5 из 5 звезд5/5 (3)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (50)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Guidelines for Implementing Process Safety ManagementОт EverandGuidelines for Implementing Process Safety ManagementОценок пока нет

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesОт EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesРейтинг: 5 из 5 звезд5/5 (1)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationОт EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationРейтинг: 1 из 5 звезд1/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationОт EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationРейтинг: 4 из 5 звезд4/5 (18)

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationОт EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationОценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsОт EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsОценок пока нет

- Chemical Process Safety: Learning from Case HistoriesОт EverandChemical Process Safety: Learning from Case HistoriesРейтинг: 4 из 5 звезд4/5 (14)

- Control of Power Electronic Converters and Systems: Volume 1От EverandControl of Power Electronic Converters and Systems: Volume 1Рейтинг: 5 из 5 звезд5/5 (1)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionОт EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionРейтинг: 2.5 из 5 звезд2.5/5 (3)

- Incidents That Define Process SafetyОт EverandIncidents That Define Process SafetyОценок пока нет

- Rules of Thumb for Maintenance and Reliability EngineersОт EverandRules of Thumb for Maintenance and Reliability EngineersРейтинг: 4.5 из 5 звезд4.5/5 (12)

- Safety Fundamentals and Best Practices in Construction IndustryОт EverandSafety Fundamentals and Best Practices in Construction IndustryОценок пока нет

- Inherently Safer Chemical Processes: A Life Cycle ApproachОт EverandInherently Safer Chemical Processes: A Life Cycle ApproachРейтинг: 5 из 5 звезд5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет