Академический Документы

Профессиональный Документы

Культура Документы

Cacttus Water

Загружено:

Selva KumarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cacttus Water

Загружено:

Selva KumarАвторское право:

Доступные форматы

CHAPTER-I 1.

INTRODUCTION

INTRODUCTION

This industrial training report exclusively deals with the information collected from all the department of cactus packaged Drinking water.

Presenting Cacttus (Packaged Drinking Water). It is our promise that every drop of our water is 100% pure, sweet and free from bacteria, viruses and any toxins as it is purified through RO technology to retain all its essential natural minerals followed by UV Sterilization and Ozonization. Our manufacturing plant is situated at road, Udumalpet, Tirupur (Dt) Tamilnadu. In our effort to maintain strict quality control, You can be rest assured that you are drinking safe & pure water when you consume Cacttus Packaging Drinking Water.

VISION

We are committed to exceed customer satisfaction by providing value added packaged drinking water with good quality and service.

MISSION

The cactus Green revolution urges us to innovate continuously, to provide every Indian access to scientifically purified and fortified drinking water that is readily available and easily affordable; and to support initiatives that rejuvenate the Earths natural sources of pristine drinking water.

CHAPTER-II 2. COMPANY PROFILE

2.1 PROFILE OF THE COMPANY

CACTTUS packaged drinking water is a product of SABARHI AQUA FARMS , which is a part of SABARHI GROUP OF COMPANIES. The SABARHI GROUP has a rich experience in various business sectors such as Hatcheries, Broiler farms, Wind farms and Real estate. Now its stepping into Food and Beverage industry.

CACTTUS packaged drinking water is located at kallapuram, udumalpet (Tk), Tirupur (DT). The plant has a production capacity of 5000 pet bottles per hour which is completely automatic and also it has its own PET bottle blowing machines for its own usage. The plant has ample space to store more than 10,000 cases. The company has been certified as a ISO 22000:2005(Food Safety Management System) company.

2.2 PRODUCT PORTFOLIO

Backed by the state-of-the-art infrastructure facility and experienced workforce, It are able to offer the renowned clients, the best quality range of packaged drinking water products and solutions which includes Packaged Mineral Water, Packaged Water, Bottled Mineral Water(5Ltr), Mineral Water(1Ltr), Bottled Mineral Water(300ml) and Packaged Mineral Water (500ml). These are offered in different customized quantities as per the needs and demands of the esteemed clients, at industry leading pricing.

Application Areas Let there be Water such is the importance of pure drinking water, which cannot be substituted by any other drink. A thirsty soul needs a drop of soothing water that brings- forth satisfaction and energy to sustain life. Water, water everywhere, not a drop to drink, so is the present situation, everywhere water is contaminated that has resulted in the advent of deadly

diseases. Henceforth, the purest of pure form of packaged drinking water finds its omnipresent application in the following segments: Restaurants (Medium and big) Malls Retail outlets Theaters Corporates Canteens

Todays tough, competitive market situations need an equally challenging attitude to win over the market uncertainties. Henceforth, It have given utmost priority to indulge theselves in offering the best available range of products that are self-descriptive in terms of reliability and cost effectiveness. The most predominant features of the company, which have enabled us to be a capable and winning organization include:

Ethical business policies Team of expert professionals Quality standards in accordance with international parameters Wide distribution network Timely delivery

Packaged Mineral Water

The most renowned clients can avail from us, highly appreciated Packaged Mineral Water that is offered in the market under the brand name of Aqua grand. With the intensive research and developmental activities It are able to render the best available range of products, as per the industry set standards, thus It have been successful in the industry.

Following features of this range have made it very popular in the market segments:

High grade quality Quality proved Laboratory tested Affordable price range

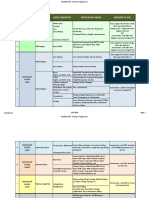

2.3 ORGANIZATION CHART

DIRECTOR ASST. PRODUCTION MANAGETR DESIGNIG DEPARTMENT

PRODUCTION MANAGETR

MARKETING

FINANCE

HEAD PURCHASE

HEAD OF QUALITY

ACCOUNTANCY

SUPERVISORS

SUPERVISORS

WORKERS

WORKERS

WORKERS

WORKERS

CHAPTER III FUNCTIONS OF DEPARTMENTS

3.1 PRODUCTION DEPARTMENT The nature of the product being highly health sensitive and quality assured, It have installed the state-of-the-art manufacturing unit. The facility is fully equipped with the most advanced techniques of production, that includes industry set standard machinery and equipment, which assures the production of qualitative range of products. Further, it have appointed the most experienced and professional technicians who maintain and upgrade the machinery, to ensure they are in working condition. The manufacturing unit is featured with the below features, that has helped us to produce qualitative and reliable range to offer to the most valued client base Large production capacity Itll maintained and updated machinery Team of competent and dedicated engineers Supervised regularly for proper functionality It has appointed a highly dexterous team of technical experts, who are involved in meeting the specifications of the most valuable clients. The team is self-motivated and integrated towards meeting the goals of the company. Segregated into different groups, depending on their relevant domain expertise and experience, they are fully committed towards rendering the products within the directed time frame. The teams main objective is to offer maximum quality products to the most renowned clients and engage themselves in fulfilling their specifications.

To enhance their performance levels, the team is provided with periodical learning sessions and trainings. The team consists of the following professionals, who are considered as an asset to the company: R&D personnel Warehousing & packaging experts Skilled production workforce Support staff Technicians

Administration executives Quality control analysts The Quality Assurance Understanding the sensitivity and prominence of the nature of product, It attach utmost

importance to maintain consistency in quality of the Packaged Drinking water. For this purpose, It have a separate quality testing laboratory which administers a series of quality testing procedures in order to authorize the product for final usage.

Following are the norms under which, the range of products are quality tested: Purity Residual deposits Odor and taste Quality of package bottles Security of seal

PRODUCTION PROCESS World Latest Technologies of Process for cactus packages drinking Water ( Bottled Water ) Production from Different Source of water Like Bore Hole , Deep Well, River Water, Sea Water etc. TECHNICAL DATA: CHLORINE DOSING SYSTEM: (CL2 )

Raw water may contain living micro-organisms and organics which are objectionable to R.O. Membrane as it may cause fouling to deteriorate the performance. Even water may contains ferrous which can be oxidized to ferric oxide which is settle down in storage tank. We have offered a Hypo chlorite dosing system for this purpose. About 3-4 ppm of sodium hypo chlorite solution is dosed in raw water storage tank. This reacts with water to form a hypo chlorite acids which acts as disinfecting agent. RAW WATER STORAGE TANK : (RWST) One No. of Raw water is required in for storage of chlorinated water having appropriate capacity. The tank is fitted with PVC pipe work & isolation valves and suitable type of level indicator. RAW WATER SUPPLY PUMP: (RWP) A Horizontal Centrifugal type of pump in Stainless Steel construction has been provided for supplying Raw Water to Pressure Sand Filter Unit. Necessary Suction / discharge pipe work in s.s construction with isolation valves are also provided up to PSF Unit. PRESSURE SAND FILTER: (PSF) Raw Water is first filtered by filtration unit in series prior feeding R.O.Plant. pressure Sand Filter Unit is provided for removal of suspended matters & turbidity from raw water. PSF Unit is a SS vertical Pressure Vessel. Internally, it is fitted with bottom collecting system. A uniform grades silica quartz sand is charged on the supporting media of pebbles and gravels. This unit is fitted with SS frontal pipe work and Multiport Valve externally. During service cycle water is passed in down ward direction through sand bed, thus entrapping suspended matter & turbid particles. Over a period of time, sand bed gets chocked due to suspended matters resulting higher pressure drop and lesser floe. At this stage filter bed need to be backwashed. When pressure drop across the sand bed increases beyond the specified limit (0.5 kg/cm^2) or quality of filtered water determinates, which ever is earlier. Regeneration involves backwash & rinsing of Sand Bed as below. For backwashing service water is passed in reverse direction of service cycle to loosen the filtering media bed. Due to this, entrapped suspended matters get free and comes out along with effluent water. Backwashing is continued for about 10- 15 minutes or till the effluent coming out is clear.

For Rinsing of Sand Bed : Service water is passed in down ward direction to settle down the sand bed. The effluent water is drained for about 5 minutes time to ensure all unclear water is drained down. ACTIVATED CARBON FILTER: (ACF) Natural water may contain Colour, Odour, Chlorine & Organics in different proportion, which is undesirable for potable application, and hence, it is necessary to remove the same from water. If raw water is chlorinated for die-infection, it is necessary to remove the free Chlorine feeding to R.O System. Chlorine being a strong oxidizing agent, it damages R.O.Membranes. Activated Carbon can remove Chlorine, Odour, & Colour while passing the water through carbon bed along with Odour & colour. This Carbon granules having larger surface area and specific property to absorb organics. ACF Unit is a FRP vertical pressure vessel. Internally it is fitted with strainer on bottom collecting system. The unit is fitted with SS frontal pipe work & MPV externally. A granular activated carbon is charged on the supporting media of Coarse & Fine Silex. During service cycle water is passed in down ward direction through Carbon Bed, which removes Chlorine & Odour from water. When pressure drop across the Carbon Bed increased beyond the specified limit of (0.8 kg/cm^2) or quality of filter water deteriorates, whichever is earlier the unit is isolated for regeneration. The regeneration involves, backwashing & rinsing of Carbon Bed. Over a period of time, life of carbon gets exhausted which can be checked during laboratory testing. Particularly iodine value is most important for this application. Generally carbon is replaced once in a year. SMBS DOSING SYSTEM: (SMBS) The Chlorinated water may oxidize the membrane and to avoid the same precautionary we have provided Sodium MetaBiSulphite dosing system Dosage rate is 4-5 mg/liter. A

HDPE chemical preparation tank with an electronics diaphragm type dosing pump is provided for this. ANTI SCALENT DOSING: (ANTI SCALENT) The hardness salts of calcium & magnesium are likely to be precipitated if concentration exceeds its solubility limit & it may faults the membranes resulting into scaling which ultimately leads to poor treated water quality from R.O.System. To prevent this a anti Scalent dosing (scale inhibitor) dosing system is provided. Normally a scale inhabitator like Perma care

191 or equivalent chemical is dosed in feed water. Dosage rate is 4-5 mg/liter. A HDPE chemical preparation tank with an electronics diaphragm type dosing pump is provided for this. MICRON CARTRIDGE FILTER : (MCF) This kind of Micron Cartridge Filter having Series of filtration with the 20 Micron , 10 Micron , 5 Micron , 1 Micron , 0.45 Micron & 0.2 Micron Nominal & Absolute Micron Cartridge. This is a Consumable Cartridge and should replace it after Days of operation. This for Extra Safety of your Product water as it comes through the followed filtration and there are some chances to slippages for any particles which can be stop through the Cartridge also 1 , 0.45 , 0.2 micron cartridge filter will also take care of Bacteriological growth up to 0.2 micron. HIGH PRESSURE PUMP : (HPP) For Reverse Osmosis Process to take place feed pressure of water need to be raised. For this purpose a Vertical Multistage Centrifugal High Pressure Pump in S.S construction is provided R.O. System requires operating pressure of about 14-16 kg/cm^2 . High-pressure pump is fitted with S.S. discharge pipe work with necessary control valves. Necessary instruments like a High Pressure Switch, Pressure Gauge and recirculation valves are provided for safer operation of system. REVERSE OSMOSIS SYSTEM : (ROM) Reverse Osmosis System rejects 97 99% of total dissolved solids by the principle of `Osmosis. This system consists of a R.O. Module assembly mounted on M.S.Skid. High pressure rating FRP Pressure Vessel is fitted on the skid which houses spirally wound membrane elements in series. In RO System feed soften water is divided into two streams viz Product & Reject water. Product water is treated water having lesser TDS. Reject water is highly concentrated water, which is not to be used for any purpose but drained. Feed water at elevated pressure is first fed to first Pressure Vessel; treated water is collected in center core tube. Treated water from each membrane is collected jointly in a common product water storage tank and reject is drained.

PRODUCT WATER STORAGE TANK : (PWST) High Pressure Switch for tripping high pressure pump in case of excessive feed pressure of R.O.System. One No. of Treated water from R.O. System is stored in a our supplied a S.S. constructed storage tank of appropriate capacity. The tank is fitted with S.S. pipe work &

isolation valves and suitable type of level indicator. One no. of transfer pump is provided in S.S. material of construction to feed the water in MCF. MICRON CARTRIDGE FILTER II & III : (MCF) During storage, atmospheric or any other contamination may take place in treated water. Hence, after passing water from R.O. System, water is once again passed through a micron cartridge filter. This is a S.S.316 Vessel fitted internally with P.P spun micron cartridge elements having absolute ratings of 1.0 micron & 0.2 microns which removes all bacterial impurities present in the water and make the water free of particulates.

ULTRA VIOLET STERILIZER : (UVS) Through R.O. treated water is free from all the micro-biological impurities like Bacteria, Virus, etc. it may redevelop again in water during prolonged storage. For dis-infection of water is essential for Reverse Osmosis Application before Filling & Sealing in bottle. Hence, a online Ultra Violet Steriliser is provided for disinfection of R.O. treated water before filling in precleaned PET Bottles. The water to be disinfected, is passed through U.V.System , which consists of U.V.Tubes which radiates high intensity Ultra Violet Rays, which in turn kills the micro organisms. This systems consists of a S.S finished surface housing with Ultraviolet Lamps fitted in it. The water to be treated is surroundings this tubes during treatment. An electrical systems is provided for production of high voltage required for U.V.Rays generation.

OZONE GENERATOR : (OZONE) Though R.O. System rejects all the micro organisms like bacterial & virus and even after passing through U.V. System it may redevelop in packed bottles over a period of time. Hence, it is necessary to disinfect R.O.Product water prior to bottling filling. This is very much essential to ensure good Mineral Water Quality as per the standards. This Ozone Generator will give your water Oxygen Rich water and remove the Bacteriological growth and also provide you the Shelf Life of your Packed Bottle water unless it open for some period of time. Also this Ozonation of water can add some taste in to your treated water.

OZONE RE-CIRCULATING TANK : (ORT) For required ppm Ozone gas mix up in finish product water. In ozone re-circulating tank water re-circulating by required flow rate pump . Ventury of ozone install out let of Pump it suction ozone and mix-up help with static mixer. This tank is provided with one no. of recirculating pump and one no. of product water transfer pump to the filling section.

PRODUCT & SERVICES Mineral Water (2ltr)

The company has acclaimed wide appreciation by offering a wide gamut of Mineral Water (1ltr) to the valuable clients. These have won the appreciation in the market segments, as they adhere to international standards and satisfy all the industry set parameters. It offer highly client friendly payment options, for the convenience of the most renowned clients.

Further, with the transparent and ethical business values, It are able to march ahead of the counterparts in the industry.

Following features of the range have made them make a mark of themselves in the industry: Hygiene packaging Approved quality of bottles Superior quality of mineral water UV treatment and RO process

Packaged Water

The company is Itll-known as one of the leading suppliers of Packaged Water, which is the known to be the most healthy and original form of water. The range delivered by us is stheced from the industry reputed vendors, who make sure to use the latest technological methods to preserve its hygienic nature. Henceforth, It ensure to offer the best range of products to the esteemed clients.

Further, the range is in constant demand due to the following attributes:

Available in 20 Ltr jar Industry approved quality Packed by ISI certified RO Plant Guarantee of zero contamination

Bottled Mineral Water (5Lr)

Backed by high end technology, It are able to offer international standard quality of Bottled Mineral Water, and cater to the diverse needs and demands of drinking water of the clients. Moreover, these are available in highly customized packaging solutions, such as 5 Ltr bottles, to ensure their easy and safe carriage and usage for diverse occasions.

Following features have made them occupy an important place in the market:

Superior quality Industry leading price Swift delivery Customized options

Bottled Mineral Water (300ml)

It are highly regarded as one of the most renowned supplier of a wide array of Bottled Mineral Water (300ml) to the renowned clients. Being the most preferred choice, It ensure to cater to the vast customer base, in accordance to their specific needs and requirements, at all times. Henceforth, It have succeeded in attaining their optimum levels of satisfaction.

The products are in constant demand due to the below factors: Tested regularly for consistency Packaged under hygienic conditions Competitive piece range Leak proof package

Packaged Mineral Water (500ml)

Supported by a strong team of professionals, It are able to deliver a wide range of Packaged Mineral Water (500ml) to the valuable clients. To ensure their originality and purity, It administer a series of strict quality testing procedures on the entire range. Moreover, these products are stheced from a certified and reliable vendor base to ensure cent percent safety and reliability.

Following features have made the range the first choice of the client base:

Affordable price range Sprayed with ozone water Health benefits Secured package

Mineral Water (1ltr)

The most, pure of the purest form of drinking water is the Mineral Water (1 ltr), offered by us. This water is known to originate from the natural water restheces in the forest areas and

natural environment. Henceforth, It bring forth the natural and original form of drinking water to quench the thirst of the most valuable clients.

The range is patronized by the esteemed clients due to the following factors: Hygiene packaging Approved quality of bottles Superior quality of mineral water UV treatment and RO process

Water Treatment Plants

The company is engaged in offering a wide variety of Water Treatment Plants, which include Mineral Water Plants, Reverse Osmosis Water Plants, Water Softener Plants, Demineralization Plants, Sand Activated Carbon and Iron Remover Filters, Modification & Services, Domestic Water Purifiers etc. These are manufactured under the strict supervision of the professionals who take care of quality and performance of plants. It offer these plants at industry leading prices.

Mineral Water Plant It are one of the leading Mineral Water Bottling Plant manufacturers and suppliers providing excellent water treatment. The excellent array of this plant is highly appreciated for its effective filtration of contaminated water. It ensure the clients that the mineral water plant provides bacteria free water, which is good for health.

Mineral Water Plant Or Packaged Drinking Water

Leveraging on the advanced and modern manufacturing facilities, It develop and offer the clients a durable range of Mineral Water Plants that are designed in compliance with the BIS

guidelines. These mineral water plants comprises pre-filtration system, reverse osmosis system, sub micron filter, ultra violet, ozonator and SS storage tank, which increase their ability to meet specialized needs. Due to its optimum quality and Itar and tear resistance, this range is water marked with ISI 14543 2004. The range of mineral water plants are ideal for usage in processing mineral waters, soft drinks, beers and juices. Features

The major impurities of waters can be classified in three main groups: Non-ionic & undissolved physical impurities. [Turbidity, Odthe, Colthe etc] Ionic and dissolved impurities [Ca, Mg, Na, So4, Cl, iron etc] Microbiological impurities [ Bacteria, Virus, Pathogens etc]

There are various processes employed to purify the water and various combination of the processes are incorporated to ensure that final composition of the product confirms to the most stringent norms. Typically a Mineral water Plant may consist of: Water Treatment Plant Packaging Plant

The Water Treatment Plant consists of One or All of the below mentioned process: 1. Chlorine/Hypo chlorite dosing system is done in the raw water for disinfection / oxidation of iron and manganese (if present) in the water before filtration. 2. Water Storage Tank Raw water, after chlorination is required to be stored to achieve a detention time as per process 3. Multi Grade Sand Filter Sand filtration is the most frequently used, robust method to remove suspended solids from water. The Filter consists of a multiple layer of sand with a variety in size and specific gravity. The Filters are designed to remove turbidity and suspended particles present in the feed water with minimum pressure drop. 4. Activated Carbon Filter Aquaion manufactures complete range of Activated Carbon Filters in different sizes.

The Activated carbon Filters are designed to remove free chlorine, organic matter, odthe and Colthe present in the feed water with minimum pressure drop. 5. Antiscalant Dosing System To prevent membrane Antiscalant dosing (scale inhibitor) system is provided. 6. Micron Filters Micron Filtration is achieved by a series of filtration with the 10 Micron and 5 Micron Cartridge Filters. 7. Reverse Osmosis System Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration 8. Ultra Violet Sterilizer Ultraviolet light deactivates the DNA of bacteria, viruses and other pathogens and destroys their ability to multiply and cause disease. Specifically, UV light causes damage to the nucleic acid of microorganisms by forming covalent bonds betIten certain adjacent bases in the DNA. The formation of such bonds prevents the DNA to reproduce. 9. Ozone Generator Though RO System rejects all the micro organisms like bacteria & virus; it may redevelop in packed bottles over a period of time. Hence, it is necessary to disinfect RO Product water prior to bottling. Mineral Water Plant

With the expertise and experience in this domain, It provide these client-specific Mineral Water Plant ISI Consultancy and Laboratory Setup services to the clients. These services not only include mineral water plant ISI Consultancy but also include training of Chemist and

Microbiologist. For appropriate laboratory set up, It also supply chemical and microbiological Lab Equipment at highly affordable prices. Pet Bottle Filling Machine

It are one of the distinguished manufacturers and suppliers of Automatic Pet Bottle Filling Machine. These are mainly used in the Mineral Water Plants. Used for filling bottles of various shapes and sizes, these filling machines are manufactured using standard filters and sieves. These can be easily installed and are resistant to breakage, and have a sturdy construction. Further, It provide customized solutions as per clients specification.

Bubble Top Filling Machine

Automatic Bubble Top Filling Machine is used in the Package Drinking Water Plant. These are available in various capacities with an adjustable filling capacity and can be tailor made as per the clients specifications. Features: Easy to operate Precision engineered Highly durable

Special Features: Neck holding No bottle no rinsing no filling and no capping The storage rinsing(chemical, hot 2 times, final water) Single stage filling Non contact sensors Separate cap hopper capacity 50 caps Material of contractions contact parts SS316L rest SS304

Modification & Services

It offer the superior Modification & Services to clients. The highly reliable services offered by us are used to produce the treated water. The trained team of professionals are monitoring the whole process and thus fulfilling the bulk demands of clients. The services offered by us are acknowledged for hassle free operations, loItr downtime and cost effectiveness.

Services Offered By Us: Operation and Maintenance Contracts (O&M) In this comprehensive Contract, It undertake complete responsibility of the Plant to produce the treated water of the designed quality & quantity. It provide the required ManpoItr, spares & consumables for trouble free operation of the Plant.

Annual Maintenance Contracts (AMC) The Annual Maintenance Contract (AMC) takes care of preventive maintenance. The AMC ensures longevity of Components, trouble-free operations and loItr downtime. Services include scheduled inspection & scheduled maintenance of the Plant. Water Audits Water Audit study is a qualitative and quantitative analysis of water consumption to identify means of reuse and recycling of water. It also enhances the efficiency of the complete water circuit. This study includes segregation of effluent streams and schemes for effectively treating them. Water Audits enctheage social responsibility by identifying wasteful use, enables estimation of the saving potential. They not only promote water conservation but also deliver cost savings & help companies safeguard public health and property. Plant Monitoring Services This Service package ensures efficient performance of the Plant. The package covers scheduled Inspection, scheduled maintenance, service visits and laboratory services. Automation It carry out the Automation of the existing Plant to reduce the manpoItr and costs. As the ManpoItr cost is getting increased by the day, the need for automating the process, which in turn calls for Automation of the Plant. It provide complete support for automating the conventional Plants to achieve consistent performance with low cost and lesser human interference. Up gradation /Revamping It upgrade/Revamp the existing Water Treatment Plants for Capacity/Quality enhancements as per the Customer need. The Up gradation/Revamping work is managed by a team of professionals with several years of experience in the Water Treatment Field. Domestic Water Purifiers

It manufacture and export a wide assortment of Domestic Water Purifiers. These purifiers are widely used for purification of water for drinking purposes. These purifiers are made of graded raw material and thus find applications in Apartments, Residential Colonies, Hospitals, Clinics, Restaurants, Hotels, and Schools etc. These are available in various sizes and capacities to meet the bulk requirements of clients.

Capacity available 12 litre/hr to 50 litre/hr. Application:

To get pure protected drinking water in houses, apartments, residential colonies, hospitals, clinics, restaurants, hotels, industries, schools, colleges, etc.

Water Treatment Plant Spares

The company is engaged in offering a comprehensive range of Water Treatment Plant Spares that are made from high quality raw material. The spare parts include Anthracites, RO Membranes, RO Housings, Filter Media, Resins etc. These spare parts play an active role in water treatment plants and thus known for easy operations. It offer these spare at most competitive prices to the clients. It offer a range of quality tested water treatment plant spares that helps in manufacturing a trouble-free range of water treatment plants. These spares are available at an highly affordable price are known for its optimum quality spares and consumables.

Water Softener Plant

It are a renowned supplier of Water Softener Plant, which are precision engineered as per the industry standards. The range is widely applicable in homes, Hotels, hospitals, institutes and various other places. These Water Softener Plants are highly efficient in providing softening the water and provide excellent quality water.

Aquaion Industrial and Domestic Water Softener are available in a wide range with maximum flow rate from 500 to 60000 LPH. In this process hard water is converted to soft water. The maximum permissible limit of hardness in water is 200 ppm(mg/lit). About 62% of India suffer from more than 200 ppm of hardness in water. But what makes water hard? Hard water contains excessive Calcium and Magnesium salt which are harmful. Applications : Home and apartments Process water for manufacturing plants Boiler feed water and cooling water make-up Beverage and food processing industry Hospital,hotel,indtitute,laundries and more

3.2 RESEARCH AND DEVELOPMENT DEPARTMENT It are aware that the R&D unit of every company is a very important section that assists in enhancing the performance of the organization to scale the heights of success. Henceforth, It

have employed a competent team of researchers who are constantly updating themselves with the new developments in the field of various water treatment plants and equipment, evolving in the industry. Moreover, they engage in carrying out result oriented research on the materials used, safety measures and come up with the most advanced technologies to imbibe on the devices and equipment along with ensuring their quality aspect. The team of researchers performs in close coordination with the production team and communicates the latest information about the new developments in the techniques of production. Thus, the R&D unit helps us in enhancing of the existing product range and also to improvise the manufacturing capacity.

3.3 WAREHOUSING & PACKAGING DEPARTMENT It have a capacious warehousing facility that enables us to store the range or products and inventories most efficiently. For this purpose, It have segregated the unit into separate units to ensure the products easy identification and retrieval. The warehouse is managed by highly experienced and efficient security and supervisory personnel to ensure the safety of the range. The packaging unit is managed by a dexterous team of skillful and highly experienced packaging experts. They ensure to use only the industry approved quality of material to pack the range. The bottlers used for filling the drinking water, offered by us are quality tested and are guaranteed of cent percent safe for usage. Thus, It are committed to provide the best range of products to the clients. Client Satisfaction Being a client oriented organization, It constantly strive hard to exceed the expectations of the clients, by offering them supreme quality Packaged Drinking Water. For this purpose, It ensure to adhere to a set of company standards and aims that include consistency in quality, timely delivery and transparency in business dealings. To attain maximum client satisfaction, It offer them, the convenience of different, customer friendly payment options like, Cheque Online DD Cash

In addition, the following factors have helped us in gaining an edge over the counterparts in the industry: Client centric approach Prompt delivery State-of-the-art infrastructure Use of advanced technology

CHAPTER IV CONCLUSION

Current information seems to indicate that, due to the presence of fluoride compounds in a great many products, we are regularly exceeding dosage that some consider healthy. Toothpaste as well as processed foods and beverages all contribute to the overall dose, which was not an issue several decades ago. This fact contributes in two ways. First, it means that we now have more fluoride coming into our bodies than was the case a few decades ago... so much more so that even the old research would indicate that we are poisoning ourselves. Secondly, all these non-tap-water sources are making tap-water fluoridation redundant... as is being shown by the steadily decreasing difference in dental decay between populations having vs not having fluoride-treated municipal water. At the very least, the argument for usefulness of treated water is much less today than it was two generations ago, and the more likely reality is that it is no longer a realistic benefit at all, especially when considering the rather significant body of data on the risks inherent.

Вам также может понравиться

- How Reverse Osmosis Works: A Look at Industrial ROОт EverandHow Reverse Osmosis Works: A Look at Industrial ROРейтинг: 2.5 из 5 звезд2.5/5 (2)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisОт EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisРейтинг: 5 из 5 звезд5/5 (1)

- Week 08Документ8 страницWeek 08Government PolytechnicОценок пока нет

- Bajaj Processpack Limited Juice Packaging Machines & Juice Packaging EquipmentsДокумент20 страницBajaj Processpack Limited Juice Packaging Machines & Juice Packaging EquipmentsBajaj Process PackОценок пока нет

- Catalog HyfluxДокумент12 страницCatalog HyfluxfatraskyОценок пока нет

- Entrepreneurship Quarter 3-Week 5-6Документ6 страницEntrepreneurship Quarter 3-Week 5-6Niko ChavezОценок пока нет

- Business Plan For Water Nature Refilling StationДокумент7 страницBusiness Plan For Water Nature Refilling StationJonah JonahОценок пока нет

- Project ReportДокумент25 страницProject ReportsallasaravananОценок пока нет

- Prince Water RefillingДокумент10 страницPrince Water RefillingMaryl AlagosОценок пока нет

- Business Plan: Erolium WaterДокумент15 страницBusiness Plan: Erolium WaterAlexander TОценок пока нет

- Attach I MentДокумент62 страницыAttach I MentFootball HDОценок пока нет

- Business Plan of "Package Drinking Water" byДокумент33 страницыBusiness Plan of "Package Drinking Water" byNIKHIL_SОценок пока нет

- IV On Royal WaterДокумент27 страницIV On Royal WaterSri KumaranОценок пока нет

- Packaged Mineral Water PlantДокумент12 страницPackaged Mineral Water PlantAmjad Pervaz100% (1)

- 2E200 Water Management PharmaceuticalДокумент44 страницы2E200 Water Management PharmaceuticalSaurabh VijОценок пока нет

- Reeverse Osmosis TrainingДокумент4 страницыReeverse Osmosis TrainingPramod MakwanaОценок пока нет

- Aquaguard Reviva UserManualДокумент20 страницAquaguard Reviva UserManualpandeypcОценок пока нет

- Broucher DataДокумент22 страницыBroucher Datarohan khariwaleОценок пока нет

- 12 CbseДокумент26 страниц12 CbseAnurag Kashyap0% (1)

- Ultra Tec Water Technologies L.L.C Dubai (Profile)Документ16 страницUltra Tec Water Technologies L.L.C Dubai (Profile)Anonymous yElIOalbОценок пока нет

- Absolute Technology Company ProfileДокумент4 страницыAbsolute Technology Company ProfilejbkrayanОценок пока нет

- Packaged Mineral Water: Production CapacityДокумент4 страницыPackaged Mineral Water: Production CapacityPassmore DubeОценок пока нет

- Bindura University of Science Education Faculty of SCIENCE Chemistry DepartmentДокумент3 страницыBindura University of Science Education Faculty of SCIENCE Chemistry DepartmentLisbonОценок пока нет

- UntitledДокумент12 страницUntitledLisbonОценок пока нет

- Summary Statement - OLDДокумент40 страницSummary Statement - OLDankit7588Оценок пока нет

- Emely Strategic PlanДокумент11 страницEmely Strategic Planbac secretariatОценок пока нет

- Riva Appliances Pvt. LTD.: Deal In: Water & Waste Water ManagementДокумент29 страницRiva Appliances Pvt. LTD.: Deal In: Water & Waste Water ManagementVikrant ShelarОценок пока нет

- Reverse Osmosis SystemДокумент2 страницыReverse Osmosis SystemTamanna NaiduОценок пока нет

- AdvancedWatertek BrochureДокумент5 страницAdvancedWatertek BrochureAnonymous whI91WzОценок пока нет

- PDW IntroДокумент6 страницPDW IntroISHFAQ ASHRAFОценок пока нет

- Equipment PlanningДокумент7 страницEquipment Planningmilton islamОценок пока нет

- Vignesh. S Aravindhkumar. K Saravanan. K Guided by Mr.S. Thangakasi Rajan M.E (PH.DДокумент33 страницыVignesh. S Aravindhkumar. K Saravanan. K Guided by Mr.S. Thangakasi Rajan M.E (PH.Dvelmurugan100% (1)

- Business Plan of Mineral Water PlantДокумент28 страницBusiness Plan of Mineral Water PlantJallo AmaduОценок пока нет

- Sander Protein SkimmersДокумент18 страницSander Protein Skimmerslleimicojon100% (1)

- UntitledДокумент5 страницUntitledLisbonОценок пока нет

- Business Plan of Mineral Water PlantДокумент27 страницBusiness Plan of Mineral Water PlantHaytham FugahaОценок пока нет

- Subic Water and Sewerage CoДокумент4 страницыSubic Water and Sewerage CoNicole Anne BorromeoОценок пока нет

- Water & Wastewater EngineeringДокумент12 страницWater & Wastewater EngineeringJan-Louis Reynders50% (2)

- 7 Water PurificationДокумент24 страницы7 Water PurificationRonnie NdozirehoОценок пока нет

- Big Dutchman Stalleinrichtung Pig Equipment Drinking Systems enДокумент6 страницBig Dutchman Stalleinrichtung Pig Equipment Drinking Systems enspuzzarОценок пока нет

- Envitech Company Profile 2013Документ13 страницEnvitech Company Profile 2013Gusryan Zari KhamsyaОценок пока нет

- Beverage Processing and Packaging PlantsДокумент20 страницBeverage Processing and Packaging Plantscor jansenОценок пока нет

- Sample Business ProposalДокумент1 страницаSample Business ProposalSheryl MH-PradaОценок пока нет

- Oxy Bee Solutions Fire Fighting STP, WTPДокумент16 страницOxy Bee Solutions Fire Fighting STP, WTPSaurabh ChaudhariОценок пока нет

- Exp Complementary ProductsДокумент84 страницыExp Complementary ProductsAhmed FarhatОценок пока нет

- Water Distillation Unit Metal WallДокумент5 страницWater Distillation Unit Metal WallYogesh BinaniОценок пока нет

- Packaged Drinking WaterДокумент8 страницPackaged Drinking WaterArit DeyОценок пока нет

- Lecture 1 Boiler Feed Water PDFДокумент12 страницLecture 1 Boiler Feed Water PDFJAIRAH SONОценок пока нет

- EugeneДокумент18 страницEugeneLinus MwafrikaОценок пока нет

- Entrepreneurship Project: Tanuja Water'S ReportДокумент16 страницEntrepreneurship Project: Tanuja Water'S ReportPrabir Kumar PatiОценок пока нет

- Business Plan of Mineral Water PlantДокумент27 страницBusiness Plan of Mineral Water PlantArjunSahoo97% (112)

- Favila - MidsayapДокумент2 страницыFavila - MidsayapPaw LabadiaОценок пока нет

- Reverse Osmosis Drinking Water System: Installation, Operation and Service ManualДокумент24 страницыReverse Osmosis Drinking Water System: Installation, Operation and Service ManualWaleed EmaraОценок пока нет

- ONEWATER PackagedDrinkingWater V0.1Документ22 страницыONEWATER PackagedDrinkingWater V0.1prasanthdusiОценок пока нет

- BottlingДокумент14 страницBottlingWasiYamanChoudhuryОценок пока нет

- Catalog: Filtration SystemsДокумент70 страницCatalog: Filtration SystemshaussmanОценок пока нет

- 1 Aqua Cold Project Report Final 21042012Документ10 страниц1 Aqua Cold Project Report Final 21042012Munna Kumar100% (1)

- Sal Con Corp BrochureДокумент12 страницSal Con Corp BrochureTong ChaipanyakulОценок пока нет

- .Viktor Project - 1700627002000Документ10 страниц.Viktor Project - 1700627002000Frankline OchiengОценок пока нет

- No-Fluff Swimming Pool Maintenance Guide for Beginners: Easy Steps to Maintain Water Chemistry, Eliminate Algae and Keep Your Pool SparklingОт EverandNo-Fluff Swimming Pool Maintenance Guide for Beginners: Easy Steps to Maintain Water Chemistry, Eliminate Algae and Keep Your Pool SparklingОценок пока нет

- Manifactiong of CoalДокумент13 страницManifactiong of CoalSelva KumarОценок пока нет

- Plant As A Source of AlkaloidsДокумент15 страницPlant As A Source of AlkaloidsSelva KumarОценок пока нет

- CompanyДокумент4 страницыCompanySelva KumarОценок пока нет

- Fertilizers. 31Документ26 страницFertilizers. 31Selva KumarОценок пока нет

- Project On Dettol Soap Reckitt and BenckiserДокумент14 страницProject On Dettol Soap Reckitt and Benckiserbipender87% (15)

- A Project Report On Indian Bath Soap IndustryДокумент64 страницыA Project Report On Indian Bath Soap IndustryAlok Prasad79% (19)

- Digital MarketingДокумент12 страницDigital MarketingSelva KumarОценок пока нет

- WOMENДокумент9 страницWOMENSelva KumarОценок пока нет

- CoalДокумент6 страницCoalSelva KumarОценок пока нет

- AUTOMATION OF HALL Retention ARRANGEMENT SYSTEMДокумент9 страницAUTOMATION OF HALL Retention ARRANGEMENT SYSTEMSelva KumarОценок пока нет

- Online Job RecurutmentДокумент8 страницOnline Job RecurutmentSelva KumarОценок пока нет

- UTR: P17010306821520: Beneficiary DetailsДокумент1 страницаUTR: P17010306821520: Beneficiary DetailsSelva KumarОценок пока нет

- CoalДокумент6 страницCoalSelva KumarОценок пока нет

- Report Anganwadi Research Final Feb10Документ14 страницReport Anganwadi Research Final Feb10Selva KumarОценок пока нет

- DocumentsДокумент30 страницDocumentsSelva KumarОценок пока нет

- Report Anganwadi Research Final Feb10Документ14 страницReport Anganwadi Research Final Feb10Selva KumarОценок пока нет

- Savings SchemsДокумент4 страницыSavings SchemsSelva KumarОценок пока нет

- Abraham LincolnДокумент5 страницAbraham LincolnSelva KumarОценок пока нет

- Project Profile For Establishment of 48 Automatic Loom: 1.0 Scope of The Project in The Area of OperationДокумент2 страницыProject Profile For Establishment of 48 Automatic Loom: 1.0 Scope of The Project in The Area of OperationSelva KumarОценок пока нет

- Care RingДокумент36 страницCare RingSelva KumarОценок пока нет

- A Study On Cunsumers Preference and Attitude Towards Purchase of Gold (With Special Reference To Pollachi Talluk)Документ5 страницA Study On Cunsumers Preference and Attitude Towards Purchase of Gold (With Special Reference To Pollachi Talluk)Selva KumarОценок пока нет

- OracleДокумент7 страницOracleSelva KumarОценок пока нет

- All Major CreditДокумент1 страницаAll Major CreditSelva KumarОценок пока нет

- Report Anganwadi Research Final Feb10Документ14 страницReport Anganwadi Research Final Feb10Selva KumarОценок пока нет

- Final DocumentationДокумент39 страницFinal DocumentationSelva KumarОценок пока нет

- Chapter 2Документ36 страницChapter 2Selva KumarОценок пока нет

- Create and Display The List of Ledger Accounts in The Books of Star LTD On 31 MarchДокумент1 страницаCreate and Display The List of Ledger Accounts in The Books of Star LTD On 31 MarchSelva KumarОценок пока нет

- Program For Form ValidationДокумент8 страницProgram For Form ValidationSelva KumarОценок пока нет

- DFT Study On Dihydrogen Bond Interactions by Substitution in XH Si .NCH and NCH .HM (X H, F, CL, BR M Li, Na, Beh, MGH) ComplexesДокумент24 страницыDFT Study On Dihydrogen Bond Interactions by Substitution in XH Si .NCH and NCH .HM (X H, F, CL, BR M Li, Na, Beh, MGH) ComplexesSelva KumarОценок пока нет

- MedisonДокумент42 страницыMedisonSelva KumarОценок пока нет

- Jurnal RustamДокумент15 страницJurnal RustamRustamОценок пока нет

- Fishing Broken Wire: WCP Slickline Europe Learning Centre SchlumbergerДокумент23 страницыFishing Broken Wire: WCP Slickline Europe Learning Centre SchlumbergerAli AliОценок пока нет

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanДокумент13 страницCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaОценок пока нет

- P3 Chapter 2 End-Of-Chapter (Higher) Mark SchemeДокумент3 страницыP3 Chapter 2 End-Of-Chapter (Higher) Mark SchemePaul LloydОценок пока нет

- Wetted Wall Gas AbsorptionДокумент9 страницWetted Wall Gas AbsorptionSiraj AL sharifОценок пока нет

- How To Make Panna CottaДокумент3 страницыHow To Make Panna CottaBintОценок пока нет

- Goat AnatomyДокумент8 страницGoat AnatomyLochi GmОценок пока нет

- Lem Cyclop Ewt Owner S Manual 10Документ10 страницLem Cyclop Ewt Owner S Manual 10josep_garcía_16Оценок пока нет

- Chapter 2Документ5 страницChapter 2ERICKA MAE NATOОценок пока нет

- HooksДокумент7 страницHooksapi-233765416Оценок пока нет

- Bubba - S Food MS-CДокумент2 страницыBubba - S Food MS-CDũng Trần QuốcОценок пока нет

- Fire Alarm SymbolsДокумент6 страницFire Alarm Symbolscarlos vasquezОценок пока нет

- Conceptual Design and Development of Shredding Machine For Agricultural WasteДокумент7 страницConceptual Design and Development of Shredding Machine For Agricultural WasteVJ CarbonellОценок пока нет

- Assessment in The Affective DomainДокумент19 страницAssessment in The Affective DomainChano MorenoОценок пока нет

- 084 - ME8073, ME6004 Unconventional Machining Processes - NotesДокумент39 страниц084 - ME8073, ME6004 Unconventional Machining Processes - NotesA. AKASH 4001-UCE-TKОценок пока нет

- NANOGUARD - Products and ApplicationsДокумент2 страницыNANOGUARD - Products and ApplicationsSunrise VenturesОценок пока нет

- Cen-Tech 63759Документ8 страницCen-Tech 63759GregОценок пока нет

- Calamity and Disaster Preparedness Chapter IXДокумент34 страницыCalamity and Disaster Preparedness Chapter IXANGEL ALBERTОценок пока нет

- State/ District-Dehradun, Uttarakhand Year 2016-17Документ20 страницState/ District-Dehradun, Uttarakhand Year 2016-17jitendra rauthanОценок пока нет

- Consumer ReportsДокумент64 страницыConsumer ReportsMadalina Pilipoutanu100% (1)

- Trophic Levels - 10% RuleДокумент5 страницTrophic Levels - 10% RulerebbiegОценок пока нет

- Carapace DigitalДокумент15 страницCarapace DigitalVillain ChatОценок пока нет

- 3 Composites PDFДокумент14 страниц3 Composites PDFKavya ulliОценок пока нет

- Scots-Supply Chain ManagementДокумент3 страницыScots-Supply Chain Managementgamer godОценок пока нет

- FT8 - Air System - Maintenance - P&W FT8 - Solar Turbines Technical BLOGДокумент3 страницыFT8 - Air System - Maintenance - P&W FT8 - Solar Turbines Technical BLOGLibyanManОценок пока нет

- Robodrill 01Документ298 страницRobodrill 01vuchinhvdcОценок пока нет

- AAA V Edgardo SalazarДокумент2 страницыAAA V Edgardo SalazarNiajhan PalattaoОценок пока нет

- Efficiency Improvement Oppertunities With BLDC Fan PDFДокумент14 страницEfficiency Improvement Oppertunities With BLDC Fan PDFjust_4_u_dear_in9549Оценок пока нет

- Battle Healing PrayerДокумент9 страницBattle Healing PrayerSolavei LoanerОценок пока нет

- Labour Laws in India FINALДокумент55 страницLabour Laws in India FINALSneha Periwal0% (1)