Академический Документы

Профессиональный Документы

Культура Документы

Is As Stratergic Tool

Загружено:

HardikОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Is As Stratergic Tool

Загружено:

HardikАвторское право:

Доступные форматы

I NTERNATI ONAL

STANDARDI ZATI ON

AS A STRATEGI C TOOL

Architecture-based approaches

to international standardization

and evolution of business models

By Junjiro Shintaku, lead author;

Koichi Ogawa, Tetsuo Yoshimoto,

co-authors

The University of Tokyo

Manufacturing Management

Research Center, Japan

THIS PUBLICATION IS COPYRIGHT PROTECTED

Copyright 2006 IEC, Geneva, Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varemb

CH-1211 Geneva 20

Switzerland

Email: 0inmail@iec.ch

Web: 1Hwww.iec.ch

About the authors

Junjiro Shintaku, lead author

Junjiro Shintaku is an Associate Professor of Corporate Strategy at the Graduate School of Economics

of the University of Tokyo, Japan, and a Research Director at the Manufacturing Management

Research Center of the University of Tokyo. He plays a leading role in Japanese academic societies

active in management studies. He is an Executive Director of the Academic Association for

Organizational Science, a Director of the Japan Academy of International Business Studies, and a

Councillor for the Business History Society of Japan. He is the co-founder and Executive Director

of the Global Business Research Center, which is a non-profit organization for industry-academia

collaborative studies.

His research has been mainly on technological innovation and corporate strategies. He has written

and edited many books in Japanese: Architecture-based Analysis of Chinese Manufacturing Industries

(2005), Field-based Research Methods (2005), Economic Analysis of Video Game Software Industry

(2003), Electronic Society and Market Economy (2002), Dynamism of Competitive Strategies (2001),

The Essence of De Facto Standard (2000), Competition in Japanese Industries (2000), and Competitive Strategies of Japanese Firms

(1994). Professor Shintaku earned a BA in economics, MA in economics and Doctorate in Economics from the University of Tokyo.

Koichi Ogawa, co-author

Koichi Ogawa is a Specially Appointed Researcher at the Manufacturing Management Research Center

of the University of Tokyo, Japan, and a Professor of Information Science and Engineering at Fudan

University, Shanghai, China. He has been in charge of R&D and business development for 30 years at

Fujitsu Ltd. He was one of the Japanese delegates to ISO/JTC1/SC23, from 1986 to 1991, as

chairman of a local working group in Japan, and contributed to the international standardization of the

5.25 inch WORM and 3.5 inch MO optical disk cartridge. His principal field of research is computer

storage technology and, since 2004, he has been working on management of technology (MOT).

He has written many articles on science and engineering. His major papers on MOT are Architecture-

based Analysis of Competitive Advantage between Japanese and Catch-up Countries (in English,

2005), Industry Rise and Business Development of Optical Storage Products (in Japanese, 2006),

Architecture-based Analysis of DVD Business and International Standardization (in Japanese, 2006).

Professor Ogawa received a Doctorate in Engineering from Meiji University in Japan.

Tetsuo Yoshimoto, co-author

Tetsuo Yoshimoto is a Specially Appointed Researcher at the Manufacturing Management Research

Center of the University of Tokyo, Japan, and a Lecturer at Doshisha University, Kyoto, Japan.

He specializes in Production Operation Management and Business Strategy. His main field of

research focuses on electronics manufacturers' production networks in Asia.

His major works are (in Japanese); Business System and Core Components Supply Network (2004),

Supplier System and Core Components Transaction (2003), The Character and Management of Cell

Production System (2002). He was born in Maizuru, Kyoto, Japan.

The University of Tokyo - Manufacturing Management Research Center, Japan

The Manufacturing Management Research Center (MMRC) at the University of Tokyo was established in 2003, first receiving financial

support from "The 21st Century COE (Centers of Excellence) Program" by The Ministry of Education, Culture, Sports, Science and

Technology. The main objective of MMRC is to provide an advanced global research base for studies on the so-called Integration-based

Manufacturing System, developed by Japanese manufacturing firms; in the first decade of the 21st century, the Integration-based

Manufacturing System has enjoyed a strong reputation worldwide. As part of this effort, the Center has organized a research consortium

with leading Japanese manufacturing companies to establish systematic knowledge on manufacturing through collaboration with firms.

MMRC also participates in numerous collaborative projects with universities and research institutions around the world.

The University of Tokyo was established in 1877 as the first national university in Japan. Essentially, it offers courses in all academic

disciplines at both undergraduate and graduate levels and provides research facilities for these disciplines. The University is known for

the excellence of its faculty and students and since its foundation, many of its graduates have been appointed leaders in government,

business, and the academic world.

www.e.u-tokyo.ac.jp/index-e.html

www.ut-mmrc.jp/e_index.html

Copyright 2006, IEC, Geneva, Switzerland

IEC CENTENARY CHALLENGE 18

Copyright 2006, IEC, Geneva, Switzerland

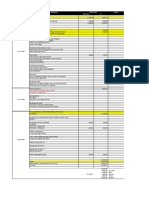

Open international standardization = modular architecture

Open technology & open design rule

accelerate diffusion and popularization of technology & product

Remove interdependency between finished product & key components

accelerate international division of labor

support rise of the industry in developing country

popularize very low cost product worldwide

World wide installed base

provides new value-added business opportunities

Closed local/de facto standard closed architecture

Closed technology & closed design rule

capsule technology & IP into product

Keep strong interdependency between product & technologies

support vertical integration of product

protect source of profit & revenue

Need open standardized product as partner for market development

accelerate collaboration with advanced countries and NIEs

2 Economic impact of international standardization

2.1 Product Architecture and International Standardization

Product architecture is a basic design concept for product functions and structures (Fujimoto, 2004) [2]0 F

1

.

The basic requirement for the product designer is how to realize a set of functions. The product is

physically structured by some components. The product designer should determine how each

function is allocated to some components. These concepts of allocation make the difference in

the interdependency among components. Based on the concept of functional allocation and

interdependency, product architecture can be classified into the two following types, modular

and integral architecture.

Integral architecture has complex and strong interdependency among components. More

than one function is allocated to each component. The design optimization of the finished

product depend on the mutual adjustment of component design itself (for example, automobile).

Modular architecture has simple and very weak interdependency among components. Only

one function is allocated to each component. The design optimization of finished product

depends on each component that is independently developed (for example, personal computers).

An architecture-based definition of standardization is summarized in Figure 1. International

standardization, such as that provided by the IEC, is defined as a form of modular architecture.

Because, in principle, it is open to every firm in many countries, and the design rules of the

standardized layers are open to the public, the finished product has high potential to be extended

not only to advanced countries but also to developing countries and can thus increase benefits to

consumers world-wide. In addition, this worldwide installed knowledge base provides new business

opportunities, such as the digital content business as seen in the DVD and mobile phone

environment, with further contribution to economic growth.

The local and/or de facto standard can be defined as integral architecture. Because technology and

design rules are largely closed or strictly controlled, firms that drive the standard forward have to

promote the finished product themselves. However, history shows that huge marketing and

1

Figures in square brackets refer to the Bibliography.

Figure 1 Architecture-based definition of standardization

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 20

Figure 2 Market expansion speed of standardized products

0

20

40

60

80

100

120

140

160

S

h

i

p

m

e

n

t

v

o

l

u

m

e

(

m

i

l

l

i

o

n

)

DVD

Recordable

DVD

Player

CD-R/RW

VCR

Mini Disc

More than 200 firms

(open standard)

Less than

5 firms

(closed standard)

Number of firms

In standardization

activity

Source: Edited by authors using market

information of TSR & GigaStream Japan

1

st

year shipment volume: 1 million per year

DVD Recordable: 2001, DVD Player: 1998,

CD-R/RW: 1996, VCR: 1978, Mini Disc: 1995

1

st

2

nd

3

rd

4

th

5

th

6

th

7

th

Year

promotion investment is needed; moreover, the product is restricted to a local and/or a niche

market. A business strategy that has been successful for the integral product is collaboration with

the open standard, which provides various business opportunities for partners. Without open

standardization, the product with integral architecture, that is, a coordination-intensive product

cannot enter the worldwide market. This shows that standardization plays a prominent role in the

economic growth of the 21st century.

2.2 Development of the optical storage industry through standardization and

modularization

The speed of market expansion depends strongly on the form of standardization, as shown in

Figure 2. The technological standard of DVD families has been standardized in an international

open forum called the DVD forum, of which more than 200 firms from 20 countries are members.

Because it is open to firms from many countries, not only the technology-leading firms of advanced

countries but also many firms from NIEs that are catching up with their developed world

counterparts (hereafter called catch-up firms) can join the DVD business. The accumulated volume

of sales for the DVD familywritable DVD drive for PC, DVD player and DVD recorder for

audiovisualhas reached over 300 million units within five years since the market opened up,

and it is still growing. However, as seen in Figure 2, the sales volume of the Mini Disc, which is a

small-sized music player that was very popular in the Japanese market of the 1990s, has been

restricted to be less than 20 million. Because the Mini Disc was standardized in closed form by only

a few Japanese and European firms, and because they did not open the key components and the

technology, it has not been well accepted outside the Japanese market. In the case of DVD, which

was standardized with many firms in the open international forum only one year after the first

product was delivered in 1997, key components of the drive, such as optical pick-up, LSI chipset,

control microcode, and electric motor, became available in the Asian-Pacific arena. Thus, the open

standard quickly changed the product architecture to modular mode and then accelerated the

division of labour. The distribution of these key components has provided the catch-up firms of

NIEs with the opportunity to join the DVD business. In other words, the open standard has played

a prominent role in creating new business opportunity for NIEs and encouraging their industry to

flourish.

Figure 2 Market expansion speed of standardized products

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 21

The product architecture of the CD-ROM and CD-R drive was initially in integral mode when these

appeared in the market. Consequently, they could not develop volume market themselves,

because there was no opportunity to change the division of labour. According to our investigation,

the innovation of the microcontroller unit (MCU) and microcode technology (firmware) radically

changed the architecture from integral to modular mode. The digital feedback servo technology of

the CD-ROM since 1994 and microcode technology of CD-Rs write strategy since 1998 are good

examples of the innovation. The former has led the CD-ROM out of the integral mode to modular

mode, because it has removed interdependency between optical pick-up and drive technology,

while the latter has removed the interdependency between recordable media and drive technology.

As shown in Figure 3, the market for the two products has expanded explosively since 1994 and

1998, respectively, because key components of each drive have been available in the market of

the Asian-Pacific arena and this has accelerated the division of labour. These cases in the DVD

and CD family lead to the conclusion that the innovation of the digital technology since the 1990s

has provided international standardization activity a prominent role in the history of industry

it contributes not only to increase consumer benefit but also to acceleration of economic

collaboration between advanced countries and NIEs. It has been said that more than 50 firms

joined the CD-ROM business in the mid 1990s and more than 300 joined the DVD business in the

early 2000s from Korea, Taiwan, Hong Kong, China, India, Dubai, Turkey, and Singapore. Before

the 1990s, when digital technology was not so powerful, international standardization could not

have played such a prominent role.

Figure 3 Market expansion speed of standardized product after modularization

As seen in Figure 4, the international standard has popularized the products in the newly

developed markets of developing countries. The number of DVD players sold in the developing

countries was less than 1 million in 1999; however, the number has drastically increased to

account for up to 63% of worldwide shipments in 2005. This is the power of the open international

standard in the environment of the digital technology. Both digital technology and standardization

have accelerated modularization of product architecture enabling the division of labour, and

popularization of products in the world.

0

20

40

60

80

100

120

140

8

6

/

9

0

8

7

/

9

1

8

8

/

9

2

8

9

/

9

3

9

0

/

9

4

9

1

/

'

9

5

9

2

/

'

9

6

9

3

/

9

7

/

9

7

9

4

/

9

8

/

9

8

9

5

/

9

9

/

9

9

9

6

/

0

0

/

0

0

9

7

/

'

0

1

/

'

0

1

9

8

/

'

0

2

/

'

0

2

9

9

/

'

0

3

/

'

0

3

0

0

/

'

0

4

/

'

0

4

0

1

/

'

0

5

/

'

0

5

Figure 3 Market expansion speed of standardized product after modularization

S

h

i

p

m

e

n

t

v

o

l

u

m

e

(

m

i

l

l

i

o

n

)

CD-R/RW

CD-ROM

DVD player

CD-ROM delivered (1986

CD-R to delivered (1990

DVD Player delivered (1997)

Integral Architecture Modular Architecture

Closed/de facto standard

Open standard

86 87 88 89 90 91 92 93 94 95 96 97 98 99 00 01

90 91 92 93 94 95 96 97 98 99 00 01 02 03 04 05

97 98 99 00 01 02 03 04 05

CD-ROM

CD-R/RW

DVD Player

Source: Edited by authors using market information of TSR & GigaStream Japan

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 22

A similar contribution by the international standard has been observed in the mobile phone industry.

The cumulative number of the subscribers in China was less than 4 million in 1995; however, the

number has increased to well over 400 million in 2005, which is almost the same as for the

expanded European Union or more than twice the number for the USA. The volume of shipments

of mobile phones by Chinese and Korean firms, for example, has been remarkable, rising to over

150 million in 2005. From the above analysis, it is clear that the international standard of the mobile

phone has played a very prominent role in stimulating the economic growth not only of China but

also of the advanced countries that have developed core technologies and set the standard.

Figure 4 Market development of DVD player in developing countries

2.3 Acceleration of technology transfer to NIEs

International standardization in open form has accelerated rapid technology transfer of finished

products from technology-leading firms to catch-up firms of NIEs. Figure 5 shows the sudden drop

in the market share of Japanese and European firms with developed technology having set the

international standard. In the case of closed/de facto standards, such as CD-ROM and CD-R/RW,

while product architecture was restricted to the integral mode, the market share of the finished

product by Japanese and European firms was more than 90%. However, this share suddenly

started to drop after the architecture changed into modular mode. On the other hand, in the case

of DVD, the drop began even in the early stages of the markets opening, because the architecture

was already modularizedit was standardized in the late 1990s, when digital technology was in a

phase of rapid innovation. It is very interesting to note that the trend of market share drop for the

DVD has been almost the same as the drop for the modularized CD-ROM drive and the

modularized CD-R/RW drive.

Figure 4 Market development of DVD player in developing counties.

0

20

40

60

80

100

120

140

160

04

S

h

i

p

m

e

n

t

v

o

l

u

m

e

(

m

i

l

l

i

o

n

)

100%

80%

60%

40%

20%

R

a

t

i

o

o

f

m

a

r

k

e

t

Worldwide

market growth

Market size of

developing countries

Market size of

developed countries

Source: Edited by authors using market information of TSR & GigaStream Japan

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 23

Figure 5 Market share change of standardized product after modularization

The product architecture of key components, such as the optical pick-up, first appeared in integral

mode and remains in the same integral mode even today. The optical pick-up is a typical product

with integral architecture or a coordination-intensive product in which there are strong

interdependencies between the core technologies. Even though the optical pick-up has been

manufactured by factories in NIEs, and has been available in the open market since 1985, the

market share of Japanese and European firms has been over 90% in the innovation-intensive

computer applications and over 80% even in less innovative audio-visual applications.

Figure 6 summarizes the architecture-based positioning of finished products and of key

components in the DVD industry. All the key components developed by technology-leading firms

in advanced countries are positioned in the integral architecture domain. The firms of NIEs cannot

join the key component business, because it is a technology- and coordination-intensive product

with integral architecture, which needs a long-term investment of education, long-term R&D, and

a wide range of industry.

Figure 5 Market share change of standardize product after modularization

0

20

40

60

80

100

120

8

6

/

9

0

8

7

/

9

1

8

8

/

9

2

8

9

/

9

3

9

0

/

9

4

9

1

/

'

9

5

9

2

/

'

9

6

9

3

/

'

9

7

9

4

/

9

8

/

9

8

9

5

/

9

9

/

9

9

9

6

/

0

0

/

0

0

9

7

/

0

1

/

0

1

9

8

/

'

0

2

/

'

0

2

9

9

/

'

0

3

/

'

0

3

0

0

/

'

0

4

/

'

0

4

0

1

/

'

0

5

/

'

0

5

M

a

r

k

e

t

S

h

a

r

e

(

%

)

Integral Architecture Modular Architecture

Market share of

Japanese firms + European

firms

Catch-up countries

joined business

DVD

Player

CD-R/RW

CD-ROM

CD-ROM

CD-ROM delivered (1986

CD-R to delivered (1990

DVD Player delivered (1997)

Closed/de facto standard Open standard

Source: Edited by authors using market information of TSR & GigaStream Japan

86 87 88 89 90 91 92 93 94 95 96 97 98 99 00 01

90 91 92 93 94 95 96 97 98 99 00 01 02 03 04 05

97 98 99 00 01 02 03 04 05

CD-ROM

CD-R/RW

DVD Player

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 24

Figure 6 Architecture-based positioning of standard leading firms

of advanced countries and catch-up firms of NIEs

On the other hand, almost all the finished products manufactured by NIEs are positioned in the

modular architecture domain. The technology-leading countries find it very hard to join the finished

product business, because it is labour-intensive low cost. However, firms in NIEs can join it by

taking advantage of their comparatively small overheads. It can be concluded that each domain

needs collaborationfirms in advanced countries cannot operate without the finished products

from NIEs. The NIEs bring the value-added key components to the worldwide market by providing

a finished product at very low cost. If the NIEs do not join the finished product business, then new

markets in developing countries cannot be opened quickly, and the market size for the DVD player

would be restricted to less than one-third of the current market or one-fifth of the future potential

market. This means that open international standards have provided the leading firms of advanced

countries with a 35 times bigger market for value-added key components, and this has

encouraged the growth of their industry. This is due to the architecture-based division of labour

created by international standardization.

Each country holds a unique and strong position in their product architecture, and this will not

change in the short term because it originates from a countrys comparative advantage based on

culture and history. It must be emphasized that international standardization since the digital

innovation era of the 1990s has created a new economic environment in which advanced countries

and NIEs can be, and will be, in symbiotic co-prosperity. Because this co-prosperity has been

created by international standardization, it can be said that the role of standardization in world

economic growth will be much more prominent in the 21st century than in the 20th century.

Figure 6 Architecture-based positioning of standard leading firms of

advanced countries and catch-up firms of NIEs

DVD Player

DVD Media (OEM)

Single DVD Recorder

Digital Chipset

DVD + R/RW, DVD-R/RW Drive

Optical Pick-up

Electric motor, Micro-

optics

Laser, Micro lens, OEIC

Dye, Stamper, Tester,

Manufacturing Equipment

Slim typed

Super-multi DVD Drive

Integral

China

Turkey

Taiwan

Korea

Japan

India

Dubai

Modular

Germany

Holland

Source: Authors interviewed DVD industry

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 25

3 New alliance business model based on international standardization

Although the catch-up firms in NIEs have a high presence in the optical storage industry, the

international division of labour between the Japanese and the catch-up firms has become very

important for the continuation of their business. The firms in the advanced courtiers focus on the

integral products and components such as the optical pick-up and LSI chipset. On the other hand,

the firms in NIEs have a competitive advantage only in the final modular product. These two parties

have had the large transaction of key components in the market.

In the optical storage industry, for example, the market share of a typical integral product, such as

the optical pick-up, is more than 80% for Japanese and European firms, while NIEs take more than

70% of the market share of such a finished product as the DVD player with modular architecture.

A similar phenomenon has been observed in the mobile phone industry, where almost all key

components with integral architecture, such as baseband chip and optical modules, have been

supplied by advanced countries (for example, Nokia, Texas Instruments, etc.).

It is very difficult for NIEs to enter the market for technology-intensive key components, because

these components require long-term investment in education and basic R&D and also require a

wide range of industry infrastructure in the country. The firms in advanced countries invest in the

technology development, product development, and market development of the technology-

intensive integral products. On the other hand, it is very difficult for the firms in advanced countries

to join the market of modularized low-cost products, such as the DVD player, because the gross

profit margin of the low cost-product is very small and they cannot absorb the large overheads for

investment. That is, the firm in advanced countries is weak in the low cost operation of modularized

products.

Recently, this international division of labour has evolved to the new alliance model. We can

observe several successful alliances between technology-leading firms in advanced countries

and catch-up firms in NIEs. These alliances are designed on the basis of architecturethis may

be defined as architecture-based alliance model.

A successful example of the alliance is a joint-venture company called HLDS where Hitachi of

Japan takes a portion of integral architecture, while LG Electronics of Korea takes a portion of

modular architecture. Hitachi is one of the firms that led the international standardization of the

DVD and has provided IP to the technological standard; while Hitachi has transferred technologies

of the modularized products, the DVD drives, to HLDS.

However, Hitachi does not transfer technologies of key components to HLDS. Key components

with integral architecture, such as the optical pick-up and the LSI chipset with microcode, have

been provided to HLDS from Hitachi of Japan. Figure 7 shows the concept of the architecture-

based alliance model. Since 2003, only three years after the collaboration started, HLDS has

become the leading optical storage manufacturer in the world. Many similar alliances have been

seen between not only Japan and NIEs but also between Europe and the NIEs (see Table 1).

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 26

Toshiba 51%

Philips 51%

JVC 51%

Hitachi 51%

Investment

Samsung 49%

Toshiba Samsung Storage

Technology (TSST)

2004

BenQ 49%

Philips BenQ Digital Storage

(PBDS)

2003

Light-on 49%

JVC Light-on Manufacturing &

Sales (JLMS)

2001

LG 49% Hitachi LG Data Storage (HLDS) 2000

Name of Joint Venture

Establish

ment

(year)

Table 1 Architecture based alliance in DVD industry

Figure 7 Architecture-based alliance model

R & D

Firm A in advanced country

Finished Products

Product

Design

Mass

Production

Product

Design

Product

Design

Joint Venture

between A and B

Finished Products

Firm B in NIEs Finished Products

R & D

Key Components

Product

Design

Mass

Production

Technology Transfer of

Modular Products

Technology Transfer of

Modular Products

Figure 7. Architecture-based alliance model

Active

Do not

active

Mass

Production

Mass

Production

Transfer of Mass

Production Technology

Supply Key Components

( with Integral Products)

Table 1 Architecture-based alliance in DVD industry

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 27

4 Economic growth through international standardization

4.1 Trade structure in East Asia

International standardization has accelerated the modularization of the product. Product

modularization has promoted the international division of labour and the alliance model described

in section 3. We can confirm the development of this new business model in macro by observing

the current trade structure in East Asia.

Figure 8 illustrates the trade structure among Japan, Korea, Taiwan, and China. In Korea and

Taiwan, there is an excess of exports from Japan, while in China, there is an excess of exports

from both Taiwan and Korea. There is a chain of manufacturing flow from Japan to Korea and

Taiwan, and further to China. Korea and Taiwan import key components and manufacturing

equipment from Japan, manufacture products using the imported materials, and export their

products to China. Low-cost, final products such as the internationally standardized DVD players

are assembled in China and exported to the US and European markets.

Figure 8 Trade in East Asia (2004)

Although some Chinese manufacturing companies export to advanced countries, the foreign-

affiliated firms in China export to the global market from China. Japanese, Korean, and Taiwanese

companies have made a huge investment in China (see Figure 9). With the advance of China, the

hollowing of the manufacturing industry has become a serious problem even in Korea and Taiwan.

However, high-tech products such as LCD panels and semiconductors are still produced in Korea

and Taiwan and exported to China.

Figure 8 Trade in East Asia (2004)

Japan

Korea

Taiwan

China:

Mainland &

Hong Kong

109

96

68

30

44

22

64

19

42

17

Sources: Prepared by JETRO from Trade Statistics, Ministry of Finance, Japan. Also data from Bureau of Foreign Trade, MOEA

(Ministry of Economic Affairs, R.O.C.) and Korean International Trade Association.

7 10

Unit: Billion $

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 28

Figure 9 Cumulative amount of direct investment in East Asia (2004)

LCD and semiconductor companies in Korea and Taiwan depend on foreign companies, especially

Japanese companies. For example, major equipment and materials for LCD panels, such as

polarizer and colour filters, are supplied to Korean and Taiwanese LCD manufacturers by

Japanese firms (see Table 2).

Taiwan has had a consistent trade deficit with Japan even though it has enjoyed a trade surplus for

years. The export industry in Taiwan depends on imports from Japan. Figure 10 shows the relation

between the total amount of exports from Taiwan, and the amount of imports from Japan. There is

a positive correlation between these two.

Figure 9 Cumulative amount of direct investment in East Asia (2004)

Japan

Korea

Taiwan

China

31,487

60

10,965

895

10,993

1,014

7,774

951

Sources: JETRO. Figure for Taiwan from Monthly Statistics of Exports, The Republic of China.

Data of Taiwan is cumulative dollars from 1991 to 2004.

41,249

Unit: Million $

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 29

Figure 10 Trade structure of Taiwan

Note: 1) CCD solar-electric generated element 2) semiconductor wafer, etc.

62.0% R KOREA (16.0%) CHINA (22.7%) HONG KONG (23.3%) Prisms and other optical devices uninstalled and polished

48.4%

HONG KONG

(10.8%)

R KOREA (15.6%) CHINA (22.0%) Printed circuit

64.8% CHINA (10.3%) TAIWAN (26.9%) R KOREA 27.6%) Other electric quantity meter (no recording device

69.4% CHINA (20.4%) R KOREA (21.3%) TAIWAN (27.7%) Other machinery aimed for specific usage

Others

77.7% THAILAND (19.5%) TAIWAN (20.6%) R KOREA (37.6%) Hot rolled and other sheet steel less than 3 mm thickness

92.8% INDIA ( 6.1%) THAILAND (24.4%) R KOREA (62.3%) Hot rolled and other sheet steel between 3-4.75 mm thickness

85.8% INDONSIA ( 3.6%) CHINA (20.3%) R KOREA (61.9%) Hot rolled and other sheet steel over 10 mm thickness

Steel

66.1% R KOREA (11.4%) HONG KONG (11.7%) CHINA (43.0%) LCD

84.9% CHINA (10.0%) TAIWAN (25.0%) R KOREA (49.9%) Glass processed

85.0% CHINA (21.5%) TAIWAN (26.7%) R KOREA (36.8%) Sheet and board made by polarized material

LCD

64.9% U S A (13.4%) R KOREA (20.0%) TAIWAN (31.5%) Stepper

79.4% U S A (15.9%) R KOREA (17.9%) TAIWAN (45.6%) Pattern etching machine for semiconductor material

76.4% R KOREA (19.8%) U S A (28.1%) TAIWAN (28.5%) Element doped for electronics industry discotic and wafer

2)

51.2% GERMANY (11.7%) CHINA (18.1%) HONG KONG (21.4%) Photoelectric semiconductor and LED

1)

45.6% CHINA (14.0%) R KOREA (14.4%) HONG KONG (17.2%) Other MIC

48.1% R KOREA (13.5%) HONG KONG (16.3%) CHINA (18.3%) Monolithic ICDigital

IC

Top 3

share in

total

export

Third Second First Item (6 digit HS code) Category

Table 2 Top 3 countries imported from Japan in 2004

Source: Based on figures provided at JETRO web page.

Table 2 Top 3 countries imported from Japan in 2004

Source: Based on figures provided at MOEA (Ministry of Economic Affairs, R.O.C.)web page.

y = 3.781x + 4E+09

R

2

= 0.9577

60

70

80

90

100

110

120

130

140

150

160

10 15 20 25 30 35 40

Import from Japan (US Bill. $)

T

o

t

a

l

E

x

p

o

r

t

(

U

S

B

i

l

l

.

$

)

1989-2000

2001-2003

line shape

(1989-2000)

Figure 10 Trade structure of Taiwan

Regression line

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 30

Similar dependence on Japan is also observed in Korean exports. Korea depends on Japan for the

equipment and materials for LCD panels and semiconductors. Korea auto makers import the outer

steel panels from Japan. The leading export companies in Korea, such as Samsung Electronics,

LG, and Hyundai, are also the top importing companies.

4.2 Market growth and change of value chain

As already mentioned in this paper, product architecture has a huge impact on the catch-up speed

of latecomers. Akamatsu (1962) [1] and Vernon (1966) [12] claimed that the production of new

products started in advanced countries and later production was transferred to the low-cost

developing countries, as the technology matured. However, they did not mention the effect of

modularization or the effect of international standardization on production transfer. As is mentioned

in section 2, modularization radically accelerates this transfer process to developing countries and

modularization is one of the key drivers for the recent remarkable growth of the Chinese

manufacturing sector.

Figure 11 shows these changes in the catch-up process. The left side of the figure shows the

catch-up model explained by Akamatsu (1962) [1] and Vernon (1966) [12]. The right side of the

figure shows that NIEs catch up and overtake the advanced countries. However, as we mentioned,

their catch-up is supported by components and equipment from advanced countries in which IP

and technical expertise are encapsulated.

However, these changes in the catch-up process do not mean that the economic gain of advanced

countries decreases. Figure 12 illustrates the change in economic gain between advanced

countries and NIEs in LCD panels. Japanese LCD companies such as Sharp commercialize LCD

panels and dominate all business in a vertical chain in the early phase of industry. Technological

progress drives the modularization of production and technical expertise is encapsulated in

production equipment. This modularization makes it easy for Korean and Taiwanese companies

to enter the LCD panel industry. One of the most important factors for success in the LCD industry

is the huge investment for large plants. Their entries caused fierce price competition. The price of

LCD panels radically decreased and a huge market emerged. Recently the share of Japanese

firms in LCD panels has been decreasing, while the share in equipment and materials is still quite

large. The share of Japanese firms in the vertical chain has decreased. However, the total amount

of Japanese economic gain is still increasing because of the total market growth.

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 31

Figure 11 Change of catch-up process

Figure 12 Change of vertical structure: price fall and market growth

Advanced Countries

NIES

Figure 11 Change of catch-up process

Advanced Countries

NIES

(1) Traditional Catch-up Model (2) Catch-up Model for Modular Products

Shorter time lag

of catch-up

Products get modularized

Exported components and

equipments

Figure 12 Change of vertical structure: price fall and market growth

Material

Components

LCD

panel

60

-

70

Materials

Components

LCD panel

P

r

i

c

e

Shrink of Vertical Share

of Japanese Firms

Radical Price Fall

Rapid Market Growth

Market Market Growth

Korea

Taiwan

Market Price

time

$

Japan

Japan

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 32

These changes in economic distribution between the advanced countries and NIEs have been

observed in various industries. Figure 13 gives a concrete example of the DVD. The DVD market

was only 1 billion dollars in 1998, when Japanese and European firms dominated the market.

After the entry of NIEs companies, the market grew rapidly to 19 billion US dollars in 2004. In the

vertical value chain, the portion of components is estimated at 47%. The market for components

(US$ 9 billion in 2004) is still dominated by Japanese and European firms and is almost nine times

the total market in 1998.

Figure 13 Shift of added value on DVD

Additionally, the large installed base of DVD players has generated an even larger content market,

as illustrated in Figure 14. Around four billion pieces of DVD media containing content such as

movies were officially sold in 2004. This content market, equal to about US$ 50 billion, is more than

double the DVD hardware market. The DVD content business was dominated by US movie

companies. DVD sales are up to 47% of their total sales in 2004 and DVD division is the biggest

sales division for US movie companies. They are very interested in the international standard for

the next generation of DVDs, although they have never manufactured DVD players. They are also

a key player in the industry and enjoy a large economic gain.

Figure 13 Shift of added value on DVD

Added value

on DVD drive

$9,180M (47%)

Mainly core components

1998

Market: 1B US$

2004

MarketUS$19,4B

Added value created by

developing countries

Added value created by

Japanese and European

firms

$6,400M (33%)

DVD drive assemblygeneral parts

Added value

on core

components

Monopoly by

Japanese and

European firms

Distribution channel

$3,850M (20%)

Distribution cost and margins

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 33

Figure 14 Content market generated by DVD

5 Concluding remarks

We have described the economic impact of international standardization using a framework of

architecture. Focusing on the optical storage industry, we have described in detail the process by

which the modularization of products and international standardization induce many entrants from

NIEs and that entry causes fierce price completion and rapid market expansion. Next, we suggest

a new type of business model based on international standards. The division of labour between

advanced companies and developing companies and their collaborative business model is

described. Finally, we have discussed the economic growth model based on the modularization

and international standardization. Advanced countries and NIEs have been able to share the

economic gain and collaboratively generate a larger market. International standardization could

contribute to global economic growth. However, an adequate process of international

standardization would be needed for this economic gain to be fully realized.

Figure 14 Content market generated by DVD

DVD drive

$9,180M (13.2%)

Mainly core components

1998: US$1B

(6M unit)

2004US$70B (285M unit)

Added-value created by

developing countries

Added-value created by

Japanese and European

firms

$6,400M (9.2%)

DVD drive assemblygeneral parts

Core

component

Monopoly by

Japanese &

European firms

Distribution channel

$3,850M (5.5%)

Distribution cost and margins

US$ 19.4B

DVD digital contents

provided mostly by Hollywood

approximate sales 4B: $50,000M (72%)

content

Copyright 2006, IEC, Geneva, Switzerland

International standardization as a strategic tool

IEC CENTENARY CHALLENGE 34

Bibliography

[1] Akamatsu, Kaname (1962) A Historical Pattern of Economic Growth in Developing

Countries, The Developing Economies, Preliminary Issue No. 1, pp. 3-25.

[2] Fujimoto, Takahiro (2004) Nihon no Monozukuri Tetsugaku [Japans Manufacturing

Philosophy], Tokyo: Nihonkeizai Shinbunsha (in Japanese).

[3] Fujimoto, Takahiro, Dongsheng Ge and Jewheon Oh (2006) Competition and Co-operation

in Automotive Steel Sheet Production in East Asia, MMRC Discussion Paper, No. 73.

http://www.ut-mmrc.jp/dp/PDF/MMRC73_2006.pdf

[4] Fujimoto, Takahiro and Takashi Oshika (2006) Seihin Aakitekucha-ron to Kokusai Boeki-ron

no Jisshobunseki: 2006 nen Kaitei-ban [Empirical Analysis of the Hypothesis of Product

Architecture and International Trade Theory], MMRC Discussion Paper, No. 72 (in

Japanese). http://www.ut-mmrc.jp/dp/PDF/MMRC72_2006.pdf

[5] Fujimoto, Takahiro and Junjiro Shintaku (2005) Chugoku Seizogyo no Aakitekucha Bunseki

[Architecture-based Analysis of Chinese Manufacturing Industries], Tokyo: Toyokeizai

Shinpousha (in Japanese).

[6] Fujimoto, Takahiro, Akira Takeishi and Yaichi Aoshima (2001) Bijinesu Aakitekucha

[Business Architecture], Tokyo: Yuhikaku (in Japanese).

[7] Ogawa, Koichi (2006) DVD ni miru Nihonkigyo no Hyojunka Jigyo Senryaku [The

Standardization Business Strategy of Japanese Firms in DVD Market], in Kokusai Kyoso

to Gurobaru-standado[International Competition and Global Standard], edited by

Keizaisangyosho Hyoujunka-keizaisei Kenkyukai, Tokyo: Nihon Kikaku Kyokai (in

Japanese).

[8] Ogawa, Koichi, Junjiro Shintaku, Tetsuo Yoshimoto (2005) Architecture-based Analysis of

Competitive Advantage Between Japanese and Catch-up Countrys Firm and Introduction

of New Global Alliance, Annals of Business Administrative Science, 4(3), pp. 21-38.

http://www.gbrc.jp/GBRC.files/journal/abas/ABAS4-3.html

[9] Shintaku, Junjiro, Koichi Ogawa and Tetsuo Yoshimoto (2006) Hikari-disuku Sangyo no

Kyoso to Kokusai-teki Kyogyo Moderu: Suriawase Yoso no Kapuseru-ka ni yoru Mojurah-ka

no Shinten. [The Competition and Architecture Based Alliance in Optical Disk Industry:

Process of Modularization by Encapsulation of Integral Based Technology], in Inobeshon

to Kyoso-yui [Innovation and Competitive Advantage], edited by Kiyonori Sakakibara and

Susumu Kouyama, Tokyo: NTT Shuppan (in Japanese).

[10] Shintaku, Junjiro, Jing-Ming Shiu, Shih-Ting Su (2006) Taiwan Ekisho-sangyo no Hatten

to Kigyo-senryaku [The Growth and Corporate Strategy of Taiwanes LCD-Panel Industry],

Akamon Management Review, 5(8), pp. 519-540. (in Japanese).

http://www.gbrc.jp/GBRC.files/journal/AMR/AMR5-8.html

[11] Shintaku, Junjiro and Tetsuo Yoshimoto (2006) Hikari-disuku no hyoujunka niyoru Kokusai

kyoso to Kokusai Kyocho Senryaku [Global Competition and Strategy of Cooperation by

Standardization of Optical Disc Products], in Kokusai Kyoso to Gurobaru-standado

[International Competition and Global Standard], edited by Keizaisangyosho Hyoujunka-

keizaisei Kenkyukai, Tokyo: Nihon Kikaku Kyokai (in Japanese).

[12] Vernon, Raymond (1966) International Investment and International Trade in the Product

Cycle, Quarterly Journal of Economics, 80(2), 190-207.

Copyright 2006, IEC, Geneva, Switzerland

Architecture-based approaches to international standardization and evolution of business models

IEC CENTENARY CHALLENGE 35

Вам также может понравиться

- Best Practice in P&ID DrawingДокумент42 страницыBest Practice in P&ID DrawingKMAC1230% (2)

- The Chinese Government and PLA's Use of Information WarfareДокумент70 страницThe Chinese Government and PLA's Use of Information WarfareGwen_100% (1)

- Best Practices P&IDДокумент42 страницыBest Practices P&IDamarnetha100% (2)

- Pre Feasibility AnalysisДокумент51 страницаPre Feasibility Analysismorerahul5889100% (1)

- S210Документ86 страницS210Sadullah AvdiuОценок пока нет

- Production Networks in Asia: A Case Study From The Hard Disk Drive IndustryДокумент23 страницыProduction Networks in Asia: A Case Study From The Hard Disk Drive IndustryADBI PublicationsОценок пока нет

- Introduction of Casino Gaming in Okinawa, Japan: A Case Study of Challenges and OpportunitiesДокумент21 страницаIntroduction of Casino Gaming in Okinawa, Japan: A Case Study of Challenges and OpportunitiesBabu GeorgeОценок пока нет

- Sony Value Chain AnalysisДокумент16 страницSony Value Chain AnalysisSista Srinivasa Murty50% (2)

- Research Paper - Readiness of Senior High School Implementation of La Salle College - Final PDFДокумент206 страницResearch Paper - Readiness of Senior High School Implementation of La Salle College - Final PDFJhe Parcs88% (8)

- Global R&D Project Management and Organization: A TaxonomyДокумент19 страницGlobal R&D Project Management and Organization: A TaxonomyLuis Filipe Batista AraújoОценок пока нет

- FE Exam Preparation Book VOL2 LimitedDisclosureVerДокумент151 страницаFE Exam Preparation Book VOL2 LimitedDisclosureVerapi-385588289% (18)

- How Companies Benefit From Standards SettingДокумент14 страницHow Companies Benefit From Standards SettingAlbert0% (1)

- Proceedings of I4SDG Workshop 2021: Giuseppe Quaglia Alessandro Gasparetto Victor Petuya Giuseppe Carbone EditorsДокумент657 страницProceedings of I4SDG Workshop 2021: Giuseppe Quaglia Alessandro Gasparetto Victor Petuya Giuseppe Carbone Editorsadam.wtadОценок пока нет

- LPG SpecificationДокумент4 страницыLPG SpecificationAdeniyi Alese50% (2)

- Forming Technology Review FINALДокумент27 страницForming Technology Review FINALHardikОценок пока нет

- Collected PlaysДокумент539 страницCollected PlaysHardikОценок пока нет

- Introduction To S88Документ56 страницIntroduction To S88Jennifer MatthewsОценок пока нет

- ISO MethodologyДокумент132 страницыISO MethodologyHardik100% (2)

- ISO - TC 258 - Project, Programme and Portfolio ManagementДокумент5 страницISO - TC 258 - Project, Programme and Portfolio ManagementFai's AlDahlanОценок пока нет

- German Standardization Roadmap Industry 4.0Документ138 страницGerman Standardization Roadmap Industry 4.0Qiong HeОценок пока нет

- The Effect of Technological Platforms On The Global Supply Chain: A Case Study On Intel's Platform Business in The PC IndustryДокумент18 страницThe Effect of Technological Platforms On The Global Supply Chain: A Case Study On Intel's Platform Business in The PC IndustryAnadi RanjanОценок пока нет

- Globalisation of The Automotive Industry: Main Features and TrendsДокумент19 страницGlobalisation of The Automotive Industry: Main Features and TrendsUsman NaeemОценок пока нет

- IMVДокумент8 страницIMVAzril InzaghiОценок пока нет

- Designfore XcellenceinhightechcompaniesДокумент14 страницDesignfore XcellenceinhightechcompaniesfinancetechyОценок пока нет

- The 13 Principles of Lean Product DevelopmentДокумент2 страницыThe 13 Principles of Lean Product DevelopmentVenkatesh Hariharan SrambikalОценок пока нет

- Japan-Oriented Creative Monozukuri (Manufacturing and Production) With TRIZДокумент9 страницJapan-Oriented Creative Monozukuri (Manufacturing and Production) With TRIZ57641Оценок пока нет

- Current Trends in Product Development During COVID-19Документ7 страницCurrent Trends in Product Development During COVID-19VIVA-TECH IJRIОценок пока нет

- Actividad de Artículo CientíficoДокумент4 страницыActividad de Artículo CientíficodanielОценок пока нет

- Strategic Procurement Through Built To Order System: An Analysis of Japanese Auto-ManufacturersДокумент18 страницStrategic Procurement Through Built To Order System: An Analysis of Japanese Auto-ManufacturersHarshaОценок пока нет

- Engineer-To-Order (ETO) Production Planning and Control: An Empirical Framework For Machinery-Building CompaniesДокумент48 страницEngineer-To-Order (ETO) Production Planning and Control: An Empirical Framework For Machinery-Building CompaniesSHAIK NISHARОценок пока нет

- Iec ProposalДокумент2 страницыIec ProposalSelvamuthukumar ExcelОценок пока нет

- (Assignment) : (Different Companies of Data Communication)Документ8 страниц(Assignment) : (Different Companies of Data Communication)Shani MalikОценок пока нет

- Drivers and Impacts in The Globalization of Corporate R&D: An Introduction Based On The European ExperienceДокумент19 страницDrivers and Impacts in The Globalization of Corporate R&D: An Introduction Based On The European ExperienceSujan GuramОценок пока нет

- I. Objective of The Training II. ContentДокумент29 страницI. Objective of The Training II. ContentPeriyanan VОценок пока нет

- STEEPanalysisasatoolforbuildingtechnologyroadmaps CLEAN REVISEDДокумент13 страницSTEEPanalysisasatoolforbuildingtechnologyroadmaps CLEAN REVISEDRavi BtechОценок пока нет

- MT5001 Desc - Assignm & Syllabus (201617)Документ8 страницMT5001 Desc - Assignm & Syllabus (201617)LiuZetongОценок пока нет

- CFP - CVIU Special Issue On Assistive Computer Vision and Robotics BIOДокумент4 страницыCFP - CVIU Special Issue On Assistive Computer Vision and Robotics BIOMuhammadRiky FirmansyahОценок пока нет

- Sustainability 14 02708 v2Документ21 страницаSustainability 14 02708 v2mehakjaanii55555Оценок пока нет

- Roadmap I4Документ138 страницRoadmap I4RESHMAОценок пока нет

- Product Development in Japanese TV Game Software: The Case of An Innovative GameДокумент31 страницаProduct Development in Japanese TV Game Software: The Case of An Innovative GameDark ResturantОценок пока нет

- Technological Innovation and International Competitiveness of Die and Mold Industry in Taiwan and KoreaДокумент12 страницTechnological Innovation and International Competitiveness of Die and Mold Industry in Taiwan and KoreariazdollarОценок пока нет

- Dization: Siemens On Added Value For Standards Users New ISO 9000 VideoДокумент48 страницDization: Siemens On Added Value For Standards Users New ISO 9000 VideowranghelОценок пока нет

- A Framework For Product DevelopmentДокумент15 страницA Framework For Product DevelopmentDorcus AnishaОценок пока нет

- The Role of Knowledge Based Engineering in Product ConfigurationДокумент9 страницThe Role of Knowledge Based Engineering in Product ConfigurationTransação autorizadaОценок пока нет

- Braglia Et Al 2019Документ28 страницBraglia Et Al 2019Sam EvangelistaОценок пока нет

- Lee Et Al. - 2021 - Model For Identifying Firm's Product Innovation DyДокумент15 страницLee Et Al. - 2021 - Model For Identifying Firm's Product Innovation Dymjobs247Оценок пока нет

- BIN3020-N UG Business Research Methods Top-Up: What Strategy Samsung Used For Its Electrons To Be InternationalДокумент15 страницBIN3020-N UG Business Research Methods Top-Up: What Strategy Samsung Used For Its Electrons To Be InternationalDima PyagayОценок пока нет

- Manufacturing As A Data-Driven Practice: Methodologies, Technologies, and ToolsДокумент25 страницManufacturing As A Data-Driven Practice: Methodologies, Technologies, and ToolsRhishavdas KОценок пока нет

- Gest International AnnouncementДокумент6 страницGest International AnnouncementFilippo GaspariniОценок пока нет

- Iso/Iec JTC 1: Internet of ThingsДокумент17 страницIso/Iec JTC 1: Internet of ThingsChristen CastilloОценок пока нет

- Chapter-1: An Exhaustive Case Study of Lean ManufacturingДокумент57 страницChapter-1: An Exhaustive Case Study of Lean ManufacturinganimeshОценок пока нет

- Implementation of Lean Manufacturing Principles in Auto PDFДокумент6 страницImplementation of Lean Manufacturing Principles in Auto PDFsagarbolisettiОценок пока нет

- Thesis Topics in Manufacturing TechnologyДокумент4 страницыThesis Topics in Manufacturing TechnologyBuyCustomEssaysOnlineOmaha100% (1)

- 23 DCSApplicationof VMto Selected Construction Projectsin Nigeria 1Документ11 страниц23 DCSApplicationof VMto Selected Construction Projectsin Nigeria 1Tolu BoltonОценок пока нет

- Advancing The Industrial Internet of Things: AuthorsДокумент25 страницAdvancing The Industrial Internet of Things: Authorspino mancusoОценок пока нет

- Knowledge Network of Toyota: Creation, Diffusion, and Standardization of KnowledgeДокумент12 страницKnowledge Network of Toyota: Creation, Diffusion, and Standardization of KnowledgeozuwoОценок пока нет

- Literature Review of Toyota Production SystemДокумент6 страницLiterature Review of Toyota Production Systemaflsjizaf100% (1)

- Toyota Production System Research PaperДокумент8 страницToyota Production System Research Papercaqllprhf100% (1)

- Methodology For Product Development in R&D CompaniesДокумент10 страницMethodology For Product Development in R&D CompaniesJosip StjepandicОценок пока нет

- Stkiisraelimarket2016 160403125536Документ141 страницаStkiisraelimarket2016 160403125536borisg3Оценок пока нет

- IJBIR070201TONELLI - Exemplo Artigo EstruturaДокумент22 страницыIJBIR070201TONELLI - Exemplo Artigo EstruturaJoseОценок пока нет

- Understanding Mobile Technologies & Current Market Trends: Event ProposalДокумент9 страницUnderstanding Mobile Technologies & Current Market Trends: Event ProposalarorickyОценок пока нет

- Smart Manufacturing Systems For Industry 4.0: A Conceptual FrameworkДокумент9 страницSmart Manufacturing Systems For Industry 4.0: A Conceptual FrameworkVikas BavaneОценок пока нет

- Uta Thesis Mechanical CheckДокумент4 страницыUta Thesis Mechanical Checkkimberlybergermurrieta100% (2)

- Taking the LEAP: The Methods and Tools of the Linked Engineering and Manufacturing Platform (LEAP)От EverandTaking the LEAP: The Methods and Tools of the Linked Engineering and Manufacturing Platform (LEAP)Dimitris KiritsisОценок пока нет

- Sustainable Product Development: Tools, Methods and ExamplesОт EverandSustainable Product Development: Tools, Methods and ExamplesDaizhong SuОценок пока нет

- RAW Materials: Jean Louis HEITZ, CRITT Matériaux AlsaceДокумент1 страницаRAW Materials: Jean Louis HEITZ, CRITT Matériaux AlsaceHardikОценок пока нет

- Characterization of Fused Cast Refractories Regarding Their Glass Defect Formation BehaviourДокумент18 страницCharacterization of Fused Cast Refractories Regarding Their Glass Defect Formation BehaviourHardikОценок пока нет

- Folder Glasstec EДокумент8 страницFolder Glasstec EHardikОценок пока нет

- Glass International 2010 - Air Liquide16742Документ3 страницыGlass International 2010 - Air Liquide16742HardikОценок пока нет

- Pi-Chi Han VitaДокумент24 страницыPi-Chi Han Vitaapi-561126393Оценок пока нет

- Hup History2017Документ37 страницHup History2017Alec NiculescuОценок пока нет

- Sao Paulo CollapseДокумент63 страницыSao Paulo CollapsepeartmОценок пока нет

- Manajemen Kinerja Dalam Pemerintahan CinaДокумент28 страницManajemen Kinerja Dalam Pemerintahan CinaGinrey Shandy AlgamОценок пока нет

- Case Study 1 Philippines China and Scarborough ShoalДокумент3 страницыCase Study 1 Philippines China and Scarborough ShoalaadlabbaoОценок пока нет

- The East Asian Currency Crisis and Recovery: Lawrence J. Lau, Ph. D., D. Soc. Sc. (Hon.)Документ46 страницThe East Asian Currency Crisis and Recovery: Lawrence J. Lau, Ph. D., D. Soc. Sc. (Hon.)Vinit TrivediОценок пока нет

- The U.S.-China Trade War and Options For TaiwanДокумент5 страницThe U.S.-China Trade War and Options For TaiwanThe Wilson CenterОценок пока нет

- 27 MayДокумент22 страницы27 MayAwais ChaudharyОценок пока нет

- Comparative Analysis - Lazaro, Jonela B. (MM2)Документ9 страницComparative Analysis - Lazaro, Jonela B. (MM2)Jonela LazaroОценок пока нет

- Insights Treasures in China Warehouse SectorДокумент152 страницыInsights Treasures in China Warehouse Sectordrmohamed120Оценок пока нет

- The Chinese Diaspora - Chinese Studies - Oxford BibliographiesДокумент3 страницыThe Chinese Diaspora - Chinese Studies - Oxford BibliographiesMelanieShiОценок пока нет

- Inventec Case StudyДокумент3 страницыInventec Case StudyMonica TrieuОценок пока нет

- Date Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)Документ1 страницаDate Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)PatOcampoОценок пока нет

- Alagappa Muthiah - Civil Society and Political Change in AsiaДокумент553 страницыAlagappa Muthiah - Civil Society and Political Change in AsiaLuis Fernando Gutiérrez DomínguezОценок пока нет

- Coal Disadvantages: 7 Week Juniors Heidt, Peterson, Silber, Clark Coal DisadvantagesДокумент196 страницCoal Disadvantages: 7 Week Juniors Heidt, Peterson, Silber, Clark Coal DisadvantagesAffNeg.ComОценок пока нет

- Peking University (Law School)Документ2 страницыPeking University (Law School)Frank MarshallОценок пока нет

- (784445670) Chapter 19 Empires in Collision OutlineДокумент5 страниц(784445670) Chapter 19 Empires in Collision OutlineasdjiofaОценок пока нет

- Koichi Iwabuchi Recentering Globalization PC Jap - RezumatДокумент17 страницKoichi Iwabuchi Recentering Globalization PC Jap - Rezumatlydia17Оценок пока нет

- Understanding Economic Development and Institutional Change: East Asian Development Model Reconsidered With Implications For ChinaДокумент21 страницаUnderstanding Economic Development and Institutional Change: East Asian Development Model Reconsidered With Implications For ChinaPhòng Cung cấp Thông tinОценок пока нет

- TAIWAN: Country or Independent State?: History/HerstoryДокумент2 страницыTAIWAN: Country or Independent State?: History/HerstoryKenneth Steven SalcedoОценок пока нет

- KFC in ChinaДокумент2 страницыKFC in ChinaRaju MauryaОценок пока нет

- China's Elegant, Flawed, Grand StrategyДокумент16 страницChina's Elegant, Flawed, Grand StrategyFa BalОценок пока нет

- Chinas Maritime Silk Road Initiative Africa and The Middle East Feats Freezes and Failures 1St Ed Edition Jean Marc F Blanchard Full ChapterДокумент68 страницChinas Maritime Silk Road Initiative Africa and The Middle East Feats Freezes and Failures 1St Ed Edition Jean Marc F Blanchard Full Chaptersharon.reavis382100% (7)

- Presentation +Global+Steel+Market+ +the+Present+and+the+FutureДокумент33 страницыPresentation +Global+Steel+Market+ +the+Present+and+the+FuturemalevolentОценок пока нет

- Taiwan'S Relations With The Outsaide WorldДокумент12 страницTaiwan'S Relations With The Outsaide WorldsmartchenzmОценок пока нет