Академический Документы

Профессиональный Документы

Культура Документы

Example Risk Assessment For A Bricklaying Company Updated 20-11-12

Загружено:

dwayjayИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Example Risk Assessment For A Bricklaying Company Updated 20-11-12

Загружено:

dwayjayАвторское право:

Доступные форматы

Example Risk Assessment for a Bricklaying Company

Setting the Scene

The manager of a successful bricklaying contractor, with help from worker representatives, carried out a general risk assessment that covered their typical work. This assessment was used when tendering for contracts to demonstrate the firms approach to health and safety. In the tender documents the manager was clear about what was needed from the principal contractor to do the job safely. The firm won a bricklaying contract for a development of three-storey flats. Work was due to start on st !uly "# #. The manager checked the construction phase plan and met the principal contractors site manager on site. This e$tra information was used to amend the general assessment so that it was specific to the work and conditions.

How was the risk assessment done?

The manager followed the guidance in Five Steps to Risk Assessment %www.healthandsafetyworksni.gov.uk&riskassessment' . To identify the ha(ards, the manager) *ead the construction web pages on www.healthandsafetyworksni.gov.uk and +,-s publication +,. /# +ealth and ,afety in 0onstruction %available from +,- 1ooks, %www.hsebooks.com' or download free at www.healthandsafetyworksni.gov.uk&construction2home2page 0hecked the manufacturers instructions for tools & machinery and the data sheet for mortar3 Thought about the work seen on sites3 and Talked to employees to help identify the significant ha(ards and particular work practices. ". The manager then wrote down who could be harmed by the ha(ards and how. 4. 5or each ha(ard identified, the manager recorded what controls, if any, were in place to manage these ha(ards. These controls were then compared to the good practice guide laid out in the manufacturers instructions or the data sheets, Health and Safety in Construction, essentials of health and safety at work publications and the +ealth and ,afety Works 6Is construction web pages. Where e$isting controls did not meet good practice the manager wrote down what further actions were needed to manage the risk.

Page 1 of 10

7. 8utting the findings of the risk assessment into practice, the manager decided and recorded who was responsible for implementing the further actions and when they should be done. When each action was completed it was ticked off and the date was recorded.

Example Risk Assessment for a Bricklaying Company

/. The manager decided that for each new site it was important to make sure the assessment was suitable and amend it depending on the particular work and conditions. 9 review and update of the general risk assessment would be made each year and staff would learn from the work on different sites.

How was the site-specific risk assessment done?

. To turn the general risk assessment into a site-specific assessment, the manager checked the following had been identified) The right ha(ards3 Who might be harmed and how3 0ontrols that would need to be taken on this particular site, and Who would be responsible for putting the controls into practice and when. ". The manager did this by) 0hecking the construction phase plan for the site. :ooking at the general layout of the site as well as what materials were to be used %in particular what weight of blocks and lintels', what e;uipment and plant would be needed, and what general rules would need to be followed3 <isiting the site3 and =iscussing the work and the site conditions and general rules with the principal contractors site manager. 4. The manager made the supervisor responsible for briefing the bricklayers about the site rules on their first day.

Important Reminder

his example risk assessment shows what kind of approach a small !"siness might take# $se it as a ro"gh g"ide to think thro"gh some of the ha%ards in yo"r !"siness and the steps yo" need to take to control the risks#

Page 2 of 10

&lease note that this is not a generic risk assessment that yo" can '"st p"t yo"r company name on and adopt wholesale witho"t any tho"ght# his wo"ld not satisfy the law ( and wo"ld not !e effecti)e in protecting people# in yo"r !"siness for yo"rself# Example Risk Assessment for Bricklaying Company E)ery !"siness is different ( yo" need to think thro"gh the ha%ards and controls re*"ired

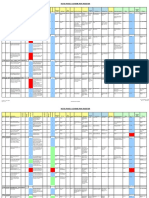

Company name+ ,ure 5oundations :td Assessment carried o"t !y+ :... 1uilder

-hat are the ha%ards? .alling from Height -ho might !e harmed and how? ,erious injury or even fatal injury could occur if a worker falls. -hat are yo" already doing?

,ate assessment was carried o"t+ # &#>& # ,ate of next re)iew+ # &#>&

-hat f"rther action do yo" need to take? ,caffold re;uirements agreed, including loading bays and appropriate load rating. ,upervisor to speak regularly to site manager to arrange scaffold alterations and ensure that weekly inspections have been carried out. -ho needs to carry o"t the action? :.1 -hen is the action needed !y? "#&#>& #

,one

9gree scaffolding re;uirements at contract stage, including appropriate load rating and provision of loading bays. 1ricklayers supervisor to check with the site manager that the correct scaffold is provided and inspected. Workers instructed not to interfere with or misuse scaffold. ,upervisor to keep an eye out for problems. :adders in good condition, ade;uately secured %lashed' and placed on firm surface. 1and stands with handrails to be used for work on internal walls.

?&#>& #

:.1

5rom) # &#>& #

----

Page 3 of 10

-hat are the ha%ards?

-ho might !e harmed and how?

-hat are yo" already doing? Workers trained to put up bandstands.

-hat f"rther action do yo" need to take?

-ho needs to carry o"t the action?

-hen is the action needed !y?

,one

Collapse of Scaffold

9ll operatives on scaffold may incur crush injuries, or worse, if the scaffold collapses on top of them.

9gree scaffolding re;uirements at contract stage, including appropriate load rating and provision of loading bays. 1ricklayers supervisor to check with the site manager that the correct scaffold is provided and inspected. 1rick guards kept in position on scaffold lifts. Waste materials removed from scaffolding and placed in skip. ,afety helmets and protective footwear %with steel toecaps and mid-soles' supplied and worn at all times. 1ricks, mortar etc to be transported and lifted to scaffold using telehandler provided by principal contractor.

,upervisor to keep a check to make sure that scaffold is not overloaded with materials.

:.1

5rom) # &#>& #

----

.alling o!'ects hitting head or !ody/ incl"ding feet

,erious head and other injuries to workers, others on site and members of the public.

,upervisor to monitor use of safety hats and protective footwear.

:.1

5rom) # &#>& #

----

0an"al Handling

9ll workers could suffer from back injury and long-term pain if regularly carrying heavy or awkward objects.

+eaviest blocks are /kg, no special arrangements necessary.

:.1

5rom) # &#>& #

----

Page 4 of 10

-hat are the ha%ards?

-ho might !e harmed and how?

-hat are yo" already doing? 8rovision of lifting bay agreed with principal contractor. 1ricks & blocks to be covered with tarpaulin when stored on site to prevent taking up water. ,pot boards to be raised with blocks to easy working height. Trolley to be used for moving loads of bricks around the scaffold lift. 0heck at tender stage for any blocks or lintels over "#kg and make arrangements. @anager to agree safe route to work area with principal contractor based upon the construction phase health and safety plan. Induction to each site to be carried out for all workers on first day.

-hat f"rther action do yo" need to take? 0oncrete lintels are well over "#kg, to be positioned using telehandler %all are accessible'. 9ll workers to be instructed not to carry materials up by hand.

-ho needs to carry o"t the action? :.1

-hen is the action needed !y? 5rom) # &#>& #

,one

----

0an"al Handling 1contin"ed2

:.1

5rom) # &#>& #

----

-orkers str"ck or cr"shed !y mo)ing )ehicles on site

Workers could suffer serious or even fatal injuries from vehicles and machines on site, particularly when reversing.

,afe route agreed with principal contractor. ,upervisor to liaise with site manager to ensure safe route stays clear.

:.1

"/&#>& #

"4&#>& #

:.1

5rom) # &#>& #

----

Instruct staff that they must never drive vehicles and plant on this site.

:.1

5rom) # &#>& #

----

Page 5 of 10

-hat are the ha%ards?

-ho might !e harmed and how?

-hat are yo" already doing?

-hat f"rther action do yo" need to take? +igh-visibility vests to be provided. ,upervisor to check vests are worn on all sites where the principal contractor re;uires them. Temporary storage locations to be agreed with the site manager. ,upervisor to ensure that workers wear safety footwear when in site.

-ho needs to carry o"t the action? :.1

-hen is the action needed !y? 5rom) # &#>& #

,one

----

:.1

5rom) # &#>& #

----

Slips and rips

9ll workers may suffer sprains or fractures if they trip over waste including brick bands.

.ood housekeeping maintained at all times. Waste including brick bands and pallet debris disposed of in skip. ,afety footwear provided to all workers. ,afe route to workplace agreed with principal contractor based on construction phase health and safety plan.

:.1

" &#>& #

7&#>& #

:.1

5rom # &#>& #

----

Stepping on nails and sharp o!'ects

9ll workers could suffer foot injuries and pallet debris. ,lips at height could result in a serious fall.

,afety boots with steel toecaps and midsoles provided to all workers Waste disposed of in skips. ,afety footwear provided to all workers.

-$plain the need to wear safety boots and dispose of waste in skips. *epeat annually.

:.1

"&#>& #

#&#>& #

Page 6 of 10

-hat are the ha%ards?

-ho might !e harmed and how?

-hat are yo" already doing? ,afe route to workplace agreed with principal contractor based on construction phase health and safety plan.

-hat f"rther action do yo" need to take? ,upervisor to check that safety boots are always worn and waste disposed of properly.

-ho needs to carry o"t the action? :.1

-hen is the action needed !y? 5rom) # &#>& #

,one

----

Ha%ard to eyes/ c"tting !ricks

1ricklayers could suffer eye injury through flying brick fragments.

,afety goggles %-6 AA 1 standard' worn when breaking bricks.

Bse of goggles to be monitored by the supervisor.

:.1

5rom) # &#>& #

----

Ha%ardo"s s"!stances/ mortar

=irect skin contact with the mortar could cause bricklayer contact dermatitis and burns.

*isk of dermatitis or cement burns and precautions e$plained to all workers. Bse cement or cement containing products within the use-by date. =irect skin contact to be avoided, 0marked 8<0 gloves used when handling mortar. .ood washing facilities on site, with hot and cold water, soap and basins large enough to wash forearms. 8rincipal contractors first aid includes emergency eyewash.

Training on how to treat e$posure to be given to all operatives. ,upervisor to be made aware of anyone with early signs of dermatitis.

:.1

"/&#>& #

C&#>& #

:.1

5rom) # &#>& #

----

Page 7 of 10

-hat are the ha%ards? 3perating Cement 0ixer

-ho might !e harmed and how? Workers could be crushed or cut if the mi$er topples or they get caught in moving parts.

-hat are yo" already doing?

-hat f"rther action do yo" need to take? ,upervisor to check mi$er daily for obvious damage.

-ho needs to carry o"t the action? :.1

-hen is the action needed !y? 5rom) # &#>& #

,one

0ement mi$er located on firm level ground. @i$er is fully guarded and guards in place during operation. @i$er is # volt and 89T tested every 4 months. 9ngle grinders replaced with block splitter, removing the risk of significant dust e$posure. The use of a grinder for chasing etc is not needed on the job.

----

,"st from c"tting !ricks

=ust e$posure could cause silicosis.

6o further action necessary.

----

-----

----

4oise from "se of e*"ipment/ eg# angle grinder

Workers using grinders or working near people who may suffer hearing loss.

9ngle grinders replaced with block splitter, removing high noise levels from our work. 0onstruction phase plan show other trades using grinders etc, should not be working close enough to cause problems.

,upervisor to monitor and talk to site manager if noisy work does start close by.

:.1

5rom) # &#>& #

----

Page 8 of 10

-hat are the ha%ards? 5i!ration from "se of e*"ipment s"ch as angle grinder

-ho might !e harmed and how? -$posure to vibration can lead to the development of Dvibration white fingerE %<W5'

-hat are yo" already doing?

-hat f"rther action do yo" need to take? 6o further action necessary.

-ho needs to carry o"t the action? ----

-hen is the action needed !y? ----

,one

9ngle grinders replaced with block splitter. 6o significant vibration left.

----

.ire 6 Explosion

9ll operatives in the vicinity could suffer from smoke inhalation or burns.

,uitable fire e$tinguisher kept in site office and welfare block. .ood housekeeping monitored by supervisor.

,upervisor to brief all workers on first day on emergency arrangements agreed with principal contractor.

:.1

# &#>& #

# &#>& #

Health iss"es relating to poor welfare facilities 6 first aid arrangements

9ll operatives.

8rincipal contractor will have facilities on site by the time bricklaying starts, including) - flushing toilet3 - hot and cold running water, soap, towels and full-si(e washbasins3 - heated canteen with kettle etc3 - first aid e;uipment3 - principal contractor will arrange clearing and ensure the necessary electrical and heating safety checks

,upervisor to brief workers on facilities and keeping them clean.

:.1

# &#>& #

# &#>& #

Page 9 of 10

-hat are the ha%ards?

-ho might !e harmed and how?

-hat are yo" already doing? are made, and - Trained first aider and appointed person on site.

-hat f"rther action do yo" need to take?

-ho needs to carry o"t the action?

-hen is the action needed !y?

,one

Assessment Re)iew ,ate+ # &#>&

Example Risk Assessment for a Bricklaying Company p"!lished !y HS-4I/ 78697# Health and Safety Exec"ti)e gratef"lly acknowledged as so"rce .

Page 10 of 10

Вам также может понравиться

- Bec 3324: Project Management Year Iii - Semester Ii Session 7Документ35 страницBec 3324: Project Management Year Iii - Semester Ii Session 7Tharindu PereraОценок пока нет

- Risk Matrix: Project: ID: Start Date: End DateДокумент2 страницыRisk Matrix: Project: ID: Start Date: End Dateketac100% (1)

- Qualitative V Quantitative Risk AssessmentДокумент5 страницQualitative V Quantitative Risk AssessmentGundeepОценок пока нет

- Prepare for Disasters with an Effective ERPДокумент8 страницPrepare for Disasters with an Effective ERPVPM13Оценок пока нет

- Guide Lines For NSC HSE PlanДокумент52 страницыGuide Lines For NSC HSE Planജിനാദ് അബ്ദുസ്സലാംОценок пока нет

- Instructor Kathryn Cassidy ProcoreДокумент4 страницыInstructor Kathryn Cassidy ProcoreSrujan NamburiОценок пока нет

- Simple Safety Risk RegisterДокумент4 страницыSimple Safety Risk RegisterChanthouen PichОценок пока нет

- 5 Step CultureSAFE CycleДокумент1 страница5 Step CultureSAFE CycleKhuda BukshОценок пока нет

- 37 Material StorageДокумент5 страниц37 Material StorageCaron KarlosОценок пока нет

- Security And Risk Management Tools A Complete Guide - 2020 EditionОт EverandSecurity And Risk Management Tools A Complete Guide - 2020 EditionОценок пока нет

- Fatal falls from heightДокумент3 страницыFatal falls from heightEric LimОценок пока нет

- Al Majal QMS - 2018Документ19 страницAl Majal QMS - 2018Adam DeviatteyОценок пока нет

- ph1 App F Risk RegisterДокумент3 страницыph1 App F Risk RegisterHugo HernandezОценок пока нет

- SS 679-2021 PreviewДокумент6 страницSS 679-2021 PreviewmasonОценок пока нет

- Carpentry Risk Assessment WordДокумент6 страницCarpentry Risk Assessment WordPrince TeruyaОценок пока нет

- SWMS - Blind IstallationДокумент12 страницSWMS - Blind IstallationParasОценок пока нет

- 16 SecurityДокумент8 страниц16 SecurityMohammed MinhajОценок пока нет

- AsdssssДокумент1 страницаAsdssssAviects Avie JaroОценок пока нет

- Measuring health and safety performanceДокумент31 страницаMeasuring health and safety performancesohaibОценок пока нет

- Risk Management FOR Hospital Management SystemДокумент9 страницRisk Management FOR Hospital Management SystemOjo SolomonОценок пока нет

- Doka FormworkДокумент124 страницыDoka FormworkTranタオОценок пока нет

- ETG3 - Guidelines For Safety Audit ReportsДокумент5 страницETG3 - Guidelines For Safety Audit ReportsRahul RamachandranОценок пока нет

- Grace Management & Construction, LLC Accident Prevention PlanДокумент94 страницыGrace Management & Construction, LLC Accident Prevention Plancw2851Оценок пока нет

- Appointment Letter As Security Inspector FOR SCRIBDДокумент1 страницаAppointment Letter As Security Inspector FOR SCRIBDGaillard GuerreroОценок пока нет

- Fleet Risk Assessment Process GuideДокумент4 страницыFleet Risk Assessment Process GuideHaymanAHMEDОценок пока нет

- Safe System of Work Plan - Building and Monument Maintenance (HSA)Документ64 страницыSafe System of Work Plan - Building and Monument Maintenance (HSA)zseyo1Оценок пока нет

- Essay Writing Sample AssignmentДокумент4 страницыEssay Writing Sample AssignmentJane AustinОценок пока нет

- Workplace Safety and Health (Risk Management) ReguДокумент3 страницыWorkplace Safety and Health (Risk Management) ReguTh NattapongОценок пока нет

- Risk Assessment and Mitigation StrategyДокумент1 страницаRisk Assessment and Mitigation StrategySachin SainiОценок пока нет

- Business Continuity Planning MethodsДокумент158 страницBusiness Continuity Planning MethodsLara Melissa DanaoОценок пока нет

- Qcs 2010 Part 18.05 JoineryДокумент5 страницQcs 2010 Part 18.05 JoineryRotsapNayrbОценок пока нет

- JHA Sample PDFДокумент2 страницыJHA Sample PDFT.DAVID DHASОценок пока нет

- Installation Methodology for Video Wall at Islamabad AirportДокумент17 страницInstallation Methodology for Video Wall at Islamabad AirportDani SalimiОценок пока нет

- I. ASSI Victor Eyo Ii. Iii. Iv. v. VIДокумент7 страницI. ASSI Victor Eyo Ii. Iii. Iv. v. VIVictor AssiОценок пока нет

- Safety Information Sheet Lifting Plans (LOLER 1998)Документ5 страницSafety Information Sheet Lifting Plans (LOLER 1998)dsn_sarmaОценок пока нет

- Construction Design and Management RegulДокумент39 страницConstruction Design and Management Regulkhx2Оценок пока нет

- Asbestos Management ProcedureДокумент6 страницAsbestos Management Procedureh4rajukuОценок пока нет

- Method Statement TempДокумент3 страницыMethod Statement TempridminjОценок пока нет

- Safety Risk Managment Plan (Lahor Project)Документ14 страницSafety Risk Managment Plan (Lahor Project)rao sajjad0% (1)

- SWMS Sample - Safe Work MethodДокумент8 страницSWMS Sample - Safe Work Methodsupasart100% (1)

- ISO Monthly Objectives and Metrics DiscussionsДокумент3 страницыISO Monthly Objectives and Metrics DiscussionsRajeshОценок пока нет

- Risk ProfilingДокумент12 страницRisk ProfilingedmeanОценок пока нет

- Annexure A - Health and Safety Baseline SpecificationДокумент53 страницыAnnexure A - Health and Safety Baseline SpecificationSindisoОценок пока нет

- Internship Interim Report: Andrew Hao Jie AbisheganadenДокумент2 страницыInternship Interim Report: Andrew Hao Jie AbisheganadenAnonymous 32vj2LXxwhОценок пока нет

- Risk Assessment Record: Residual RatingДокумент2 страницыRisk Assessment Record: Residual RatingRome AdolОценок пока нет

- Safety MS SingaporeДокумент2 страницыSafety MS SingaporeRaymondGomezBlancoОценок пока нет

- Project Risk ManagementДокумент25 страницProject Risk ManagementCassandri LabuschagneОценок пока нет

- Ibrahim Saad C.V Storekeeper, "Manufacture - Supply Chain"Документ5 страницIbrahim Saad C.V Storekeeper, "Manufacture - Supply Chain"Ibrahim Mohamed Saad Ibrahim67% (3)

- hsg47 - Avoiding Danger From Underground Services PDFДокумент40 страницhsg47 - Avoiding Danger From Underground Services PDFAchilleas21Оценок пока нет

- Madda Walabu University: Construction Health and Safety Management COTM 5303Документ47 страницMadda Walabu University: Construction Health and Safety Management COTM 5303ABU BEBEK AhmОценок пока нет

- Attachment 1 Risk AssessmentДокумент9 страницAttachment 1 Risk Assessmentjaouad id boubkerОценок пока нет

- Safety Method Statement: U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - ÁДокумент12 страницSafety Method Statement: U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - ÁnabillyusofОценок пока нет

- 2.4.2 Site Security Management PlanДокумент1 страница2.4.2 Site Security Management PlanAkbar AsyisyamОценок пока нет

- Software Engineering Unit 7-RiskДокумент27 страницSoftware Engineering Unit 7-RiskHarshita GopuОценок пока нет

- NEOM-NPR-SOP 09.1 - New and Expectant Mothers Rev 02Документ15 страницNEOM-NPR-SOP 09.1 - New and Expectant Mothers Rev 02mohammadsoboh55Оценок пока нет

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. AДокумент1 страницаSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordОценок пока нет

- GN For Contractor - BiДокумент122 страницыGN For Contractor - Bitoyakatob186Оценок пока нет

- R-Business Continuity Plan Examining of Multi-Usable FrameworkДокумент8 страницR-Business Continuity Plan Examining of Multi-Usable FrameworkJosé Manuel Sánchez Murga100% (1)

- Method Statements of Road WorksДокумент38 страницMethod Statements of Road WorksivanlewizОценок пока нет

- 43 Checklist Prevention WRULDsДокумент6 страниц43 Checklist Prevention WRULDsdwayjayОценок пока нет

- 1998 JunДокумент15 страниц1998 JundwayjayОценок пока нет

- Iosh Ms SampleДокумент9 страницIosh Ms SampledwayjayОценок пока нет

- How To Complete Your Iosh Project AssessmentДокумент12 страницHow To Complete Your Iosh Project Assessmentdwayjay100% (2)

- Understanding Action VerbsДокумент4 страницыUnderstanding Action VerbsDieter SchuffenhauerОценок пока нет

- Maintenance of Flats: Example Risk Assessment ForДокумент5 страницMaintenance of Flats: Example Risk Assessment FordwayjayОценок пока нет

- Construction Risk Assessments IndexДокумент41 страницаConstruction Risk Assessments Indexmasoodae100% (4)

- Iosh Ms SampleДокумент9 страницIosh Ms SampledwayjayОценок пока нет

- Examiners' Report NEBOSH National General Certificate in Occupational Health and Safety (NGC1)Документ12 страницExaminers' Report NEBOSH National General Certificate in Occupational Health and Safety (NGC1)dwayjayОценок пока нет

- Examiners Reports NGC2 Only September 2011 NGC2Документ11 страницExaminers Reports NGC2 Only September 2011 NGC2dwayjayОценок пока нет

- Igi PapersДокумент1 страницаIgi PapersdwayjayОценок пока нет

- Igi PapersДокумент1 страницаIgi PapersdwayjayОценок пока нет

- Scaffolds Scaffolding Work General GuideДокумент16 страницScaffolds Scaffolding Work General GuideTukachungurwa Byarugaba AlexОценок пока нет

- Opti Tower Health and Safety File Oct 12Документ387 страницOpti Tower Health and Safety File Oct 12Pieter HerbstОценок пока нет

- Guide HSE Plan ElementsДокумент16 страницGuide HSE Plan ElementsernestoОценок пока нет

- Faculty of Business BBSH4103 Hazard Management MAY 2019Документ12 страницFaculty of Business BBSH4103 Hazard Management MAY 2019Ben AzarelОценок пока нет

- Philippine Occupational Health and Safety StandardsДокумент5 страницPhilippine Occupational Health and Safety Standardsshema alim100% (1)

- Plumbing N1 Hands-On!Документ16 страницPlumbing N1 Hands-On!Future Managers Pty Ltd38% (8)

- Regulation Cs 3.0Документ3 страницыRegulation Cs 3.0Vaibhav NautiyalОценок пока нет

- Overcoating of Lead-Based Paint On Steel StructuresДокумент51 страницаOvercoating of Lead-Based Paint On Steel Structuresspahicdanilo100% (1)

- Safety and Health Committee OSHA 1994. Safety and Health Officer SHO Malaysia. Mesyuarat Jawatankuasa Keselamatan Dan Kesihatan Pekerjaan. JKKP 1996Документ25 страницSafety and Health Committee OSHA 1994. Safety and Health Officer SHO Malaysia. Mesyuarat Jawatankuasa Keselamatan Dan Kesihatan Pekerjaan. JKKP 1996Zainorin Ali100% (8)

- Midas Copper Conductive Paint MSDSДокумент2 страницыMidas Copper Conductive Paint MSDSAdan Arribasplata SeguinОценок пока нет

- Stairways & Ladders - A Guide To OSHA RulesДокумент15 страницStairways & Ladders - A Guide To OSHA Ruleseafarmihar2554100% (3)

- Role and Responsibilty of Safety OfficerДокумент6 страницRole and Responsibilty of Safety Officerrsandye50% (2)

- Material Safety Data Sheet (MSDS)Документ71 страницаMaterial Safety Data Sheet (MSDS)vvns4519888Оценок пока нет

- 6.4 Accident Investigation 6 Edit BДокумент100 страниц6.4 Accident Investigation 6 Edit BHilmyZulkifliОценок пока нет

- HSE Asbestos The Survey GuideДокумент74 страницыHSE Asbestos The Survey GuideRoger AttwoodОценок пока нет

- What to Include in an Induction ProgrammeДокумент3 страницыWhat to Include in an Induction Programmed4deepanОценок пока нет

- Procedure Investigation AnalysisДокумент7 страницProcedure Investigation AnalysisLisa SwansonОценок пока нет

- Method Statement TrenchДокумент25 страницMethod Statement Trenchabou bakarОценок пока нет

- Unit IV Industrial SafetyДокумент55 страницUnit IV Industrial SafetySaravanan Shanmugam100% (2)

- Ya SonnaДокумент7 страницYa SonnaTeuku M. Zachari AlamsyahОценок пока нет

- Puh ProcedureДокумент36 страницPuh ProcedureAbdülhamit KAYYALİОценок пока нет

- Occupational Health and Safety (OHS) PolicyДокумент17 страницOccupational Health and Safety (OHS) PolicyTimmydipsy Azelav100% (2)

- Safety Patient Handling in Nursing PDFДокумент40 страницSafety Patient Handling in Nursing PDFGumDrop100% (1)

- AD EHS RI CoP 10.0 - Rehabilitation and Return To WorkДокумент10 страницAD EHS RI CoP 10.0 - Rehabilitation and Return To WorkSubhi HSОценок пока нет

- Salt Storage Handbook 2013Документ24 страницыSalt Storage Handbook 2013Patricio TamayoОценок пока нет

- Health and Safety ManualДокумент19 страницHealth and Safety ManualClarkFedele27100% (1)

- Excavation & Trenching ProcedureДокумент38 страницExcavation & Trenching Procedurecobansss100% (4)

- Amr 363-16Документ1 страницаAmr 363-16Matt OwenОценок пока нет

- Cap 642Документ272 страницыCap 642afrodizzyОценок пока нет

- Assignment EOH3202 Occupational HealthДокумент5 страницAssignment EOH3202 Occupational HealthChristopher OwensОценок пока нет