Академический Документы

Профессиональный Документы

Культура Документы

LPPM Filling Chiesa

Загружено:

Kmilo Giraldo0 оценок0% нашли этот документ полезным (0 голосов)

34 просмотров8 страницA great number of castings were poured by the Low Pressure Permanent Mold process for a wide range of filling times and pouring temperatures. One casting was a 2mm-wall (0.080 in.) cover weighing 0.13kg (0.27lb) and the other was a 7kg (15.4lbs) bell housing with walls varying in thickness from 6 to 25mm (0. To 1 in.

Исходное описание:

Оригинальное название

Lppm Filling Chiesa

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документA great number of castings were poured by the Low Pressure Permanent Mold process for a wide range of filling times and pouring temperatures. One casting was a 2mm-wall (0.080 in.) cover weighing 0.13kg (0.27lb) and the other was a 7kg (15.4lbs) bell housing with walls varying in thickness from 6 to 25mm (0. To 1 in.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

34 просмотров8 страницLPPM Filling Chiesa

Загружено:

Kmilo GiraldoA great number of castings were poured by the Low Pressure Permanent Mold process for a wide range of filling times and pouring temperatures. One casting was a 2mm-wall (0.080 in.) cover weighing 0.13kg (0.27lb) and the other was a 7kg (15.4lbs) bell housing with walls varying in thickness from 6 to 25mm (0. To 1 in.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

Measuring Mold Cavity Filling Time in Low Pressure Permanent Mold

Casting of Aluminum A356 Parts

F. Chiesa , and N. Gigure

Centre de Mtallurgie du Qubec, Trois-Rivires, Qubec

B. Duchesne

Collge de Trois-Rivires, Trois-Rivires, Qubec

J. Baril

Technologie de lAluminium et du Magnsium, Trois-Rivires, Qubec

Copyright 2011 American Foundry Society

ABSTRACT

In the present work, a great number of castings were

poured by the Low Pressure Permanent Mold process

for a wide range of filling times and pouring

temperatures. One casting was a 2mm-wall (0.080 in.)

cover weighing 0.13kg (0.27lb) and the other was a

7kg (15.4lbs) bell housing with walls varying in

thickness from 6 to 25mm (0.25 to 1 in.).

Type K thermocouple wires (0.12mm diameter

[0.0045 in.], with a response time of 0.1s) were

connected to a data logger (20 readings per second) to

detect the passage of the liquid metal front, allowing

an accurate measurement of the filling time (0.05s).

As the filling time is obtained by subtracting the

passage times recorded by two identical

thermocouples, the time lags cancels out with no

detrimental effect on the accuracy.

This allowed to determine a slowing factor (SF)

defined as the ratio of the actual measured filling time

to the filling time calculated based on the static

equilibrium level. Slowing factor was found to vary

from 1, for very slow rates of filling, to values greater

than 2 for extremely steep pressure ramps. For typical

industrial production conditions, SF is in the range 1.3

to 1.6 and appears to be closer to 1.0 for thin castings.

It was found that the pouring temperature had little

effect on SF except for extremely low pouring

temperatures (below 700C or 1292F).

INTRODUCTION

The Low Pressure Permanent Mold casting (LPPM)

process is used for producing aluminum and

magnesium parts. It is a novel process for pouring

magnesium alloys,

1,2

but a mature one as far as

aluminum alloys are concerned.

3

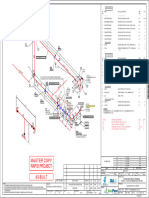

The principle of the

LPPM process is shown in Figure 1. The liquid metal,

located under the mold, is pushed up a transfer tube by

applying a gas pressure on the surface of the melt.

This process presents a host of advantages over gravity

casting, including:

a) Tranquil and perfectly controlled bottom filling of

the mold cavity as illustrated in Figure 1;

b) Superior feeding without risers. In LPPM, the

typical feeding pressure is 900mB versus 100-

200mB for riser fed gravity castings;

c) Thinner walls may be obtained as compared to

gravity filling (as thin as 2mm);

d) The yield is typically 85%, versus 60% in gravity

casting, leading to less returns in the melt, hence a

cleaner metal with consequent energy savings and

reduced melting furnace capacity (tons/h);

e) The liquid metal is cleaner because it is extracted

from underneath the melt surface; and

f) No metal handling by the operator results in better

ergonomics and a perfectly repeated filling at each

cycle.

Among these advantages, the control of the filling is

the most spectacular: by varying the rate of increase of

the pressure applied on the melt, the filling may be

sped up or slowed down at will with great ease.

Filling in the LPPM process has been previously

studied.

4,5

However, the actual time necessary to fill

the mold cavity is not known because the pressure

applied on the melt cannot be strictly related to the

level of the melt in the mold as discussed in the

following section.

Paper 11-003.pdf, Page 1 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

Fig. 1. Principle of LPPM casting.

RELATING PRESSURE AND MELT LEVEL

The LPPM casting process allows the production of

high integrity light metal parts with a high

productivity. LPPM permits very close control of the

filling process. However, the mold cavity being

closed, it is difficult to accurately know the filling time

of the mold cavity, as easily as it is in the case of an

open cavity typical of the gravity poured permanent

molds. The known pressure rise applied on the surface

of the melt allows a calculation of theoretical filling

time, which is always substantially less than the actual

filling time, particularly at high rates. The knowledge

of this actual filling time is necessary to the modeling

of the process, and more importantly, for the

comprehension of phenomena such as superheat

losses, air entrapment and turbulence, leading to

casting defects such as misruns, cold-shuts and

sagging of the cope surface.

The equilibrium level of the metal (i.e. when the liquid

metal is at rest) in the transfer tube and the mold

cavity depends only on the pressure applied on the

surface of the melt inside the pressure tight crucible:

This level will be called the theoretical level. Each

increase in pressure of 1 mB will result in the liquid

aluminum level rising by 4mm.

Consequently, the equilibrium altitude, or theoretical

level can be mathematically derived using the simple

law stating that the difference in pressure p between

two points with a difference in altitude of h (in m) is

equal to p (in Pa) =.g.h, where is the density of

the fluid (2600 kg.m

-3

for liquid aluminum) and g the

acceleration of gravity (9.81 m.s

-2

)

However, this will not be the case in real life because

of the following reasons:

a) Part of the pressure force is used to accelerate the

liquid metal at the entrance of the transfer tube and

to counter viscous forces, so that the actual metal

level will be lower than the theoretical level.

b) Depending on the filling rate with respect to the

venting of the mold, the difficulty in expelling the

air from the mold cavity will result in a pressure

build up which will prevent the liquid metal level

to rise as fast as it should.

For instance, let us assume that the pressure ramp

shown in Figure 2 is applied on the melt surface (0-

500mB in 10s, or 50mB/s), while the top of the mold

is 1500mm above the melt surface. This means that the

theoretical level will rise at a rate of 200 mm/s as

indicated by the blue line in Figure 3. The top of the

mold (at altitude 1500mm) will thus be reached after

7.5s, when the pressure is 375mB as shown by the

white arrow in Figure 2.

Fig. 2. Typical pressure curve in LPPM casting.

Fig. 3. Melt level progression corresponding to the

pressure curve of Fig.2 as a function of venting.

0

20

40

60

80

100

120

140

160

0 2 4 6 8 10 12 14 16 18

time, s

m

e

t

a

l

h

e

i

g

h

t

a

b

o

v

e

p

o

t

l

e

v

e

l

,

c

m

theoretical (4mm/mB) well vented mold poorly vented mold

Paper 11-003.pdf, Page 2 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

However, in a normally vented mold, this relatively

steep pressure rise will result in a lag mainly due to an

air pressure build up in the mold cavity. The actual

melt level progression in the mold will follow the red

curve in Figure 3 while a poorly vented mold will

result in the very slow filling depicted by the yellow

curve in the same figure.

Figure 4 shows typical curves of the pressure build up

in the mold cavity recorded by a manometer during

four consecutive fillings of the LPPM cast bell

housing referred to in the next chapter; in this

particular case, the rate in pressure rise over the

surface of the liquid metal was 15mB/s. The curves in

Figure 4 recorded during these four consecutive cycles

indicate that the backpressure varied between 25 and

40mB under identical pouring conditions; this scatter

is probably due to variations in mold tightness at each

mold closing.

0

10

20

30

40

50

0 1 2 3 4 5 6 7 8 9 10 11

time, s

p

r

e

s

s

u

r

e

,

m

B

Fig. 4. Pressure build-up in cavity during filling.

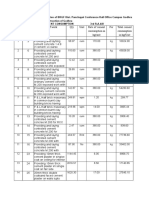

FILLING A 7kg (15.4lbs) A356 BELL HOUSING

The filling times of a 7kg finished casting were

measured for different pressure ramps and the SF

obtained by dividing the measured filling time by the

theoretical filling time corresponding to

metallostatic equilibrium.

The filling times were measured by detecting the

arrival of the flow via two quick response

thermocouples encapsulated in thin copper sheaths;

they were located as indicated in Figure 5 and the

recording rate was 20 readings per second.

The LPPM press used in our filling experiments is

shown in Figure 6 and schematized in Figure 7 where

the correspondence between the pressure applied on

the melt and the altitude is indicated.

Fig. 5. Location of the two thermocouple tips

allowed measuring of the filling times (red dots).

Fig. 6. LPPM press with close-up on mold (at right).

Figure 7 states that when the crucible is full, assuming

a very slow rise in pressure over the melt, the mold

cavity will start filling when the pressure reaches

88mB, and will finish filling when the pressure

reaches 143mB.

Paper 11-003.pdf, Page 3 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

Fig. 7. Relationship between pressure and level.

However, as explained above, the actual pressures will

be greater than 88 and 143mB, all the more since the

filling is fast and the venting of the mold is poor.

The measurement of the filling times was done in the

course of a campaign where the 40 bell housings

shown in Figure 8 were produced. Nine initial pours

were necessary to run in the mold and reach a dynamic

thermal equilibrium.

Figure 9 shows the recorded temperature cycling in the

mold during the whole campaign (49 pours); the

positions of the thermocouples inserted in the mold are

represented by a red dot on the models shown at two

different view angles in Figure 9.

Fig. 8. Production of the casting campaign when

filling times were measured (40 castings).

Fig. 9. Recorded mold temperature cycling at locations indicated by the two red dots on the casting models.

Paper 11-003.pdf, Page 4 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

300

320

340

360

380

400

420

440

10 12 14 16 18 20 22 24

time (s)

t

e

m

p

e

r

a

t

u

r

e

(

C

)

EXPERIMENTAL RESULTS (BELL HOUSING)

A typical response from the two thermocouples used

to measure the filling time is shown in Figure 10. It

pertains to pour #34 with a melt temperature of 745C

(1373F), a pressure ramp of 0-300mB in 25s (12mB/s)

corresponding to a theoretical filling time of 4.7s. The

detailed analysis of the curve shows that the filling

time is 21.3-14.9= 6.4s. The slowing factor is thus

equal to SF=6.4s/4.7s=1.36 in this particular instance.

Slowing factor was calculated in a similar fashion for

19 normal pours, i.e. pours at a temperature between

745C and 755C(1373F and 1391F) and pressure

ramps of 15mB/s and 12mB/s, or 0-300mB pressure

rise in 20s and 25s respectively. The results are shown

in Figure 11 for 12 pours at 15mB/s and 7 pours at

12mB/s.

It shows that under normal conditions, the SF is

about 1.5 with a higher dispersion when the filling is

faster. This would entail that a more reproducible

filling is achieved when the filling is slower.

Fig. 10. Typical response from the thermocouples

measuring the filling time. (pour#34)(See Fig.5)

Fig.11.Slowing factor for normal filling times (Bell

housings).

The SF was also calculated for extreme values of

filling time, namely for pressure ramps of 0-300mB in

5, 10, 15, 35, 60, 75 and 90s and pouring temperatures

of 720C, 695C, 685C, 681C and 664C(1328F, 1283F,

1265F, 1258F, and 1227F respectively). This is shown

in Figures 12 and 13.

Fig. 12. Slowing factor over a wide range of filling

times (1:18 ratio.)(Bell housings)

The leftmost bar in the graph of Figure 12 indicates

that for 0-300mB pressure ramp duration of 5s, the

theoretical filling time is 0.9s and the slowing factor is

equal to 2.27; hence the measured filling time has been

2.1s.

Likewise, the rightmost bar in the same graph

corresponds to a 0-300mB pressure ramp duration of

90s, i.e. a very slow rate of filling; in this case, the

theoretical filling time is 16.5s, the SF is 1.10,

calculated from the measured filling time of 18.1s. The

graph shows, quite expectedly, that SF is close to 1 for

very slow filling times; it increases up to 2.3 for

extremely steep pressure ramps; this results from the

growing difficulty in expelling the air entrapped in the

mold cavity. For normal ramp durations of 5 to 10s,

the value of SF lies around 1.5. The graph on Figure

13 lumps the results obtained for normal 0-300mB

pressure ramp durations of 15s, 20s, and 25s and for a

range of pouring temperatures comprised between

300

350

400

450

500

550

0 10 20 30 40 50

time (s)

t

e

m

p

e

r

a

t

u

r

e

(

C

)

Paper 11-003.pdf, Page 5 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

664C and 750C (1227F and 1382F). It shows that the

SF increases slightly as the pouring temperature drops,

probably due to the increased viscosity of the melt.

0

0.5

1

1.5

2

660 680 700 720 740 760

pouring temperature (C)

s

l

o

w

i

n

g

f

a

c

t

o

r

,

S

F

Fig. 13. Slowing factor over a wide range of

pouring temperatures for a normal range of

filling times.(Bell housings)

EXPERIMENTAL RESULTS (THIN CASTING)

Similar filling times were measured when pouring thin

wall castings, one of which is shown in place in the

mold and after ejection in Figure 14. The cluster

comprises two mirror-copy covers used to encase an

airplane seat adjustment device. The massive feeding

and gating system represents 70% of the total weight

of the cluster.

Fig. 14. Cover castings (1kg two-part cluster).

Figure 15 shows the 72 clusters which were poured in

one campaign for a range of 0-300mB pressure ramp

durations of 2s (150mB/s), 4s, 6s, 8s, 12s, 16s, and 20s

(15mB/s).

Fig. 15. Clusters poured in the present study.

Three thermocouples represented in red in Figure 16

were inserted in the mold to record the thermal

history; their responses are shown in Figure 18. The

filling time was measured by fast response

thermocouples in green on the same figure separated

by a vertical distance of 211mm or 8.3 in. (Figure 17).

In the same manner as was done for the bell housings,

dividing the actual measured filling times by the

theoretical filling times allowed to determine the SF

for pouring temperatures of 720C, 740C and

760C(1328F, 1364F, and 1400F) . The results are

plotted in Figure 19 for these 3 pouring temperatures.

Looking at the three leftmost bars indicates that, for a

very steep pressure ramp of 0-300mB lasting 2s, the

theoretical filling time is 0.45s and the slowing factors

are 4.7, 2.8 and 2.3 for pouring temperatures of 720,

740 and 760C. This translates to actual filling time of

2.1, 1.2 and 1.0s respectively. However, for slower

(and more reasonable) filling rates, SF is always less

than 1.5 and did not depend much on the pouring

temperature between 720C and 760C(1328F and

1400F).

Similarly to what was observed in the bell housing

experiments, and for the same reason, SF decreases as

the filling is slower. The actual filling time is

generally closer to the theoretical filling time than for

the bell housing experiments; this may be explained

by the fact that a much lesser amount of air must be

expelled from the cavity, especially in the final stage

of the filling process.

Fig. 16. Thermocouples inserted in mold.

Fig. 17. Vertical distance separating the two

thermocouples measuring the fill time.

Paper 11-003.pdf, Page 6 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

Temperature at 3 locations in the mold during the casting campaign

300

350

400

450

500

550

600

10:20 10:50 11:20 11:50 12:20 12:51 13:21 13:51 14:21 14:52

time (hrs:min)

t

e

m

p

e

r

a

t

u

r

e

(

C

)

Fig. 18. Response of the thermocouples represented in red on Figure 16.

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

s

l

o

w

i

n

g

f

a

c

t

o

r

,

S

F

2/0.45 4/0.9 6/1.3 8/1.75 12/2.6 16/3.5 20/4.5

time to reach 300mB (s) / theoretical filling time ( s)

760C

740C

720C

Fig. 19. Slowing factor over a wide range of filling times (1:10.)(Thin casting)

CONCLUSIONS

By measuring the filling time of a thin and a bulky

casting under a range of process conditions, it was

possible to determine the SF, ratio of the actual filling

time to the theoretical filling time based on the static

level equilibrium of the melt. SF allows a calculation

of the filling time of the mold cavity after the pressure

ramp of the LPPM process is selected. The knowledge

of SF is very useful to input a realistic mold filling

time when modeling the filling of a LPPM mold.

A SF value of 1 indicates that the actual filling time is

equal to the theoretical time; this corresponds to an

extremely slow mold filling, when no back pressure

builds up inside the mold cavity. A value of SF of 2

means that the actual filling time is twice the time

calculated based on the pressure ramp applied on the

melt and the height of the casting.

Paper 11-003.pdf, Page 7 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

It was determined that;

1) In the case of the bell housing (Casting thickness

ranging from 6mm to 25mm, or 0.25 to 1), at

pouring temperatures between 745C and 755C

(1373C and 1391F), SF varies from 2.26 to 1.07

when the theoretical filling time is increased from

0.9 to 16.5s. For a normal theoretical filling

time of 4s (corresponding to an actual filling time

of about 6s), SF increases from 1.4 to 1.8 when

the pouring temperature decreases from 750C to

664C (1382F to 1227F).

2) In the case of the thin casting (2mm wall cover

housing), SF slowly decreases from 1.49 to 1.14

when the theoretical filling time is increased from

0.9 to 4.5s. Except for extreme pressure rises

where SF can reach 4.69 for a pouring

temperature of 720C (1328F), the value of SF

does not depend much on the pouring temperature

between 720C and 760C (1328F and 1400F).

ACKNOWLEDGMENTS

The authors wish to acknowledge the contribution of

Ministre du Dveloppement conomique, de

lInnovation et de lExportation of Qubec and of the

Canadian Foundation for Innovation to the

infrastructure which made this research possible.

Part of the operating expenses for this project was

covered by the Qubec government Programme

dAide la Recherche Technologique. The authors

are also indebted to TMA (Technologie de

lAluminium et du Magnsium) for making their

facilities and personnel available for the casting runs.

REFERENCES

1. Peng, L.M., Wang, Y.X., Fu P.H., Jing, W.J.,

Luo, A.A., Venna, R., "Numerical

Simulation and Process Development for

Low Pressure Die Casting of Magnesium

Alloy Wheel", AFS Transactions, Vol.

118, paper 10-077 (2010)

2. Sheng, Y., Chen, S., Nath, J., Low Pressure

Casting Process Simulation and Tooling

Design for HIMAC's Magnesium

Automotive Control Arm, AFS

Transactions, Vol. 116, paper 08-148 (2008)

3. Chiesa, F., Duchesne, B., Morin. G., Baril, J.,

Comparing Low Pressure Permanent Mold

Casting of Aluminum A356 and Magnesium

AZ91E, AFS Transactions, Vol. 116, paper 08-

028 (2008)

4. Lee, J.R., Singh, D.P.K., Chen, Z.W.,

Improvement of the Low Pressure Permanent

Mould Pressurization Sequence for Wheel

Casting, AFS Transactions, Vol. 111, paper

03-016 (2003)

5. Chiesa, F., Duchesne, B., Morin, G.,

Influence of Artificial Cooling and pressure

application on the metallurgical quality in the

LPPM Casting of Aluminium Al Si7 Mg03,

Conference of Metallurgists, Proceedings of

the symposium Light Metals in Transport

Applications, pp.27-42., Toronto (August

25-30, 2007)

Paper 11-003.pdf, Page 8 of 8

AFS Proceedings 2011 American Foundry Society, Schaumburg, IL USA

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- 001 Plunger PDFДокумент4 страницы001 Plunger PDFKmilo GiraldoОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- High Integrity Aluminum (GENERAL)Документ140 страницHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- Design Guidelines For Components Die Cast in Creep-Resistant Magnesium Alloys MRI153M and MRI230D PDFДокумент6 страницDesign Guidelines For Components Die Cast in Creep-Resistant Magnesium Alloys MRI153M and MRI230D PDFKmilo GiraldoОценок пока нет

- Machine SystemsДокумент79 страницMachine SystemsKmilo Giraldo100% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- High Integrity Aluminum (GENERAL)Документ140 страницHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- Operating Manual (Deh 1450ub) Eng Esp PorДокумент84 страницыOperating Manual (Deh 1450ub) Eng Esp PorKmilo GiraldoОценок пока нет

- Temperature Control PDFДокумент60 страницTemperature Control PDFKmilo GiraldoОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Mesh Cast 20091Документ456 страницMesh Cast 20091Kmilo Giraldo100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Manual General DycoteДокумент30 страницManual General DycoteKmilo GiraldoОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Reversal Patterns PDFДокумент4 страницыReversal Patterns PDFKmilo GiraldoОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Gas Porosity (GENERAL)Документ28 страницGas Porosity (GENERAL)Kmilo Giraldo100% (5)

- ProCAST20091 TutorialsДокумент213 страницProCAST20091 TutorialsKmilo Giraldo100% (1)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Tooling Standard (Die Casting)Документ39 страницTooling Standard (Die Casting)Kmilo GiraldoОценок пока нет

- DefectДокумент8 страницDefectKmilo GiraldoОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Shrinkage Porosity (GENERAL)Документ28 страницShrinkage Porosity (GENERAL)Kmilo GiraldoОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Temperature ControlДокумент60 страницTemperature ControlKmilo Giraldo100% (4)

- Intro To Die Casting PDFДокумент116 страницIntro To Die Casting PDFKmilo Giraldo100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Stream GateДокумент75 страницStream GateKmilo GiraldoОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- ICE Check Certificate RegisterДокумент10 страницICE Check Certificate RegisterKam LauОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Masonry Construction ProcessДокумент38 страницMasonry Construction Processbereket gОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Asme Material SpecsДокумент4 страницыAsme Material SpecsRajwinder Singh100% (1)

- FlameOFF Fire Barrier PaintДокумент2 страницыFlameOFF Fire Barrier PaintmurdicksОценок пока нет

- REFRACTICA - The Refractory Maintenance NewsletterДокумент8 страницREFRACTICA - The Refractory Maintenance Newslettersumay banerjeeОценок пока нет

- Absorption Coefficient Chart-Building Materials-Part 1Документ4 страницыAbsorption Coefficient Chart-Building Materials-Part 1Marcus MasangkayОценок пока нет

- 21 L0 Is 2101 Piping Material Specification 06 9Документ1 страница21 L0 Is 2101 Piping Material Specification 06 9karthiОценок пока нет

- Evonik Polyimide p84nt Technical BrochureДокумент8 страницEvonik Polyimide p84nt Technical BrochureAnonymous rUr4olUОценок пока нет

- UX Comparison ChartДокумент2 страницыUX Comparison ChartRonal SolisОценок пока нет

- Granolithic FlooringДокумент16 страницGranolithic FlooringDinesh Perumal50% (2)

- Casquillo Roscados para Metales Kobsert-En-1000Документ16 страницCasquillo Roscados para Metales Kobsert-En-1000WANKEL25Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ptfe Hoses Hydraulic Hose Flexible Metal Hoses Stripwound Metal Hoses Corrugated HosesДокумент16 страницPtfe Hoses Hydraulic Hose Flexible Metal Hoses Stripwound Metal Hoses Corrugated Hosessreelu100% (1)

- Manual Res Eb Ec 015Документ8 страницManual Res Eb Ec 015Levina YosheОценок пока нет

- SA-4820M00350-70541-10_00 - markup drawingДокумент1 страницаSA-4820M00350-70541-10_00 - markup drawingMohd Effiezool YaserОценок пока нет

- Schedule of Rates 2014Документ10 страницSchedule of Rates 2014A. S. M. Elias ShahОценок пока нет

- 90° Anchor BoltДокумент2 страницы90° Anchor BoltJovito EdillonОценок пока нет

- Literature Review On Sandcrete BlocksДокумент5 страницLiterature Review On Sandcrete Blocksbij0dizytaj2100% (1)

- Item No. Part No. Name of Part Material No. Reqd DescriptionДокумент3 страницыItem No. Part No. Name of Part Material No. Reqd DescriptionjohangomezruizОценок пока нет

- Plumber Practice Test 1Документ8 страницPlumber Practice Test 1docino1417100% (2)

- Densyl Mastic: Composition PrimerДокумент2 страницыDensyl Mastic: Composition PrimerAloka KarunarathneОценок пока нет

- AASHTO93 Flexible 2018Документ61 страницаAASHTO93 Flexible 2018sultonОценок пока нет

- API-510 QuestionsДокумент21 страницаAPI-510 Questionssjois_hs100% (1)

- LEDE Products Catalog - CompressedДокумент24 страницыLEDE Products Catalog - CompressedAhmad ShiplyОценок пока нет

- OMN-FAC-200 Coating Specification For Surface Production FacilitiesДокумент20 страницOMN-FAC-200 Coating Specification For Surface Production FacilitiesSaifullahОценок пока нет

- Glenium Stream 2 v5Документ2 страницыGlenium Stream 2 v5Jaga Nath100% (2)

- Go Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionДокумент2 страницыGo Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionmohamedabubackerОценок пока нет

- Cement ConsumptionДокумент2 страницыCement ConsumptionAliasgar LokhandwalaОценок пока нет

- Cvi 02350Документ31 страницаCvi 02350abguyОценок пока нет

- Materials Take-Off and Cost EstimatesДокумент6 страницMaterials Take-Off and Cost Estimatesianiroy13Оценок пока нет