Академический Документы

Профессиональный Документы

Культура Документы

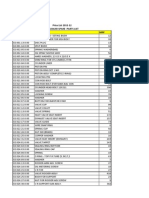

Fitting

Загружено:

Paijo TejoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fitting

Загружено:

Paijo TejoАвторское право:

Доступные форматы

A.

66

0.81

0.88

0.69

0.125

0.68

1.25

0.75

0.97

1.00

0.75

0.250

0.88

1.25

...

A

B

C

T

N

P

R

A

B

C

T

N

P

R

1.12

1.31

0.88

0.260

1.00

1.38

1.06

0.97

1.00

0.75

0.13

0.75

1.38

1.00

0.81

0.88

0.69

0.125

1.31

1.50

1.00

0.275

1.25

1.50

1.06

1.12

1.31

0.88

0.138

0.88

1.50

1.00

0.97

1.00

0.75

0.125

1.50

1.81

1.12

0.321

1.50

1.88

1.31

1.31

1.50

1.00

0.161

1.12

1.88

1.25

1.12

1.31

0.88

0.125

1.75

2.19

1.31

0.336

1.75

2.00

1.50

1.50

1.81

1.12

0.170

1.38

2.00

1.44

1.31

1.50

1.00

0.125

2.00

2.44

1.38

0.391

2.25

2.38

1.69

Class 6000

1.75

2.19

1.31

0.196

1.75

2.38

1.62

Class 3000

1.50

1.81

1.12

0.145

Class 2000

Dimensions, in

2.38

2.97

1.69

0.417

2.50

2.62

1.81

2.00

2.44

1.38

0.208

2.25

2.62

1.75

1.75

2.19

1.31

0.153

2.50

3.31

1.72

0.436

3.00

3.12

1.88

2.38

2.97

1.69

0.219

2.50

3.12

1.75

2.00

2.44

1.38

0.158

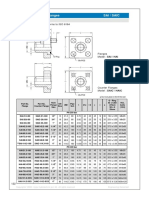

Dimensions of Typical Commercial Forged-Steel Threaded Fittings (ASME B16.11-1996)

Manufacturers catalogs should be consulted for dimensions of street elbows and of laterals since these two types

of ttings are no longer covered by ANSI Standards.

0.81

0.88

0.69

0.125

A

B

C

T

TABLE A2.8

3.25

4.00

2.06

0.476

3.62

3.38

2.00

2.50

3.31

1.72

0.281

3.00

3.38

1.88

2.38

2.97

1.69

0.168

3.75

4.75

2.50

0.602

4.25

3.62

2.50

3.25

4.00

2.06

0.301

3.62

3.62

2.38

3.00

3.62

2.06

0.221

4.19

5.75

3.12

0.655

5.00

4.25

2.69

3.75

4.75

2.50

0.348

4.25

4.25

2.58

3.38

4.31

2.50

0.236

4.50

6.00

3.12

0.735

6.25

4.75

2.94

4.50

6.00

3.12

0.440

4.75

4.75

2.69

4.19

5.756

3.12

0.258

A.67

0.420

0.430

0.555

0.565

0.690

0.700

0.855

0.865

1.065

1.075

1.330

1.340

1.675

1.685

1.915

1.925

2.406

2.416

2.906

2.921

3.535

3.550

4.545

4.560

Socket

bore

diameter

B

0.138

0.161

0.168

0.38

0.38

0.50

0.75

0.62

0.62

0.62

0.50

0.50

0.368

0.327

0.301

0.238

0.218

0.208

0.196

0.130

0.38

0.50

0.125

Socket

C

0.337

0.300

0.276

0.218

0.200

0.191

0.179

0.154

0.147

0.126

0.119

0.095

Body

G

Class 3000

0.38

Depth

of

socket

min.

...

...

...

0.374

0.307

0.273

0.273

0.238

0.204

0.172

0.158

0.135

Socket

C

0.531

0.438

0.375

0.344

0.281

0.250

0.250

0.219

0.188

0.158

0.195

0.124

Body

G

Class 6000

...

...

...

0.477

0.438

0.418

0.392

0.337

0.322

...

...

...

Socket

C

...

...

...

0.436

0.400

0.382

0.358

0.308

0.294

...

...

...

Body

G

Class 9000

0.254

0.284

0.349

0.379

0.478

0.508

0.607

0.637

0.809

0.839

1.034

1.064

1.365

1.395

1.595

1.625

2.052

2.082

2.439

2.499

3.038

3.098

3.996

4.056

Class

3000

...

...

...

0.141

0.171

0.235

0.265

0.344

0.374

0.451

0.481

0.599

0.629

0.800

0.830

1.145

1.175

1.323

1.353

1.674

1.704

Class

6000

...

...

...

...

0.222

0.282

0.404

0.464

0.569

0.629

0.866

0.926

1.070

1.130

1.473

1.533

...

...

Class

9000

Bore diameter

of tting D

2.62

2.25

1.62

1.50

1.25

1.06

0.88

0.75

0.62

0.53

0.44

0.44

Class

3000

...

...

...

1.62

1.50

1.25

1.06

0.88

0.75

0.62

0.53

0.44

Class

6000

...

...

...

2.12

1.50

1.38

1.25

1.12

1.00

...

...

...

Class

9000

90 ells, tees, crosses

1.62

1.25

1.12

1.00

0.81

0.69

0.56

0.50

0.44

0.31

0.31

0.31

Class

3000

...

...

...

1.12

1.00

0.81

0.69

0.56

0.50

0.44

0.31

0.31

Class

6000

45 ells

Center to bottom of socket (A)

* Dimensions for caps and reducers are not standardized. Refer to manufacturers literature for dimensions.

Values are lower/upper limits.

For tolerances, refer to Table A2.10.

Nominal

pipe size

Wall thickness, minimum

TABLE A2.9 Dimensions of Typical Commercial Forged-Steel Socket-Welding Fittings*

(ASME B16.11-1996)

...

...

...

1.12

1.00

0.88

0.81

0.75

0.62

...

...

...

Class

9000

0.75

0.75

0.75

0.75

0.50

0.50

0.50

0.38

0.38

0.25

0.25

0.25

Couplings

E

1.88

1.75

1.69

1.62

1.25

1.19

1.12

0.94

0.88

0.69

0.62

0.62

Half

couplings F

Laying lengths

A.68

PIPING FUNDAMENTALS

TABLE A2.10 Center-to-Bottom and

Laying Length Tolerances for Classes 3000,

6000, and 9000 Socket-Welding Fittings

(from ASME B16.11-1996)

Tolerances plus or minus

NPS

0.03

0.03

0.06

0.06

0.06

0.08

0.08

0.08

0.08

0.10

0.10

0.10

0.06

0.06

0.12

0.12

0.12

0.16

0.16

0.16

0.16

0.20

0.20

0.20

0.03

0.03

0.06

0.06

0.06

0.08

0.08

0.08

0.08

0.10

0.10

0.10

1

1

1

2

2

3

4

Refer to Table A2.9 for nomenclature.

FIGURE A2.4 Typical welding outlet ttings.

A.69

PIPING COMPONENTS

TABLE A2.11 Dimensions of Typical Commercial 90 Long-Radius Butt-Welding Elbows

(ASME B16.9-1993)

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to face

A

Pipe

schedule

number*

Weight

(approx)

(lb)

Standard

1

1

0.840

1.050

1.315

1.660

0.622

0.824

1.049

1.380

0.109

0.113

0.133

0.140

1

1

1

1

40

40

40

40

0.2

0.2

0.4

0.6

1

2

2

3

1.900

2.375

2.875

3.500

1.610

2.067

2.469

3.068

0.145

0.154

0.203

0.216

2

3

3

4

40

40

40

40

0.9

1.4

2.9

4.5

3

4

5

6

4.000

4.500

5.563

6.625

3.548

4.026

5.047

6.065

0.226

0.237

0.258

0.280

5

6

7

9

40

40

40

40

6.4

8.7

14.7

22.9

8

10

12

14

8.625

10.750

12.750

14.000

7.981

10.020

12.000

13.250

0.322

0.365

0.375

0.375

12

15

18

21

40

40

30

46.0

81

119

154

16

18

20

22

16.000

18.000

20.000

22.000

15.250

17.250

19.250

21.250

0.375

0.375

0.375

0.375

24

27

30

33

30

20

20

201

256

317

385

24

26

28

30

24.000

26.000

28.000

30.000

23.250

25.250

27.250

29.250

0.375

0.375

0.375

0.375

36

39

42

45

20

458

539

626

720

32

34

36

42

32.000

34.000

36.000

42.000

31.250

33.250

35.250

41.250

0.375

0.375

0.375

0.375

48

51

54

63

818

926

1040

1420

A.70

PIPING FUNDAMENTALS

TABLE A2.11 Dimensions of Typical Commercial 90 Long-Radius Butt-Welding Elbows

(ASME B16.9-1993) (Continued )

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to face

A

Pipe

schedule

number*

Weight

(approx)

(lb)

Extra strong

1

1

0.840

1.050

1.315

1.660

0.546

0.742

0.957

1.278

0.147

0.154

0.179

0.191

1

1

1

1

80

80

80

80

0.3

0.3

0.5

0.8

1

2

2

3

1.900

2.375

2.875

3.500

1.500

1.939

2.323

2.900

0.200

0.218

0.276

0.300

2

3

3

4

80

80

80

80

1.0

2.0

3.8

6.1

3

4

5

6

4.000

4.500

5.563

6.625

3.364

3.826

4.813

5.761

0.318

0.337

0.375

0.432

5

6

7

9

80

80

80

80

8.7

11.9

20.6

34.1

8

10

12

14

8.625

10.750

12.750

14.000

7.625

9.750

11.750

13.000

0.500

0.500

0.500

0.500

12

15

18

21

80

60

69

109

157

202

16

18

20

22

16.000

18.000

20.000

22.000

15.000

17.000

19.000

21.000

0.500

0.500

0.500

0.500

24

27

30

33

40

30

30

265

338

419

508

24

26

28

30

24.000

26.000

28.000

30.000

23.000

25.000

27.000

29.000

0.500

0.500

0.500

0.500

36

39

42

45

20

20

20

606

713

829

953

32

34

36

42

32.000

34.000

36.000

42.000

31.000

33.000

35.000

41.000

0.500

0.500

0.500

0.500

48

51

54

63

20

20

20

1090

1230

1380

1880

Schedule 160

1

1

1

2

1.315

1.660

1.900

2.375

0.815

1.160

1.338

1.689

0.250

0.250

0.281

0.343

1

1

2

3

160

160

160

160

0.6

1.0

1.4

2.9

2

3

4

5

2.875

3.500

4.500

5.563

2.125

2.624

3.438

4.313

0.375

0.438

0.531

0.625

3

4

6

7

160

160

160

160

4.9

8.3

17.6

32.2

6.625

8.625

10.750

12.750

5.189

6.813

8.500

10.126

0.718

0.906

1.125

1.312

6

8

10

12

9

12

15

18

160

160

160

160

53

117

226

375

A.71

PIPING COMPONENTS

TABLE A2.11 Dimensions of Typical Commercial 90 Long-Radius Butt-Welding Elbows

(ASME B16.9-1993) (Continued )

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to face

A

Pipe

schedule

number*

Weight

(approx)

(lb)

Double extra strong

1

1

1

1.050

1.315

1.660

1.900

0.434

0.599

0.896

1.100

0.308

0.358

0.382

0.400

1

1

1

2

0.4

0.7

1.2

1.8

2

2

3

3

2.375

2.875

3.500

4.000

1.503

1.771

2.300

2.728

0.436

0.552

0.600

0.636

3

3

4

5

3.4

6.5

10.7

15.4

4

5

6

8

4.500

5.563

6.625

8.625

3.152

4.063

4.897

6.875

0.674

0.750

0.864

0.875

6

7

9

12

21.2

37.2

61

114

* Pipe schedule numbers in accordance with ASME B36.10M.

Weights are not tabulated in ASME B16.9.

This size and thickness does not correspond with any schedule number.

Wrought-Steel Butt-Welding Fittings

Wrought-steel welding ttings include elbows, tees, crosses, reducers, laterals, lapjoint stub ends, caps, and saddles.

Wrought-steel ttings are made to the dimensional requirements of ASME B16.9

in sizes NPS (DN 15) through NPS 48 (DN 1200). Also, short-radius elbows and

returns are produced in accordance with ASME B16.28 in sizes NPS (DN 15)

through NPS 24 (DN 600). The wrought tting materials conform to ASTM A234,

A403, or A420, the grades of which have chemical and physical properties equivalent

to that of the mating pipe. ASME B16.9 requires that the pressure-temperature

rating of the tting equal or exceed that of the mating pipe of the same or equivalent

material, same size, and same nominal wall thickness. The pressure-temperature

rating may be established by analysis or by proof testing. Short-radius elbows and

returns (tting centerline bend radius is equal to the tting NPS) manufactured

under ASME B16.28 are rated at 80 percent of the rating calculated for seamless

straight pipe of the same size and nominal thickness and same or equivalent material.

Therefore, both standards require that, in lieu of specifying any pressure rating,

the pipe wall thickness and pipe material type with which the ttings are intended

to be used be identied on the tting.

Pressure testing of the ttings is not required by either standard. However, the

ttings are required to be capable of withstanding, without leakage, a test pressure

equal to that prescribed in the specication of the pipe with which the tting is

recommended to be used.

Both ASME B16.9 and B16.28 prescribe dimensions and manufacturing tolerances of wrought butt-welded ttings. The standards establish laying dimensions,

A.72

PIPING FUNDAMENTALS

TABLE A2.12 Dimensions of Typical Commercial 90 Short-Radius Elbows

(ASME B16.28-1994)

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to face

A

Pipe

schedule

number*

Weight

(approx)

(lb)

Standard

1

1

1

2

1.315

1.660

1.900

2.375

1.049

1.380

1.610

2.067

0.133

0.140

0.145

0.154

1

1

1

2

40

40

40

40

0.3

0.4

0.6

1.0

2

3

3

4

2.875

3.500

4.000

4.500

2.469

3.068

3.548

4.026

0.203

0.216

0.226

0.237

2

3

3

4

40

40

40

40

1.9

3.0

4.2

5.7

5

6

8

10

5.563

6.625

8.625

10.750

5.047

6.065

7.981

10.020

0.258

0.280

0.322

0.365

5

6

8

10

40

40

40

40

9.7

15.2

30.5

54

12

14

16

18

12.750

14.000

16.000

18.000

12.000

13.250

15.250

17.250

0.375

0.375

0.375

0.375

12

14

16

18

30

30

79

102

135

171

20

22

24

26

20.000

22.000

24.000

26.000

19.250

21.250

23.250

25.250

0.375

0.375

0.375

0.375

20

22

24

26

20

20

212

256

305

359

28

30

32

34

28.000

30.000

32.000

34.000

27.250

29.250

31.250

33.250

0.375

0.375

0.375

0.375

28

30

32

34

415

480

546

617

36

42

36.000

42.000

35.250

41.250

0.375

0.375

36

48

692

1079

A.73

PIPING COMPONENTS

TABLE A2.12 Dimensions of Typical Commercial 90 Short-Radius Elbows

(ASME B16.28-1994) (Continued )

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to face

A

Pipe

schedule

number*

Weight

(approx)

(lb)

Extra strong

1

2

2

3

1.900

2.375

2.875

3.500

1.500

1.939

2.323

2.900

0.200

0.218

0.276

0.300

1

2

2

3

80

80

80

80

0.7

1.3

2.5

4.0

3

4

5

6

4.000

4.500

5.563

6.625

3.364

3.826

4.813

5.761

0.318

0.337

0.375

0.432

3

4

5

6

80

80

80

80

5.7

7.8

13.7

22.6

8

10

12

14

8.625

10.750

12.750

14.000

7.625

9.750

11.750

13.000

0.500

0.500

0.500

0.500

8

10

12

14

80

60

45.6

72

104

135

16

18

20

22

16.000

18.000

20.000

22.000

15.000

17.000

19.000

21.000

0.500

0.500

0.500

0.500

16

18

20

22

40

30

30

177

225

278

333

24

26

28

30

24.000

26.000

28.000

30.000

23.000

25.000

27.000

29.000

0.500

0.500

0.500

0.500

24

26

28

30

20

20

20

404

474

581

634

32

34

36

42

32.000

34.000

36.000

42.000

31.000

33.000

35.000

41.000

0.500

0.500

0.500

0.500

32

34

36

42

20

20

20

722

817

913

1430

* Pipe schedule numbers in accordance with ASME B36.10M.

Filling weights are not tabulated in ASME B16.28.

This size and thickness has no corresponding schedule number.

Dimensional data for pipe sizes NPS 26 and larger are not included in ASME B16.28.

which remain xed for each size and type of tting irrespective of the tting wall

thickness. Tables A2.11, A2.12, A2.13, A2.14, and A2.15 list the laying dimensions

and approximate weights for selected tting sizes, pipe schedules, and congurations.

Laterals are not governed by any national standard. However, dimensions of

laterals commonly used are given in Table A2.16. Working pressures are rated at

40 percent of the allowable working pressure established for pipe from which laterals

are made. Where full allowable pipe pressures must be met, the laterals are generally

made from heavier pipe with ends machined to match standard pipe dimensions.

Dimensional tolerances of laterals vary not more than 1/32 in (1.0 mm) for sizes

up to and including NPS 8 (DN 200) and 1/16 in (2.0 mm) for sizes NPS 10 (DN

250) through NPS 24 (DN 600).

A.74

PIPING FUNDAMENTALS

TABLE A2.13 Dimensions of Typical Commercial Straight Butt-Welding Tees

(ASME B16.9-1993)

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to end

C

Center

to end

M

Pipe

schedule

number*

Weight

(approx)

(lb)

Standard

1

1

0.840

1.050

1.315

1.660

0.622

0.824

1.049

1.380

0.109

0.113

0.133

0.140

1

1

1

1

1

1

1

1

40

40

40

40

0.3

0.4

0.8

1.3

1

2

2

3

1.900

2.375

2.875

3.500

1.610

2.067

2.469

3.068

0.145

0.154

0.203

0.216

2

2

3

3

2

2

3

3

40

40

40

40

2.0

2.9

5.2

7.4

3

4

5

6

4.000

4.500

5.563

6.625

3.548

4.026

5.047

6.065

0.226

0.237

0.258

0.280

3

4

4

5

3

4

4

5

40

40

40

40

9.8

12.6

19.8

29.3

8

10

12

14

8.625

10.750

12.750

14.000

7.981

10.020

12.000

13.250

0.322

0.365

0.375

0.375

7

8

10

11

7

8

10

11

40

40

30

53

91

132

172

16

18

20

22

16.000

18.000

20.000

22.000

15.250

17.250

19.250

21.250

0.375

0.375

0.375

0.375

12

13

15

16

12

13

15

16

30

20

20

219

282

354

437

24

26

28

30

24.000

26.000

28.000

30.000

23.250

25.250

27.250

29.250

0.375

0.375

0.375

0.375

17

19

20

22

17

19

20

22

20

493

634

729

855

32

34

36

32.000

34.000

36.000

31.250

33.250

32.250

0.375

0.375

0.375

23

25

26

23

25

26

991

1136

1294

A.75

PIPING COMPONENTS

TABLE A2.13 Dimensions of Typical Commercial Straight Butt-Welding Tees

(ASME B16.9-1993) (Continued )

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to end

C

Center

to end

M

Pipe

schedule

number*

Weight

(approx)

(lb)

Extra strong

1

1

0.840

1.050

1.315

1.660

0.546

0.742

0.957

1.278

0.147

0.154

0.179

0.191

1

1

1

1

1

1

1

1

80

80

80

80

0.3

0.5

0.9

1.6

1

2

2

3

1.900

2.375

2.875

3.500

1.500

1.939

2.323

2.900

0.200

0.218

0.276

0.300

2

2

3

3

2

2

3

3

80

80

80

80

2.4

3.7

6.4

9.4

3

4

5

6

4.000

4.500

5.563

6.625

3.364

3.826

4.813

5.761

0.318

0.337

0.375

0.432

3

4

4

5

3

4

4

5

80

80

80

80

12.6

16.4

26.4

42.0

8

10

12

14

8.625

10.750

12.750

14.000

7.625

9.750

11.750

13.000

0.500

0.500

0.500

0.500

7

8

10

11

7

8

10

11

80

60

76

118

167

203

16

18

20

22

16.000

18.000

20.000

22.000

15.000

17.000

19.000

21.000

0.500

0.500

0.500

0.500

12

13

15

16

12

13

15

16

40

30

30

271

351

442

548

24

26

28

30

24.000

26.000

28.000

30.000

23.000

25.000

27.000

29.000

0.500

0.500

0.500

0.500

17

19

20

22

17

19

20

22

20

20

20

20

607

794

910

1065

32

34

36

32.000

34.000

36.000

31.000

33.000

35.000

0.500

0.500

0.500

23

25

26

23

25

26

20

20

20

1230

1420

1610

Schedule 160*

1

1

0.840

1.050

1.315

1.660

0.466

0.614

0.815

1.160

0.187

0.218

0.250

0.250

1

1

1

1

1

1

1

1

160

160

160

160

0.4

0.6

1.1

1.9

1

2

2

3

1.900

2.375

2.875

3.500

1.338

1.689

2.125

2.626

0.281

0.343

0.375

0.438

2

2

3

3

2

2

3

3

160

160

160

160

3.0

4.9

7.8

12.2

4

5

6

8

4.500

5.563

6.625

8.625

3.438

4.313

5.189

6.813

0.531

0.625

0.718

0.906

4

4

5

7

4

4

5

7

160

160

160

160

22.8

38.5

59

120

10

12

10.750

12.750

8.500

10.126

1.125

1.312

8

10

8

10

160

160

222

360

A.76

PIPING FUNDAMENTALS

TABLE A2.13 Dimensions of Typical Commercial Straight Butt-Welding Tees

(ASME B16.9-1993) (Continued )

Nominal

pipe size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Center

to end

C

Center

to end

M

Pipe

schedule

number*

Weight

(approx)

(lb)

Double extra strong

1

1

0.840

1.050

1.315

1.660

0.252

0.434

0.599

0.896

0.294

0.308

0.358

0.382

1

1

1

1

1

1

1

1

0.4

0.6

1.3

2.4

1

2

2

3

1.900

2.375

2.875

3.500

1.100

1.503

1.771

2.300

0.400

0.436

0.552

0.600

2

2

3

3

2

2

3

3

3.7

5.7

9.8

14.8

3

4

5

6

4.000

4.500

5.563

6.625

2.728

3.152

4.063

4.897

0.636

0.674

0.750

0.864

3

4

4

5

3

4

4

5

20.2

26.6

43.4

68

8.625

6.875

0.875

118

* Pipe schedule numbers in accordance with ASME B36.10M. Other thicknesses available.

Fitting weights are not tabulated in ASME B16.9.

This size and thickness does not correspond with any schedule number.

Forged Branch Fittings

Under the various pressure piping codes, branch connections may be made by

welding the branch pipe or a welding outlet tting to the run pipe, provided sufcient

reinforcement is available to compensate for the material removed from the run

pipe to create the branch opening. The reinforcement may be in the form of excess

material already available in the run and branch pipes, or it may be added. At the

writing of this book, national standards governing the dimensions, tolerances, and

manufacture of welding outlet ttings had not been issued. However, MSS-SP-97,

1995, has been developed to cover forged-carbon-steel 90 branch outlet ttings in

butt-welding, socket-welding, and threaded outlet ends. The standard provides

essential dimensions, nish, tolerances, and testing requirements. Because of the

absence of strict standards, manufacturers produce welding outlet ttings of their

own proprietary designs. These ttings must comply with the codes governing the

systems in which the ttings are to be installed. The ttings, when installed in

accordance with the manufacturers recommendations, include the required reinforcement. The dimensions of these ttings vary; standardized dimensions and

properties must be obtained from the manufacturers. Also, designers must

consider the appropriate parameters (e.g., stress intensication factors).

Figure A2.4 shows several types of welding ttings, which are proprietary; the

terminology used varies with the manufacturer. The ttings are produced in carbon

and alloy steels under the ASTM specications for forgings permitted by applicable codes.

A.77

PIPING COMPONENTS

TABLE A2.14 Dimensions of Typical Commercial Concentric and Eccentric

Butt-Welding Reducers (ASME B16.9-1993)

Weight (approx), lb (concentric or eccentric)

Nominal

pipe

size

Length

H

Standard

Extra

strong

Schedule

160

Double

extra strong

1

1

0.2

0.2

0.3

0.3

0.3

0.3

...

0.4

2

2

2

0.3

0.3

0.3

0.4

0.4

0.4

0.4

0.5

0.5

0.4

0.5

0.5

1

1

2

2

2

0.5

0.5

0.5

0.5

0.5

0.6

0.6

0.6

0.7

0.7

0.7

0.8

2

2

2

2

0.5

0.5

0.6

0.6

0.6

0.6

0.7

0.8

0.8

0.9

0.9

1.0

1.0

1.0

1.0

1.2

1

2

1

1

3

3

3

3

0.8

0.9

0.9

0.9

1.0

1.0

1.1

1.2

1.4

1.4

1.4

1.6

1.7

1.6

1.8

1.9

1

1

1

2

3

3

3

3

1.3

1.4

1.5

1.6

1.7

1.7

1.8

2.0

2.3

2.2

2.2

2.7

3.0

3.1

3.0

3.3

1

1

3

2

2

3

3

3

3

1.7

1.8

2.0

2.1

2.2

2.1

2.6

2.8

3.1

3.1

3.4

3.7

4.1

4.0

4.0

4.6

4

4

4

4

4

2.3

2.5

2.7

2.9

3.0

3.2

3.1

3.5

3.8

4.0

...

...

...

...

...

5.8

5.8

5.7

5.9

6.8

1

1

1

1

3 2

2

3

A.78

PIPING FUNDAMENTALS

TABLE A2.14 Dimensions of Typical Commercial Concentric and Eccentric

Butt-Welding Reducers (ASME B16.9-1993) (Continued )

Weight (approx), lb (concentric or eccentric)

Nominal

pipe

size

Length

H

Standard

Extra

strong

Schedule

160

Double

extra strong

1

2

4 2

3

3

4

4

4

4

4

2.7

3.1

3.3

3.5

3.6

3.8

3.9

4.4

4.7

4.8

5.6

5.6

5.5

6.5

...

6.6

6.6

6.3

7.7

8.2

2

2

5 3

3

4

5

5

5

5

5

5.0

5.5

5.7

5.8

5.9

6.6

7.2

7.8

8.0

8.3

10.6

10.2

10.2

...

12.4

12.2

11.7

11.1

13.3

14.2

2

3

6 3

4

5

5

5

5

5

5

7.6

8.0

8.1

8.1

8.6

9.9

11.1

11.6

12.0

12.6

15.8

15.1

...

17.2

18.8

18.8

18.5

17.3

19.1

21.4

6

6

6

6

12.8

13.1

13.4

13.9

16.1

18.6

19.5

20.4

...

26.9

29.6

32.1

27.9

25.7

29.2

32.7

4

5

10

6

8

7

7

7

7

21.1

21.8

22.3

23.2

25.3

28.7

29.8

31.4

50

48

50

58

5

6

12

8

10

8

8

8

8

30.5

31.1

32.1

33.4

39.1

40.6

37.4

43.6

78

75

86

94

6

8

10

12

13

13

13

13

55

57

60

63

74

76

79

83

14

3

4

5

6

A.79

PIPING COMPONENTS

TABLE A2.15 Dimensions of Typical Commercial Butt-Welding Standard Caps (ASME

B16.9-1993 Except as Noted)

Nominal

pipe

size

Outside

diameter

(OD)

Inside

diameter

(ID)

Wall

thickness

T

Length

E

Tangent

S

Dish

radius

R

Knuckle

radius

r

Pipe

schedule

number*

1

1

0.840

1.050

1.315

1.660

0.622

0.824

1.049

1.380

0.109

0.113

0.133

0.140

1

1

1

1

0.74

0.93

1.10

1.02

0.54

0.72

0.92

1.35

0.10

0.14

0.17

0.23

40

40

40

40

0.1

0.2

0.3

0.4

1

2

2

3

1.900

2.375

2.875

3.500

1.610

2.067

2.469

3.068

0.145

0.154

0.203

0.216

1

1

1

2

0.95

0.83

0.68

1.02

1.41

1.81

2.15

2.69

0.27

0.34

0.41

0.51

40

40

40

40

0.4

0.6

0.9

1.4

3

4

5

6

4.000

4.500

5.563

6.625

3.548

4.026

5.047

6.065

0.226

0.237

0.258

0.280

2

2

3

3

1.39

1.26

1.48

1.70

3.11

3.52

4.42

5.31

0.59

0.67

0.84

1.01

40

40

40

40

2.1

2.5

4.2

6.4

8

10

12

14

8.625

10.750

12.750

14.000

7.981

10.020

12.000

13.250

0.322

0.365

0.375

0.375

4

5

6

6

1.68

2.13

2.62

2.81

6.98

8.77

10.50

11.60

1.33

1.67

2.00

2.21

40

40

30

11.3

20.0

29.5

35.3

16

18

20

22

16.000

18.000

20.000

22.000

15.250

17.250

19.250

21.250

0.375

0.375

0.375

0.375

7

8

9

10

2.81

3.31

3.81

4.31

13.34

15.08

16.84

18.60

2.54

2.88

3.21

3.54

30

20

20

44.3

57

71

86

24

26

28

30

24.000

26.000

28.000

30.000

23.250

25.250

27.250

29.250

0.375

0.375

0.375

0.375

10

10

10

10

4.31

3.81

3.31

2.81

20.35

22.10

23.85

25.60

3.88

4.21

4.54

4.88

20

102

110

120

125

32

34

36

42

32.000

34.000

36.000

42.000

31.250

33.250

35.250

41.250

0.375

0.375

0.375

0.375

10

10

10

12

2.31

1.81

1.31

1.31

27.35

29.10

30.85

36.10

5.21

5.54

5.88

6.88

145

160

175

230

* Pipe schedule numbers in accordance with ASME B36.10M.

This size and thickness does not correspond with any schedule number.

Weight

(approx)

(lb)

A.80

PIPING FUNDAMENTALS

TABLE A2.16 Dimensions of Typical Commercial Butt-Welding Laterals

Nominal

pipe

size

Standard

L and E

Weight

(approx)

(lb)

Extra strong

L and E

Weight

(approx)

(lb)

Straight

1

1

1

2

5

6

7

8

1

1

2

2

1.7

2.4

3.2

5.0

6

7

8

9

2

1

2

2

2.5

3.8

5.4

7.7

2

3

3

4

9

10

11

12

2

3

3

3

9.2

12.6

17.2

20.8

10

11

12

13

2

3

3

3

13.5

18.8

25.6

32.8

5

6

8

10

13

14

17

20

3

3

4

5

31.4

42.4

76

124

15

17

20

24

3

4

5

5

49.8

79

140

202

12

14

16

18

24

27

30

32

5

6

6

7

180

218

275

326

27

31

34

37

6

6

7

8

273

340

433

526

20

24

35

40

8

9

396

544

40

47

8

10

628

882

TRAPS

Steam Traps

The function of a steam trap is to discharge condensate from steam piping or steam

heating equipment without permitting live steam to escape. Some principal types

of steam traps are:

Float

Thermostatic

Thermodynamic

Inverted bucket

Вам также может понравиться

- Maw Sby Denver Apartment Exterior East ElevationДокумент1 страницаMaw Sby Denver Apartment Exterior East ElevationPaijo TejoОценок пока нет

- Pages From Piusi Cube 70mc EspДокумент1 страницаPages From Piusi Cube 70mc EspPaijo TejoОценок пока нет

- Alamat APIДокумент1 страницаAlamat APIPaijo TejoОценок пока нет

- Input EchoДокумент42 страницыInput EchoPaijo TejoОценок пока нет

- ICD EPC Volume 2 Final-ToCДокумент6 страницICD EPC Volume 2 Final-ToCPaijo TejoОценок пока нет

- T-L R, (,li U $: LrillllДокумент4 страницыT-L R, (,li U $: LrillllPaijo TejoОценок пока нет

- Outstading BQ Clarification With SgiДокумент2 страницыOutstading BQ Clarification With SgiPaijo TejoОценок пока нет

- DD DNV Gardu PLN Alt1 ModelДокумент1 страницаDD DNV Gardu PLN Alt1 ModelPaijo TejoОценок пока нет

- Link Brochure Dropbox.Документ2 страницыLink Brochure Dropbox.Paijo TejoОценок пока нет

- Detail GensetДокумент1 страницаDetail GensetPaijo TejoОценок пока нет

- Power Ups DataДокумент1 страницаPower Ups DataPaijo TejoОценок пока нет

- ICD EPC Volume 2 FinalДокумент1 страницаICD EPC Volume 2 FinalPaijo TejoОценок пока нет

- 20409: Optimal Design of Cooling Towers Eusiel Rubio-Castro1, Medardo Serna-González1, José M. Ponce-Ortega1 and Arturo Jiménez-Gutiérrez2 1Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, 2Instituto Tecnológico de Celaya, Celaya, Guanajuato, MéxicoДокумент27 страниц20409: Optimal Design of Cooling Towers Eusiel Rubio-Castro1, Medardo Serna-González1, José M. Ponce-Ortega1 and Arturo Jiménez-Gutiérrez2 1Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, 2Instituto Tecnológico de Celaya, Celaya, Guanajuato, MéxicoRajat Yadav YaduvanshiОценок пока нет

- Sound System (Baru)Документ26 страницSound System (Baru)Paijo TejoОценок пока нет

- Tire Rolling ResistanceДокумент2 страницыTire Rolling ResistancePaijo TejoОценок пока нет

- Kayu Jati - Salvador ProductionДокумент3 страницыKayu Jati - Salvador ProductionPaijo TejoОценок пока нет

- Valve ScheduleДокумент2 страницыValve SchedulePaijo TejoОценок пока нет

- Coefficient of Friction,..Документ2 страницыCoefficient of Friction,..Paijo TejoОценок пока нет

- Fire PumpДокумент1 страницаFire PumpPaijo TejoОценок пока нет

- Pump Data SheetДокумент1 страницаPump Data SheetPaijo TejoОценок пока нет

- Basic MaterialДокумент1 страницаBasic MaterialPaijo TejoОценок пока нет

- Tank design parametersДокумент3 страницыTank design parametersPaijo TejoОценок пока нет

- Calculate Lifecycle Costs of Equipment with 13 FactorsДокумент2 страницыCalculate Lifecycle Costs of Equipment with 13 FactorsPaijo TejoОценок пока нет

- Tte033 7403 01 Filling Station DetailДокумент1 страницаTte033 7403 01 Filling Station DetailPaijo TejoОценок пока нет

- Tte033-7001-03 Pipe Support & ConfigurationДокумент1 страницаTte033-7001-03 Pipe Support & ConfigurationPaijo TejoОценок пока нет

- Tte033-7101-06 General Standard DetailДокумент1 страницаTte033-7101-06 General Standard DetailPaijo TejoОценок пока нет

- Diesel oil transfer pump calculationДокумент1 страницаDiesel oil transfer pump calculationPaijo TejoОценок пока нет

- Rail LoadingДокумент1 страницаRail LoadingPaijo TejoОценок пока нет

- Dust Control SystemsДокумент15 страницDust Control SystemsPaijo TejoОценок пока нет

- Tte033 7403 01 Filling Station DetailДокумент1 страницаTte033 7403 01 Filling Station DetailPaijo TejoОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Systems Operation: Shutdown SIS Previous ScreenДокумент18 страницSystems Operation: Shutdown SIS Previous ScreenWladimir AmaguañaОценок пока нет

- Plate Heat Exchanger TurbulenceДокумент1 страницаPlate Heat Exchanger TurbulenceIsmeel AdamОценок пока нет

- Coated Boltnut Flange SizeДокумент1 страницаCoated Boltnut Flange SizeWenonaОценок пока нет

- Spool Valves and Hydraulic CircuitsДокумент7 страницSpool Valves and Hydraulic CircuitsDINESHASHOKОценок пока нет

- H10 FlowДокумент5 страницH10 FlowHoracio EspinosaОценок пока нет

- What Is A Surge TankДокумент5 страницWhat Is A Surge TankHari RОценок пока нет

- Scrubber Design (Packed Column)Документ11 страницScrubber Design (Packed Column)Peddy NesaОценок пока нет

- HvacДокумент6 страницHvacHashimIdreesОценок пока нет

- Pipe SizingДокумент8 страницPipe SizingNind's ChefОценок пока нет

- Calibration Certificate - Turbine - Unit#1Документ2 страницыCalibration Certificate - Turbine - Unit#1SaidОценок пока нет

- A-Series Exploded Diagrams - Spares 04-20Документ6 страницA-Series Exploded Diagrams - Spares 04-20TomОценок пока нет

- ButtWeld Swivel Flange - ISO 6164Документ1 страницаButtWeld Swivel Flange - ISO 6164nemi90Оценок пока нет

- Reciprocating Pump PratishthaДокумент13 страницReciprocating Pump Pratishthamike rosaОценок пока нет

- Catalog 410A: Energy Conscious A/C SolutionsДокумент48 страницCatalog 410A: Energy Conscious A/C SolutionsLaura Ximena Rojas NiñoОценок пока нет

- OSP078 IC DAS 8009 Rev.0 Pressure Differential Indicator DatasheetДокумент4 страницыOSP078 IC DAS 8009 Rev.0 Pressure Differential Indicator DatasheetAhmedОценок пока нет

- Dixon Valv FireComplete RevisedДокумент196 страницDixon Valv FireComplete Revisedjlvega18100% (1)

- Valve Types and Symbols PDFДокумент164 страницыValve Types and Symbols PDFHassan AlbrehawyОценок пока нет

- NFPA Pipe Schedule PDFДокумент2 страницыNFPA Pipe Schedule PDFimran100% (1)

- Sub system equipment statusДокумент32 страницыSub system equipment statusAous HОценок пока нет

- Well Test CompleteДокумент342 страницыWell Test CompleteTarek100% (3)

- 2018 Excela-Flange BOBTAIL PDFДокумент22 страницы2018 Excela-Flange BOBTAIL PDFJimmy RojasОценок пока нет

- Cutting Torch SafetyДокумент1 страницаCutting Torch SafetyDocholosoОценок пока нет

- HMV 135 02 H1 52559 e 12.03 CДокумент12 страницHMV 135 02 H1 52559 e 12.03 CxxshОценок пока нет

- AG-Series Quick Release Couplings Performance SpecsДокумент2 страницыAG-Series Quick Release Couplings Performance SpecsrweidlingОценок пока нет

- RS-B screw compressors – powerful and compact air solutionsДокумент9 страницRS-B screw compressors – powerful and compact air solutionsRUN GOОценок пока нет

- TRANSPORT PHENOMENA I: Laminar Pipe Flow Velocity ProfileДокумент78 страницTRANSPORT PHENOMENA I: Laminar Pipe Flow Velocity ProfileIteoluwakiishi AberuagbaОценок пока нет

- Train-1 Process Flow DiagramДокумент1 страницаTrain-1 Process Flow DiagramHtoo Htoo KyawОценок пока нет

- ON-OFF FLOAT VALVE Sizes R11/4" - DN 600Документ2 страницыON-OFF FLOAT VALVE Sizes R11/4" - DN 600sergethomas2010Оценок пока нет

- Kirloskar MRP Price ListДокумент144 страницыKirloskar MRP Price Listengg2012elect84% (25)

- Ewd HDJ100 LHD Ecu 10Документ1 страницаEwd HDJ100 LHD Ecu 10Miguel Raposo100% (2)