Академический Документы

Профессиональный Документы

Культура Документы

Catalogo Sporlan II

Загружено:

Adán Castro GallegosИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Catalogo Sporlan II

Загружено:

Adán Castro GallegosАвторское право:

Доступные форматы

March 2011 / CATALOG 744

Subcritical CO2 Innovations

Energy Conscious Products & Solutions for Supermarkets

CATALOG 744 Page 1

Subcritical CO2 Innovations

Energy Conscious Products & Solutions for Supermarkets

As a world leader in refrigerant ow controls, Sporlan Division of Parker Hannin continues to meet the challenges of the future. Our growing line of products for CO2 set new standards for robust design and advanced technology. This condensed catalog contains product information specically for CO2 applications. By including a minimum of engineering information we are able to provide a concise reference to pertinent data and specications on Sporlan CO2 products. For additional engineering information, a complete Sporlan Catalog or CD, please contact your nearest Sporlan Sales Ofce, Authorized Sporlan Wholesaler or log on to www.sporlan.com.

Contents

Page

For further information on the products featured in this catalog, see Bulletin number listed below.

Acid Test Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 40-10 Catch-All Filter-Driers Liquid & Suction Line . . . . . . . . . . . . . . . . . . . . . . . . . . 14 40-10 Distributors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 20-10 Electronic Temperature Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 100-9, 100-20, 100-40, 100-50-1, 100-50-2 Pressure-Temperature Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Form 10-135 SeeAll Moisture & Liquid Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 70-10 Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 30-10 Suction Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 80-10

*To request individual Sporlan Product Bulletins, contact your nearest Sporlan Sales Ofce or Wholesaler, write Parker Hannin, Sporlan Division, Washington, Missouri or visit our website at www.sporlan.com. 2011 Parker Hannin Corporation, Sporlan Division, Washington, Missouri FOR USE ON REFRIGERATION and/or AIR CONDITIONING SYSTEMS ONLY

Page 2 CATALOG 744

Subcritical CO2

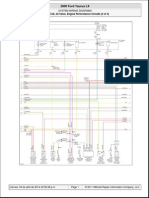

R-744 Cascade System Schematic

Oil Differential Pressure Valve

Conventional System Low Side Stage

CO2

Brazed Plate Heat Exchange CO2 Condenser

Oil Reservoir

Oil Separator

Check Valve

Replaceable Catch-All

Receiver

SASeeAll Liquid Header

Oil Filter

Evaporators

SER RSFReplaceable Suction Filter Oil Level Control SEI Suction Header CDS-9 Step Motor Evaporator Control Valve Liquid Line Solenoid Valve CDS-7 Step Motor Evaporator Control Valve Liquid Line Solenoid Valve

R-744 Secondary System Schematic

Conventional System Low Side Stage

Brazed Plate Heat Exchange CO2 Condenser

Check Valve

Receiver

Pump

Replaceable Catch-All SASeeAll Supply Header

Evaporators

Liquid Solenoid Valve

Liquid Solenoid Valve Return Header

Note: No pressure relief or ball valves shown. Relief valves must be present where liquid CO2 can be trapped. All components must be properly pressure rated and protected for safe installation.

CATALOG 744 Page 3

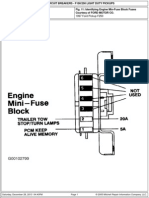

UL Guidelines

CO2

Use this table to determine the maximum start to discharge pressure relief valve setting for each component in the system. It is the system designers responsibility to determine the correct pressure relief valve setting. The pressures listed are NOT the maximum rated pressure of the product.

Maximum Safety Pressure Relief Valve Setting Guidelines*

PRODUCT MODEL UL REFERENCED Start To Discharge Pressure Relief Valve Setting 420 psig 29 barg FUTURE UL APPROVALS Start To Discharge Pressure Relief Valve Setting* 600 psig 41.36 barg

Distributors

All E2xxxx-HP E5xxxx-HP E6xxxx-HP E9xxxx-HP E10xxxx-HP E14xxxx-HP E19xxxx-HP E25xxxx-HP E35xxxx-HP C-030 Series C-050 Series C-080 Series C-160 Series C-300 Series C-410 Series C-600 Series C-R420 Series C-R480 Series C-R960 Series C-R1440 Series C-R1920 Series All (up to 1-5/8 ODF) RSF-480 Series RSF-960 Series SER Series SEI Series CDS Series (up to 1-5/8 ODF) 952505

Solenoid Valves

420 psig 29 barg

600 psig 41.36 barg

Catch-All Filter-Driers (Sealed)

420 psig 29 barg

600 psig 41.36 barg

Catch-All Filter-Driers (Replaceable Core)

420 psig 29 barg 420 psig 29 barg 420 psig 29 barg 420 psig 29 barg 420 psig 29 barg 420 psig 29 barg

600 psig 41.36 barg 600 psig 41.36 barg 500 psig 34.47 barg 600 psig 41.36 barg 600 psig 41.36 barg

See-All Moisture and Liquid Indicators Replaceable Suction Filters Electric Expansion Valves Electric Evaporator Control Valves Pressure Transducer (0-500 psi)

*UL 207 Standard is referenced in establishing the maximum start to discharge pressure relief valve settings.

Failure or improper selection or improper use of the products described herein or related items can cause death, personal injury and property damage.

This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise. The user, through its own analysis and testing, is soley responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the products in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors. To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably forseeable uses of the components or systems.

Page 4 CATALOG 744

Distributors

All Sporlan distributors are ready for service with CO2 . The following tables are provided for making selections based on procedure explained in Bulletin 20-10.

CO2

1126 1651

NOZZLE TYPE PERM. PERM. L L J J J (R) G G G (R) E E E (R) C C C C (R) SIDE CONNECTION 3/8 or 1/2 ODF 3/8 or 1/2 ODF 1/2 or 5/8 ODF 5/8 or 7/8 ODF MATERIAL

Quick Reference

CONNECTION SIZE Inches 1/2 ODM TYPICAL EEV TYPES SER 1.5 - 20 SEI 0.5 - 11 SER 1.5 - 20 SERI G SEI 30 SER 20 SERI G, J SEI 30, 50 SER 20 SERI J, K SEI 30, 50 SEI 50 DISTRIBUTOR TYPE 1613 1616 D260 D262 1620 1622 1651(R) 1112 1113 1653(R) 1115 1116 1655 (R) 1117 1126 1128 1657(R) MAXIMUM NUMBER OF CIRCUITS 3/16 1/4 5/16 3/8 6 4 8 6 4 6 4 9 6 4 6 4 9 7 4 7 5 7 6 4 2 12 8 6 4 12 9 6 4 15 10 9 6 20 15 20 12 10 7 18 15 9 7 24 18 15 12 28 25 21 16 26 18 14 11

5/8 ODM

#360 BRASS

7/8 ODM

1-1/8 ODM

1-3/8 ODM

#377 BRASS #360 BRASS

Dimensions

A D C B

C D B A

Specications

NUMBER OF CIRCUITS & TUBING SIZES AVAILABLE NOZZLE ORIFICE NUMBERS AVAILABLE NOZZLE & RETAINER RING SIZE INLET CONNECTION Inches DIMENSIONS DISTRIBUTOR A 1.96 Inches B 0.81 C

.497 .503

mm D 0.82 A 49.8 B 21 C

12.6 12.8

D 21

Type D260

2 to 6 2 to 4 7 to 9 5 to 6 2 to 4

Net Weight - Approximately 2 oz. (60 g)

3/16 1/4 3/16 1/4 5/16 5/32 3/16 1/4 5/32 3/16 1/4 5/16 3/16 1/4

1/9 thru 8

1/2 ODM Solder

Type D262

Net Weight - Approximately 3 oz. (80 g)

1/9 thru 8

1/2 ODM Solder

2.44

1.00

.497 .503

0.81

62.0

25.4

12.6 12.8

21

Type 1613

2 to 7 2 to 6 2 to 4 8 to 10 7 to 8 5 to 6 2 to 4 2 to 6 2 to 4

Net Weight - Approximately - Approximately 2 oz. (60 g)

1/2 thru 5

PERM.

1/2 ODM Solder

1.17

0.81

.498 .500

0.50

29.7

21

12.6 12.7

13

Type 1616

Net Weight - Approximately - Approximately 3 oz. (80 g)

1/2 thru 5

PERM.

1/2 ODM Solder

1.55

1.00

.498 .500

0.50

39.4

25.4

12.6 12.7

13

Type 1620

Net Weight - Approximately 2 oz. (60 g)

1/9 thru 8

5/8 ODM Solder

1.14

0.81

.623 .625

0.69

29.0

21

15.8 15.9

18

CATALOG 744 Page 5

Distributors

Specications

NUMBER OF CIRCUITS & TUBING SIZES AVAILABLE NOZZLE ORIFICE NUMBERS AVAILABLE NOZZLE & RETAINER RING SIZE INLET CONNECTION Inches DIMENSIONS DISTRIBUTOR A Inches B C

.623 .625

CO2

mm D A B C

15.8 15.9

Type 1622

7 to 9 5 to 7 2 to 4

Net Weight - Approximately 3 oz. (80 g)

3/16 1/4 5/16 3/16 1/4 5/16 3/8 3/16 1/4 5/16 3/8 3/16 1/4 5/16 3/8 3/16 1/4 3/16 1/4 5/16 3/8 3/16 1/4 5/16 3/8 3/16 1/4 5/16 3/8

1/9 thru 8

5/8 ODM Solder

1.63

1.00

0.63

41.4

25.4

16

Type 1112

5 to 7 4 to 6 2 to 4 2

Net Weight - Approximately 4 oz. (110 g)

1/6 thru 20

7/8 ODM Solder

1.72

0.91

.873 .875

1.00

43.7

23

22.2 +/ 0.03

25.4

Type 1113

8 to 12 7 to 8 5 to 6 3 to 4 11 to 15 9 to 10 7 to 9 5 to 6

Net Weight - Approximately 5 oz. (140 g)

1/6 thru 20

7/8 ODM Solder

1.78

1.16

.873 .875

0.88

45.2

29.5

22.2 +/ 0.03

22

Type 1115

Net Weight - Approximately 9 oz. (250 g)

2 thru 30

1-1/8 ODM Solder

2.44

1.50

1.123 1.125

1.12

62.0

38.1

28.52 28.58

28.4

Type 1116

16 to 20 11 to 15

Net Weight - Approximately 9 oz. (250 g)

2 thru 30

1-1/8 ODM Solder

2.44

1.75

1.123 1.125

1.12

62.0

44.4

28.52 28.58

28.4

Type 1117

16 to 18 11 to 15 9 7

Net Weight - Approximately 1 lb. (450 g)

3 thru 50

1-3/8 ODM Solder

2.56

1.75

1.373 1.375

1.31

65.0

44.4

34.87 34.92

33.3

Type 1126

19 to 24 15 to 18 10 to 15 8 to 12

Net Weight - Approximately 1 lb., 6 oz. (620 g)

3 thru 50

1-3/8 ODM Solder

2.81

2.38

1.373 1.375

1.12

71.4

60.5

34.87 34.92

28.4

Type 1128

25 to 28 19 to 25 16 to 21 13 to 16

Net Weight - Approximately 1 lb., 10 oz. (740 g)

3 thru 50

1-3/8 ODM Solder

3.12

3.00

1.373 1.375

1.38

79.2

76.2

34.87 34.92

35.1

Page 6 CATALOG 744

Distributors

Capacities

NOZZLE NUMBER 1/9 1/6 1/4 1/3 1/2 3/4 1 1-1/2 2 2-1/2 3 4 5 6 8 10 12 15 17 20 25 30 35 40 50 TUBE DIAMETER Inches 3/16 1/4 5/16 3/8

0 1.60 12 1.36 18 1.16

CO2

Tons psi F kW bar C

DISTRIBUTOR NOZZLE CAPACITIES EVAPORATOR TEMPERATURE F 0 0.42 0.64 1.03 1.35 1.87 2.82 3.77 5.48 7.53 9.39 11.3 15.1 18.6 22.3 26.9 30.1 37.2 46.1 51.6 62.2 78.2 89.3 107 120 156 -20 0.30 0.46 0.74 0.97 1.34 2.02 2.71 3.94 5.40 6.74 8.09 10.8 13.3 16.0 19.3 21.6 26.7 33.1 37.0 44.6 56.1 64.1 77.1 86.5 112 -40 0.23 0.35 0.56 0.73 1.01 1.53 2.05 2.98 4.09 5.09 6.11 8.18 10.1 12.1 14.6 16.3 20.2 25.0 28.0 33.7 42.4 48.5 58.3 65.4 84.8

NOZZLE NUMBER 1/9 1/6 1/4 1/3 1/2 3/4 1 1-1/2 2 2-1/2 3 4 5 6 8 10 12 15 17 20 25 30 35 40 50 TUBE DIAMETER Inches 3/16 1/4 5/16 3/8

-20 1.87 72 0.73 300 1.36 450 1.16

-20 1.27 1.96 3.15 4.13 5.71 8.62 11.5 16.8 23.0 28.7 34.5 46.2 56.9 68.3 82.2 92.2 114 141 158 190 239 273 329 369 478

DISTRIBUTOR NOZZLE CAPACITIES EVAPORATOR TEMPERATURE C -30 0.97 1.49 2.4 3.14 4.34 6.55 8.77 12.8 17.5 21.8 26.2 35.1 43.3 51.9 62.5 70.0 86.5 107 120 145 182 208 250 280 364

-40 0.76 1.17 1.88 2.46 3.41 5.14 6.88 10.0 13.7 17.1 20.6 27.5 34.0 40.7 49.1 55.0 67.9 84.2 94.2 113 143 163 196 220 285

DISTRIBUTOR CAPACITY PER TUBE (Tons) EVAPORATOR TEMPERATURE F 0 -20 -40 1.31 0.84 0.60 3.80 2.44 1.73 7.73 4.97 3.54 14.0 8.99 6.40

LIQUID TEMPERATURE F 10 20 30 CORRECTION FACTOR FOR NOZZLE AND TUBES 1.25 1.00 0.83 TUBE LENGTH (Inches) 30 36 42 48 54 60 CORRECTION FACTOR, TUBE LENGTH 1.07 1.00 0.95 0.90 0.86 0.82 0.79 24 40 0.71 66 0.76

DISTRIBUTOR CAPACITY PER TUBE (kW) EVAPORATOR TEMPERATURE C -20 -30 -40 3.86 2.71 2.02 11.2 7.86 5.86 22.8 16.0 11.9 41.2 29.0 21.6

LIQUID TEMPERATURE C -15 -10 -5 0 CORRECTION FACTOR FOR NOZZLE AND TUBES 1.48 1.19 1.00 0.86 TUBE LENGTH (mm) 760 900 1050 1200 1350 1500 CORRECTION FACTOR, TUBE LENGTH 1.07 1.00 0.95 0.90 0.86 0.82 0.79 600 1650 0.76 5 0.75 1800 0.73

Nozzle ratings based on P = 35 psi (2.4 bar) Tube ratings based on P = 10 psi (0.69 bar), 30 inches (760 mm) length

CATALOG 744 Page 7

Solenoid Valves

Selection - Capacity Rating

Capacity, MOPD and Electrical specications are required.

All solenoid valves are tested and rated in accordance with A.R.I. Standard No. 760-2001.

CO2

Liquid Capacity Selection Table

Tons psi F

TYPE NUMBER E Series Extended Connections Without Manual Lift Stem With Manual Lift Stem Normally Closed Normally Closed E2S120-HP E5S130-HP E6S130-HP ME6S130-HP E6S140-HP ME6S140-HP E9S240-HP ME9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP ME14S250-HP E19S270-HP ME19S270-HP E25S270-HP E25S290-HP ME25S290-HP ME35S190-HP ME35S1110-HP

Ratings based on 20F liquid, -20F evaporator temperature.

CONNECTIONS ODF SOLDER Inches 1/4 3/8 3/8 1/2 1/2 5/8 1/2 5/8 7/8 7/8 1-1/8 1-1/8 1-3/8

Cv 0.15 0.53 0.93 1.53 2.10 2.98 4.57 7.81 13.3

PORT SIZE Inches 0.075 0.150 3/16 9/32 5/16 7/16 19/32 25/32 1

TONS OF REFRIGERATION 1 0.66 2.34 4.20 6.84 9.35 13.3 20.3 34.7 56.3 PRESSURE DROP psi* 2 3 4 0.95 1.16 1.34 3.33 4.09 4.73 5.90 9.64 13.2 18.8 28.8 49.1 82.2 7.21 11.8 16.2 23.0 35.3 60.2 103 8.30 13.6 18.7 26.5 40.8 69.6 120 5 1.51 5.30 9.26 15.2 20.9 29.6 45.6 77.9 136

kW bar C

TYPE NUMBER E Series Extended Connections Without Manual Lift Stem With Manual Lift Stem Normally Closed Normally Closed E2S120-HP E5S130-HP E6S130-HP ME6S130-HP E6S140-HP ME6S140-HP E9S240-HP ME9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP ME14S250-HP E19S270-HP ME19S270-HP E25S270-HP E25S290-HP ME25S290-HP E35S190-HP ME35S190-HP ME35S1110-HP

CONNECTIONS ODF SOLDER Inches 1/4 3/8 3/8 1/2 1/2 5/8 1/2 5/8 7/8 7/8 1-1/8 1-1/8 1-3/8

Kv 0.13 0.46 0.81 1.32 1.81 2.57 3.95 6.75 11.5

PORT SIZE mm 1.9 3.8 4.8 7.1 7.9 11 15 20 26

kW OF REFRIGERATION 0.07 2.31 8.12 14.6 23.7 32.5 46.1 70.4 120 196 PRESSURE DROP bar* 0.1 0.2 0.3 2.76 3.93 4.84 9.73 13.9 17.0 17.4 28.3 38.8 55.1 84.3 144 238 24.4 39.9 54.8 77.8 119 204 347 29.8 48.8 67.1 95.2 147 250 433 0.4 5.60 19.7 34.3 56.3 77.4 110 169 289 506

Ratings based on -5C liquid, -30C evaporator temperature. * Do not use below 1 psi (0.07 bar) pressure drop. For other liquid line temperatures use liquid correction factors below. Maximum Operating Pressure Differential (MOPD) for the AC coil is 450 psi (31.0 bar). Maximum Rated Pressure (MRP) = 700 psig (48.3 barg).

0 1.13

LIQUID TEMPERATURE F 10 20 30 CORRECTION FACTOR, LIQUID CAPACITY RATING 1.07 1.00 0.93

40 0.86

-20

1.18

LIQUID TEMPERATURE C -15 -10 -5 0 CORRECTION FACTOR, LIQUID CAPACITY RATING

1.12 1.06 1.00 0.94

5

0.87

These factors include corrections for liquid refrigerant density and net refrigerating effect and are based on an average evaporator temperature of 40F (5C). For each 10F (10C) reduction in evaporating temperature, capacities are reduced by approximately 1-1/2%.

Disclaimer: Some CO2 systems do not use oil or lubrication in their systems. If so, the lack of lubrication in the system may cause the internal components of the valve to wear prematurely resulting in eventual failure of the valve. This disclaimer is for solenoid valves only.

Page 8 CATALOG 744

Solenoid Valves

Suction Capacity Selection Table

Tons psi F

CO2

kW bar C

TYPE NUMBER E Series Extended Connections Without Manual With Manual Lift Stem Lift Stem Normally Closed Normally Closed E2S120-HP E5S130-HP E6S130-HP ME6S130-HP E6S140-HP ME6S140-HP E9S240-HP ME9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP ME14S250-HP E19S270-HP ME19S270-HP E25S270-HP E25S290-HP ME25S290-HP ME35S190-HP ME35S1110-HP

SUCTION CAPACITY RATINGS Tons EVAPORATOR TEMPERATURE F 0 0.15 0.52 0.98 1.57 2.13 3.04 4.55 7.81 11.2 -10 0.13 0.47 0.90 1.45 1.96 2.79 4.18 7.17 10.2 -20 0.12 0.43 0.82 1.32 1.79 2.55 3.81 6.55 9.23 -30 0.11 0.39 0.75 1.20 1.63 2.32 3.46 5.95 8.32 -40 0.10 0.35 0.68 1.09 1.47 2.10 3.13 5.38 7.45

TYPE NUMBER E Series Extended Connections Without Manual With Manual Lift Stem Lift Stem Normally Closed Normally Closed E2S120-HP E5S130-HP E6S130-HP ME6S130-HP E6S140-HP ME6S140-HP E9S240-HP ME9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP ME14S250-HP E19S270-HP ME19S270-HP E25S270-HP E25S290-HP ME25S290-HP ME35S190-HP ME35S1110-HP

SUCTION CAPACITY RATINGS kW EVAPORATOR TEMPERATURE C -20 0.52 1.83 3.45 5.52 7.49 10.7 16.0 27.5 39.4 -25 0.46 1.65 3.16 5.10 6.89 9.81 14.7 25.2 35.9 -30 0.42 1.51 2.88 4.64 6.30 8.97 13.4 23.0 32.5 -35 0.38 1.37 2.64 4.22 5.73 8.16 12.2 20.9 29.3 -40 0.35 1.23 2.39 3.83 5.17 7.39 11.0 18.9 26.2

Ratings based on 20F (-5C) liquid, 25F (14C) superheat, 1 psi (0.07 bar) P.

Discharge Gas Capacity Selection Table

Tons psi F

kW bar C

TYPE NUMBER E Series Extended Connections Without Manual With Manual Lift Stem Lift Stem Normally Closed Normally Closed E2S120-HP E5S130-HP E6S130-HP ME6S130-HP E6S140-HP ME6S140-HP E9S240-HP ME9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP ME14S250-HP E19S270-HP ME19S270-HP E25S270-HP E25S290-HP ME25S290-HP ME35S190-HP ME35S1110-HP

DISCHARGE CAPACITY RATINGS Tons P - psi 2 0.21 0.75 1.40 2.26 3.07 4.38 6.59 11.3 16.7 5 0.34 1.20 2.20 3.57 4.85 6.91 10.5 17.9 27.5 10 0.48 1.70 3.09 5.03 6.86 9.76 14.8 25.4 40.1 25 0.77 2.72 4.85 7.91 10.8 15.4 23.5 40.0 66.2 50 1.25 4.39 7.46 11.1 16.9 23.2 34.5 55.0 96.5

TYPE NUMBER E Series Extended Connections Without Manual With Manual Lift Stem Lift Stem Normally Closed Normally Closed E2S120-HP E5S130-HP E6S130-HP ME6S130-HP E6S140-HP ME6S140-HP E9S240-HP ME9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP ME14S250-HP E19S270-HP ME19S270-HP E25S270-HP E25S290-HP ME25S290-HP ME35S190-HP ME35S1110-HP

DISCHARGE CAPACITY RATINGS kW P - bar 0.15 0.78 2.75 5.11 8.27 11.2 16.0 24.1 41.3 61.3 0.3 1.11 3.91 7.19 11.7 15.9 22.6 34.2 58.5 89.4 0.7 1.71 6.02 10.9 17.7 24.2 34.5 52.4 89.6 142 1.5 2.52 8.87 15.9 25.9 35.4 50.3 76.9 131 215 4.0 4.67 16.45 27.9 41.6 63.4 87.2 129 206 363

Ratings based on 20F (-5C) condensing, isentropic compression plus 50F (28C), -20F (-30C) evaporator, 5F (-15C) suction gas at the compressor.

LIQUID TEMPERATURE F 0 10 20 30 40 CORRECTION FACTOR, SUCTION AND DISCHARGE RATING 1.07 1.04 1.00 0.96 0.92

-20

1.10

LIQUID TEMPERATURE C -15 -10 -5 0 5 CORRECTION FACTOR, SUCTION AND DISCHARGE RATING

1.07 1.03 1.00 0.97 0.93

CATALOG 744 Page 9

Solenoid Valves

Type E2 and E5 Series

The E5 Series are hermetic solenoid valves with pilot operated disc construction. These valves may be mounted horizontally, on their side or in a vertical line. The E5 series solenoid valves feature extended solder type connections as standard. One important benefit to the user is that all valves in the E5 series can be installed using either low or no silver content brazing alloy. The MKC-l coil is Class F temperature rated and is provided as standard, therefore a high temperature coil is not required for discharge service.

CO2

Ordering Instructions

When ordering complete valves, specify Valve Type, Connections, Voltage and Cycles. When ordering Body Assembly, specify Valve Type E5S130-HP Type and Connections. When ordering Coil Assembly ONLY, specify Coil Type, Voltage and Cycles. Example: MKC-1 120/50-60.

Dimensions

D VALVE SERIES TYPE A B C FITTING DEPTH ODF E OFFSET

1.56 40 mm Coil Removal Approved C

2.92 74 mm

Inches

E2 E5 E2S120-HP E5S130-HP 4.63 4.56 0.55 0.53 1.96 2.48 0.31 0.29 0.23

mm

E2 E5 E2S120-HP E5S130-HP COIL RATINGS STANDARD VOLTS/CYCLES 24/50-60 120/50-60 208-240/50-60 120-208-240/50-60 WATTS AC DC 118 116 14 13 50 63 8 7.4 6

E5 Series

D B E A

10

15

Specications - MKC-1 Coil

Tons psi F

kW bar C

CONNECTIONS ODF - Inches

PORT SIZE Inches

VALVE SERIES

TYPE

Cv

TONS of REFRIGERATION PRESSURE DROP 3 psi 1.16 4.09

VALVE SERIES

PORT SIZE mm

MOPD psi AC DC

CONNECTIONS ODF - Inches

NOMINAL LIQUID CAPACITIES TYPE

Kv

MOPD bar AC DC

NOMINAL LIQUID CAPACITIES kW of REFRIGERATION PRESSURE DROP 0.2 bar 3.93 13.9

E2 E5

E2S120-HP E5S130-HP

1/4 3/8

0.15 0.53

0.075 0.150

450 400

E2 E5

E2S120-HP E5S130-HP

1/4 3/8

0.13 0.46

1.9 3.8

31.0 27.6

Capacities based on 20F (-6.7C) liquid temperature, -20F (-29C) evaporator

temperature. For other liquid line temperatures use liquid correction factors below. Maximum Operating Pressure Differential (MOPD) for the AC coil is 450 psi (31 bar). Maximum Rated Pressure (MRP) = 700 psig (48.3 barg).

Dual voltage 4-wire coils, 120-208-240/50-60 are available at slight additional cost.

Available with conduit boss, junction box, or DIN at no extra charge. For capacity at other pressure drops, see page 7 and 8. See disclaimer on page 7.

For other voltages and cycles, consult Sporlan Division of Parker, Washington, MO.

Page 10 CATALOG 744

Solenoid Valves

Type E6 Series

The E6 Series are compact solenoid valves with pilot operated disc construction for refrigeration and air conditioning. These valves may be mounted horizontally, on their side or in a vertical line. They are suitable for suction line service because very low pressure differential, 1 psi, is required for full operation. The Type E6 series solenoid valves feature extended solder type connections as standard. One important benefit to the user is that all valves in the E6 series can be installed without disassembly using either low or no silver content brazing alloy. The MKC-l coil is Class F temperature rated and is provided as standard, therefore a high temperature coil is not required for discharge service.

CO2

Type E6S130-HP

Ordering Instructions

When ordering complete valves, specify Valve Type, Connections, Voltage and Cycles. When ordering Body Assembly, specify Valve Type and Connections. When ordering Coil Assembly ONLY, specify Coil Type, Voltage and Cycles. Example: MKC-1 120/50-60.

Dimensions

D VALVE SERIES TYPE A B* C FITTING DEPTH ODF E OFFSET

1.56 40 mm Coil Removal Approved C

2.92 74 mm

Inches

E6 E6S130-HP E6S140-HP E6S130-HP E6S140-HP 4.63 5.00 118 127 0.75 2.44 0.31 0.38 7.9 9.7 0.31

E6 Series

E D 1.64 42 mm

WATTS AC DC

mm

E6 19 62 7.9

* Add 1.12 (28 mm) for valves with Manual Lift Stem.

*B

A

COIL RATINGS STANDARD VOLTS/CYCLES 24/50-60 120/50-60 208-240/50-60 120-208-240/50-60

10

15

Optional 1/2 Conduit Boss

Specications - MKC-1 Coil

Tons psi F

kW bar C

CONNECTIONS ODF - Inches

PORT SIZE Inches

VALVE SERIES

TYPE

Cv

TONS of REFRIGERATION PRESSURE DROP 3 psi 7.21

VALVE SERIES

PORT SIZE mm

MOPD psi AC DC

CONNECTIONS ODF - Inches

NOMINAL LIQUID CAPACITIES TYPE

Kv

MOPD bar AC DC

NOMINAL LIQUID CAPACITIES kW of REFRIGERATION PRESSURE DROP 0.2 bar 24.4

E6

E6S130-HP ME6S130-HP ME6S140-HP

3/8 1/2

0.93 3/16 450 400

E6

E6S130-HP ME6S130-HP ME6S140-HP

3/8 1/2

0.81

4.8

31.0 27.6

Capacities based on 20F (-6.7C) liquid temperature, -20F (-29C) evaporator temperature. For other liquid line temperatures use liquid correction factors below. Maximum Operating Pressure Differential (MOPD) for the AC coil is 450 psi (31 bar). Maximum Rated Pressure (MRP) = 700 psig (48.3 barg). Dual voltage 4-wire coils, 120-208-240/50-60 are available at slight additional cost. For other voltages and cycles, consult Sporlan Division of Parker, Washington, MO.

Available with conduit boss, junction box, or DIN at no extra charge. For mounting holes and/or bracket information, see Bulletin 30-11 E6 series with mounting holes are NOT standard. For capacity at other pressure drops, see page 7 and 8. See disclaimer on page 7.

CATALOG 744 Page 11

Solenoid Valves

Types E9, E10, E14, E19 and E25 Series

Types E9, E10, E14, E19 and E25 Series are compact solenoid valves with pilot operated disc construction for refrigeration and air conditioning. These valves may be mounted horizontally, on their side or in a vertical line. These valves are also suitable for suction line service because very low pressure differential, 1 psi, is required for full operation. The E9, E10, E14, E19 and E25 series solenoid valves feature extended solder type connections as standard. One important benefit to the user is that all valves in the E9, E10, E14, E19 and E25 series series can be installed without disassembly using either low or no silver content brazing alloy. The MKC-2 and OMKC-2 coils are Class F temperature rated and are provided as standard, therefore a high temperature coil is not required for discharge service.

CO2

Type E14S250-HP

Ordering Instructions

When ordering complete valves, specify Valve Type, Connections, Voltage and Cycles. When ordering Body Assembly, specify Valve Type and Connections. When ordering Coil Assembly ONLY, specify Coil Type, Voltage and Cycles. Example: MKC-2 120/50-60; OMKC-2 120/50-60.

Dimensions

C VALVE SERIES NORMALLY CLOSED TYPE A *B D FITTING DEPTH E OFFSET

1.75 44 mm Coil Removal Approved Listed C

3.17 81 mm

ODF 0.31 0.38 0.50 0.38 0.50 0.75 0.75 0.91 7.9 9.7 13.0 9.7 13.0 19.0 19.0 23.0

Inches

E9 E10 E14 E19 E25 E9S230-HP E9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP E19S270-HP E25S270-HP E25S290-HP E9S230-HP E9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP E19S270-HP E25S270-HP E25S290-HP 4.63 5.00 6.50 5.00 6.88 7.13 7.50 8.50 118 127 165 127 175 181 191 216 0.69 0.75 0.69 0.85 0.46 0.81 0.72 0.72 18.0 9.7 12.7 9.7 11.7 21.0 18.0 18.0 2.65 2.70 2.74 3.13 3.26 3.41 3.81 3.81 67 69 69 80 83 87 97 97 0.39 0.33 0.31 0.38 9.9 7.9 9.7 9.7

E10 Series

E D 1.89 48 mm

*B

mm

COIL RATINGS STANDARD VOLTS/CYCLES 24/50-60 120/50-60 208-240/50-60 120-208-240/50-60 WATTS AC DC E9 E10 E14 E19 E25

15

18

Optional 1/2 Conduit Boss

* Add 1.12 (28 mm) for valves with Manual Lift Stem.

Specications - MKC-2 and OMKC-2 Coil

Tons psi F

kW bar C

CONNECTIONS ODF - Inches

PORT SIZE Inches

VALVE SERIES

TYPE

Cv

TONS of REFRIGERATION PRESSURE DROP 3 psi 11.8

VALVE SERIES

PORT SIZE mm

MOPD psi AC DC

CONNECTIONS ODF - Inches

NOMINAL LIQUID CAPACITIES TYPE

Kv

MOPD bar AC DC

NOMINAL LIQUID CAPACITIES kW of REFRIGERATION PRESSURE DROP 0.2 bar 39.9

E9 E10 E14 E19 E25

E9S230-HP E9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP E19S270-HP E25S270-HP E25S290-HP

3/8 1/2 5/8 1/2 5/8 5/8 7/8 7/8 1-1/8

1.53 9/32 2.10 5/16 450 400

E9 E10 E14 E19 E25

16.2 23.0 25.3 60.2

2.98 7/16 4.57 19/32 7.81 25/32

E9S230-HP E9S240-HP E9S250-HP E10S240-HP E10S250-HP E14S250-HP E19S270-HP E25S270-HP E25S290-HP

3/8 1/2 5/8 1/2 5/8 5/8 7/8 7/8 1-1/8

1.32 1.81 2.57 3.95 6.75

7.1 7.9 11 15 20 31.0 27.6

54.8 77.8 119 204

Capacities based on 20F (-6.7C) liquid temperature, -20F (-29C) evaporator temperature. For other liquid line temperatures use liquid correction factors below. Maximum Operating Pressure Differential (MOPD) for the AC coil is 450 psi (31 bar). Maximum Rated Pressure (MRP) = 700 psig (48.3 barg).

Dual voltage 4-wire coils, 120-208-240/50-60 are available at slight additional cost. For other voltages and cycles, consult Sporlan Division of Parker, Washington, MO. Available with conduit boss, junction box, or DIN at no extra charge. For capacity at other pressure drops, see page 7 and 8. See disclaimer on page 7.

Page 12 CATALOG 744

Solenoid Valves

Types E35 Series

Types E35 Series solenoid valves are pilot operated for refrigeration and air conditioning applications. They are suitable for suction service because very low pressure differential, 1 psi, is required for full operation. The E35 Series may be mounted horizontally, on their side or in a vertical line. The Type E35 series solenoid valves feature extended solder type connections as standard. One important benefit to the user is that all valves in the E35 series can be installed without disassembly using either low or no silver content brazing alloy. The MKC-1 and OMKC-1 coils are Class F temperature rated and are provided as standard, therefore a high temperature coil is not required for discharge service.

CO2

Ordering Instructions

When ordering complete valves, specify Valve Type, Connections, Voltage and Cycles. When ordering Body Assembly, specify Valve Type and Connections.

Type ME35S1110-HP

Q 1-5/8 ODM Type L tubing may be slipped over 1-3/8 fitting, without the use of a coupling. When ordering Coil Assembly ONLY, specify Coil Type, Voltage and Cycles. Example: MKC-1 120/50-60; OMKC-1 120/50-60.

Dimensions

C NORMALLY CLOSED VALVE SERIES NORMALLY OPEN TYPE A B D FITTING DEPTH *E OFFSET

1.56 40 mm Coil Removal Approved Listed

ME35 Series

ODF

Inches

E35 E35S190-HP E35S1110-HP E35S190-HP E35S1110-HP 10.06 11.06 256 281 5.03 5.53 128 140 4.81 5.94 0.91 0.97 23 25 0.84 0.84

mm

E35 122 151 21 21

E D B A B

* Add 1.12 (28 mm) for valves with Manual Lift Stem.

COIL RATINGS STANDARD VOLTS/CYCLES 24/50-60 120/50-60 208-240/50-60 120-208-240/50-60 WATTS AC DC

1.64 42 mm

10

15

Optional 1/2 Conduit Boss

Specications - MKC-1 and OMKC-1 Coil

Tons psi F

kW bar C

CONNECTIONS ODF - Inches

PORT SIZE Inches

VALVE SERIES

TYPE

Cv

TONS of REFRIGERATION PRESSURE DROP 3 psi 103

VALVE SERIES

PORT SIZE mm

MOPD psi AC DC 450 400

CONNECTIONS ODF - Inches

NOMINAL LIQUID CAPACITIES TYPE

Kv

MOPD bar AC DC

NOMINAL LIQUID CAPACITIES kW of REFRIGERATION PRESSURE DROP 0.2 bar 347

E35

1-1/8 ME35S190-HP 13.3 ME35S1110-HP Q1-3/8

E35

1-1/8 ME35S190-HP 11.5 ME35S1110-HP Q1-3/8

26 31.0 27.6

Capacities based on 20F (-6.7C) liquid temperature, -20F (-29C) evaporator temperature. For other liquid line temperatures use liquid correction factors below. Maximum Operating Pressure Differential (MOPD) for the AC coil is 450 psi (31 bar). Maximum Rated Pressure (MRP) = 700 psig (48.3 barg).

Dual voltage 4-wire coils, 120-208-240/50-60 are available at slight additional cost. For other voltages and cycles, consult Sporlan Division of Parker, Washington, MO. Available with conduit boss, junction box, or DIN at no extra charge. For capacity at other pressure drops, see page 7 and 8. See disclaimer on page 7.

CATALOG 744 Page 13

Solenoid Valves

Identication

Nomenclature - E Series

M E 10 S 2 5 0 *Connections Manual Lift Stem Design Series Port Size in 1/32 Connections Solder Coil Size Q, W Connection Size in 1/8 0 - ODF X ODF 1 - ODF X ODM 2 - ODM X ODF 3 - ODM X ODM

CO2

Coil Connection S- Spade E - DIN 43650A

Type E series is identified by an expanded nomenclature. The system of valve identity based on port size. In addition, the E series identifies the connection size and type. The advantage of the E series nomenclature system is that it allows ease in valve identification of the standard line and can provide considerable information about special valves supplied to manufacturers. For connections and other special features consult Sporlan Division of Parker, Washington, MO.

Q The MKC-1, OMKC-1, MKC-2 and OMKC-2 are fungus proof and meet MIL-I-631C. W The standard MKC-1 and MKC-2 are class F rated. * Standard connections are ODF inlet x ODF outlet on E Series valves. Minimum quantities may be required for other connections.

Application

Compressor Capacity Reduction Service

Sporlan Solenoid Valves may be used in conjunction with Sporlan Discharge Bypass Valves for capacity reduction service. For capacity information and further details on the Discharge Bypass Valves see pages 36 to 39 or consult Sporlan Division of Parker, Washington, MO.

Transformer Selection for Low-Voltage Control Systems

Filter-Driers are Essential

Dirt and other system contaminants present a problem for refrigeration and air conditioning controls. Since pilot operated solenoid valves operate with rather close tolerances, system cleanliness is imperative. The Sporlan Catch-All Filter-Drier filters out minute particles of dirt and other foreign matter, thus protecting the valve. Sporlan recommends using a Catch-All Filter-Drier ahead of every solenoid valve on all refrigeration and air conditioning applications. Contact Sporlan before adding a Catch-All Filter-Drier in the discharge line.

Many systems utilize low voltage controls, requiring the use of a transformer for voltage reduction, normally to 24 volts. The selection of a transformer is not accomplished by merely selecting one that has the proper voltage requirements. The volt-ampere (VA) rating is equally important. To determine the VA requirement for a specific solenoid valve, refer to the chart below. It should be noted, that insufficient transformer capacity will result in reduced operating power or lowering of the MOPD value. If more than one solenoid valve and/or other accessories are operated from the same transformer, then the transformer VA rating must be determined by adding the individual accessories VA requirements.

Fusing

Sporlan Solenoid Valves are not supplied with fuses. Fusing should be according to local codes. We recommend fusing the hot leg of the valve wiring with fast acting fuses and the valve should be grounded either through the fluid piping or the electrical conduit.

COIL KIT

24 VOLTS/ 50-60 CYCLES CURRENT-AMPERES INRUSH HOLDING 0.63 1.4

120 VOLTS/ 50-60 CYCLES CURRENT-AMPERES INRUSH 0.39 0.60 HOLDING 0.14 0.26

240 VOLTS/ 50-60 CYCLES CURRENT-AMPERES INRUSH 0.19 0.31 HOLDING 0.09 0.13

TRANSFORMER RATING VOLTS-AMPERES FOR 100% OF RATED MOPD OF VALVE 60 100

MKC-1 OMKC-1 MKC-2 OMKC-2

1.9 3.1

All current values are based on 60 cycles.

Volt-ampere ratings are based on inrush currents. Above values are based on the most severe conditions. Consult Sporlan Division of Parker, Washington, MO for coil characteristics on specific valve types.

Page 14 CATALOG 744

Filter-Driers

The universal acceptance of the Catch-All Filter-Drier is due to its unique molded porous core, consisting of a blend of highly effective desiccants. The quality features built into it assure years of service on any refrigeration system. Moisture The Catch-All Filter-Drier removes moisture from the refrigerant by adsorbing and retaining it deep within the desiccant granules. The blend of desiccants used in the Catch-All Filter-Drier are specially formulated for exceptional water removal.

CO2

Foreign Matter The Catch-All Filter-Drier will filter out scale, solder particles, carbon, sludge, dirt or any other foreign matter with negligible pressure drop. Fine particles that would go through an ordinary strainer are removed down to a minimum size in one pass filtration. The large filtering area of the Catch-All Filter-Drier core permits it to collect a large amount of dirt without plug up. Acid The Catch-All Filter-Drier is unexcelled in acid removal ability. The hydrochloric, hydrofluoric, and various organic acids are adsorbed and held by the desiccant in a manner similar to the

C US

Sealed Type Liquid Line and Suction Line Specications

Tons F psi

LISTED

SOLDER DIAMETER SOCKET DEPTH of BODY Inches Inches 0.38 0.44 0.38 0.44 0.44 0.38 0.44 0.44 0.50 0.38 0.44 0.44 0.50 0.62 0.62 0.75 0.44 0.50 0.62 0.62 0.75 0.96 0.50 0.62 0.75 0.96 0.75 0.96 2.62 2.44 1.75

C SERIES LIQUID LINE TYPE SAE FLARE C-032 C-032-F C-032-FM C-033 C-052 ODF SOLDER C-032-S C-032-CAP C-032-CAP-T C-033-S C-052-S C-0525-S C-053-S C-082-S C-0825-S C-083-S C-084-S C-162-S C-1625-S C-163-S C-164-S C-165-S C-167-S C-303-S C-304-S C-305-S C-306-S C-307-S C-309-S C-414-S C-415-S C-417-S C-419-S C-607-S C-609-S

SUCTION LINE TYPE ODF SOLDER C-083-S-T-HH C-084-S-T-HH C-164-S-T-HH C-165-S-T-HH C-166-S-T-HH C-167-S-T-HH C-305-S-T-HH C-306-S-T-HH C-307-S-T-HH C-309-S-T-HH C-417-S-T-HH C-419-S-T-HH C-607-S-T-HH C-609-S-T-HH

VOLUME of CONNECTION SIZE DESICCANT Inches Cubic Inches 1/4 Extended 1/4 Male 1/4 Male - Inlet 1/4 Female - Outlet 1/4 Female - Inlet 1/4 Male - Outlet 3/8 1/4 5/16 1/4 Male - Inlet 1/4 Female - Outlet 1/4 Male - Inlet 1/4 Female - Outlet 3/8 1/4 5/16 3/8 1/2 1/4 5/16 3/8 1/2 5/8 3/4 7/8 3/8 1/2 5/8 3/4 7/8 1-1/8 3/8 1/2 5/8 7/8 1-1/8 7/8 1-1/8 3

OVERALL LENGTH Inches SAE FLARE 4.19 3.81 3.81 4.69 4.75 ODF SOLDER 3.81 5.81 3.88 4.19 4.38 4.31 5.12 5.31 5.25 5.44 5.75 5.94 5.88 6.00 6.31 6.75 6.93 8.88 9.00 9.25 9.65 9.80 9.75 9.05 9.35 9.81 9.75 16.00 16.00

C-052-F C-052-FM C-053 C-082 C-083 C-084 C-162 C-163 C-164 C-165 C-303 C-304 C-305

4.19 4.19 5.19 5.62 6.06 6.31 6.25 6.75 6.94 7.25 9.69 9.88 10.19 9.56 9.94 10.25

16

3.00

30

3.00

C-413 C-414 C-415

41

3.50

60

3.00

UL and ULC Listed Guide SMGT-File No. SA-1756. Maximum Rated Pressure of 650 psig.

CATALOG 744 Page 15

Filter-Driers

adsorption of moisture. Tests have demonstrated that the CatchAll Filter-Drier has superior acid removal ability when compared to competitive driers. This ability, along with its excellent ability to clean up the oil, is responsible for the excellent field performance in cleaning up severely contaminated systems. Oil, Sludge and Varnish Even the best refrigeration oils break down to produce varnish, sludge and organic acids. Only the Catch-All Filter-Drier is capable of removing these products of oil decomposition.

CO2

Special Applications A special HH core Catch-All FilterDrier is available to remove wax which frequently causes difficulty on low temperature refrigeration systems. For cap tube systems, use the C-032-CAP or C-032-CAP-T Catch-All which has fittings suitable for attaching to any size capillary tube. Remember...Its the CORE that counts!

Sealed Type Liquid Line and Suction Line Specications

kW C bar

US

LISTED

SOLDER DIAMETER SOCKET DEPTH of BODY mm mm 10 11 10 11 11 10 11 11 13 10 11 11 13 16 16 19 11 13 16 16 19 24 13 16 19 24 19 24 67 62 44

C SERIES LIQUID LINE TYPE SAE FLARE C-032 C-032-F C-032-FM C-033 C-052 ODF SOLDER C-032-S C-032-CAP C-032-CAP-T C-033-S C-052-S C-0525-S C-053-S C-082-S C-0825-S C-083-S C-084-S C-162-S C-1625-S C-163-S C-164-S C-165-S C-167-S C-303-S C-304-S C-305-S C-306-S C-307-S C-309-S C-414-S C-415-S C-417-S C-419-S C-607-S C-609-S

SUCTION LINE TYPE ODF SOLDER C-083-S-T-HH C-084-S-T-HH C-164-S-T-HH C-165-S-T-HH C-166-S-T-HH C-167-S-T-HH C-305-S-T-HH C-306-S-T-HH C-307-S-T-HH C-309-S-T-HH C-417-S-T-HH C-419-S-T-HH C-607-S-T-HH C-609-S-T-HH

CONNECTION SIZE Inches 1/4 Extended 1/4 Male 1/4 Male - Inlet 1/4 Female - Outlet 1/4 Female - Inlet 1/4 Male - Outlet 3/8 1/4 5/16 1/4 Male - Inlet 1/4 Female - Outlet 1/4 Male - Inlet 1/4 Female - Outlet 3/8 1/4 5/16 3/8 1/2 1/4 5/16 3/8 1/2 5/8 3/4 7/8 3/8 1/2 5/8 3/4 7/8 1-1/8 3/8 1/2 5/8 7/8 1-1/8 7/8 1-1/8

VOLUME of DESICCANT cm 3

OVERALL LENGTH mm SAE FLARE 106 ODF SOLDER 97 148 99 106 111 109 130 135 133 138 146 151 149 152 160 171 176 226 229 235 245 249 248 230 237 249 248 406 406

49

97 97 119 121

C-052-F C-052-FM C-053 C-082 C-083 C-084 C-162 C-163 C-164 C-165 C-303 C-304 C-305

82

106 106 132 143 154 160 159 171 176 184 246 251 259 243 252 260

147

262

76

492

76

C-413 C-414 C-415

672

89

983

76

UL and ULC Listed Guide SMGT-File No. SA-1756. Maximum Rated Pressure of 44.8 barg.

Page 16 CATALOG 744

Filter-Driers

Sealed Type Liquid Line Ratings and Selection Recommendations

Tons F psi

CO2

kW C bar

TYPE

WSURFACE FILTERING AREA Square Inches SEALED TYPE

QREFRIGERANT FLOW CAPACITY Tons at 1 psi P

TYPE

WSURFACE FILTERING AREA cm 2 SEALED TYPE

QREFRIGERANT FLOW CAPACITY kW at 0.07 bar P

C-032 C-032-CAP C-032-S C-032-F C-032-FM C-033 C-033-S C-052 C-052-S C-052-F C-052-FM C-0525-S C-053 C-053-S C-082 C-082-S C-0825-S C-083 C-083-S C-084 C-084-S C-162 C-162-S C-1625-S C-163 C-163-S C-164 C-164-S C-165 C-165-S C-303 C-303-S C-304 C-304-S C-305 C-305-S C-307-S C-414 C-414-S C-415 C-415-S C-417-S C-419-S C-607-S C-609-S

2.02 9 4.90 5.37 2.89 15 4.76 5.77 6.52 2.89 21 5.06 6.36 7.22 12.2 13.5 2.89 5.06 6.36 7.22 14.2 15.4 19.4 22.4 6.37 53 14.2 15.4 20.9 23.8 30.4 16.1 17.4 22.3 24.8 31.1 34.3 41.1 47.0

33

67

106

C-032 C-032-CAP C-032-S C-032-F C-032-FM C-033 C-033-S C-052 C-052-S C-052-F C-052-FM C-0525-S C-053 C-053-S C-082 C-082-S C-0825-S C-083 C-083-S C-084 C-084-S C-162 C-162-S C-1625-S C-163 C-163-S C-164 C-164-S C-165 C-165-S C-303 C-303-S C-304 C-304-S C-305 C-305-S C-307-S C-414 C-414-S C-415 C-415-S C-417-S C-419-S C-607-S C-609-S

7.03 58 17.0 18.6 10.0 97 16.5 20.0 22.7 10.0 135 17.6 22.1 25.1 42.4 46.9 10.0 17.6 22.1 25.1 49.4 53.6 67.4 77.6 22.1 342 49.4 53.6 72.5 82.5 105 55.7 60.5 77.4 86.0 108 119 143 163

213

432

684

Q Ratings based on 20F (-5C) liquid, -20F (-30C) evaporator temperature. W The filtration area is equal to the core surface area plus the large internal surface available for depth filtration. The variation in flow ratings of filter-driers having the same size core and shell is caused by the difference in connection sizes used.

CATALOG 744 Page 17

Filter-Driers

Replaceable Core Type

ODF Solder Connections The rugged construction of the Replaceable Core Catch-All has proven itself in the field for many years. The design features include: 1. The famous molded porous core for maximum contaminant removal. The core cannot swell, powder or pack assuring ease of installation and removal. 2. The bolt and nut attachment of the end plate provides simple trouble-free installation. 3. The internal construction gives a one piece assembly and assures proper core alignment.

CO2

RCW-48

C-969-G

US

LISTED

4. A complete line of fitting sizes all with copper fittings. 5. No plastic parts are used all internal parts are plated steel. 6. A corrosion resistant powder paint protects the exterior of the shell.

Specications

TYPE C-R424-G C-R425-G C-R427-G C-485-G C-487-G C-489-G C-4811-G C-4813-G C-967-G C-969-G C-9611-G C-9613-G C-1449-G C-14411-G C-14413-G C-19211-G C-19213-G VOLUME of CONNECTIONS OPTIONAL NUMBER of CORE PART DESICCANT ODF SOLDER SECONDARY CORES or NUMBER Inches FILTER* FILTER ELEMENTS Cubic Inches cm3 1/2 5/8 1 RCW-42 42 688 7/8 5/8 7/8 1-1/8 FS-480 1 48 787 1-3/8 1-5/8 7/8 RCW-48, 1-1/8 RC-4864 FS-960 2 96 1573 1-3/8 or 1-5/8 RC-4864-HH 1-1/8 1-3/8 FS-1440 3 144 2360 1-5/8 1-3/8 FS-19200 4 192 3146 1-5/8 FILTER ELEMENT PART NUMBER MOUNTING BRACKETS A-175-1 OVERALL LENGTH Inches mm 9.00 229 9.06 230 9.44 240 9.15 232 9.30 236 9.50 241 9.60 244 9.60 244 14.84 377 15.04 382 15.14 385 15.14 385 20.58 523 20.68 525 20.68 525 26.22 666 26.22 666

RPE-48-BD

A-685

RPE-48-BD RPE-48-BD RPE-48-BD

A-685 A-685 A-685

UL and ULC Listed Guide SMGT-File No. SA-1756. C-480 through C-1920 Series shells have a 650 psig (44.8 barg) rating. *Optional Secondary Filter must be purchased separately. O-rings (p/n 621-025) are supplied with each secondary filter, but can be purchased separately. The secondary filter cannot be used if the shell is installed in the suction line. Type numbers with G suffix indicate that unit is supplied with 1/4 female pipe connection in the end plate and pipe plug. For liquid line service and angle charging valve for system charging purposes can be installed in place of the pipe plug. Angle charging and Schrader type access valves are available from your Sporlan Wholesaler.

Liquid Line Ratings and Selection Recommendations

Tons psi F

kW bar C

TYPE

WSURFACE FILTERING AREA Square Inches

QREFRIGERANT FLOW CAPACITY Tons at 1 psi P

TYPE

WSURFACE FILTERING AREA cm 2

QREFRIGERANT FLOW CAPACITY kW at 0.07 bar P

REPLACEABLE CORE TYPE WITH HIGH WATER CAPACITY CORES (See page 19) C-R424-G 16.0 C-R425-G 67 19.1 C-R427-G 26.1 C-485-G 20.7 C-487-G 64 33.7 C-489-G 60.9 C-967-G 55.3 128 C-969-G 68.6 C-1449-G 83.6 192 C-14411-G 94.3 C-19211-G 119 C-19213-G 256 139 C-19217-G 147

REPLACEABLE CORE TYPE WITH HIGH WATER CAPACITY CORES (See page 19) C-R424-G 55.5 C-R425-G 432 66.4 C-R427-G 90.6 C-485-G 72.0 C-487-G 413 117 C-489-G 211 C-967-G 192 826 C-969-G 238 C-1449-G 290 1239 C-14411-G 327 C-19211-G 412 C-19213-G 1652 484 C-19217-G 509

Q Ratings based on 20F (-5C) liquid, -20F (-30C) evaporator temperature. W The filtration area is equal to the core surface area plus the large internal surface available for depth filtration. The variation in flow ratings of filter-driers having the same size core and shell is caused by the difference in connection sizes used.

Page 18 CATALOG 744

Filter-Driers

Suction Line Filter-Drier Ratings

for New Systems and Clean-up after Burnout

CO2

Selection Instructions

The flow capacities are rated at the maximum recommended pressure drop for permanent installation. To ensure the suction line filter-drier has ample contaminant removal ability, selection must be based on flow capacity and the amount of desiccant required for system clean-up. The suction line filter-drier must be large enough to adequately remove acid, moisture and solid contaminants without causing nuisance plug-ups. Sizing is especially important for sealed type suction line filter-driers since they should be sized to clean a small system with one service call. To reduce the pressure drop through replaceable core shells, substitute cores with filter elements (see page 19) after the system has been cleaned up. The 6171-5 screen should be discarded when cores are replaced with RPE-48-BD elements in RSF shells. For complete description of the suggested system clean-up procedure, request Bulletin 40-10.

Suction Line Flow Capacity

Tons psi F

kW bar C

EVAPORATOR TEMPERATURE PRESSURE DROP (psi) C-083-S-T-HH C-084-S-T-HH C-144-S-T-HH C-145-S-T-HH C-146-S-T-HH C-147-S-T-HH C-149-S-T-HH C-164-S-T-HH C-165-S-T-HH C-166-S-T-HH C-167-S-T-HH C-305-S-T-HH C-306-S-T-HH C-307-S-T-HH C-309-S-T-HH C-417-S-T-HH C-419-S-T-HH C-437-S-T-HH C-439-S-T-HH C-4311-S-T-HH C-4313-S-T-HH C-607-S-T-HH C-609-S-T-HH RSF-487-T RSF-489-T RSF-4811-T RSF-4813-T RSF-4817-T RSF-4821-T RSF-9611-T RSF-9613-T RSF-9617-T RSF-9621-T RSF-9625-T 3.0 4.15 4.15 4.15 7.05 9.64 10.4 13.9 5.54 6.42 8.02 9.15 6.88 8.99 10.8 11.9 12.2 12.4 16.1 20.3 22.3 24.6 13.5 15.2 20.4 24.6 29.9 32.2 34.8 37.5 40.7 50.9 50.9 59.1 60.5

-20F 8.0* 35.4 42.3 51.7 55.8 60.0 64.4 81.6 87.5 87.5 102 104

EVAPORATOR TEMPERATURE PRESSURE DROP (bar) C-083-S-T-HH C-084-S-T-HH C-144-S-T-HH C-145-S-T-HH C-146-S-T-HH C-147-S-T-HH C-149-S-T-HH C-164-S-T-HH C-165-S-T-HH C-166-S-T-HH C-167-S-T-HH C-305-S-T-HH C-306-S-T-HH C-307-S-T-HH C-309-S-T-HH C-417-S-T-HH C-419-S-T-HH C-437-S-T-HH C-439-S-T-HH C-4311-S-T-HH C-4313-S-T-HH C-607-S-T-HH C-609-S-T-HH RSF-487-T RSF-489-T RSF-4811-T RSF-4813-T RSF-4817-T RSF-4821-T RSF-9611-T RSF-9613-T RSF-9617-T RSF-9621-T RSF-9625-T 0.20 13.8 13.8 13.8 23.4 32.1 34.8 46.5 18.4 21.4 26.7 30.4 22.9 29.9 36.0 39.8 40.7 41.3 53.6 67.4 74.3 81.8 45.0 50.5 68.0 81.8 99.6 107 116 125 135 169 169 197 201

-30C 0.55* 120 143 175 189 203 218 237 296 296 344 353

SEALED TYPE

REPLACEABLE CORE TYPE

*Denotes TEMPORARY INSTALLATION. Cores for system clean-up; RPE-48-BD Filter Elements should be installed after clean-up. Ratings based on 20F (-5C) liquid, 25F (14C) superheat. Rated in accordance with ARI Standard 730.

REPLACEABLE CORE TYPE

SEALED TYPE

CATALOG 744 Page 19

Filter-Driers

Signicance of the Type Number

The letters and numerals in the Catch-All type number each have a significance. The C indicates Catch-All. The first two or three digits indicate cubic inches of desiccant. The last one or two digits indicate fitting size in eighths of an inch. For sealed models, a -S following the last digit indicates solder fittings, and no letter indicates a flare fitting. Replaceable core models (C-420 and larger) only have solder connections and the -S is omitted. Examples are: C-083 is 8 cu. in. and 3/8 flare, C-309-S is 30 cu. in. and 1-1/8 solder, C19213-G is 192 cu. in. and 1-5/8 solder.

CO2

Other suffix letters indicate special qualities. For example: -T indicates a pressure tap consisting of a Schrader type access valve on the inlet end of the Catch-All. -HH indicates a charcoal style core for wax removal and clean-up after a hermetic motor burnout. -F indicates a female flare outlet fitting with a male flare inlet fitting. -FM indicates a female flare inlet fitting with a male flare outlet fitting. -CAP indicates a Catch-All particularly designed for installation on capillary tube systems.

Replaceable Cores and Pleated Filter Elements Order Separately

Cores for replaceable core type filter-driers are molded of exactly the same desiccants that are used in the popular sealed filter-driers. Cores are individually packed in metal cans, fully activated and hermetically sealed against moisture and dirt. Filter Elements are dried and packed in individual sealed metal cans. This method of packaging prevents the element from picking up moisture from the atmosphere. Detailed instructions are printed on each can. Each can contains a triple gasket consisting of a new end plate gasket, an end plate gasket for certain competitive filter-driers and a core gasket where desired. See the specifications on page 25 for the number of cores required for each type drier. RCW-42 High Water Capacity Core Order as separate item Fits ONLY shell type C-R424, C-R425 and C-R427. Designed specially for use with POE oils. This core should be used on systems that have a ruptured water cooled condenser, or that have been exposed to the atmosphere, or for some reason have a high amount of moisture in the system. RC-4864 Activated Core Order as separate item Fits types C-480 thru C-19200 Series shells and Replaceable Suction Filter (RSF) shells. This is the standard core suitable for most installations in the liquid or suction line applications. RCW-48 High Water Capacity Core Order as separate item Fits types C-480 thru C-19200 Series shells and Replaceable Suction Filter (RSF) shells. Designed specially for use with POE oils. This core should be used on systems that have a ruptured water cooled condenser, or that have been exposed to the atmosphere, or for some reason have a high amount of moisture in the system. RC-4864-HH Activated Charcoal Core Order as separate item Fits types C-480 thru C-19200 Series shells and Replaceable Suction Filter (RSF) shells. This core should be used for wax removal on low temperature systems, and for clean-up of systems that have had a hermetic motor burnout. RPE-48-BD Filter Element Order as separate item Fits types C-480 thru C-19200 Series shells and Replaceable Suction Filter (RSF) shells. This element should be used in RSF shells installed in the suction line to obtain the lowest possible pressure drop. In cleaning up a system after a hermetic motor burnout, cores should be used first. Then after the system is thoroughly clean, this filter element can be installed in the RSF shell.

HH Style Catch-All for Wax Removal

Small amounts of wax are often a problem on low temperature systems. Even well engineered systems frequently contain minute quantities of wax which are sufficient to clog expansion valve screens or cause sticking of the valve. Sporlan has developed a special blend of desiccants including activated charcoal which removes small amounts of wax in the liquid line before this wax can cause trouble at the expansion valve. These Catch-All Filter-Driers have been very successful in correcting trouble jobs in the field. Select an HH Style Catch-All Filter-Drier if wax problems occur on low temperature systems. In addition to their wax removal ability, these filter-driers will remove all of the other harmful contaminants that the standard filter-driers remove. Listed in the table are various Catch-All models that incorporate the HH style core.

TYPE C-052-HH C-082-HH C-083-HH C-162-HH C-163-HH C-163-S-HH C-164-HH C-164-S-HH C-165-HH C-165-S-HH CONNECTIONS Inches 1/4 SAE Flare 1/4 SAE Flare 3/8 SAE Flare 1/4 SAE Flare 3/8 SAE Flare 3/8 ODF Solder 1/2 SAE Flare 1/2 ODF Solder 5/8 SAE Flare 5/8 ODF Solder TYPE C-303-HH C-304-HH C-304-S-HH C-305-HH C-305-S-HH C-414-HH C-415-HH C-417-S-HH RC-4864-HH CONNECTIONS Inches 3/8 SAE Flare 1/2 SAE Flare 1/2 ODF Solder 5/8 SAE Flare 5/8 ODF Solder 1/2 SAE Flare 5/8 SAE Flare 7/8 ODF Solder Replaceable Core

Page 20 CATALOG 744

Moisture and Liquid Indicator

8 Outstanding Benets

1. The SeeAll Moisture and Liquid Indicator provides a true moisture indication for refrigerants. The dark green indicates dry and a bright yellow indicates wet. The one indicator avoids the confusion found in models with two elements. You cannot pick the wrong element when checking the moisture content of the system. 2. Reliable and accurately calibrated color change points. The SeeAll Moisture and Liquid Indicator is accurately calibrated in parts per million of moisture for each refrigerant. All moisture indicators change color on the basis of relative saturation of the refrigerant. Therefore, liquid line temperature must be considered if an accurate calibration is to be obtained. For easy comparison, a color chart is part of the label. 3. Color changes are easily distinguished and reversible. The indicators color differs so widely between WET and DRY conditions that there is no possibility of confusion between the two. Colors will reverse as often as moisture concentration in the system changes. 4. Large full view sight glass. The SeeAll Moisture and

CO2

Liquid Indicator has an extra large crystal clear sight glass for viewing the refrigerant. Bubbles indicate a shortage of refrigerants or a restriction in the liquid line. 5. Indicator protected from discoloration and dirt. The indicator is protected by a filter pad and screen. This prevents washing of the indicator by the refrigerant and protects it from system contamination and turbulence. 6. Replaceable indicator element. The color indicator paper can be changed on the new fused glass models without removing the SeeAll from the line. Replacement is through the bottom (see SA-14SU below). Request the K-SA-4 kit. 7. Disassembly of the smaller sizes not required. The extended steel fittings on solder models in the smaller sizes make it unneccesary to disassemble for installation since steel conducts only one eighth as much heat as copper. 8. A double duty plastic cap is supplied to keep the glass free from dust, dirt and grease. It also permits the service engineer to use his own discretion concerning instructions to his customers on observing the SeeAll Moisture and Liquid Indicator.

SA-13FM

SA-14U

SA-14UU

SA-13FU

SA-14SU

SA-13S

SA-213

Specications - Inches

FEMALE & MALE MALE FLARE CONNECFLARE TION OVERALL TYPE TYPE OVERALL SIZES LENGTH NO. LENGTH NO. Inches Inches Inches 1/4 SA-12 2.87 SA-12FM 2.56 3/8 SA-13 3.37 SA-13FM 2.97 1/2 SA-14 3.81 SA-14FM 3.44 5/8 SA-15 4.13 7/8 1-1/8 1-3/8 1-5/8 MALE FLARE x SWIVEL NUT TYPE OVERALL LENGTH NO. Inches 3.64 4.13 4.44

Listed by Underwriters Laboratories, Inc. Guide SEYW File No. SA3182

SA-13U SA-14U SA-15U

SWIVEL NUT x FEMALE FLARE x SWIVEL NUT SWIVEL NUT OVERALL TYPE LENGTH TYPE OVERALL LENGTH NO. NO. Inches Inches SA-13UU 3.95 SA-13FU 3.19 SA-14UU 4.50 SA-14FU 3.75 SA-15UU 4.75

SWIVEL NUT x ODF SOLDER TYPE OVERALL LENGTH NO. Inches SA-13SU SA-14SU SA-15SU 4.19 4.62 4.89

ODF SOLDER TYPE NO. SA-12S SA-13S SA-14S SA-15S SA-17S SA-19S QSA-211 QSA-213 OVERALL LENGTH Inches 4.62 4.87 6.31 7.97

mm

CONNECTION SIZES Inches 1/4 3/8 1/2 5/8 7/8 1-1/8 1-3/8 1-5/8 FEMALE & MALE FLARE OVERALL TYPE OVERALL TYPE NO. LENGTH NO. LENGTH mm mm SA-12 72.9 SA-12FM 65.0 SA-13 85.6 SA-13FM 75.4 SA-14 96.8 SA-14FM 87.4 SA-15 105 MALE FLARE MALE FLARE x SWIVEL NUT TYPE OVERALL LENGTH NO. mm 92.5 105 113 SWIVEL NUT x FEMALE FLARE x SWIVEL NUT SWIVEL NUT OVERALL TYPE OVERALL TYPE LENGTH LENGTH NO. NO. mm mm SA-13UU 100 SA-13FU 81 SA-14UU 114 SA-14FU 95.3 SA-15UU 121 SWIVEL NUT x ODF SOLDER TYPE OVERALL LENGTH NO. mm 106 117 124 ODF SOLDER TYPE NO. SA-12S SA-13S SA-14S SA-15S SA-17S SA-19S QSA-211 QSA-213 OVERALL LENGTH mm 117 124 160 202

SA-13U SA-14U SA-15U

SA-13SU SA-14SU SA-15SU

Maximum Rated Pressure for all models is 650 psig (44.8 barg). Overall width is: 1.31 (33.3 mm) for 1/4 and 3/8 sizes. 1.58 (40.1 mm) for 1/2 and 5/8 sizes, and 1.38 (35.1 mm) for 7/8 and 1-1/8 sizes. Most solder connections can be used as male fittings as well as female fittings. The 1/4 ODF is 3/8 ODM, the 3/8 ODF is 1/2 ODM, the 1/2 ODF is 5/8 ODM, and the 5/8 ODF is 3/4 ODM. Models with female flare and/or swivel nut connections are supplied with a copper gasket in the fitting. Q These models have copper connections and feature a removable element cartridge for replacement cartridge specify AC-20.

CATALOG 744 Page 21

Replaceable

The Replaceable Suction Filter shell, used with RPE-48-BD pleated filter element, is designed to be installed in the suction line of new systems to remove circulating contaminants.

CO2

How Its Used

Sporlan Replaceable Suction Filters are installed in the suction line of refrigeration or air conditioning systems to remove contaminants that may be in the system at startup.

Design Benets

RSF-4817-T

High ow capacity Corrosion resistant coating on shell Can be used with desiccant cores for clean-up after burnout Various tting sizes up to 1-5/8 line size Access valve supplied for pressure drop measurement or charging psi F

The Replaceable Suction Filter has large fittings permitting the use of a small shell on a system with large line sizes, resulting in considerable economy. The angle construction is suitable of flow in either direction, which results in easy installation even on compact racks. The Replaceable Suction Filters should be used with cores for cleaning up a system after a hermetic motor burnout. Select the RC-4864, RC-4864-HH or RCW-48 replaceable cores. After cleanup, install RPE-48-BD elements in the shells.

Selection

The table below gives information for choosing the proper model for a given system. The filter elements are supplied in hermetically sealed metal cans. For flow capacity WITH CORES, see page 18.

Flow Capacity - Tons

CONNECTIONS Inches ODF SOLDER TYPE

kW bar C

RSF-487-T RSF-489-T RSF-4811-T RSF-4813-T RSF-4817-T RSF-4821-T RSF-9611-T RSF-9613-T

7/8 1-1/8 1-3/8 1-5/8 2-1/8 2-5/8 1-3/8 1-5/8

FLOW CAPACITY EVAPORATOR TEMPERATURE 40F PRESSURE DROP psi 1 2 3 12.6 18.5 23.2 19.8 29.0 36.4 29.2 42.9 53.8 One 36.3 53.4 67.0 RPE-48-BD 48.6 71.4 89.5 64.1 94.2 118 31.3 46.1 57.7 Two 41.8 61.4 76.9 RPE-48-BD NUMBER OF FILTER ELEMENTS

TYPE

388

776

9.30 9.37 9.60 9.60 9.37 9.75 15.14 15.14

RSF-487-T RSF-489-T RSF-4811-T RSF-4813-T RSF-4817-T RSF-4821-T RSF-9611-T RSF-9613-T

7/8 1-1/8 1-3/8 1-5/8 2-1/8 2-5/8 1-3/8 1-5/8

FLOW CAPACITY EVAPORATOR TEMPERATURE 5C PRESSURE DROP bar 0.07 0.14 0.20 43.1 63.4 77.3 67.6 99.3 121 99.7 147 179 One 2503 124 183 223 RPE-48-BD 166 244 298 219 322 393 157 192 107 Two 5006 143 210 256 RPE-48-BD NUMBER OF FILTER ELEMENTS

OVERALL LENGTH Inches

Ratings based on 20F (-5C) liquid, 25F (14C) superheat. Listed by Underwriters Laboratories, Inc. Guide SMGT File No. SA-1756. RSF shells have a 500 psig (34.5 barg) M.R.P. rating. Note: Ratings are in accordance with ARI Standards 730. Flow capacity (tons/kW) with cores is approximately 40% of the above values.

Acid Test Kits - Type TA-1

Designed to Test Mineral, Alkylbenzene and POE Lubricants

Thoroughly eld proven Takes the guesswork out of service work TA-1

Design Benets

Builds Customer Condence Show the test results of the

acid test kit to customers, or perform the test in their presence. In this way they realize you are using the most up-to-date scientific method for system maintenance. Showing customers the test results will also help to convince them to spend the money necessary to do a proper clean-up job. Customers who are thoroughly confident of your abilities will be more interested in establishing preventive maintenance programs. Accurate and Reliable Using a simple, scientific method, you can precisely measure the amount of acid in a lubricant sample

taken from a contaminated system. The test procedure has been proven by extensive field experience. Convenient The TA-1 is convenient to use. The TA-1 has premeasured solutions supplied in bottles with screw caps for easy handling. The kit may be used on the job site, or a lubricant sample can be saved and tested in the presence of the equipment owner. Lubricant Sample Used for Test Since lubricant is the scavenger, it gives the best indication of acid in the system. Less than an ounce of lubricant is required. Quick to Use Once the lubricant sample is obtained...it will take only minutes to perform the test. Simply mix the solutions and lubricant to be tested. Shake, and the resulting color tells the complete story. Cost The cost of the test kit is very inexpensive. The TA-1 is normally used on a pass or fail basis.

OVERALL LENGTH mm 236 238 244 244 238 248 385 385

CONNECTIONS Inches ODF SOLDER

FILTER AREA Square Inches

FILTER AREA cm 2

Page 22 CATALOG 744

Electronic Temperature Control Systems

Electric Expansion Valves

SEI, SER and SERI Sporlan Electric Expansion Valves (EEVs) are currently available in nominal R-744 capacities from 1 to 100 tons (3.5 to 350 kW). Specific system conditions will dictate which product is necessary to control the application. Details can be reviewed with the Sporlan Sales Engineer. The SER and SEI are Electronically Operated Step Motor flow control valves, intended for the precise control of liquid refrigerant flow. Synchronized signals to the motor provide discrete angular movement, which translates into precise linear positioning of the valve piston. Valve pistons and ports are uniquely characterized, providing improved flow resolution and performance. The SER and SEI valves are easily interfaced with microprocessor based controllers, including Sporlan supplied controllers. All Sporlan EEVs are rated for at least 620 psig (42 barg) MRP.

CO2

SEI

SERI SEI-50 SER

Specications

VALVE TYPE SEI 0.5, 1, 2, 3.5, 6, 8.5, 11 SEI 30 SEI 50* SER 1-1/2 SER 6 SER 11 SER 20 SERI G SERI J SERI K INLET Inches 1/4, 3/8, 1/2 ODF 1/4, 3/8, 1/2 SAE 5/8, 7/8, 1-1/8 ODF 7/8, 1-1/8, 1-3/8 ODF 3/8, 1/2, 5/8 ODF 3/8, 1/2, 5/8 ODF 3/8, 1/2, 5/8 ODF 1/2, 5/8, 7/8, 1-1/8 ODF 5/8, 7/8 ODF 7/8, 1-1/8 ODF 1-1/8 ODF OUTLET Inches 3/8, 1/2, 5/8 ODF 1/2 SAE 5/8, 7/8, 1-1/8, 1-3/8 ODF 7/8, 1-1/8, 1-3/8, 1-5/8 ODF 3/8, 1/2, 5/8 ODF 3/8, 1/2, 5/8, 7/8 ODF 1/2, 5/8, 7/8, 1-1/8 ODF 5/8, 7/8, 1-1/8, 1-3/8 ODF 1/2, 5/8, 7/8, 1-1/8 ODF 7/8, 1-1/8, 1-3/8 ODF 7/8, 1-1/8, 1-3/8, 1-5/8 ODF CONFIGURATION Angle Angle Straight through Angle Angle Angle Angle Angle / Straight through Angle / Straight through Angle / Straight through CABLE LENGTH Feet Meters

10, 20, 30, 40

3, 6, 9, 12

*Not suitable for bi-directional applications.

Capacities Direct Expansion

Tons psi F

VALVE TYPE SEI 0.5 SEI 1 SEI 2 SEI 3-1/2 SEI 6 SEI 8-1/2 SEI 11 SEI 30 SEI 50 SER 1-1/2 SER 6 SER 11 SER 20 SERI G SERI J SERI K

NOMINAL CAPACITY (Tons) 1 2 3 7 13 18 19 62 100 3 12 23 40 47 84 150

0F 100 0.65 1.43 2.91 4.76 8.99 12.7 13.6 43.6 72.7 2.18 8.72 16.0 29.1 32.8 59.1 107 150 0.80 1.75 3.56 5.82 11.0 15.6 16.7 53.4 89.0 2.67 10.7 19.6 35.6 40.2 72.4 131 200 0.93 2.02 4.11 6.72 12.7 18.0 19.2 61.7 103 3.09 12.3 22.6 41.1 46.5 83.6 152 250 1.03 2.25 4.60 7.52 14.2 20.1 21.5 69.0 115 3.45 13.8 25.3 46.0 51.9 93.4 169 300 1.13 2.47 5.04 8.24 15.6 22.0 23.5 75.6 126 3.78 15.1 27.7 50.4 56.9 102 186

-20F PRESSURE DROP ACROSS VALVE (psi) 150 200 250 300 350 0.80 0.93 1.04 1.13 1.23 1.75 2.02 2.26 2.47 2.67 3.57 4.12 4.60 5.04 5.45 5.83 6.73 7.53 8.24 8.90 11.0 12.7 14.2 15.6 16.8 15.6 18.0 20.1 22.1 23.8 16.7 19.2 21.5 23.6 25.5 53.5 61.8 69.0 75.6 81.7 89.1 103 115 126 136 2.67 3.09 3.45 3.78 4.08 10.7 12.3 13.8 15.1 16.3 19.6 22.6 25.3 27.7 30.0 35.7 41.2 46.0 50.4 54.5 40.3 46.5 52.0 56.9 61.5 72.5 83.7 93.5 102 111 131 152 170 186 201

-40F 200 0.92 2.00 4.09 6.69 12.6 17.9 19.1 61.4 102 3.07 12.3 22.5 40.9 46.2 83.1 151 250 1.03 2.24 4.57 7.48 14.1 20.0 21.4 68.6 114 3.43 13.7 25.2 45.7 51.7 92.9 169 300 1.13 2.46 5.01 8.19 15.5 21.9 23.4 75.2 125 3.76 15.0 27.6 50.1 56.6 102 185 350 1.22 2.65 5.41 8.85 16.7 23.7 25.3 81.2 135 4.06 16.2 29.8 54.1 61.1 110 199 400 1.30 2.83 5.79 9.46 17.9 25.3 27.0 86.8 145 4.34 17.4 31.8 57.9 65.3 118 213

CATALOG 744 Page 23

Electronic Temperature Control Systems

Electric Expansion Valves

SEI, SER and SERI

CO2

Capacities Direct Expansion

kW bar C

VALVE TYPE SEI 0.5 SEI 1 SEI 2 SEI 3-1/2 SEI 6 SEI 8-1/2 SEI 11 SEI 30 SEI 50 SER 1-1/2 SER 6 SER 11 SER 20 SERI G SERI J SERI K 0 1.13

NOMINAL CAPACITY (kW) 3.5 7 10 25 45 63 67 220 350 10 42 80 140 165 290 520

-20C 8 2.43 5.30 10.8 17.7 33.4 47.3 50.5 162 270 8.11 32.4 59.4 108 122 220 398 12 2.98 6.49 13.2 21.6 40.9 57.9 61.9 199 331 9.93 39.7 72.8 132 149 269 488 16 3.44 7.49 15.3 25.0 47.2 66.9 71.4 229 382 11.5 45.8 84.0 153 173 311 563 20 3.84 8.37 17.1 27.9 52.8 74.8 79.9 256 427 12.8 51.3 94.0 171 193 347 630 40 0.86

-30C PRESSURE DROP ACROSS VALVE (bar) 12 16 20 24 2.98 3.44 3.84 4.21 6.48 7.49 8.37 9.17 13.2 15.3 17.1 18.7 21.6 25.0 27.9 30.6 40.9 47.2 52.8 57.8 57.9 66.8 74.7 81.9 61.9 71.4 79.9 87.5 198 229 256.0 281 331 382 427 468 9.92 11.5 12.8 14.0 39.7 45.8 51.2 56.1 72.8 84 93.9 103 132 153 171 187 149 173 193 211 269 310 347 380 487 563 629 689 -20

1.18

-40C 16 3.42 7.44 15.2 24.8 46.9 66.4 71.0 228 380 11.4 45.6 83.5 152 172 309 560 20 3.82 8.32 17.0 27.8 52.5 74.3 79.4 255 424 12.7 50.9 93.4 170 192 345 626 24 4.18 9.11 18.6 30.4 57.5 81.4 86.9 279 465 14.0 55.8 102 186 210 378 685 28 4.52 9.84 20.1 32.8 62.1 87.9 93.9 301 502 15.1 60.3 110 201 227 408 740 5

0.87

LIQUID TEMPERATURE (F) 10 20 30 CORRECTION FACTOR, LIQUID CAPACITY RATING 1.07 1.00 0.93

LIQUID TEMPERATURE (C) -15 -10 -5 0 CORRECTION FACTOR, LIQUID CAPACITY RATING

1.12 1.06 1.00 0.94

Liquid Flow Coefcients

VALVE TYPE SEI 0.5 SEI 1 SEI 2 SEI 3-1/2 SEI 6 SEI 8-1/2 SEI 11 SEI 30 SEI 50 SER 1-1/2 SER 6 SER 11 SER 20 SERI G SERI J SERI K Cv 0.01 0.03 0.07 0.11 0.20 0.29 0.30 0.98 1.63 0.05 0.20 0.36 0.65 0.74 1.33 2.41 Kv 0.01 0.03 0.06 0.09 0.17 0.25 0.26 0.85 1.41 0.04 0.17 0.31 0.57 0.64 1.15 2.08

Page 24 CATALOG 744

Electronic Temperature Control Systems

Electric Evaporator Control Valves

CDS-4, -7, -9, -16 and -17 The CDS valves are designed for more precise and energy efficient control of temperatures in evaporators. Proper temperature is obtained by regulating refrigerant flow in CDS-9 the evaporator in response to signals generated by an electronic controller and sensor combination. The valves are built around balanced ports, which allows input power of only 4 watts, less than one quarter of the power used by older heat motor and analog designs. When not actively stepping, power to the motor is removed for further energy savings. The step motors used are standard 12-volt DC bipolar designs, which in concert with the integral gear reduction, give the valves unsurpassed accuracy and repeatability over the entire operating range. Since the valves are powered from an external controller, no pilot lines or high to low side bleeds

CO2

are required. The properly applied CDS valve and controller can replace standard mechanical evaporator pressure regulators (EPR), suction stop solenoid valves, and conventional thermostats. All CDS valves may be applied as head pressure control, or liquid line differential valves for R-744. Contact Sporlan for more information. All Sporlan CDS valves are rated at 620 psig (42 barg) MRP. Due to the step motor design, the CDS series are the first evaporator control valves that may be sized to contribute NO additional pressure drop to the suction line. Simplified cartridge design allows all moving parts to be replaced as a unit. Only the valve body is left in the line. This will allow maintenance or repair without unsweating the entire valve.

Specications

(Standard Connections and Cable Lengths are in BOLD type.) TYPE CDS-4 CDS-7 CDS-9 CDS-16 CDS-17 CONNECTIONS ODF SOLDER Inches 1/2, 5/8, 7/8 5/8, 7/8, 1-1/8, 1-3/8 1-3/8 1-3/8, 1-5/8 Straight Through 10 Angle Straight Through 3 S-Stripped and Tinned CONFIGURATION CABLE LENGTH Feet Meters CABLE ENDS

Flow Capacity - Suction Vapor

Tons psi F

kW bar C

TYPE CDS-4

CDS-7

CDS-9

CDS-16

CDS-17

EVAPORATOR TEMP. F 0 -20 -40 0 -20 -40 0 -20 -40 0 -20 -40 0 -20 -40

PRESSURE DROP ACROSS VALVE psi 0.5 1 3 5 10 2.17 3.05 5.22 6.70 9.40 1.83 2.57 4.39 5.64 7.92 1.51 2.12 3.62 4.65 6.53 6.06 8.38 14.0 17.8 24.6 5.14 7.11 11.9 15.1 20.9 4.27 5.91 9.89 12.6 17.4 9.07 12.6 21.2 27.1 37.6 7.68 10.7 18.0 22.9 31.8 6.37 8.85 14.9 19.0 26.4 15.0 20.7 34.6 43.9 60.7 12.7 17.6 29.4 37.3 51.5 10.6 14.6 24.4 31.0 42.9 16.3 22.6 38.2 48.7 67.8 13.7 19.1 32.3 41.2 57.4 11.4 15.9 26.8 34.2 47.6

TYPE CDS-4

CDS-7

CDS-9

CDS-16

CDS-17

EVAPORATOR TEMP. C -20 -30 -40 -20 -30 -40 -20 -30 -40 -20 -30 -40 -20 -30 -40

PRESSURE DROP ACROSS VALVE bar 0.03 0.07 0.20 0.40 0.70 6.79 10.3 17.2 24.1 31.7 5.80 8.79 14.7 20.6 27.1 4.88 7.38 12.3 17.3 22.8 19.1 28.3 46.3 64.1 83.3 16.4 24.4 39.8 55.1 71.6 13.9 20.6 33.7 46.6 60.6 28.5 42.6 70.1 97.4 127 24.5 36.6 60.2 83.6 109 20.7 30.9 50.8 70.6 92.1 47.2 70.1 114 158 205 40.6 60.3 98.4 136 177 34.4 51.0 83.3 115 150 51.0 76.4 126 175 229 43.8 65.5 108 151 197 36.9 55.3 91.2 127 166

Ratings based on 20F (-5C) liquid, 25F (14C) superheat.

LIQUID TEMPERATURE (F) 10 20 30 40 CORRECTION FACTOR, SUCTION CAPACITY RATING 1.07 1.04 1.00 0.96 0.92 0

-20

1.10

LIQUID TEMPERATURE (C) -15 -10 -5 0 CORRECTION FACTOR, SUCTION CAPACITY RATING

1.07 1.03 1.00 0.97

5

0.93

CATALOG 744 Page 25

Electronic Temperature Control Systems

Electric Evaporator Control Valves

CDS-4, -7, -9, -16 and -17

CO2

Flow Capacity - Liquid

Tons psi F

kW bar C

TYPE CDS-4 CDS-7 CDS-9 CDS-16 CDS-17

Cv 2.88 7.28 11.2 17.9 20.4

0.5 9.26 24.3 37.0 59.9 66.8

PRESSURE DROP ACROSS VALVE psi 1 3 5 10 13.0 22.3 28.6 40.1 33.6 56.2 71.4 98.7 51.5 86.6 110 153 82.7 138 175 242 93.0 157 200 279

TYPE CDS-4 CDS-7 CDS-9 CDS-16 CDS-17

Kv 2.49 6.30 9.72 15.5 17.6

0.03 29.8 78.4 119 193 216

PRESSURE DROP ACROSS VALVE bar 0.07 0.20 0.40 0.70 45.1 75.4 106 139 117 191 264 343 179 294 408 532 287 469 648 841 323 533 741 968

Ratings based on 20F (-5C) liquid, -20F (-30C) evaporator temperature.

0 1.13

LIQUID TEMPERATURE (F) 10 20 30 CORRECTION FACTOR, LIQUID CAPACITY RATING 1.07 1.00 0.93

40 0.86

-20

1.18

LIQUID TEMPERATURE (C) -15 -10 -5 0 CORRECTION FACTOR, LIQUID CAPACITY RATING

1.12 1.06 1.00 0.94

5

0.87

Controller Packages

Sporlan offers a variety of controllers for use in refrigeration and air conditioning systems. Applications include self-contained food service equipment, cold rooms and chillers. With over 80 different models, Sporlan can satisfy almost any customer requirement. Small, standalone controllers include the compact Kelvin II and larger Superheat and Refrigeration controllers. All are designed to provide true pressure/temperature superheat control of any system using Sporlan Electric Expansion Valves (EEVs). Chiller controllers offer true pressure/temperature superheat control for two Sporlan EEVs and are available in Fahrenheit/psi or Celsius/Bar versions. Sporlan offers many purpose built controllers, such as subcoolers for supermarket refrigeration, as well as head pressure, temperature only and pressure only.

CONTROLLER PACKAGES Kelvin II RCS Temperature Control Dual Temp. Control SELF CONTAINED EQUIPMENT Omnistat Low Temp. Omnistat Med. Temp. DISPLAY Optional 3 Alphanumeric 2 Numeric 2 Numeric COMMUNICATION RS-485 RS-485 None None RELAYS One Four None None

Cold rooms can be controlled with RCS, which has onboard remote communication, and master-slave settings for defrost control. Included real time clocks allow defrost initialization times to be set precisely and relays allow control of fans, solenoids, alarms and compressors. Many of the controllers can be customized for specific needs, or sup plied in an enclosure, please contact Product Manager, Electronic Products, Sporlan Division.

Kelvin II

INPUTS* 1 Press, 2 Temp. 1 Press, 4 Temp. 1 Temperature 2 Temperature

RCS

VALVES 1 SER or SEI 1 SER or SEI 1 CDS 2 CDS

3 Digit 3 Digit

RS 485 Optional RS 485 Optional

One Three

Defrost, Product, Digital** Defrost, Product, Digital**

N/A N/A

* See accessories page 26, only Sporlan approved sensors may be used. ** All products control temperature, other functions not available on all models.

Page 26 CATALOG 744

Electronic Temperature Control Systems

Controller Packages

TCB Temperature Control Board / IB Interface Board The TCB interface/controller was designed to allow all Sporlan step motors to be modulated in response to an externally generated signal. The IB and TCB will accept a 4-20 milliamp, or 0-10 volt DC inputs and will stroke the valve in proportion to that signal. The TCB and IB will allow use of the CDS valves with an existing DDC system or other generic temperature controller for hot gas bypass, evaporator temperature, or reclaim applications. While the TCB and IB will also control Sporlans line of SER and SEI step motor electric expansion valves, an external signal must be generated in response to superheat and not simply temperature. Please contact Sporlan for more information. When the TCB is purchased with optional set point potentiometer and sensor, the TCB becomes a stand alone single point temperature control for the CDS valves. The sensor is installed in the air stream or affixed to the pipe containing the liquid to be controlled. The potentiometer is set to the temperature desired, and the TCB will modulate the valve to maintain tight temperature control. The TCB can be configured to close on rise or open on rise and requires only an external 24 volt AC 40 VA power source. The TCB incorporates separate pump down, open valve, and close valve contacts for use with external relays to allow even greater control choices. The TCB and IB have screw terminals for easy connections, and should be mounted in a control panel or other enclosure.

CO2

SMA-12 Step Motor Actuator The SMA-12 is an instrument designed to help diagnose systems with step motor valves by proving operation of the step motor. The unit is powered by two 9 volt alkaline batteries and will power any standard 12-volt DC bipolar step motor. Step rate is selectable at 1, 50, 100 or 200 steps per second and will stroke the motor in both the open and closed directions. Red lamps indicate continuity of the motor windings and battery power, and binding posts are provided for quick connection of the motor leads. In the event of a controller failure, the SMA-12 can be used to manually open or close the valve or manually step it to any position. The SMA-12 is the basic troubleshooting tool for all step motor valve operated systems.

ITEM NUMBER 953276 953277 DESCRIPTION SMA-12 SMA-12 w/Pigtail CONNECTOR Binding Post Packard Pigtail Item #958112

INTERFACE BOARDS TCB TCB with Potentiometer IB-2 IB-2Q IB-6 IB-Q 4-20 ma, 0-10 VDC 4-20 ma, 0-10 VDC Temperature Sensor

INPUT CDS CDS CDS-4, -7 SERI G, J, K CDS-9, -16, -17 SER, SEI

VALVES*

* Interface boards may be used with electric expansion valves SER and SEI only when used with external superheat controllers. Contact Sporlan for more information.

ACCESSORIES 0-500 psig (0-34.5 bar) Pressure Transducer 10 Cable (Yellow Color Code) Surface Sensor - 2K (Black Color Code) Well Sensor Air Sensor Omnistat Sensor

ITEM NUMBERS 952505 952662 952795 952669 952899

APPLICATION Head Pressure and CO 2 Applications only All All except IB and TCB less Potentiometer All except IB and TCB less Potentiometer OmniStat only

CATALOG 744 Page 27

Pressure Temperature Chart

Refrigerant 744

At Sea Level