Академический Документы

Профессиональный Документы

Культура Документы

IC-S-200 Dynamic Cone Penetrometer

Загружено:

Rm1262Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

IC-S-200 Dynamic Cone Penetrometer

Загружено:

Rm1262Авторское право:

Доступные форматы

DURHAM GeO.

AON JNDfCAfOR

2175 West Park Court Stone Mountain, GA 30087

Phone: 800.S370864 7704657557 Fax: 770465-7447

S-200 & S-205 DYNAMIC CONE PENETROMETER

(S-20004) USE AND OPERATING GUIDELINES

BACKGROUND:

the Standard Penetration Test (SPT) has its roots in the empirical observation of blows per unit measure of driving casing. The SPT method requires mechanized to raise and drop a l40~lb mass 30-in. Numerous methods have been developed to miniaturize the SPT such that hand operated tools could be used at shallow depths where confined spaces or the need for expedience excludes the use of a mechanized SPT device. The late Prof. George Sowers developed one of the more popular devices in 1959 for field exploration and the evaluation of lightly loaded shallow spread footings during the construction phase. For underlying theory the reader is encouraged to consult the following reference: George F. Sowers and Charles S. Hedges, Dynamic Cone for Shallow In-Situ Penetration Testing, Vane Shear and Cone Penetrations Resistance Testing of In-Situ Soils, ASTM STP 399, American Society and Materials, 1966, pg. 29. Copies can be purchased from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428- (610) 832-9500 Fax: (610) 832-9555. As the item is copyrighted, Durham Geo cannot provide copies. The Dynamic Cone Penetrometer (DCP) illustrated in Figure Ia, uses a 15-lb steel mass falling 20-in to strike an anvil to penetrate a 1.5-in diameter 45 degree cone that has been seated in the bottom of a hand auge:red hole. The device has been used extensively in the Southeastern region of the USA and calibrated with standard SPT results. The original correlations by Sowers are shown in Figure lb. Of course, similar correlation could be developed for soils of other regions and of differing geologic derivation.

OPERATING INSTRUCTIONS: 1. The penetration test is performed in the bottom of a hand au.gered hole generally 3 to 6-in diameter. 2. Auger to the desired test depth taking care to remove as much of the bottom cuttings as practical. Use the auger cuttings to identify and visually classify the soil. WARNING: Handle the Dynamic Cone Penetrometer with care. Do not grasp the E-rod between the pull out anvil and the driving anvil as the 15-lb sliding weight moves easily along this part 1Jfthe riJd. 3. Gently lower the sliding drive hammer, extension rods and drive point to the bottom of the borehole. 4. Making sure the assembly is plumb set the cone 2-in into the undisturbed bottom of the hole such that the cone is completely embedded. NOTE: Laying a flat straight edge such as a survey stake across the borehole and marldng a ueginning reference point will expedite measurements. 5. Maintaining the assembly in a plumb position, drive the cone point 1-3/4-in (44mm) using the ring weight and allowing it to free fall 20-in (bringing the ring weight to the uppermost position against the pullout anvil will assure a 20-in drop). Count and record the number of blows required to achieve 1-3/4-in (44mm) penetration. 6. If desired, perform a second and third penetration test by driving the cone additional 1-3/4-in (44mm) increments. Beyond three increments the effect of shaft friction may become apparent. 7. Remove the DCP assembly from the borehole taking care not to place hands between the anvil and keeping clear of the sliding weight. 8. Auger to the next test location and repeat steps 1 through 7.

Experience has shown that the DCP can be effectively used in auger holes to depths of 15 to 20-ft. Beyond these depths it becomes cumbersome to handle the string of rods by hand. Also, correlations have not been verified for deeper depths where energy losses from thread joints and rod inertia have not been considered.

E Rod

Pulout Anvil

. Q

N

15 lb Steel Ring Weight

Driving Aavtl

Sliding Drive Hammer

o.

10

15

. 20

25

30

Cone Penetrometer Resistanct (blows per increment}

CWYIA-ftgiltPiedllolltHIII a. IS\ C111p1ct111 sail c. 9K CGIIpiCtld Mil 0. IS~ COIIIpiCted Sol E Colstal Plait sols F,...._d!Min

.. ..

:

0

Cone Point

Figure la

Figure lb

REORDER PARTS

S-200 Dynamic Cone Penetrometer Test Set consists of the following:

QTY.

I

DRIVE TUBE ACCESSORY

The Cone and Adapter Rod Assembly can be replaced with the S-20030 Drive Tube Assembly for taking 3xl0-in tube (S-20035) samples in augered holes.

PART NO.

S-20003 S-20001 S-20025 S-t 1010 S-11030 S-11020 S-20004A

DESCRIPTION

Sliding Drive Hammer Assembly Drive Point (Cone} w/1-ft Adapter Rod 30-in Extension Rods w!E-Drill Threads 3-1/4-in Standard Auger Head 36-in Hand Auger Extensions Tee Handle Use and Operating Guidelines

1 4

I

4

I I

Вам также может понравиться

- Reinforcement of Concrete StructuresДокумент13 страницReinforcement of Concrete StructurestevredeОценок пока нет

- Russell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresДокумент238 страницRussell PHD 2015 Progressive Collapse of Reinforced Concrete Flat Slab StructuresRm1262Оценок пока нет

- Technoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureДокумент13 страницTechnoslide Elastomeric-Plain-Sliding-Bearings-For-Bridges-Structures-BrochureRm1262Оценок пока нет

- ADA441347Документ17 страницADA441347habibur Rahman KhanОценок пока нет

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireДокумент6 страницAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262Оценок пока нет

- The Concrete Society - Fire DamageДокумент6 страницThe Concrete Society - Fire DamageRm1262Оценок пока нет

- Ijsrp p46106 PDFДокумент14 страницIjsrp p46106 PDFKannan JaganОценок пока нет

- Henderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksДокумент50 страницHenderson, Johnson & Wood 2002 Enhancing The Whole Life Structural Performance of Multi-Storey Car ParksRm1262Оценок пока нет

- Electric Rolling Bridge, Scientific American 24 August 1889 p120Документ2 страницыElectric Rolling Bridge, Scientific American 24 August 1889 p120Rm1262Оценок пока нет

- Extend Abstract - 67792 - Joao GeadaДокумент10 страницExtend Abstract - 67792 - Joao GeadaRm1262Оценок пока нет

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireДокумент6 страницAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262Оценок пока нет

- IMIESA April 2021Документ60 страницIMIESA April 2021Rm1262Оценок пока нет

- BK Series Kilcher Bearing StripsДокумент6 страницBK Series Kilcher Bearing Stripsforbeska100% (1)

- Mera DilДокумент12 страницMera DilIqbal AhmadОценок пока нет

- Retrofitting and Rehabilitation of Fire PDFДокумент134 страницыRetrofitting and Rehabilitation of Fire PDFVarun TyagiОценок пока нет

- Exhibit 5f - Concept - Design - Submission 100-119Документ20 страницExhibit 5f - Concept - Design - Submission 100-119NasserZakiОценок пока нет

- Structural Scheme Design Guide by ArupДокумент129 страницStructural Scheme Design Guide by ArupNatalie Sullivan100% (15)

- UJ Postgraduate Engineering ManagementДокумент4 страницыUJ Postgraduate Engineering ManagementRm12620% (1)

- Arup DesignYearbook 2010Документ39 страницArup DesignYearbook 2010Si MonaОценок пока нет

- Guide To Lifting Equipment Testing Inspections 2015Документ8 страницGuide To Lifting Equipment Testing Inspections 2015Rm1262Оценок пока нет

- Cranerunwaybeams 4ed bk180 PDFДокумент13 страницCranerunwaybeams 4ed bk180 PDFMacОценок пока нет

- Arup Scheme Design Guide 2006Документ139 страницArup Scheme Design Guide 2006Boris Escubio100% (1)

- STEEL CONFERENCE EXPANSION JOINTSДокумент4 страницыSTEEL CONFERENCE EXPANSION JOINTSCharles Orebola OresanwoОценок пока нет

- Swing Jib CranesДокумент2 страницыSwing Jib CranesRm1262Оценок пока нет

- A Challenge For Designers of Steel Silos PDFДокумент6 страницA Challenge For Designers of Steel Silos PDFRm1262Оценок пока нет

- BinsДокумент17 страницBinsRm1262Оценок пока нет

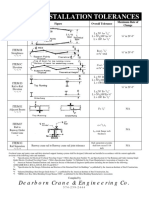

- Crane Runway Installation Tolerances-BechtelДокумент1 страницаCrane Runway Installation Tolerances-BechtelRm1262Оценок пока нет

- Flange BendingДокумент2 страницыFlange BendingMotoro AkinwoleОценок пока нет

- Narayangharh-Mugling HighwayДокумент85 страницNarayangharh-Mugling HighwayRm1262Оценок пока нет

- How Silos FailДокумент14 страницHow Silos FailMedhat Hasanain100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

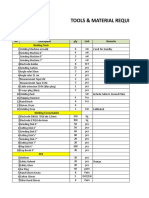

- Material & Consumables RequirementsДокумент6 страницMaterial & Consumables RequirementsDoc TorОценок пока нет

- Material Science LEDДокумент10 страницMaterial Science LEDIndhujaОценок пока нет

- Masterseal AДокумент6 страницMasterseal Aapi-283891975Оценок пока нет

- Ajuste de Bomba VRZДокумент37 страницAjuste de Bomba VRZJose David Huanca Taype100% (1)

- General Properties of Elastomers Summary ChartДокумент1 страницаGeneral Properties of Elastomers Summary ChartvenkatramanОценок пока нет

- Fabriano Art Papir Katalog 2018Документ37 страницFabriano Art Papir Katalog 2018Milan Stojanović100% (1)

- XT702PДокумент3 страницыXT702PBDMОценок пока нет

- HS-800 2C Technical Data SheetДокумент3 страницыHS-800 2C Technical Data SheetĐạt LêОценок пока нет

- ResumeДокумент1 страницаResumeNovianto NugrohoОценок пока нет

- Project Solutions Cost Estimating MethodДокумент8 страницProject Solutions Cost Estimating Methodelmfp7774676Оценок пока нет

- 9 Catalogo Accesorios de Perforacion para PV 275Документ12 страниц9 Catalogo Accesorios de Perforacion para PV 275Anonymous kjJfuvMMОценок пока нет

- Boiler Efficiency ExperimentДокумент4 страницыBoiler Efficiency ExperimentHaziq ZaimОценок пока нет

- Crazy Taxi Naomi ManualДокумент87 страницCrazy Taxi Naomi ManualbrtnomОценок пока нет

- 39cne A18 1iomДокумент22 страницы39cne A18 1iomkkmsОценок пока нет

- A1AC Boundary Sample CastingДокумент4 страницыA1AC Boundary Sample CastingShiva SrtОценок пока нет

- Green University of Bangladesh: Department of Textile EngineeringДокумент9 страницGreen University of Bangladesh: Department of Textile EngineeringGreen University TextileОценок пока нет

- ECODAN AtW Split WWW - ZubadanДокумент2 страницыECODAN AtW Split WWW - ZubadanFlorentin GheorghitaОценок пока нет

- Minolta Ep1050 ServiceДокумент266 страницMinolta Ep1050 ServiceSunny SinghОценок пока нет

- Course On LNG Business-Session12Документ31 страницаCourse On LNG Business-Session12Rahul Atodaria100% (1)

- MNL46 ForewordДокумент16 страницMNL46 ForewordvonipkoОценок пока нет

- Chiller Plant Control - Io Summary: Chilled Water SystemДокумент2 страницыChiller Plant Control - Io Summary: Chilled Water SystemMohammed AminuddinОценок пока нет

- Materi5 Biaya Material HandlingДокумент44 страницыMateri5 Biaya Material HandlingIllyas JanuОценок пока нет

- Bs 7671 2001Документ6 страницBs 7671 2001jelenapopovic81100% (2)

- Sika Hydrotite CJ-Type 2012-01-1Документ5 страницSika Hydrotite CJ-Type 2012-01-1pandavision76Оценок пока нет

- Aalco Metals LTD Aluminium AlloyДокумент2 страницыAalco Metals LTD Aluminium Alloyanwarali1975Оценок пока нет

- Mini Dairy Plant Lumbini 2065Документ56 страницMini Dairy Plant Lumbini 2065fdamaОценок пока нет

- Multiple Reaction System-1Документ35 страницMultiple Reaction System-1ANZWAYNEОценок пока нет

- Plaster ProfilesДокумент16 страницPlaster ProfilesSami LouisОценок пока нет

- ASTTM D 4435 - Rock Nail TestДокумент5 страницASTTM D 4435 - Rock Nail TestmetropodikasОценок пока нет

- Voice 487Документ1 страницаVoice 487Momen AyassrhОценок пока нет