Академический Документы

Профессиональный Документы

Культура Документы

Double Girder Box Type EOT Crane Design

Загружено:

Jeevan HingneИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Double Girder Box Type EOT Crane Design

Загружено:

Jeevan HingneАвторское право:

Доступные форматы

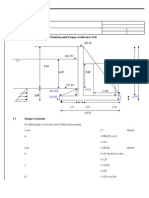

General Input Length, L Fy E70 Electrodes Allowable shear stress Unbraced Length Mejor Unbraced Length Minor Since

the compression flange carries a uniform load, assume that it is restrained against rotation. Maximum Moment Maximum Shear A a) Selection of the Web Plate Recommended height of Web Provided height of Web Final height of Web, hw /h h/tw

SI 26.88

FPS 88.20 50 21 88.20 88.20

ft ksi ksi ft ft

5640 250

k-ft Kip

L/12

7.35 ft 9.51 ft 7.35 ft

b)

h/tw So tw c) For closely spaced stiffner

242.79 in 0.36 in

h/tw So tw Final thickness of Web d) hw tw Aweb h/tw Allowable bending stress Fb

282.84 in 0.31 in 0.50 in 88.20 0.50 44.10 176.40 30 in in in2 ksi

0.6 Fy

check if reduction of the allowable bending stress

hw/tw So Allowable bending stress must be reduced

137.18 176.40

Fb = 0.6 Fy

30 ksi

Reduced allowable bending stress, Fb' B Selection of Flange Plates

27.93 ksi

Af = bf*tf The minimum flange thickness in order to prevent flange local buckling is

20.13 in2

Kc

0.38 & h/tw

tf So bf = Af/tf C Design for bending stress, Moment of Inertia Final Section Dimention Web h Web t Flange w Flange t 88.20 0.50 20.00 1.20 151594.8 3399.0 5.1 176.40

1.11 but use 18.20 but use

in in in in in4 in3 in

7.35 0.04 1.67 0.10

I, Moment of Inertia S, Section Modulus rT h/tw

M1 M2 M1/M2

6578 k-ft 5640 k-ft 1.17

Cb But max value is 2.3 So Cb

3.38 2.3

Lu lu/rT

88.20 209.50 68.50 153.17 19.91 27.93 Ok

ft

fb Fb'

ksi ksi

Intermediate stiffeners

584/SQRT Fy 380/SQRT Fy h/tw So Fv Developed Shear Stress So Intermediate Stiffeners are required

77.50 53.74 176.40 2.67 250

B Find the location of the first stiffener from each end. B.1 At Left

Ra Aw fv Substitute for Fv = fv

250 kip 88.20 in2 2.83 ksi

Cv Kv So a/h So a B.2 At Right Same as Left B.3 Intermediate Stiffner

0.16 5.66 1.79 157.98 in

< <

0.8 OK 9.34 NOT OK

a max provide a B.4 fv a/h kv Cv

191.61 in 85 in 2.83 0.96 9.75 0.28

< <

1 OK 0.8 OK

Fv

12.66

>

2.83 OK

E fv

Check combined shear and bending in the web. 2.83 ksi

Fb fb

37.1 ksi 19.69 ksi Fb>fb OK

Size of Stiffner

Ast (Total area of a pair of stiffner) 1.05 in2 Ast (Area of a single stiffner) 0.52 in2 Each stiffener should be checked for the buckling requirement bs*ts bs/ts So, bs ts but provided ts 0.52 13.44 13.44 0.20 in 0.32 in

ts

9.68 in4

bs But provided bs Ist

2.65 in 6.8 in 10.37

>

9.68 OK

Member Dimension Hw, h 2900 mm Tw, tw 25 mm Wf, wf 2000 mm Tf, tf 12 mm

114.17 0.98 78.74 0.47

in in in in

9.51 0.08 6.56 0.04

ft ft ft ft

OR OR OR

88.20 in 114.17 in 88.20 in

> 70 i.e

176.40

1.20 in 20.00 in

ft ft ft ft

General Input Length, L Fy E70 Electrodes Allowable shear stress Unbraced Length Mejor Unbraced Length Minor Since the compression flange carries a uniform load, assume that it is restrained against rotation. Maximum Moment Maximum Shear A a) Selection of the Web Plate Recommended height of Web Provided height of Web Final height of Web, hw /h h/tw

SI 33.70

FPS 110.57 50 21 110.57 110.57

ft ksi ksi ft ft

7937 57

k-ft Kip

L/12

9.21 ft 9.57 ft 9.21 ft

b)

h/tw So tw c) For closely spaced stiffner

242.79 in 0.46 in

h/tw So tw Final thickness of Web d) hw tw Aweb h/tw Allowable bending stress Fb

282.84 in 0.39 in 0.50 in 110.57 0.50 55.28 221.14 30 in in in2 ksi

0.6 Fy

check if reduction of the allowable bending stress

hw/tw So Allowable bending stress must be reduced

137.18 221.14

Fb = 0.6 Fy

30 ksi

Reduced allowable bending stress, Fb' B Selection of Flange Plates

25.72 ksi

Af = bf*tf The minimum flange thickness in order to prevent flange local buckling is

24.28 in2

Kc

0.34 & h/tw

tf So bf = Af/tf C Design for bending stress, Moment of Inertia Final Section Dimention Web h Web t Flange w Flange t 110.57 0.50 32.00 0.50 211341.4 3788.5 7.4 221.14

1.25 but use 19.48 but use

in in in in in4 in3 in

9.21 0.04 2.67 0.04

I, Moment of Inertia S, Section Modulus rT h/tw

M1 M2 M1/M2

500 7937 0.06

k-ft k-ft

Cb But max value is 2.3 So Cb

1.82 1.82

Lu lu/rT

110.57 180.30 60.89 136.15 25.14 25.72 Ok

ft

fb Fb'

ksi ksi

Intermediate stiffeners

584/SQRT Fy 380/SQRT Fy h/tw So Fv Developed Shear Stress So Intermediate Stiffeners are required

77.50 53.74 221.14 1.70 57

B Find the location of the first stiffener from each end. B.1 At Left

Ra Aw fv Substitute for Fv = fv

57 kip 110.57 in2 0.52 ksi

Cv Kv So a/h So a B.2 At Right Same as Left B.3 Intermediate Stiffner

0.03 1.62 #NUM! #NUM! in

< <

0.8 OK 9.34 NOT OK

a max provide a B.4 fv a/h kv Cv

152.84 in 85 in 0.52 0.77 13.04 0.24

< <

1 OK 0.8 OK

Fv

13.22

>

0.52 OK

E fv

Check combined shear and bending in the web. 0.52 ksi

Fb fb

40.5 ksi 24.91 ksi Fb>fb OK

Size of Stiffner

Ast (Total area of a pair of stiffner) 0.25 in2 Ast (Area of a single stiffner) 0.12 in2 Each stiffener should be checked for the buckling requirement bs*ts bs/ts So, bs ts but provided ts 0.12 13.44 13.44 0.10 in 0.32 in

ts

23.91 in4

bs But provided bs Ist

1.29 in 6.8 in 10.37

<

23.91 NOT OK

h1

108.57 in

Member Dimension Hw, h 2900 mm Tw, tw 25 mm Wf, wf 2000 mm Tf, tf 12 mm

114.17 0.98 78.74 0.47

in in in in

9.51 0.08 6.56 0.04

ft ft ft ft

OR OR OR

110.57 in 114.84 in 110.57 in

2764.24 mm 2871.00 mm 2764.24 mm

> 70 i.e

221.14

0.50 in 32.00 in

ft ft ft ft

Beam Weight Beam Length hw tw bf tf

96.73 mm 2300 12.5 1000 25

in 92.00 0.50 40.00 1.00

ft A, in2 46.00 40.00

Unit wt V, ft3 30.90 25.56

0.49 Wt, kip 15.1 12.5

kip/ft3 kip kip

Beam Stiffener Weight 1 Stiffener Width 170.00 Stiffener 1 No 15 mm bs 2300.00 ts 8.00 Beam Stiffener Weight 2 Stiffener Width 150.00 Stiffener 1 No 15 mm bs 606.00 ts 8.00 Beam Stiffener Weight 3 Stiffener Width 96.73 Stiffener 1 No 16 mm bs 100.00 ts 10.00

mm in 92.00 0.32

ft A, in2 29.44

Unit wt V, ft3 0.12

0.49 Wt, kip 0.1

kip/ft3

kip

mm in 24.24 0.32

ft A, in2 7.76

Unit wt V, ft3 0.03

0.49 Wt, kip 0.0

kip/ft3

kip

ft in 4.00 0.40 A, in2 1.60

Unit wt V, ft3 1.07

0.49 Wt, kip 0.5

kip/ft3

kip

Beam Weight Beam Length hw tw bf tf

111.00 mm 1900 12.5 1300 25

in 76.00 0.50 52.00 1.00

ft A, in2 38.00 52.00

Unit wt V, ft3 29.29 27.44

0.49 Wt, kip 14.4 13.4

kip/ft3 kip kip

155.68 Total No 4 4 Wt, kip 60.56 50.09 Wt, Ton 27.53 22.77

Stiffener S Total No 15

2000 Wt, kip 0.82

mm Wt, Ton 0.37

6.67

ft

Stiffener S Total No 15

2000 Wt, kip 0.19

mm Wt, Ton 0.09

6.67

ft

Total No 16

Wt, kip 8.43

Wt, Ton 3.83

Total No 8 8

Wt, kip 114.82 107.58

Wt, Ton 52.19 48.90

L Top Plate Web Bottom plate Stiffner 1 Stiffner 2 Offset K C B W T 2000 2850 2000

T 25 10 25

15 2900 2887.5 2875 1950 10

Part Top Pl Web " Bott " Total D E Sc St

Area 50000 57000 50000 157000 41.3 119824.8

x Dist. 12.5 2875 2887.5

Moment 625000 163875000 144375000 6487069

CG to NA 28.8 12.5 2846.2

Dist 2 830.5 156.3 8100746.8

x Area 50000 57000 50000

I ea. Part

Вам также может понравиться

- Gantry CraneДокумент18 страницGantry Craneamirthraj7494% (16)

- Monorail calculation beam sizingДокумент5 страницMonorail calculation beam sizingSulakxan Kuru100% (2)

- Solid Mechanics (Bending of A T Beam Lab Report)Документ12 страницSolid Mechanics (Bending of A T Beam Lab Report)rajesh yadavОценок пока нет

- Gantry Crane Beam Design CalculationДокумент2 страницыGantry Crane Beam Design CalculationReda Elawady67% (6)

- Crane Bracket - AvestaДокумент55 страницCrane Bracket - AvestamaheshbandhamОценок пока нет

- Design 10-Ton Crane GirderДокумент13 страницDesign 10-Ton Crane GirderDavid_PuenОценок пока нет

- Crane BeamДокумент8 страницCrane BeamastorОценок пока нет

- Spreader Beam CalculationДокумент4 страницыSpreader Beam CalculationMateen KhanОценок пока нет

- Double Girder Box Type Eot Crane Design v2.0Документ64 страницыDouble Girder Box Type Eot Crane Design v2.0deua2004100% (1)

- 5T X 25.5m DG CraneДокумент10 страниц5T X 25.5m DG CraneRv VaghasiaОценок пока нет

- Design of Gantry GirderДокумент30 страницDesign of Gantry GirderSandesh PrajapatiОценок пока нет

- Gantry GirderДокумент12 страницGantry GirderRakeshkumar T RОценок пока нет

- CraneBeam v1 1Документ44 страницыCraneBeam v1 1harry_1981Оценок пока нет

- Eot Crane DetailДокумент2 страницыEot Crane DetailRakesh SharmaОценок пока нет

- Gantry Girders - Sections and Design - Construction - Civil Engineering PDFДокумент12 страницGantry Girders - Sections and Design - Construction - Civil Engineering PDFDinesh VermaОценок пока нет

- Crane Girder and Channel Design DetailsДокумент1 страницаCrane Girder and Channel Design DetailsAnonymous RXXdbl36AОценок пока нет

- Crane Girder Design-5T-5.7m SpanДокумент32 страницыCrane Girder Design-5T-5.7m SpanKyatoor SantoshОценок пока нет

- 1984Документ46 страниц1984Praveen Kumar85% (13)

- Gantry Girder LoadingДокумент6 страницGantry Girder Loadingajith chandranОценок пока нет

- Gantry Crane BeamДокумент2 страницыGantry Crane BeamocktosinagaОценок пока нет

- Crane 5TANДокумент11 страницCrane 5TANAnh Do VoОценок пока нет

- Crane Girder1Документ10 страницCrane Girder1Atul SinghОценок пока нет

- Design of Through Type Plate GirderДокумент9 страницDesign of Through Type Plate GirderAnju Kl0% (1)

- Crane Wheel Load CalculationДокумент2 страницыCrane Wheel Load CalculationPraveen ShresthaОценок пока нет

- Design of MonorailДокумент9 страницDesign of MonorailAnonymous Q8XIGqHyCОценок пока нет

- Crane Beam DesignДокумент13 страницCrane Beam DesignMarcelo DelgadoОценок пока нет

- Hoist DesignДокумент16 страницHoist DesignluisparedesОценок пока нет

- Crane Stub Weld DesignДокумент1 страницаCrane Stub Weld DesignkalpanaadhiОценок пока нет

- Girder DesignДокумент2 страницыGirder DesignsinthianОценок пока нет

- Crane Girder Design Sheet - ASD 2005Документ36 страницCrane Girder Design Sheet - ASD 2005Panha Menh100% (3)

- Crane GirderДокумент43 страницыCrane GirderAlma M. LaraОценок пока нет

- Gantry Girder - 9.5M SpanДокумент20 страницGantry Girder - 9.5M Spanslash100% (1)

- Calculate CB Fault Currents for SubstationsДокумент3 страницыCalculate CB Fault Currents for SubstationsAnkur SangwanОценок пока нет

- 762X267X197Crane Gantry Girder Design (BS5950)Документ5 страниц762X267X197Crane Gantry Girder Design (BS5950)Ravindu Jayalath100% (1)

- Crane Beam Web Splice DesignДокумент7 страницCrane Beam Web Splice DesignCrystal JaneОценок пока нет

- Crane Girder DesignДокумент6 страницCrane Girder Designarzu50% (2)

- Design of Gantry Girder SpreadsheetДокумент7 страницDesign of Gantry Girder SpreadsheetMayuresh KudveОценок пока нет

- Lifting LugДокумент5 страницLifting LugFarid Tata100% (1)

- Design calculations for 11m span crane gantry girderДокумент20 страницDesign calculations for 11m span crane gantry girderkushaljp8989Оценок пока нет

- Crane GirderДокумент55 страницCrane GirderRaveendra Babu Cherukuri100% (1)

- Crane Wheel Load EccentricityДокумент2 страницыCrane Wheel Load Eccentricitypranit_rai0% (1)

- Crane gantry calculation data sheetДокумент7 страницCrane gantry calculation data sheetvinit soodОценок пока нет

- Crane Load-Chemical Storage ShelterДокумент44 страницыCrane Load-Chemical Storage ShelterAndreas HendiОценок пока нет

- Design Calculation of Gantry GirderДокумент7 страницDesign Calculation of Gantry GirderKushal ChhetriОценок пока нет

- 5-50t Electric Hook Overhead CraneДокумент28 страниц5-50t Electric Hook Overhead Cranemohamed100% (1)

- Column DesignДокумент17 страницColumn Designअरुण कुमार सोनीОценок пока нет

- Design of Base Plate & Anchor Bolts For Service Water Tank (Narimanam Site)Документ3 страницыDesign of Base Plate & Anchor Bolts For Service Water Tank (Narimanam Site)Yatendra TyagiОценок пока нет

- Design of Gantry GirderДокумент15 страницDesign of Gantry Girdervineetkothari1Оценок пока нет

- BEAM BOX Built-Up SectionДокумент13 страницBEAM BOX Built-Up Sectionmoseslugtu6324Оценок пока нет

- Gantry Girder UnprotectedДокумент95 страницGantry Girder Unprotectedjignesh14283% (12)

- Crane Girder Capacity CalculationДокумент4 страницыCrane Girder Capacity Calculationsatoni12Оценок пока нет

- Single Girder EOT Cranes (SG-EOT)Документ5 страницSingle Girder EOT Cranes (SG-EOT)Nikhil PoriyaОценок пока нет

- Ancient cranes lifted constructionДокумент25 страницAncient cranes lifted constructionIshaan00748850% (2)

- Reinf. AreaДокумент67 страницReinf. AreaWaheed AhmadОценок пока нет

- Preliminary checking of dowel capacity in chimneyДокумент4 страницыPreliminary checking of dowel capacity in chimneyTeguh Owner'sОценок пока нет

- 10.0m LIGHTING POLES - Concrete Design BS8110Документ7 страниц10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianОценок пока нет

- Cantilever R.C.C. Retaining Wall Design by Mr. Win Aung Cho, P.E., C Eng, S.E., M.ASCE / 2018Документ10 страницCantilever R.C.C. Retaining Wall Design by Mr. Win Aung Cho, P.E., C Eng, S.E., M.ASCE / 2018Sachin SharmaОценок пока нет

- Base Plate DesignДокумент4 страницыBase Plate DesignPradeep Kumar RajОценок пока нет

- McNamara third floor beam dimensions and propertiesДокумент2 страницыMcNamara third floor beam dimensions and propertiesmmediboyinaОценок пока нет

- Desiner 88.6Документ28 страницDesiner 88.6ramin005Оценок пока нет

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsОт EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsРейтинг: 5 из 5 звезд5/5 (1)

- Manually Operated Crane Span 8.6 M Crane Capacity 10 T 100 KNДокумент1 страницаManually Operated Crane Span 8.6 M Crane Capacity 10 T 100 KNJeevan HingneОценок пока нет

- Retaining WallДокумент1 страницаRetaining WallJeevan HingneОценок пока нет

- "Monorail" - Monorail Beam Analysis: Program DescriptionДокумент7 страниц"Monorail" - Monorail Beam Analysis: Program DescriptionvenkieeОценок пока нет

- ANSI EnclosedtrackДокумент30 страницANSI EnclosedtrackJeevan HingneОценок пока нет

- NTPC Limited: (A Govt. of India Enterprise) Solapur Super Thermal Power Project Fatatewadi, Dist - Solapur (Mah.)Документ3 страницыNTPC Limited: (A Govt. of India Enterprise) Solapur Super Thermal Power Project Fatatewadi, Dist - Solapur (Mah.)Jeevan HingneОценок пока нет

- Is 800 Menon RCC Design Raft Design IanbattДокумент1 страницаIs 800 Menon RCC Design Raft Design IanbattJeevan HingneОценок пока нет

- Circular Water Tank Design and Reinforcement LayoutДокумент28 страницCircular Water Tank Design and Reinforcement LayoutLachu M. SharmaОценок пока нет

- Manually Operated Crane Span 8.6 M Crane Capacity 10 T 100 KNДокумент1 страницаManually Operated Crane Span 8.6 M Crane Capacity 10 T 100 KNJeevan HingneОценок пока нет

- Plot Plan PT Plant 14-05-12 ModelДокумент1 страницаPlot Plan PT Plant 14-05-12 ModelJeevan HingneОценок пока нет

- Gantry 12.5 Leff 14.45 W 50 KN Adding 25% To Account Impact 17 62.5 KN Max 58.67 KNM 355.5758 cm4 MB 250Документ2 страницыGantry 12.5 Leff 14.45 W 50 KN Adding 25% To Account Impact 17 62.5 KN Max 58.67 KNM 355.5758 cm4 MB 250Jeevan HingneОценок пока нет

- Design of Counterfort Retaining Wall (Empty Condition) On D/S)Документ18 страницDesign of Counterfort Retaining Wall (Empty Condition) On D/S)Jeevan HingneОценок пока нет

- CSLiftStation 2009Документ22 страницыCSLiftStation 2009Jeevan HingneОценок пока нет

- Is 800 Menon RCC Design Raft Design IanbattДокумент1 страницаIs 800 Menon RCC Design Raft Design IanbattJeevan HingneОценок пока нет

- Design ConstantsДокумент5 страницDesign ConstantsJeevan HingneОценок пока нет

- S1a1 Raj Isps Tsps I 2002Документ1 страницаS1a1 Raj Isps Tsps I 2002Jeevan HingneОценок пока нет

- Vepl 1956 1211Документ13 страницVepl 1956 1211Jeevan HingneОценок пока нет

- Guide To Design Criteria For Bolts and Riveted JointsДокумент352 страницыGuide To Design Criteria For Bolts and Riveted JointsHomero Silva96% (24)

- JДокумент1 страницаJJeevan HingneОценок пока нет

- Ib ml/4EI MA MB/2Документ5 страницIb ml/4EI MA MB/2Jeevan HingneОценок пока нет

- 21-11-12 SummaryДокумент17 страниц21-11-12 SummaryJeevan HingneОценок пока нет

- Scour Depth CalculationsДокумент1 страницаScour Depth CalculationskishoredataОценок пока нет

- Delhi Schedule RateДокумент403 страницыDelhi Schedule RateJagdish GiriОценок пока нет

- 1 Introduction HSFGДокумент2 страницы1 Introduction HSFGSushanta TakhellambamОценок пока нет

- Strength of MaterialsДокумент833 страницыStrength of MaterialsSuvendu ParidaОценок пока нет

- Design, Analysis and Optimization of Thin Walled Semi-Monocoque Wing Structures Using Different Structural Idealizations in The Preliminary Design PhaseДокумент319 страницDesign, Analysis and Optimization of Thin Walled Semi-Monocoque Wing Structures Using Different Structural Idealizations in The Preliminary Design Phaserokhgireh_hojjatОценок пока нет

- Crane Runway Beam Design - Beam Section Check Using CSA S16-14 Code-3Документ4 страницыCrane Runway Beam Design - Beam Section Check Using CSA S16-14 Code-3sergiooiОценок пока нет

- Prestressed Steel BeamДокумент35 страницPrestressed Steel BeamVaibhav GaikarОценок пока нет

- Concrete Encased Composite Column ACI - AISCДокумент14 страницConcrete Encased Composite Column ACI - AISCAli KhalafОценок пока нет

- Pryda TrussedДокумент24 страницыPryda TrussedLowel Bonsato0% (1)

- Lecture 10.3: Single Span Beams: Objective/ScopeДокумент21 страницаLecture 10.3: Single Span Beams: Objective/ScopeDenis DimićОценок пока нет

- UB Powerpoint TemplateДокумент54 страницыUB Powerpoint TemplateEloiza Lajara RamosОценок пока нет

- Rolled Steel Angle Dimensions and Properties TableДокумент91 страницаRolled Steel Angle Dimensions and Properties TablekamleshyadavmoneyОценок пока нет

- Advantages and DisadvantagesДокумент14 страницAdvantages and Disadvantagespaul machariaОценок пока нет

- Structural steel beam dimensions and properties tableДокумент42 страницыStructural steel beam dimensions and properties tableShekh Muhsen Uddin AhmedОценок пока нет

- Lean-On Bracing Reference GuideДокумент96 страницLean-On Bracing Reference GuideRafael Alburquerque CruzОценок пока нет

- Flexural Member DesignДокумент50 страницFlexural Member DesignremedanОценок пока нет

- CEBA-IARW Design Maintenance Modernization Guide - 2018 Update - FINALДокумент402 страницыCEBA-IARW Design Maintenance Modernization Guide - 2018 Update - FINALEduardo Depiné TarnowskiОценок пока нет

- Study of Castellated Beam Using Stiffeners: A Review: Siddheshwari. A. Patil, Popat. D. KumbharДокумент5 страницStudy of Castellated Beam Using Stiffeners: A Review: Siddheshwari. A. Patil, Popat. D. Kumbhardiksha balwadОценок пока нет

- Optimal Design of Welded I-Beam of Slewing Pillar Jib Crane: IMK-14 - Istrazivanje I Razvoj December 2018Документ9 страницOptimal Design of Welded I-Beam of Slewing Pillar Jib Crane: IMK-14 - Istrazivanje I Razvoj December 2018Türk saldırma sanayiОценок пока нет

- Composite Beam Design ExampleДокумент7 страницComposite Beam Design Exampledgreally1gmailcom100% (1)

- Plate Girders: Sequence of Fabrication of Plate GirderДокумент16 страницPlate Girders: Sequence of Fabrication of Plate Girderraunak upadhyayaОценок пока нет

- CAEPIPE Technical Reference ManualДокумент388 страницCAEPIPE Technical Reference ManualrtadicherlaОценок пока нет

- Wood Joists PDFДокумент27 страницWood Joists PDFRicaRDOОценок пока нет

- Equivalent Section CalculatorДокумент13 страницEquivalent Section Calculatorstavros_stergОценок пока нет

- Lecture Plate Girder Intro DSS 2Документ37 страницLecture Plate Girder Intro DSS 2Amarendra KojjaОценок пока нет

- Recommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11Документ6 страницRecommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11perdhana2000Оценок пока нет

- Lecture-7-Analysis and Design of T BeamsДокумент72 страницыLecture-7-Analysis and Design of T Beamskumar reddy100% (1)

- Mechanics of Materials: Pure BendingДокумент42 страницыMechanics of Materials: Pure BendingHind AwadОценок пока нет

- Tabla de Perfiles EstructuralesДокумент24 страницыTabla de Perfiles EstructuralesBrandonОценок пока нет

- PreviewpdfДокумент76 страницPreviewpdfrichardОценок пока нет

- NUS Composite Beam IДокумент20 страницNUS Composite Beam IbsitlerОценок пока нет

- Research Article: Minimum Weight Design of Sinusoidal Corrugated Web Beam Using Real-Coded Genetic AlgorithmsДокумент14 страницResearch Article: Minimum Weight Design of Sinusoidal Corrugated Web Beam Using Real-Coded Genetic AlgorithmsTamir EnkhОценок пока нет