Академический Документы

Профессиональный Документы

Культура Документы

Micro Fluidics

Загружено:

lgroscheИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Micro Fluidics

Загружено:

lgroscheАвторское право:

Доступные форматы

PAPER

www.rsc.org/loc | Lab on a Chip

Microfluidics assisted synthesis of well-defined spherical polymeric microcapsules and their utilization as potential encapsulants

Sinoj Abraham,a Eun Ho Jeong,b Takahiro Arakawa,c Shuichi Shoji,c Kyung Chun Kim,b Il Kim*a and Jeung Sang Go*bd

Received 19th December 2005, Accepted 28th March 2006 First published as an Advance Article on the web 10th April 2006 DOI: 10.1039/b518006f In this article, the development of a novel technique to fabricate spherical polymeric microcapsules by utilizing microfluidic technology is presented. Atom transfer radical polymerization (ATRP) was employed to synthesize well-defined amphiphilic block copolymers. An organic polymer solution was constrained to adopt the spherical droplets in a continuous water phase at a T-junction microchannel, and the generation of the droplets was studied quantitatively. The flow conditions of two immiscible solutions were adjusted for the successful generation of the polymer droplets. The morphology of the microcapsules was examined. The efficiency of these polymer microcapsules as containers for the storage and controlled release of loaded molecules was evaluated by encapsulating the microcapsules with Congo-red dye and investigating the release performance using temperature controlled UV-VIS spectroscopy.

Introduction

Recently, considerable interest has been shown in the fabrication of polymeric microcapsules at the nano-to-micrometre scale with uniform characteristics and functional properties.14 Specifically, the potential utilization of polymeric microcapsules as encapsulants enabling the controlled release of drugs,5,6 dyes,79 and enzymes911 has led to speculation on a wide range of biomedical, drug delivery and industrial applications for such microcapsules. To satisfy the increasing lack of encapsulation materials, various routes for fabricating microcapsules have emerged.1114 These recently developed methods offer new alternatives for the controlled synthesis of stable and functional spheres for various applications. Rapid maturation of versatile analytical procedures such as micro total analysis systems has accelerated the methodology of microcapsule fabrication which is now the focus of a wide area of research.15 Intensive study of microfluidic techniques has enabled the rapid development of micro-chemical processing plants for facile handling of mixtures of immiscible chemical reagents such as organic and aqueous solutions.1618 Especially, the microchannel-confined reaction has decreased the amount of reagent consumption and has enabled a certain lateral control to be imposed on the solutions under flow conditions.1820 Studies on droplet formation in a microchannel network are also reported for the preparation of water-in-oil droplets.21,22 Any appropriate compound present in the solution phase will self-organize in a supramolecular

a Department of Polymer Science and Engineering, Pusan National University, Busan, 609-735, S. Korea b School of Mechanical Engineering, Pusan National University, Jangjeon-dong, Geumjeong-Gu, Busan, 609-735, S. Korea. E-mail: micros@pusan.ac.kr; Fax: +82 51 512 5236; Tel: +82 51 510 3512 c Major in Nano-science and Nano-engineering, Waseda University, 3-4-1, Ohkubo Shinjuku, Tokyo, 169-8555, Japan d RIMT, Pusan National University, Busan, 609-735, S. Korea

fashion due to the interaction between both solutions within the limits of droplet size and shape. Amphiphilic block copolymers have proven to be the best candidates for exhibiting the behavior of molecular selforganization. The research interest of block copolymers stems from their ability to self-assemble to form nanostructures with well-defined morphology and size.2327 Recent reports on the block copolymer vesicles have provided a milestone in the discovery of polymersomes.28,29 Modern advancements in controlled radical polymerizations (CRP) have facilitated the microstructure design and synthesis of block copolymers, leading to various fascinating architectures.30 Atom transfer radical polymerization (ATRP) is a powerful CRP technique for the synthesis of well-defined polymers with desired properties.3133 Among the family of block copolymers, poly(styrene-block-methylmethacrylate) (PS-b-PMMA) has gained much attention due to its high degree of long range micro domain seperation.34 The hydrolysed derivatives of this block copolymer were also used as stabilizers for tuning the optical properties of quantum dots applicable to photonics, sensors and bio-labelling.35 In this contribution, we describe a novel method for producing uniform polymer microcapsules using a flowthrough droplet-based supramolecular self-assembly of the block copolymer in the microchannel. Due to hydrodynamic instability, the introduction of immiscible fluids forms uniform droplets in the microchannel, and we extend this fluidic behavior to the fabrication of polymeric microcapsules. PS-b-PMMA copolymers are synthesized by ATRP and are chemically modified by partial hydrolysis in order to incorporate a hydrophilic property. The microcapsules are produced in a crossed microchannel network, and droplet generation is visualized by using a fluorescent microscope. The hollow cavity of the microcapsules is characterized by the SEM image, which is obtained after O2 plasma ashing of the polymer surface. Finally, we measure the release performance

This journal is The Royal Society of Chemistry 2006

752 | Lab Chip, 2006, 6, 752756

of the encapsulated dye using temperature controlled UV-VIS spectroscopy.

Synthesis of organic encapsulation material

Commercial copper(I) bromide (CuBr, Aldrich 99.999%), N,N,N9,N9,N0-pentamethyldiethylenetriamine (PMDETA, Aldrich 99%), benzyl bromide (Aldrich 98%) and Congo red (Aldrich 97%) were prepared. Monomers, styrene (Aldrich 99%) and methyl methacrylate (MMA, Aldrich 99%) were purified by the standard distillation process and were stored in a dry atmosphere of purified nitrogen. Dichloromethane (DCM) and butyl acetate (BA) were also purified according to the standard procedure. The synthesis of poly(styrene-b-methylmethacrylate) copolymers by ATRP has been well described previously.36,37 Polymerization reactions were performed under a purified nitrogen atmosphere using standard Schlenk techniques. Accordingly, in a schlenk flask, the calculated amounts of catalyst (CuBr/PMDETA), solvent (butyl acetate), monomer (styrene) and initiator (benzyl bromide) were added sequentially and stirred until the Cu complex was formed. It was then allowed to polymerize at 110 uC until over 80% monomer conversion was obtained. An aliquot of the sample was withdrawn for analysis by using a nitrogen purged syringe. Block copolymers were further synthesized by adding the second monomer (MMA) in the same reaction flask and was polymerized. The block copolymers were then precipitated in hexane and purified by reprecipitation. The final bromine terminated block copolymer was purified by passing it through an ion-exchange resin and was then precipitated in hexane. The molecular weight and the polydispersity index (PDI) of the polymers were estimated by gel permeation chromatography (GPC) (Hewlett Packard Model 1100 series) equipped with a refractive index detector. The estimated values were 9837 g mol21 and 1.08, respectively. A part of the PMMA block was further hydrolysed to methacrylic acid using a 20% dilute sulfuric acid solution.38 The block copolymer was dissolved in toluene in a round bottom flask, and the dilute sulfuric acid was added in a ratio of 1 : 30. The reaction flask was then heated up to 60 uC for 10 h with continuous stirring; it was subsequently quenched in an ice-water bath. The product was washed thoroughly with water in order to remove H2SO4 and dried overnight at 50 uC under vacuum. The 1H NMR spectrum (Varian Unity Plus300) of the polymers was recorded in CDCl3 (d1) at 25 uC using tetramethylsilane as the internal reference. [1H NMR: d = 1.18 to 1.23 (MMA backbone CH3), 1.87 to 2.41 (backbone CH2), 2.9 to 3.29 (backbone CH), 3.6 (methacrylate CH3), 6.94 to 7.24 (aromatic protons) and 11.2 (carboxylic acid OH) ppm.] The NMR analysis showed that more than 50% of the methacrylate moieties were converted to methacrylic acid. The molecular structure of the block copolymer is depicted in Fig. 1.

Fig. 1 Microscopic image of droplet generation. Stabilised water was injected through the side channels at a constant flow rate, and polymer solution was infused through the middle channel to form droplets with predictable and uniform size. Schematic self-assembly of the copolymer is also shown in the inset. The molecular structure of the amphiphilic block-copolymer, having polystyrene as the hydrophobic part and PMMA together with PMAA as the hydrophilic part, is depicted below.

substrate of dimensions 20 mm 6 30 mm by using double-step deep reactive ion etch (DRIE).39,40 The channel was fabricated to be 100 mm deep and 100 mm wide with three inlets and one outlet. Then, for optical visualization, 100 mm-thick Pyrex glass (# 7740) was anodically bonded with the silicon substrate to form the channel. The crossed network channels enabled the injection of an organic phase through the middle channel and an aqueous phase through two side channels.

Flow-through microcapsule generation

In order to produce polymer microspheres in the microchannel, we used the droplet-phase flow. The pre-synthesized amphiphilic block copolymer was dissolved in DCM and was infused into the middle inlet of the microchannel using a flow rate of 5 mL min21. The water containing 3% PVA as a droplet stabilizer was introduced into the two side channels using a flow rate of 5 mL min21. The flow rates of the two solutions were adjusted to obtain a stable periodic droplet generation.

Lab Chip, 2006, 6, 752756 | 753

Fabrication of the microfluidic platform

An in-channel micro chemical processing device with a crossed microchannel was fabricated on a 200 mm-thick silicon

This journal is The Royal Society of Chemistry 2006

Fig. 4 The FESEM images of the microcapsules are visualised. The microcapsules appear to have perfect spherical shape with an average diameter of 30 mm. Porous openings on the surface are visualised in the magnified image in the inset.

Fig. 2 Evaluation of droplet size and pitch by varying the ratio of inlet flow rates. Qo and Qw are the flow rates of the organic phase and the aqueous phase, respectively.

The continuous droplet phase flow was visualized using a highsensitive fluorescent microscope (Olympus IX-51) and was imaged using a high speed CCD camera (Dynamic range PCO1200 hs) (Fig. 1). The drop break-off at the T-junction channel was governed by the balance between the interfacial viscous stress and the surface tension of the solutions. Especially, the size and the pitch of the flow were precisely controlled by the ratio of the inlet flow rates (Fig. 2). The polymer droplets were drained and dispersed on a clean hydrophilic silicon wafer. They were then dried by slow evaporation to remove the solvent trapped inside them. The release of solvent from the polymer droplets caused them to shrink in size, from 80 mm diameter to about 40 mm, within one hour after draining. The microscopic images show clear shrinkage (Fig. 3).

hollow inner cavities and porous outer surfaces. The surface morphology and the size of the microcapsules were investigated using a Field Emission Scanning Electron Microscope and the porous outer surface was visualised as shown in Fig 4. The sizes of the fabricated microcapsules seemed to be identical within a range of 30 mm. In order to examine the hollow characteristics of the microcapsules, its surface was partially etched by using O2 plasma ashing at 100 W for 2 min. Fig. 5 shows qualitatively that the inner part of the microcapsule is empty. To detach microcapsules from the substrate, the microcapsule-adhered silicon wafer was dipped into a beaker filled with the deionized water, and was sonicated for 6 h. The PVA layer gradually dissolved in water and thus the microcapsules were detached from the surface. Then, the microcapsules were filtered by using a microfilter with a pore size of 10 mm. The residing water and solvent in the microcapsule were removed by vacuum evaporation at 60 uC. Finally, the microcapsules were obtained after heat treatment in a vacuum oven for 2 h at a temperature of 90 uC, which is near the glass transition temperature of at least one block of the copolymer. This process ensured complete solvent evaporation and also facilitated the self-assembly of the microdomains of the block copolymer, resulting in an increased stability of microcapsules.

Evaluation of microcapsule

Based on the slow evaporation process and the block copolymer self-assembly, microcapsules were formed having

Encapsulation of release molecules

Congo-red dye was loaded into the microcapsules to examine the potential for encapsulating foreign molecules and releasing them in specific surroundings. The obtained microcapsules were immersed into distilled water (30 ml) containing dissolved

Fig. 3 Microscopic images of droplets which clearly demonstrate that shrinkage occurs after draining onto the surface of the silicon wafer. The left image shows the average diameter of the droplets as 80 mm. After one hour, the droplets shrank to about 40 mm, as shown in the right image. This process of solvent evaporation helps to form microcapsules with porous openings on the surface.

Fig. 5 SEM images of the polymeric microcapsules after removing a small layer of the surface by plasma ashing. The images clearly demonstrate the hollow inner cavity of the microcapsules.

754 | Lab Chip, 2006, 6, 752756

This journal is The Royal Society of Chemistry 2006

Congo-red dye of 6.5 6 1026 g cc21 at room temperature. Then, the microcapsule suspended dye solution was sonicated over a day and kept for another day to ensure the maximal degree of encapsulation. The encapsulation efficiency of the microcapsules was evaluated using UV-Visible spectroscopy (Shimadzu UV-1650PC). It was observed that about 20% of dye from the solution was enclosed in the microcapsules. Congo-red is a well-known azo-dye with a hydrophobic center and charged ends. Accordingly, as water moves into the porous cavity of the microcapsules, the dissolved dye molecules also get adsorbed through the pores and preferably get attached onto the inner polystyrene walls of the microcapsules. In this way, the dye could be loaded in the microcapsules. The microcapsules were further filtered and dried under vacuum. In addition, non-hydrolyzed polymer microcapsules were also produced by using the same fabrication processes. Under the same experimental conditions, the dye encapsulation rate of non-hydrolyzed microcapsules was obtained to be about 17% of total dye concentration in solution, which is almost the same encapsulation performance compared with that of the hydrolyzed polymer microcapsules.

Fig. 7 The time-dependent release of dye from the microcapsules at pH = 7 and at 30 uC, 50 uC and 70 uC together with the release from microcapsules fabricated using the non-hydrolyzed polymer.

Evaluation of microcapsule release

The release performance of the microcapsules encapsulated with dye was investigated by using the same UV-VIS spectrometer equipped with a uniform temperature controlled UV cuvette. The measurement was performed by varying the pH and the temperature. The microcapsules were loaded to the UV cuvette containing KH2PO4/NaOH buffer solutions of pH 7 and pH 7.8. The constant temperature for the solution was achieved by active control of the sensitive heater attached to the cuvette with a thermocouple. The spectrometer was programmed to scan automatically every 30 min for 20 h. For both pH conditions, the UV profiles were obtained at three

different temperatures of 30 uC, 50 uC and 70 uC. Fig. 6 shows the measured UV curve of the dye release at a temperature of 50 uC and a pH of 7.8. It was noted that the release rate was slightly faster in the first few hours, and about the half of the total amount of dye was released within 4 h. When the pH was increased to pH 7.8, the release rate became faster and a high percentage of release was obtained. The increase in temperature of the solution influenced the release sensitively. The time dependence of dye release from microcapsules at the different conditions is represented in Figs. 7 and 8. For comparative evaluation, the

Fig. 6 UV-visible absorption spectra of the released Congo-red dye from the microcapsules to the phosphate buffer solution (pH = 7.8) at 50 uC. Over time, the amount of dye released from the microcapsules increases, which is shown by a gradual acclivity in the UV absorbance.

Fig. 8 Release kinetics of the dye at pH = 7.8. The dye molecules were released from the inner cavity of the microcapsules in a controlled manner. The release rate depends on the swelling of the capsules due to the ionization of methacrylic acid moiety.

This journal is The Royal Society of Chemistry 2006

Lab Chip, 2006, 6, 752756 | 755

release performance of encapsulated dye from the nonhydrolysed polymer microcapsule is also included. The release performance of the microcapsule depends on the swelling of the microcapsule in the solution and the diffusivity of the dye. Poly(methacrylic acid) is an ionizable hydrophilic polymer and its swelling behaviour is greatly influenced by the ionizationdeionization activity of the carboxylic acid groups in buffer solution. At high pH, the COOH groups become ionized, and the charged COO2 groups repel each other, which leads to high swelling. The small release rate of the encapsulated molecules from the non-hydrolysed microcapsules is caused by the absence of this ionization effect. The stability of the dye molecules is also enhanced due to its ionization in the high pH environment, which results in an increased diffusivity averting all nonbonding interactions with the polymer walls. Furthermore, an increase in the solution temperature accelerates the ionisation reactions, and also creates a more suitable environment for controlled release. The coupled mechanisms ensure an enhanced release efficiency of the dye from the microcapsules at a high pH stipulation. Additionally, their highly porous nature rules these microcapsules out for controlled delivery applications, such as drug delivery, even if this is one of the most important parameters which control the drug release. To this end, more investigations must be also advanced.

Conclusions

In this work, a new microfluidics-based approach has been demonstrated that offers a convenient and finely controllable route for synthesizing polymer microcapsules whereby the particle size can be tuned freely. Functional block copolymers were synthesized by a one-pot ATRP process and were chemically modified to accomplish a hydrophilic nature. Spherical polymer droplets were formed at a T-junction microchannel and their generation behavior was extensively examined. Morphological studies were carried out and the hollow inner cavity of the microcapsules was visualized after performing plasma ashing. The versatility of these microcapsules for encapsulation was assessed by filling them with Congo-red dye, and the release performance was evaluated under various pH levels and temperatures. Further investigations on employing different functional polymers and on the in-channel purification of microcapsules for various practical applications are being conducted.

Acknowledgements

This work was supported by Korea Research Foundation Grant funded by the Korean Government (MOEHRD) (KRF-042-D00016).

References

1 G. Ibarz, L. Dahne, E. Donath and H. Mohwald, Adv. Mater., 2001, 13, 13241327. 2 D. Lee, M. F. Rubner and R. E. Cohen, Chem. Mater., 2005, 17, 10991105.

3 A. Fery, F. Dubreuil and H. Mohwald, New J. Phys., 2004, 6, 18. 4 F. Caruso, Adv. Mater., 2001, 13, 1122. 5 I. Gill and A. Ballesteros, J. Am. Chem. Soc., 1998, 120, 85878598. 6 C. Berkland, K. Kim and D. W. Pack, J. Controlled Release, 2001, 73, 5974. 7 J. Guo, W. Yang, Y. Deng, C. Wang and S. Fu, Small, 2005, 7, 737743. 8 N. Zydowicz, E. Nzimba-Ganyanad and N. Zydowicz, Polym. Bull., 2002, 47, 457463. 9 R. V. Parthasarathy and C. R. Martin, J. Appl. Polym. Sci., 1996, 62, 875886. 10 G. J. Wang, L. Y. Chu, W. M. Chen and M. Y. Zhou, J. Membr. Sci., 2005, 252, 279284. 11 A. M. Tinsley-Bown, R. Fretwell, A. B. Dowsett, S. L. Davis and G. H. Farrar, J. Controlled Release, 2000, 66, 229241. 12 T. J. Young, K. P. Johnston, K. Mishima and H. Tanaka, J. Pharm. Sci., 1999, 88, 640650. 13 M. Luck, K. F. Pistel, Y. X. Li, T. Blunk, R. H. Muller and T. Kissel, J. Controlled Release, 1998, 55, 107120. 14 Y. Kawashima, H. Yamamoto, H. Takeuchi, T. Hino and T. Niwa, Eur. J. Pharm. Biopharm., 1998, 45, 4148. 15 S. Iwamoto, K. Nakagawa, S. Sugiura and M. Nakajima, AAPS PharmSciTech, 2002, 3, 3. 16 T. Wu, Y. Mei, J. T. Cabral, C. Xu and K. L. Beers, J. Am. Chem. Soc., 2004, 126, 98809881. 17 C. Xu, T. Wu, C. M. Drain, J. D. Batteas and K. L. Beers, Macromolecules, 2005, 38, 68. 18 B. Zheng, L. S. Roach and R. F. Ismagilov, J. Am. Chem. Soc., 2003, 125, 1117011171. 19 P. J. A. Kenis, R. F. Ismagilov and G. M. Whitesides, Science, 1999, 285, 8385. 20 P. J. A. Kenis, R. F. Ismagilov, S. Takayama, G. M. Whitesides, S. Li and H. S. White, Acc. Chem. Res., 2000, 33, 841847. 21 T. Nisisako, T. Torii and T. Higuchi, Lab Chip, 2002, 2, 2426. 22 S. L. Anna, N. Bontoux and H. A. Stone, Appl. Phys. Lett., 2003, 82, 364366. 23 T. Thurn-Albrecht, J. Schotter, G. A. Kastle, N. Emley, T. Shibauchi, L. Krusin-Elbaum, K. Guarini, C. T. Black, M. T. Tuominen and T. P. Russel, Science, 2000, 290, 21262129. 24 I. W. Hamley, Angew. Chem., Int. Ed., 2003, 42, 16921712. 25 T. Thurn-Albrecht, R. Steiner, J. DeRouchey, C. M. Stafford, E. Huang, M. Bal, M. Tuominen, C. J. Hawker and T. P. Russel, Adv. Mater., 2000, 12, 787791. 26 C. Park, J. Yoon and E. L. Thomas, Polymer, 2003, 44, 67256760. 27 M. Lazzari and M. A. Lopez-Quintela, Adv. Mater., 2003, 15, 15831594. 28 J. A. Opsteen, J. J. L. M. Cornelissen and J. C. M. Van Hest, Pure Appl. Chem., 2004, 76, 13091319. 29 D. E. Discher and A. Eisenberg, Science, 2002, 297, 967973. 30 O. W. Webster, Science, 1991, 251, 887892. 31 J. S. Wang and K. Matyjaszewski, J. Am. Chem. Soc., 1997, 119, 674680. 32 M. Kato, M. Kamigaito, M. Sawamoto and T. Higashimura, Macromolecules, 1995, 28, 17211723. 33 K. A. Davis and K. Matyjaszewski, Macromolecules, 2000, 33, 40394047. 34 U. Jeong, D. Y. Ryu, D. H. Kho, J. K. Kim, J. T. Goldbach, D. H. Kim and T. P. Russell, Adv. Mater., 2004, 16, 533536. 35 C. W. Wang and M. G. Moffitt, Langmuir, 2004, 20, 1178411796. 36 C. Keary, X. Zhang, T. E. Hogen-Esch and J. S. Wang, Polym. Int., 2002, 51, 647652. 37 K. Matyjaszewski, D. A. Shipp, G. P. Mcmurtry, S. C. Gaynor and T. Pakula, J. Polym. Sci., Part A: Polym. Chem., 2000, 38, 20232031. 38 A. A. F. Cesar-Oliveira, S. Zaioncz, A. R. S. Oliveira, M. C. R. Almeida, S. F. Zawadzki, L. Akcelrud, M. Aguiar, D. Tabak and E. F. Lucas, Polimeros, 1999, 9, 156162. 39 J. S. Go and S. Shoji, Sens. Actuators, A, 2004, 114, 438444. 40 M. Kanai, S. Ikeda, J. Tanaka, J. S. Go, H. Nakanishi and S. Shoji, Sens. Actuators, A, 2004, 111, 3236.

756 | Lab Chip, 2006, 6, 752756

This journal is The Royal Society of Chemistry 2006

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Micro FluidicsДокумент5 страницMicro FluidicslgroscheОценок пока нет

- Micro ReactorДокумент7 страницMicro ReactorMaxwell Quezada FelizОценок пока нет

- Micro ReactorДокумент7 страницMicro ReactorMaxwell Quezada FelizОценок пока нет

- Web - Hku.hk - Ashum - Published Articles - Designer Emulsions Using MicrofluidicsДокумент10 страницWeb - Hku.hk - Ashum - Published Articles - Designer Emulsions Using MicrofluidicslgroscheОценок пока нет

- Bookchapter Microfluidic TechniquesДокумент21 страницаBookchapter Microfluidic TechniqueslgroscheОценок пока нет

- 11.microreactors: Jens Ducrée and Roland Zengerle 11. MicroreactorsДокумент72 страницы11.microreactors: Jens Ducrée and Roland Zengerle 11. MicroreactorsJoe ChawalitОценок пока нет

- Colloids and Surfaces B: BiointerfacesДокумент6 страницColloids and Surfaces B: BiointerfaceslgroscheОценок пока нет

- CFD Algorithms For Hydraulic EngineДокумент0 страницCFD Algorithms For Hydraulic EnginelgroscheОценок пока нет

- Bayareh, Mortazavi - 2011 - Binary Collision of Drops in Simple Shear Flow at Finite Reynolds Numbers Geometry and Viscosity Ratio EffecДокумент8 страницBayareh, Mortazavi - 2011 - Binary Collision of Drops in Simple Shear Flow at Finite Reynolds Numbers Geometry and Viscosity Ratio EffeclgroscheОценок пока нет

- Kuzmin Et Al. - 2011 - Three-Dimensional Binary-Liquid Lattice Boltzmann Simulation of Microchannels With Rectangular Cross SectionsДокумент11 страницKuzmin Et Al. - 2011 - Three-Dimensional Binary-Liquid Lattice Boltzmann Simulation of Microchannels With Rectangular Cross SectionslgroscheОценок пока нет

- L. Marchisio, Dennis Vigil, O. Fox - 2003 - Implementation of The Quadrature Method of Moments in CFD Codes For Aggregation-Breakage ProДокумент15 страницL. Marchisio, Dennis Vigil, O. Fox - 2003 - Implementation of The Quadrature Method of Moments in CFD Codes For Aggregation-Breakage ProlgroscheОценок пока нет

- Alopaeus, Koskinen, Keskinen - 1999 - Simulation of The Population Balances For Liquid-Liquid Systems in A Nonideal Stirred Tank. Part 1Документ13 страницAlopaeus, Koskinen, Keskinen - 1999 - Simulation of The Population Balances For Liquid-Liquid Systems in A Nonideal Stirred Tank. Part 1lgroscheОценок пока нет

- LLECMOD Simulation ProgramДокумент11 страницLLECMOD Simulation ProgramNatalia SchiesslОценок пока нет

- Andresen, Arntzen, Sjøblom - 2000 - Stability of Model Emulsions and Determination of Droplet Size Distributions in A Gravity SeparatorДокумент12 страницAndresen, Arntzen, Sjøblom - 2000 - Stability of Model Emulsions and Determination of Droplet Size Distributions in A Gravity SeparatorlgroscheОценок пока нет

- Flow Past A Sphere Ch3Документ48 страницFlow Past A Sphere Ch3mheinricОценок пока нет

- Fluids CH 67Документ20 страницFluids CH 67lgroscheОценок пока нет

- 2 5stokesДокумент6 страниц2 5stokesSingh AnujОценок пока нет

- Ullmann S Enc of Industrial Chemistry PolimerizationДокумент134 страницыUllmann S Enc of Industrial Chemistry PolimerizationlgroscheОценок пока нет

- Ullmann S Enc of Industrial Chemistry PolimerizationДокумент134 страницыUllmann S Enc of Industrial Chemistry PolimerizationlgroscheОценок пока нет

- Stokes Analytical SolutionДокумент7 страницStokes Analytical SolutionlgroscheОценок пока нет

- Oscillatory Vapor-Liquid Transport Phenomena in A Packed C85Документ10 страницOscillatory Vapor-Liquid Transport Phenomena in A Packed C85lgroscheОценок пока нет

- A Numerically Convergent Lagrangian-Eulerian Simulation Method For Dispersed Two-Phase FlowsДокумент3 страницыA Numerically Convergent Lagrangian-Eulerian Simulation Method For Dispersed Two-Phase FlowslgroscheОценок пока нет

- Pride & Prejudice - Jane AustenДокумент273 страницыPride & Prejudice - Jane Austenagape_1st7100% (16)

- CFD HandbookДокумент275 страницCFD HandbookWahid AliОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Emission CharacteristicsДокумент48 страницEmission CharacteristicsBALAJIОценок пока нет

- PDFДокумент24 страницыPDFousmaneОценок пока нет

- Towards Recycling of Textile FibersДокумент75 страницTowards Recycling of Textile FibersMusa EltayebОценок пока нет

- BP Energol GR-XP 150Документ2 страницыBP Energol GR-XP 150Moutaz IsmailОценок пока нет

- Din 1690Документ7 страницDin 1690saravananОценок пока нет

- Mole Concept (Scholar Paper)Документ4 страницыMole Concept (Scholar Paper)Rudraksh AhujaОценок пока нет

- Chapter No 6 - Chemical KineticsДокумент45 страницChapter No 6 - Chemical KineticsTanish SalviОценок пока нет

- BQPS HR RepoprtДокумент8 страницBQPS HR RepoprtImaad MotanОценок пока нет

- Poly 103Документ20 страницPoly 103Sharifah Zulaikha BenYahyaОценок пока нет

- DISC Thermal AnalysisДокумент11 страницDISC Thermal AnalysisAkrit Kumar ChaturvediОценок пока нет

- GTZ - Lead-Acid Battery RecyclingДокумент10 страницGTZ - Lead-Acid Battery RecyclingViju K G100% (1)

- Re-Evaluation of The 2,2-Diphenyl-1-Picrylhydrazyl Free Radical (DPPH) Assay For Antioxidant ActivityДокумент10 страницRe-Evaluation of The 2,2-Diphenyl-1-Picrylhydrazyl Free Radical (DPPH) Assay For Antioxidant Activitycentro surcolombiano de investigación en café uscoОценок пока нет

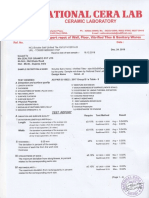

- 12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Документ3 страницы12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Shaikh MohammedHanifSultanОценок пока нет

- 08 024Документ40 страниц08 024Hoang QuyОценок пока нет

- Balancing Equations 39Документ5 страницBalancing Equations 39Ignacio Jr. Paguyo100% (1)

- Water Chemistry - Mark Benjamin - 2nd EdДокумент935 страницWater Chemistry - Mark Benjamin - 2nd EdPedro Casa Grande Rosa95% (19)

- The History Behind The Discovery of Benzene RingsДокумент1 страницаThe History Behind The Discovery of Benzene Ringsekadarma55100% (5)

- Hydrocarbon and Alkyl Halide-1Документ10 страницHydrocarbon and Alkyl Halide-1Aarya Vardhan ShandilyaОценок пока нет

- 001 - Shell Turbo Oil CC 32Документ2 страницы001 - Shell Turbo Oil CC 32Irvan NandaОценок пока нет

- Spectrofluorimetry: Minia University Faculty of Pharmacy Department of Analytical ChemistryДокумент35 страницSpectrofluorimetry: Minia University Faculty of Pharmacy Department of Analytical ChemistryAhmed Zaghloul100% (2)

- Evaluation and Analysis of Soil Stabilization With Some Non Conventional Additives IJERTV9IS070265Документ8 страницEvaluation and Analysis of Soil Stabilization With Some Non Conventional Additives IJERTV9IS070265slv buildersОценок пока нет

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)Документ5 страницGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)joshi madhavОценок пока нет

- Grade 11 Physics Module6Документ83 страницыGrade 11 Physics Module6JohnRenzoMolinarОценок пока нет

- Pressure Test in Accordance With The Standard Din en 13445: Inspecta GroupДокумент14 страницPressure Test in Accordance With The Standard Din en 13445: Inspecta GroupNanang PhОценок пока нет

- BOS-M.Sc. Syllabus - 23-09-VBSPU 2022Документ57 страницBOS-M.Sc. Syllabus - 23-09-VBSPU 2022Susheel MishraОценок пока нет

- Biosurfactant 7Документ8 страницBiosurfactant 7Aranrie MosesОценок пока нет

- Alb BiosДокумент2 страницыAlb BiosrichardОценок пока нет

- Electrochimica Acta: Abrar Khan, Raja Arumugam Senthil, Junqing Pan, Sedahmed Osman, Yanzhi Sun, Xin ShuДокумент10 страницElectrochimica Acta: Abrar Khan, Raja Arumugam Senthil, Junqing Pan, Sedahmed Osman, Yanzhi Sun, Xin Shusalsa bilaОценок пока нет

- 2 Color in FoodДокумент44 страницы2 Color in FoodAbdul RahmanОценок пока нет

- Facility Inspection Report Nitric Acid PlantДокумент8 страницFacility Inspection Report Nitric Acid Plantlaoy aolОценок пока нет