Академический Документы

Профессиональный Документы

Культура Документы

18, Sukumar Roy Path, SAIL Co-Operative Housing Society, City Centre

Загружено:

nishantsukumaranИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

18, Sukumar Roy Path, SAIL Co-Operative Housing Society, City Centre

Загружено:

nishantsukumaranАвторское право:

Доступные форматы

NISHANT SUKUMARAN

18, Sukumar Roy Path, SAIL Co-operative Housing Society, City Centre, Durgapur-713216, Cell: +91-9332146612

E Mail: nishant.sukumaran@gmail.com

SUMMARY

I am a business graduate with over ten years of experience in Manufacturing and Business Process Improvement. Excellent

analytical skills with proficiency in Process Analysis & Control, Business strategy, Financial Analysis and a sound

knowledge of managing Operations in a large production unit . Keen to leverage the industry experience and business

learning’s in taking up strategic roles.

EDUCATION

Master in Business Administration (M. B. A), August 2009

HULT INTERNATIONAL BUSINESS SCHOOL, Boston/Dubai (In Dean’s list for academic excellence)

Six Sigma Green Belt (PMI accredited), August 2009

Bachelor of Technology (Manufacturing Engineering), May 1998

NATIONAL INSTITUTE OF FOUNDRY AND FORGE TECHNOLOGY, (A Govt. of India & U.N.D.P Project), Ranchi

University, India

PROFESSIONAL EXPERIENCE

INTERNSHIP - AXIOM TELECOM, DUBAI, UAE, July 2009 – August 2009

Undertook a month long consulting project with Axiom Telecom and delivered a mini business that aims at generating

additional revenue of Dirham’s 450 million in the next three years. The plan was in line with the strategic growth objective

of Axiom and was constructed after applying the tools and frameworks of innovation .The project was done in

collaboration with the IXL Centre for Innovation, USA.

INDUSTRY ANALYSIS (UAE): HR TRENDS IN RECESSIONARY TIMES, April2009- August 2009

Part of the core team that designed and conducted an Industry Analysis on HR trends in UAE after the onset of recession.

The survey was across 11 industry sectors and included interviews with CEO’s and top officials of 80+ companies in the

UAE. The survey is due to be published in leading Business Journals.

PRAXAIR INDIA LIMITED, BANGALORE, INDIA, www.praxair.com

Praxair is world’s leading industrial gas manufacturer. It’s a ‘fortune 300’ company.

Senior Application Specialist, Business Development (Steel and Allied sector) May 2008 – August 2008

I was responsible for the planning and implementation of the business strategies for the spread of gas business in Eastern

India. Identified new markets and implemented the latest R&D initiatives. Highly technology driven and target based

assignment.

• Studied and formed the feasibility report of oxygen enrichment of combustion air in a Reheating furnace,

Mini Blast furnaces and EAF’s.

• Negotiated a deal worth Rs.15 million for the pilot implementation of the Oxy Fuel Burners.

STEEL AUTHORITY OF INDIA LIMITED, DURGAPUR STEEL WORKS, INDIA, www.sail.co.in

India’s largest steel maker with six integrated Steel Mills. SAIL as a company produces 12 million tons of crude steel

annually. The Durgapur works is an integrated steel mill with annual capacity of 2 million tons of crude steel.

Deputy Manager (SMS-Operations) June2005 – April 2008

In my role as a shift manager, managed major facilities such as the Hot Metal Mixer, Ladle Placement Bay, V.A.D. unit

and the B.O.F. steel making facility (LD Converter).Planned and scheduled the production process to meet the target

production volumes and quality. Initiated and guided process improvement initiatives in the shop floor. I supervised forty

workmen in a plant with a highly unionized and aggressive labor force.

• Achieved the second best production figures in a shift (22 heats) in the history of the B.O.F. shop in the

Durgapur works.

• Identified as a leading young manager and sent to the Port Talbot mill of M/s CORUS, U.K, to study the

finer aspects of steel plant management.

• Integrated the new Ladle Furnace with the Steel Melting Shop by conducting in-house trials and aligning

the staff for the change in technology and process.

• Part of the team to implement “Quality Circles” and 5 ‘S’ work place management system.

Assistant Manager of Operations Sep1998 – May 2005

I managed the maintenance and calibration of all the major hardware in the B.O.F. shop. I was in charge of a furnace

operation and its refractory maintenance. I performed thermodynamic and metallurgical calculations to run the

computerized model for furnace operation.

• Successfully complied with all the requirements of the ISO: 9001-2000 requirements with respect to

equipment maintenance schedule and its calibration.

• Vendor relationship management.

• Prepared the in-house training manuals for critical equipments and safety manual for visiting vocational

trainees

• Specialized in Steel making through the Basic Oxygen Steel – Continuous Casting steel making route.

AWARDS

Awarded certificate of honor by the Durgapur chapter of “Indian Institute Of Metals” for contributions in reducing the

nitrogen level in wheel grade steels manufactured in the Durgapur Steel Works

AFFILIATIONS AND SKILLS

Languages: English, Malayalam, Bengali and Hindi. Beginner in Arabic (Eton Language School)

Affiliations: West Bengal Science Forum and Hult International Business Strategy Club

Work Authorization: India

Вам также может понравиться

- Naukri HimanshuSukhralia (17y 0m)Документ3 страницыNaukri HimanshuSukhralia (17y 0m)Amit SinhaОценок пока нет

- Resume-Rahul Srivastava KGДокумент4 страницыResume-Rahul Srivastava KGrahul srivastavaОценок пока нет

- Naukri SANDEEPKUMAR (14y 0m)Документ2 страницыNaukri SANDEEPKUMAR (14y 0m)Amit SinhaОценок пока нет

- SUNFLAGДокумент56 страницSUNFLAGsandy maliОценок пока нет

- Abdulhabib Dhanani Mumbai 39.00 YrsДокумент5 страницAbdulhabib Dhanani Mumbai 39.00 YrsNoushad N HamsaОценок пока нет

- Vishwanath-Cv Latest 1Документ6 страницVishwanath-Cv Latest 1Gurpreet KaurОценок пока нет

- Aniket Kuwar: Semiconductor/ Ultra High Pure Fab. Utilities Expert (Gas Chemical)Документ4 страницыAniket Kuwar: Semiconductor/ Ultra High Pure Fab. Utilities Expert (Gas Chemical)aniketkuwar06Оценок пока нет

- Sip Project SailДокумент68 страницSip Project SailRavi Kant RajОценок пока нет

- Profile Summary: Key Impact AreasДокумент3 страницыProfile Summary: Key Impact AreasSUMIT JAIN0% (1)

- Ajay Tomar 4Документ3 страницыAjay Tomar 4Ajay TomarОценок пока нет

- Resume - Prakash Kumar - IED ManagerДокумент3 страницыResume - Prakash Kumar - IED ManagerSoundhara Pandian SamuvelОценок пока нет

- 01 VKT - 2012 April Version Aditiya Rev 1Документ4 страницы01 VKT - 2012 April Version Aditiya Rev 1Vinod Kumar TurkiОценок пока нет

- Shashi Dinanath Thakur..Документ4 страницыShashi Dinanath Thakur..Shashi ThakurОценок пока нет

- Vijay Pal: GB ProjectДокумент4 страницыVijay Pal: GB ProjectpalvjОценок пока нет

- Ajay TomarДокумент3 страницыAjay TomarAjay TomarОценок пока нет

- Mechanical Engineer: Mukesh Kumar NagarДокумент4 страницыMechanical Engineer: Mukesh Kumar NagarMukesh NagarОценок пока нет

- Umer CV - EditedДокумент4 страницыUmer CV - Editedعمر خیامОценок пока нет

- Ilt Cv. LatestДокумент8 страницIlt Cv. LatestrandelОценок пока нет

- Reliability EngineeringДокумент5 страницReliability Engineeringshivaprasadmvit100% (2)

- Tour Report BSRMДокумент57 страницTour Report BSRMGakiya SultanaОценок пока нет

- Resume - Michael GassiДокумент5 страницResume - Michael GassiJoshua BuckleyОценок пока нет

- Udhaya Kumar Chennai 12.04 YrsДокумент8 страницUdhaya Kumar Chennai 12.04 YrsAabid DiwanОценок пока нет

- Hridayeshwar Jha: Director, Projects-Since April 2016Документ4 страницыHridayeshwar Jha: Director, Projects-Since April 2016SOURAV SINGHОценок пока нет

- CV For Project Manager - EngineerДокумент4 страницыCV For Project Manager - EngineerShaikh IbrahimОценок пока нет

- Mark Knofler: Career OverviewДокумент2 страницыMark Knofler: Career OverviewknoflerОценок пока нет

- K V Sanil Mon Marketing Manager Resume....Документ3 страницыK V Sanil Mon Marketing Manager Resume....Sanil MonОценок пока нет

- ReportДокумент18 страницReportKrishna KKОценок пока нет

- KV Sanil Mon Marketing Resume.Документ3 страницыKV Sanil Mon Marketing Resume.Sanil MonОценок пока нет

- Project Report TietДокумент59 страницProject Report TietshrutiОценок пока нет

- CV Masoodk BDДокумент4 страницыCV Masoodk BDMasood KhanОценок пока нет

- Umer CV - UPDATED PROFILEДокумент2 страницыUmer CV - UPDATED PROFILEimranluqmanОценок пока нет

- Resume: Area: Functional Consultant / ERP Project CoordinatorДокумент4 страницыResume: Area: Functional Consultant / ERP Project CoordinatorVikas RawalОценок пока нет

- SAIL IISCO Marketing ProjectДокумент74 страницыSAIL IISCO Marketing ProjectUjjal Banerjee80% (5)

- SM - Presentation Viva NamitaДокумент33 страницыSM - Presentation Viva NamitaMayur ApparelsОценок пока нет

- 1 CV Gayan Rantharu AttanayakeДокумент6 страниц1 CV Gayan Rantharu AttanayakeRantharu AttanayakeОценок пока нет

- CV Gayan Rantharu Attanayake-Application For The Post of Project ManagerДокумент6 страницCV Gayan Rantharu Attanayake-Application For The Post of Project ManagerRantharu AttanayakeОценок пока нет

- Gayan Rantharu Attanayake: ObjectivesДокумент6 страницGayan Rantharu Attanayake: ObjectivesRantharu AttanayakeОценок пока нет

- Nantha CVДокумент3 страницыNantha CVnantha kumarОценок пока нет

- Project Report: Master of Business AdministrationДокумент99 страницProject Report: Master of Business Administrationkamal67543Оценок пока нет

- CV Kareem Mohamed 0623deДокумент2 страницыCV Kareem Mohamed 0623deKareem MohamedОценок пока нет

- Ratio Analysis of Appu International LudhianaДокумент47 страницRatio Analysis of Appu International LudhianaAjay KumarОценок пока нет

- Vino PDFДокумент4 страницыVino PDFvinothОценок пока нет

- ObjectiveДокумент6 страницObjectiveElencheliyan PandeeyanОценок пока нет

- CV - Sakthi.pДокумент3 страницыCV - Sakthi.pVenkatesh KumarОценок пока нет

- Study On Training & Development at Jindal Saw LTD by NonameДокумент63 страницыStudy On Training & Development at Jindal Saw LTD by NonameAbhi Ag100% (1)

- SULAIMAN Engineering Design ProfessionalДокумент2 страницыSULAIMAN Engineering Design ProfessionalSulaiman Dawood BarryОценок пока нет

- HK CV VBДокумент5 страницHK CV VBVijayBharati100% (2)

- 8th To REST FinalДокумент31 страница8th To REST FinalSonalisurveОценок пока нет

- 01 VKT - 2012 JanДокумент6 страниц01 VKT - 2012 JanVinod Kumar TurkiОценок пока нет

- Anshul Sharma.Документ3 страницыAnshul Sharma.Rajesh SharmaОценок пока нет

- Re Sum en 2007 UploadДокумент3 страницыRe Sum en 2007 Uploadapi-3697640Оценок пока нет

- CV MasoodKДокумент4 страницыCV MasoodKMasood KhanОценок пока нет

- Deepak ResumeДокумент4 страницыDeepak ResumeDeepak SinghОценок пока нет

- Rajiv Singal: Plaksa Solutions Pvt. Ltd.Документ2 страницыRajiv Singal: Plaksa Solutions Pvt. Ltd.Rajiv Singal33% (3)

- Shashi Dinanath Thakur Resume (MBA + B.E.Mechanical)Документ4 страницыShashi Dinanath Thakur Resume (MBA + B.E.Mechanical)shashithkr5489100% (1)

- Aniket Kuwar: Semiconductor Fab Utilities Expert (Gas Chemical)Документ5 страницAniket Kuwar: Semiconductor Fab Utilities Expert (Gas Chemical)aniketkuwar06Оценок пока нет

- RINLДокумент21 страницаRINLSarbari GangulyОценок пока нет

- ResumeДокумент5 страницResumeSuman DasОценок пока нет

- Skills: Industrial/Mechanical EngineerДокумент4 страницыSkills: Industrial/Mechanical EngineerBivek SapkotaОценок пока нет

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessОт EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessОценок пока нет

- Compressed Air HSEДокумент50 страницCompressed Air HSEOdalis ToscanoОценок пока нет

- David L Ellis Resume 2007Документ2 страницыDavid L Ellis Resume 2007dleoelОценок пока нет

- Mozambique Power CrisisДокумент34 страницыMozambique Power CrisisYouzhnyОценок пока нет

- Crusher Guide Ch440Документ5 страницCrusher Guide Ch440biro_4100% (1)

- Changes in ISO 50001 2018-StandardДокумент5 страницChanges in ISO 50001 2018-Standardnishi vats100% (1)

- Tishman Speyer RFP ResponseДокумент49 страницTishman Speyer RFP ResponseNat LevyОценок пока нет

- Testing of InsulationДокумент27 страницTesting of Insulationகவி பாரதி முத்துசாமிОценок пока нет

- Centrifugal Pump (Various Air Handling Methods)Документ21 страницаCentrifugal Pump (Various Air Handling Methods)karthick_mariner92Оценок пока нет

- The Bombay Electricity Duty Rules, 1962Документ24 страницыThe Bombay Electricity Duty Rules, 1962Amey Patwardhan100% (1)

- O9 Orcun KokturkДокумент15 страницO9 Orcun KokturkRajKumar KalimuthuОценок пока нет

- Building Blocks of PINCH Technology-Lect 8 PDFДокумент8 страницBuilding Blocks of PINCH Technology-Lect 8 PDFSukanta K. DashОценок пока нет

- 2015-5-15 ASA Best Practice ESDДокумент12 страниц2015-5-15 ASA Best Practice ESDPIYUSH100% (1)

- Falling Film Evaporators in The Food IndustryДокумент4 страницыFalling Film Evaporators in The Food IndustryAgung SiswahyuОценок пока нет

- Technologies Palm OilДокумент2 страницыTechnologies Palm OilediasianagriОценок пока нет

- Earthing SystemДокумент9 страницEarthing SystemmaheshshettymteducarОценок пока нет

- FGD InstallationsДокумент6 страницFGD InstallationsdsoОценок пока нет

- 2014 SPI CatalogДокумент36 страниц2014 SPI Catalog805 CreativeОценок пока нет

- Kseb Ad Report 11-12Документ110 страницKseb Ad Report 11-12jahabarsathickОценок пока нет

- PLC - Oil and Gas Regulation in Brazil - Overview PDFДокумент34 страницыPLC - Oil and Gas Regulation in Brazil - Overview PDFLegend AnbuОценок пока нет

- Bharat Petroleum Corporation LimitedДокумент17 страницBharat Petroleum Corporation LimitedBhakti KaliaОценок пока нет

- Flare Gas Recovery & Zero Flare SolutionsДокумент16 страницFlare Gas Recovery & Zero Flare SolutionsEddie TaiОценок пока нет

- Demand Factor-Diversity Factor-Utilization Factor-Load FactorДокумент11 страницDemand Factor-Diversity Factor-Utilization Factor-Load FactorPurple NippleОценок пока нет

- PICV-Fig1932 IOM-Hatts PDFДокумент4 страницыPICV-Fig1932 IOM-Hatts PDFSujit RajanОценок пока нет

- Spohn FerencДокумент29 страницSpohn Ferencemy1188Оценок пока нет

- The Basics of Connecting LoadsДокумент1 страницаThe Basics of Connecting LoadsrajuanthatiОценок пока нет

- Sustainable Finance Final Report enДокумент100 страницSustainable Finance Final Report enmanopp16Оценок пока нет

- Genius SW-HF 5.1 5000.rarДокумент26 страницGenius SW-HF 5.1 5000.rarzzorox100% (3)

- Ion Plasma NitridingДокумент8 страницIon Plasma NitridingAdvanced Nitriding SolutionsОценок пока нет

- Request Letter For Acceptance Dispatched RTU and Associated ItemsДокумент2 страницыRequest Letter For Acceptance Dispatched RTU and Associated ItemsGauravKumarОценок пока нет

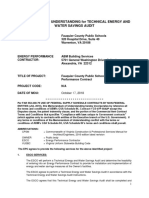

- FINAL ABM and Fauquier County Public Schools Energy Study AgreementДокумент14 страницFINAL ABM and Fauquier County Public Schools Energy Study AgreementFauquier NowОценок пока нет