Академический Документы

Профессиональный Документы

Культура Документы

5988 9343en

Загружено:

Thanh Thanh Hai Le0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров6 страницInstrument Control in Pharmaceutical Laboratories

Оригинальное название

5988-9343EN

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документInstrument Control in Pharmaceutical Laboratories

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров6 страниц5988 9343en

Загружено:

Thanh Thanh Hai LeInstrument Control in Pharmaceutical Laboratories

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

I

n 1997, the US Food and Drug Administration

(FDA) issued a regulation that details criteria that

must be met for the acceptance of electronic records,

electronic signatures and handwritten signatures.

1

This regulation, entitled Rule 21 CFR Part 11,

permits electronic records to be used in place of

paper records and handwritten signatures. The rule

applies to all industry segments regulated by FDA

that must adhere to good laboratory practice (GLP),

good clinical practice (GCP) and current good

manufacturing practice (cGMP).

The new regulation requires analytical laborato-

ries to demonstrate the following:

use of validated existing and new equipment and

computer systems

secure retention of electronic records to instantly

reconstruct the analysis

user-independent, computer-generated

time-stamped audit trails

system and data security, data integrity and

confidentiality through limited authorized

system access

use of secure electronic signatures for closed and

open systems

use of digital signatures for open systems.

Although the rule is well documented, information

technology (IT) professionals and analysts in labora-

tories are often unsure about its implementation.

The biggest problem is to find a compromise

between doing too much and satisfying minimum

requirements.

Frequently asked questions

Exactly which records should be retained,

particularly when data have to be re-evaluated

several times before they can finally be accepted?

How should computer-generated audit trails be

implemented; what should be tracked and after

To comply with the US Food and Drug Administrations 21 CFR Part 11 (and the

draft guidance published on 20 February 2003), reliable, robust and validatable

communication between computers and analytical instruments has become

increasingly important. This article demonstrates that monitoring and feedback

mechanisms for instrument control and communication can drastically simplify

compliance with Part 11, because they make the generation of electronic raw data

records trustworthy and reliable. It also evaluates typical communication protocols

used, and lists selection criteria for instrument control and data acquisition systems.

Instrument Control in

Pharmaceutical Laboratories

Compliance with 21 CFR Part 11

and the New Draft Guidance

Wolfgang Winter

is worldwide product manager,

networked data systems.

Tel. +49 7243 602 454

Fax +49 7243 602 501

wolfgang_winter@agilent.com

Ludwig Huber

is worldwide product

marketing manager, HPLC.

Tel. +49 7243 602 209

Fax +49 7243 602 501

ludwig_huber@agilent.com

Agilent Technologies GmbH,

PO Box 1280,

D-76337 Waldbronn, Germany.

a

r

t

w

o

r

k

W

a

r

r

e

n

J

o

n

e

s

o

r

i

g

i

n

a

l

i

m

a

g

e

s

P

h

o

t

o

d

i

s

c

which entries; and does the user of

the system have to confirm the

entries as being logged?

How should signatures be linked

with the electronic records?

Is computerized instrument

control in the scope of Part 11?

What can be done with existing

instruments that lack the

appropriate functionality?

How can you ensure that long-

term archiving allows the

possibility to replay data after

10 or more years?

In 1999, FDA published compliance

policy guide 7153.17

2

and issued a

total of five draft guidance docu-

ments relating to Part 11, which have

been vividly discussed and com-

mented on in the affected industries.

However, on 20 February 2003, FDA

published a new guidance on Scope

and Applications (www.fda.gov/

OHRMS/DOCKETS/98fr/03d-0060-

gdl0001.PDF and www.labcompli-

ance.com/conferences/s991.htm) and

withdrew all other draft guidances.

The new draft guidance states FDAs

intention of interpreting Part 11

more closely in line with its cGMP

initiative, focussing on risk-based

inspections. According to the new

draft guidance, Part 11 will continue

to apply to records that are required

by the predicate rules, and which are

maintained in electronic format in

addition to paper, and are relied on

to perform regulated activities.

Typically, this is the case for records

managed by chromatography data

systems used in analytical laborato-

ries in industries regulated by FDA.

The authors will discuss the impact

of the new draft guidance in more

detail in the April 2003 issue of

Pharmaceutical Technology Europe.

Additionally, other associations in

the industry have also acted to

develop guidelines on how to imple-

ment Part 11. For example, the

Parenteral Drug Association (PDA)

has formed a task force on Part 11

(PDAs Good Electronic Records

Management [GERM]) and a special

interest group of the Good

Automated Manufacturing Practice

(GAMP) Forum has released a draft

paper.

3

FDA also plans to release

more guidance documents; Part 11

itself just defines the framework

now that the industry is working on

concrete implementation plans to

comply, many practical system and

process issue arise. Ongoing updates

are important and can be found at

www.labcompliance.com under

e-signatures (21 CFR 11).

Who must comply with 21 CFR?

Huber, Winter and Nickel have

published a series of articles on

the implementation of Part 11 in

analytical laboratories.

49

These

articles demonstrate how access to

the system and to critical system

functions could be limited to autho-

rized personnel. They also explain

how the integrity of data can be

assured at the time of data analysis

and evaluation and how creation,

modification and deletion of records

are logged in a computer-generated

audit trail. They also discuss how

data can be archived and accurately

retrieved after several years. These

articles focus mainly on compliance

and management of data generated

by analytical data systems.

A frequently asked question is

should computers that just control

analytical instruments, but do not

acquire data, comply with Part 11? If

FDA ever looked at or asked for

paper printouts of the parameters,

the answer is simply, yes. Without

proper documentation of the instru-

ment control parameters, it becomes

difficult to prove that a given result

was generated according to the

appropriate procedure or mono-

graph. If a computer was used for this

procedure, and if, at any time, the

control parameters are stored on a

durable storage device (typically the

computers hard disk or a storage card

for the instrument), Part 11 applies.

In this article, we will discuss levels

of instrument control and data acquisi-

tion; electronic records associated with

instrument control; tracking of instru-

ment characteristics, events and errors

in an electronic logbook; and cross-

manufacturer instrument control.

Levels of instrument control

Analytical laboratories typically

operate a diversified installed base of

instruments, often from a variety of

manufacturers. As most modern

instruments need to be controlled by

a computer system, the instrument

control parameters have to be

treated in the same way as the rest of

the metadata.

Instrument control of a device can

be implemented at varying levels of

sophistication and complexity

(Table I). Often, instrument para-

meters have to be set manually using

the instruments own panel and key-

board, with the signal being recorded

by an analoguedigital converter

(Level 1). This is often the approach

chosen to integrate an instrument

into a system from a different manu-

facturer. In these cases, it is typically

impossible to obtain a printout of the

instrument settings that are used

during an analysis. Analysts are

forced to document instrument

parameters manually. Furthermore,

analoguedigital converters do not

always support BCD (binary-coded

decimal) or barcode input (from an

autosampler) that can be used to

positively correlate an injection with

a given sample using the sample

name or at least a vial number.

Many systems implement a

rudimentary level of instrument con-

trol (Level 2). This is often obtained

through reverse-engineering of the

communication protocols for

another manufacturers instrument,

and supports the basic parameters of

an instrument, such as solvent com-

position, flow, oven temperature and

detector wavelength. If the manufac-

turer of the instrument did not

disclose the control codes, it may be

much more difficult to obtain an

officially supported (that is, approved

and guaranteed) solution with

appropriate validation documents

from the supplier. Also, additional

effort should be planned to perform

qualification and other validation

tasks on such a system. As the

manufacturer of the original

instrument may be neither aware

nor responsible for the implementa-

tion of the communication, instru-

ment firmware updates may result

in non-functional communication to

the data system. The implementa-

tion of error handling and logging is

Although the rule is well documented,

information technology (IT)

professionals and analysts in

laboratories are often unsure about its

implementation.

typically weak in this category.

When selecting a system that is

supposed to control instrumentation

from other manufacturers, it is

important to verify that the control

codes were obtained from the

manufacturer of the instrument and

not reverse-engineered.

In most cases, manufacturers

implement full instrument control

(Level 3) for their own systems. This

facilitates keeping a complete set of

raw and metadata together with the

proper documentation. In this

category, one can also expect quite

sophisticated error reporting and

handling, which makes it easier to

verify that an analysis was indeed

completed without technical failures

or to diagnose an error.

Some manufacturers have

implemented an additional level of

instrument capabilities that can be

controlled from within the data

system. These functions are the basis

for the execution of detailed and

sophisticated instrument diagnostics

as well as other service functions. This

includes provisions for preventive

maintenance and early maintenance

feedback (EMF), a technique

initially used in the aeronautics

industry (to alert technical personnel

to perform due maintenance jobs

proactively before something fails),

which is now used in the pharma-

ceutical and other industries.

More importantly, systems

implemented at this level provide

sophisticated support for tracking

instruments or module serial num-

bers and firmware revisions. This

information is not only convenient

and important for inventory tracking

of validated equipment, but can also

be used to verify some of the device

check functions required by Part 11.

In Level 4 instrument control

implementations, all communication

(including commands and data

transfer) is performed using a hand-

shake. A handshake basically means

that the recipient of a data record

must actively acknowledge receipt of

the record by notifying the sender.

For example, the controller sends a

command such as START to the

device, the device interprets the

command and acknowledges OK,

START. If, for any reason, the

device is not able to execute the

command, it sends a negative receipt

such as NOT OK, NO START.

This approach clearly avoids

situations in which the controller is

unaware that instructions sent to the

device have not been executed.

Relevance of communication

protocols for data integrity

Below is a discussion of widely used

instrument communication protocols

and their strengths and weaknesses in

terms of data integrity and traceability

according to 21 CFR Part 11. We will

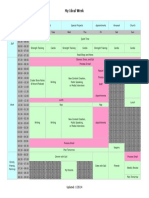

Level Parameters Impact on Part 11

Table I Levels of instrument control.

Level 1 Start/stop (no digital instrument control and Metadata: instrument parameters must be

Parameter set-up on the instrument, data acquisition). documented manually.

synchronization using external contacts Device checks: positive ID of sample vials

to start and stop an analysis, analogue may not be available (using barcodes or

signal acquisition. BCD input).

Level 2 Basic instrument parameter, for example, Audit trail: typically no instrument error

Rudimentary digital instrument control flow rate of an HPLC (high performance information available requires additional

for example, through LAN (local area liquid chromatography) pump or the inspections to determine the validity of

network), RS 232, GPIB. wavelength of an HPLC detector. the measurements.

Validation: could be more difficult to support

if reverse-engineered.

Level 3 All control parameters, including injector Audit trail and metadata: full documentation

Full digital instrument control for programme, method sequencing. of instrument parameters used to

example, through LAN, RS 232, GPIB. Wavelength calibration. generate a result.

Error recording.

Level 4 Handshake protocol between controller and Advanced error prevention and detection.

Advanced functions. device (active acknowledgement of correct Validation: facilitates the execution of

receipt). instrument qualification and preventive

Self diagnostics and early maintenance maintenance.

feedback (EMF). Qualifies for device checks required by the

Automatic tracking of serial and product rule.

numbers, electronic instrument logbook. Guaranteed and reproducible execution

Supports advanced tagging of components, of data acquisition independent of

for example column ID tags. current data system load (facilitates the

Instrument performs real-time data qualification of data integrity and traceability).

acquisition and synchronization

independently of the computer.

use GPIB (general purpose interface

bus) as an example, which is widely

used as the IEEE 488 standard.

Contrasting examples are

networking protocols, such as the

well-known and ubiquitous transmis-

sion control protocol/Internet pro-

tocol (TCP/IP) that is used for any

intranet or Internet communication.

This discussion cannot, and is not

intended to be, a detailed description

of the technology. A wide range of

publications covers these aspects

accurately and in greater technical

detail.

1012

Instrument communication

via GPIB

GPIB is a parallel communication

interface that can connect up to

15 devices on a common bus. All

communication, including commands

and data, is performed using a hard-

ware handshake for every byte. All

devices connected to the bus

participate in this handshake.

As a consequence, every device on

the bus can influence the ongoing

communication and cause severe

communication problems such as bus

hang-ups or data corruption. These

problems may be caused by a

firmware error or a hardware failure

in one of the participating devices

(for example, the printer). But also

switching a seemingly idle GPIB

device on or off during ongoing com-

munication may generate a problem.

Even though the electrical specifica-

tions of GPIB do not prohibit these

scenarios, the combination of chip-

set implementation, the firmware

and the application software often

lead to that failure. (See Table II for

a summary of GPIB characteristics.)

Instrument communication via

LAN (TCP/IP)

TCP/IP, often described as the

language of the Internet, enables

devices to exchange information over

a network (Table III). The key idea is

to break information into pieces or

packets. The packets are specifi-

cally structured to allow error detec-

tion and error correction by using

redundancy mechanisms such as

checksums (this is how they differ

from the majority of GPIB imple-

mentations described above). A

checksum is, in principle, a running

total of all transmitted bits that are

attached to the packet and it is used

by the recipient to back-calculate

and compare with the original

checksum provided by the sender. If

a mismatch is detected, retransmis-

sion is requested. This technique

guarantees an error-free data trans-

port and represents an excellent

basis for the implementation of

device checks and system

checks mandated by 21 CFR

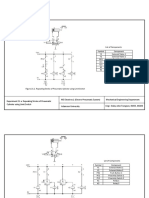

Part 11. Figure 1 illustrates a typical

configuration of networked instru-

ments in a distributed, client/server

environment.

Communication in a TCP/IP

environment is, by definition, highly

dynamic. Addition or removal of idle

devices in the network does not

affect ongoing communication

between the other participants. In

contrast to most GPIB implementa-

tions, TCP/IP supports safety proce-

dures requiring instrumentation that

is not in use to be switched off

without the risk of data loss.

Recommendations for selecting

instrument control and data

acquisition systems

1. The level of control of instru-

mentation used in the laboratory

must be assessed.

2. If instrument communication uses

proprietary interfaces, check for

adherence to your internal IT

support guidelines.

3. Find out what levels of control are

offered by hardware manufacturers.

4. For instrumentation not directly

controlled by the data system

(Level 1), plan the procedures

necessary to document

instrument parameters.

5. For instrumentation claimed to be

controlled, determine whether the

Strength Weakness Recommendation

Table II Characteristics of GPIB.

Fast enough for high-speed data Limited number of devices on the same bus (15). N/A

acquisition (for example, spectral data Restrictions on total data rate on the bus.

from diode array or mass-selective Distance limitations (maximum of 2 m

detectors). between devices).

GPIB permits bidirectional, addressed The standard does not define power on/off Avoid powering down idle GPIB devices

information to be sent (allows for the of idle devices during ongoing communication. while other devices are acquiring data, to

implementation of device checks As all devices must electrically participate in minimize the risk of data loss or data

according to 21 CFR Part 11). the handshake, switching a device off during corruption.

communication may hang up the entire

communication system. This can lead to data loss.

N/A Remote monitoring of instrument functions Requires separate operational qualification

requires a computer (instrument controller) of the instrument controller.

that functions as an information broker

next to the instrument.

N/A Requires proprietary GPIB interfaces in the Subject to (re)qualification particularly

instruments as well as the computers. if PC models and operating systems change.

Verify compatibility with support

guidelines from your IT support group.

communication protocols were

obtained with approval and

support of the instrument

manufacturer.

6. For instruments for which

communication protocols were

apparently developed by reverse

engineering, plan additional

qualification and acceptance tests

to obtain a high degree of

assurance that control and

communication are accurate

and reliable.

7. Adapt internal procedures to take

advantage of the additional

diagnostics, maintenance and

tracking functions to validate,

maintain and document the

system and the measurements

obtained with it.

8. Define test cases for the boundary

conditions.

Does the system reliably

Strength Weakness Recommendation

Table III Characteristics of TCP/IP.

Suited to high-speed data acquisition (for example, spectral data N/A Proactively plan network infrastructure and segmentation,

from diode array or mass-selective detectors). particularly in large labs with many instruments.

Inherent mechanisms for error detection and correction N/A Reliable instrument communication should be verified

(an important measure for data integrity and the basis for during system qualification.

device checks according to 21 CFR Part 11). Turn off idle instruments not in use.

Networked instruments help eliminate PCs from the lab bench. N/A Proactively plan lab layout and where computers are

Remote status information is available directly from the required (and where they are superfluous!) to support

instrument and does not necessarily require an extra the workflow.

instrument controller (computer) as information broker.

Allows the use of cheaper, widely used, standard N/A Ask for a list of recommended models from your IT

interfaces (such as standard Ethernet LAN cards for the PC). support group.

control. We have defined the different

levels of instrument control capabili-

ties that can exist in modern analytical

data systems. Level 4 instrument con-

trol not only supports an instruments

command set, but uses an advanced

control layer with handshake

protocols between software and

connected instruments. This level

offers advanced functions that allow

automatic tracking of instrument

identification or configuration

information, and it is a prerequisite

for the implementation of EMF.

Electronic records generated by an

instrument are only reliable and

trustworthy if the communication

between instrument and the system

controller is reliable and trustworthy.

Level 4 instrument control is an

adequate mechanism to ensure this.

References

1. Code of Federal Regulations, Title 21,

Food and Drugs, Part 11 Electronic

Records; Electronic Signatures; Final Rule,

Federal Register 62(54), 1342913466.

2. United States FDA, Compliance Policy

Guide: 21 CFR Part 11; Electronic

Records, Electronic Signatures

(CPG 7153.17).

3. Good Automated Manufacturing Practice

(GAMP) Special Interest Group,

Complying with 21 CFR Part 11:

Electronic Records and Signatures, Final

Draft, September 2000. Available from

the GAMP website (www.gamp.org).

4. L. Huber, Implementing 21 CFR in

Analytical Laboratories, Part 1: Overview

and Requirements, BioPharm 12(11),

2834 (1999).

synchronize all devices required

for an analysis?

Could a contact closure problem

lead to a situation where it goes

unnoticed that a device such as a

detector did not start?

If the instrument has a local user

interface, does it track parameter

changes performed at the local

interface while data are being

acquired by the computer?

Alternatively, is the local interface

locked while data are being

acquired?

Does the system quickly detect

power failures of a connected

device or are data lost until a

time-out situation occurs?

Conclusion

Part 11 enforcement practices have

drastically emphasized the importance

of reliable and traceable instrument

Server

Remote access

Office PC

Office PC

Figure 1 Configuration of networked instruments in a distributed, client/server environment.

5. W. Winter and L. Huber, Implementing

21 CFR Part 11 in Analytical Laboratories,

Part 2: Security Aspects for Systems and

Applications, BioPharm 13(1), 4450

(2000).

6. W. Winter and L. Huber, Implementing 21

CFR Part 11 in Analytical Laboratories,

Part 3: Ensuring Data Integrity in Electronic

Signatures,BioPharm 13(3), 4549 (2000).

7. L. Huber and W. Winter, Implementing

21 CFR Part 11 in Analytical Laboratories,

Part 4: Data Migration and Long-Term

Archiving for Ready Retrieval, BioPharm

13(6), 5864 (2000).

8. W. Winter and L. Huber, Implementing

21 CFR Part 11 in Analytical

Laboratories, Part 6: Biometric

Identification: Limits and Possibilities, in

Implementing 21 CFR Part 11 in

Analytical Laboratories (2000) pp 4043,

a supplement to BioPharm.

9. C. Nickel, W. Winter and L. Huber,

Implementing 21 CFR Part 11 in

Analytical Laboratories, Part 6: Making

Legacy Systems Compliant, in

Implementing 21 CFR Part 11 in

Analytical Laboratories (2000) pp 4447,

a supplement to BioPharm.

10. W. Winter, Dynamic Interprocess

Communication between a Spectro-

photometer and a Spreadsheet, Faculty

for Physical Electronics, University of

Karlsruhe (TH), Germany (1989).

11. M.F. Arnett et al., Understanding Basic

Networking Concepts, in Inside TCP/IP

(New Riders Publishing, Indianapolis,

USA, 1994, ISBN 1-56205-354-X)

pp 5154.

12. ANSI/IEEE Std 488.1-1987 revision of

ANSI/IEEE Std 488-1978: An American

National Standard IEEE Standard

Digital Interface for Programmable

Instrumentation.

Article Reprinted from the

21CFR Part 11 supplement

(March 2003) issue of:

Article Reprint: 0548

Agilent Publication Number: 5988-9343 EN

Вам также может понравиться

- A 177 e Records Practice PDFДокумент8 страницA 177 e Records Practice PDFlastrajОценок пока нет

- Mechanical Vibrations and Condition MonitoringОт EverandMechanical Vibrations and Condition MonitoringРейтинг: 5 из 5 звезд5/5 (1)

- Data IntegrityДокумент29 страницData IntegrityAnonymous wJfnifXkОценок пока нет

- Overview CompilationДокумент12 страницOverview CompilationSanjeevSharmaОценок пока нет

- 3BSE077527 en FDA 21 CFR Part 11 Electronic Records and Signatures - Solutions For The Life Sciences IndustryДокумент12 страниц3BSE077527 en FDA 21 CFR Part 11 Electronic Records and Signatures - Solutions For The Life Sciences IndustryNeoОценок пока нет

- 21 CFR 11: Regulations for electronic recordsДокумент61 страница21 CFR 11: Regulations for electronic recordsPoornaBasuriОценок пока нет

- Abb Part11Документ12 страницAbb Part11ruggy_646037Оценок пока нет

- Retrospective Validation of A CDS Feb 99 PDFДокумент9 страницRetrospective Validation of A CDS Feb 99 PDFImran AsgharОценок пока нет

- Risk-Based Approach To 21 CFR Part 11 (Part 1) : Definition of Electronic RecordДокумент4 страницыRisk-Based Approach To 21 CFR Part 11 (Part 1) : Definition of Electronic Recordrouss1906Оценок пока нет

- Pharmaceutical ValidationДокумент28 страницPharmaceutical ValidationMohamed KamalОценок пока нет

- Title 21 CFR Part 11Документ12 страницTitle 21 CFR Part 11shivani172Оценок пока нет

- Validation of Computerised Systems Core DocumentДокумент10 страницValidation of Computerised Systems Core DocumentLunn_scribd100% (1)

- Shimatzu - Class VP - FDA-21Документ7 страницShimatzu - Class VP - FDA-21umare_sauaruОценок пока нет

- Eres Wincc v13 enДокумент23 страницыEres Wincc v13 enFernando Jaime Alonso MartínezОценок пока нет

- FDA Computerized Systems in Drug EstablishmentsДокумент25 страницFDA Computerized Systems in Drug Establishmentsmariel mendozaОценок пока нет

- Computer System Valiadation ControllingДокумент77 страницComputer System Valiadation ControllingArdieОценок пока нет

- Annex 11Документ5 страницAnnex 11antonygamalpharmaОценок пока нет

- Siemens WinCC v13 CFR 21 Part 11Документ22 страницыSiemens WinCC v13 CFR 21 Part 11zombiecorpОценок пока нет

- MHRA GXP Data Integrity ConsultationДокумент14 страницMHRA GXP Data Integrity ConsultationBhagyesh Kulakrni100% (1)

- 21 CFR Part 11 Industry Overview Ready For An FDA InspectionДокумент6 страниц21 CFR Part 11 Industry Overview Ready For An FDA InspectionSergio OviedoОценок пока нет

- Computer System Validation (CSV) : Comparisons Between (GMP VS CGMP, GLP VS GCP, 21 CFR PART 11 VS EU 11)Документ4 страницыComputer System Validation (CSV) : Comparisons Between (GMP VS CGMP, GLP VS GCP, 21 CFR PART 11 VS EU 11)T 1Оценок пока нет

- 21 CFR Part 11 Compliance Assessment: An Oracle White Paper January 2009Документ18 страниц21 CFR Part 11 Compliance Assessment: An Oracle White Paper January 2009Massimiliano CamilloОценок пока нет

- 21 CFR Part 11 ComplianceДокумент2 страницы21 CFR Part 11 Compliancepham hoang quanОценок пока нет

- Protect system output and privacyДокумент31 страницаProtect system output and privacyLynssej BarbonОценок пока нет

- 21 CFR 11 Compliance - WatersДокумент12 страниц21 CFR 11 Compliance - WatersNitin KashyapОценок пока нет

- A 199 Acc Part11 White Paper VendorДокумент10 страницA 199 Acc Part11 White Paper VendorlastrajОценок пока нет

- Validation+Computerised+Systems +version+2-0 Dec 2007Документ19 страницValidation+Computerised+Systems +version+2-0 Dec 2007Tan MakОценок пока нет

- Computer System ValidationДокумент24 страницыComputer System ValidationMin ThuraОценок пока нет

- Godfrey - Mark Manual of Petroleum Measurement Standards Chapter 21 EFM Final PDFДокумент20 страницGodfrey - Mark Manual of Petroleum Measurement Standards Chapter 21 EFM Final PDFIman AkbariОценок пока нет

- 59801305Документ5 страниц59801305AnjamSoodОценок пока нет

- Anomaly Checks For Relay SettingsДокумент20 страницAnomaly Checks For Relay Settingsbdsrl0% (1)

- Title 21 CFR Part 11: ContentДокумент4 страницыTitle 21 CFR Part 11: Contentmahadev jadhavОценок пока нет

- Handbook For V&V of Digital SystemsДокумент282 страницыHandbook For V&V of Digital Systemsbruno_gallo_3Оценок пока нет

- Composite Batch Report and 21 CFR 11: Chris Morse Honeywell Process Solutions Bracknell UK PhoneДокумент8 страницComposite Batch Report and 21 CFR 11: Chris Morse Honeywell Process Solutions Bracknell UK PhoneMarc OlivéОценок пока нет

- Computer System ValidationДокумент2 страницыComputer System ValidationVishal VakilОценок пока нет

- Chromatography Data Systems IV: Managing Change in A Changing WorldДокумент8 страницChromatography Data Systems IV: Managing Change in A Changing Worldnaren23Оценок пока нет

- EUROLAB Software GuidanceДокумент31 страницаEUROLAB Software GuidanceDalia Margarita Gallaga TownsОценок пока нет

- Alarm Management Best Practices for Regulated IndustriesДокумент6 страницAlarm Management Best Practices for Regulated IndustriesmlwillerОценок пока нет

- PICS - Guidance On GP For SC in GXP EnvironmentsДокумент54 страницыPICS - Guidance On GP For SC in GXP EnvironmentsTrilok Chander ManthaОценок пока нет

- 9.B Regulatory AspectsДокумент6 страниц9.B Regulatory AspectsGirgis AiadОценок пока нет

- 2012 Mar MaintainingДокумент5 страниц2012 Mar MaintainingJoãoCarlosMidonОценок пока нет

- Guidelines For Immunoassay Data Processing1: Dudley, 2 P. P. Eklns, 3 D. J. and R. P. C. Rodgers6Документ8 страницGuidelines For Immunoassay Data Processing1: Dudley, 2 P. P. Eklns, 3 D. J. and R. P. C. Rodgers6Cristina PatrinichiОценок пока нет

- Computer System Validation in Pharmaceutical IndustryДокумент9 страницComputer System Validation in Pharmaceutical IndustryUmair HussainОценок пока нет

- The Effect of Information Technology On The Audit Function: Answers To Review QuestionsДокумент4 страницыThe Effect of Information Technology On The Audit Function: Answers To Review QuestionsroxanneОценок пока нет

- 21 CFR Part 11 You Should Know These RequirementsДокумент6 страниц21 CFR Part 11 You Should Know These RequirementsRegulatonomous OpenОценок пока нет

- IVT Network - Data Integrity - FDA and Global Regulatory Guidance - 2014-11-03Документ6 страницIVT Network - Data Integrity - FDA and Global Regulatory Guidance - 2014-11-03depardieu1973Оценок пока нет

- EurolabДокумент31 страницаEurolabtecsen100% (1)

- Chapter 8 - Solution ManualДокумент17 страницChapter 8 - Solution ManualjuanОценок пока нет

- VALIDATION OF COMPUTERSДокумент4 страницыVALIDATION OF COMPUTERSBrian WilliamsОценок пока нет

- CliniIndia: Clinical Data ManagementДокумент5 страницCliniIndia: Clinical Data ManagementAnuj TripathiОценок пока нет

- Chapter 5Документ21 страницаChapter 5tewodrosbayisaОценок пока нет

- Computer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Документ12 страницComputer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Nitin KashyapОценок пока нет

- 1.5 Historical Data Storage and Evaluation: G. C. BuckbeeДокумент12 страниц1.5 Historical Data Storage and Evaluation: G. C. BuckbeeNigo VillanОценок пока нет

- FDA Expectation On Software ValidationДокумент40 страницFDA Expectation On Software ValidationHong HuangОценок пока нет

- Hot Gas Path Management Control Level (Part 27)Документ4 страницыHot Gas Path Management Control Level (Part 27)Gasser ElfahamОценок пока нет

- Computer Validation SystemДокумент31 страницаComputer Validation SystemSourav Ghosh DastidarОценок пока нет

- Chapter 28 - Answer PDFДокумент11 страницChapter 28 - Answer PDFjhienellОценок пока нет

- Computer in Pharm. Technology 97Документ9 страницComputer in Pharm. Technology 97Ram C DhakarОценок пока нет

- A Deep Learning Approach For Fusing Sensor Data From Screw CompressorsДокумент18 страницA Deep Learning Approach For Fusing Sensor Data From Screw CompressorsNawal DaoudiОценок пока нет

- An Economical and Eco-Friendly Industrial ProcessДокумент5 страницAn Economical and Eco-Friendly Industrial ProcessThanh Thanh Hai LeОценок пока нет

- Solubility of Gases in WaterДокумент4 страницыSolubility of Gases in WaterThanh Thanh Hai LeОценок пока нет

- Met531 2Документ38 страницMet531 2Thanh Thanh Hai LeОценок пока нет

- Determination of Organophosphorus Pesticide Residues in VegetablesДокумент7 страницDetermination of Organophosphorus Pesticide Residues in VegetablesThanh Thanh Hai LeОценок пока нет

- Food Safety App Notebook - WebДокумент68 страницFood Safety App Notebook - WebThanh Thanh Hai LeОценок пока нет

- Determination of Carbamate Residues in FruitsДокумент14 страницDetermination of Carbamate Residues in FruitsThanh Thanh Hai LeОценок пока нет

- LCTech Application AflatoxinsДокумент4 страницыLCTech Application AflatoxinsThanh Thanh Hai LeОценок пока нет

- Residual Solvents USP 467Документ10 страницResidual Solvents USP 467Shridhar AnishettyОценок пока нет

- Food Analysis by Core Shell ColumnsДокумент4 страницыFood Analysis by Core Shell ColumnsThanh Thanh Hai LeОценок пока нет

- Optimization Method For Determination of CarbofuranДокумент8 страницOptimization Method For Determination of CarbofuranThanh Thanh Hai LeОценок пока нет

- EPA Method 531.1 (Carbamate in Water)Документ23 страницыEPA Method 531.1 (Carbamate in Water)Thanh Thanh Hai LeОценок пока нет

- Extraction, Clean-Up, and HPLC Detection of CarbarylДокумент5 страницExtraction, Clean-Up, and HPLC Detection of CarbarylThanh Thanh Hai LeОценок пока нет

- CT 25 (908-911)Документ4 страницыCT 25 (908-911)Thanh Thanh Hai Le100% (1)

- Determination of Organic CompoundsДокумент6 страницDetermination of Organic CompoundsThanh Thanh Hai LeОценок пока нет

- 5990 4917enДокумент32 страницы5990 4917enThanh Thanh Hai LeОценок пока нет

- 5989 1334enДокумент4 страницы5989 1334enThanh Thanh Hai LeОценок пока нет

- 5990 3677enДокумент42 страницы5990 3677enThanh Thanh Hai LeОценок пока нет

- Carbamate in Fruit by LC-MSДокумент13 страницCarbamate in Fruit by LC-MSThanh Thanh Hai LeОценок пока нет

- 5989 2549enДокумент40 страниц5989 2549enThanh Thanh Hai LeОценок пока нет

- MMDДокумент48 страницMMDVishal VajatОценок пока нет

- CE Current ProblemДокумент8 страницCE Current ProblemThanh Thanh Hai LeОценок пока нет

- 59657824Документ8 страниц59657824Thanh Thanh Hai LeОценок пока нет

- Chemical Analysis Group: Capillary Electrophoresis InstrumentДокумент12 страницChemical Analysis Group: Capillary Electrophoresis InstrumentThanh Thanh Hai LeОценок пока нет

- 5990 7706enДокумент10 страниц5990 7706enThanh Thanh Hai LeОценок пока нет

- Agilent CE System: A Quick Start Guide To Maintenance and TroubleshootingДокумент12 страницAgilent CE System: A Quick Start Guide To Maintenance and TroubleshootingThanh Thanh Hai LeОценок пока нет

- Quality Control of Pharmaceutical Drugs - Turning Analysis and Performance Data Into Comprehensible ChartsДокумент12 страницQuality Control of Pharmaceutical Drugs - Turning Analysis and Performance Data Into Comprehensible ChartsThanh Thanh Hai LeОценок пока нет

- 5962 8417eДокумент4 страницы5962 8417eThanh Thanh Hai LeОценок пока нет

- CE Cleaning ElectrodesДокумент16 страницCE Cleaning ElectrodesThanh Thanh Hai LeОценок пока нет

- Installation Qualification Protocol Agilent Capillary Electrophoresis SystemДокумент20 страницInstallation Qualification Protocol Agilent Capillary Electrophoresis SystemThanh Thanh Hai LeОценок пока нет

- 59802499Документ2 страницы59802499Thanh Thanh Hai LeОценок пока нет

- Bowing Styles in Irish Fiddle Playing Vol 1 - David LythДокумент58 страницBowing Styles in Irish Fiddle Playing Vol 1 - David LythEmma Harry100% (1)

- Gfps System Specification PVC C Metric en PDFДокумент24 страницыGfps System Specification PVC C Metric en PDFMohammed sabatinОценок пока нет

- 6.unit I 2 MarksДокумент3 страницы6.unit I 2 MarksprasanthprpОценок пока нет

- Offline Typing Project WorkДокумент2 страницыOffline Typing Project WorkUsman al-HassamОценок пока нет

- Konica Bizhub 7272 - User ManualДокумент436 страницKonica Bizhub 7272 - User Manualfaco1723Оценок пока нет

- The Device Is Running PDFДокумент22 страницыThe Device Is Running PDFBint MustaphaОценок пока нет

- List of ComponentsДокумент2 страницыList of ComponentsRainwin TamayoОценок пока нет

- Manual, contact info and schematic for GSM moduleДокумент10 страницManual, contact info and schematic for GSM modulethaiОценок пока нет

- Cisco CCIE CCNP RS Study Flashcards Ver 49Документ102 страницыCisco CCIE CCNP RS Study Flashcards Ver 49niboozОценок пока нет

- Casing & Compressor of Air ConditionerДокумент22 страницыCasing & Compressor of Air ConditionerAbdullah Zakirin Abdul 'AzamОценок пока нет

- My Ideal Week PDFДокумент1 страницаMy Ideal Week PDFAnonymous QE45TVC9e3Оценок пока нет

- New Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)Документ3 страницыNew Components Help Prevent Air Leaks in Improved Fuel Ratio Control Groups (1278)TASHKEELОценок пока нет

- Product Specification: Part Name: OEL Display Module Part ID: UG-2864HSWEG01 Doc No.: SAS1-9046Документ30 страницProduct Specification: Part Name: OEL Display Module Part ID: UG-2864HSWEG01 Doc No.: SAS1-9046mariОценок пока нет

- BS en 50160 2007Документ24 страницыBS en 50160 2007Pepe Eulogio OrtízОценок пока нет

- Master Plumber Exam Coverage (Philippines)Документ4 страницыMaster Plumber Exam Coverage (Philippines)Eugene Micarandayo100% (3)

- Abrasive Cleaning SystemДокумент4 страницыAbrasive Cleaning SystemSulfikar SalimОценок пока нет

- SKFДокумент26 страницSKFRahul ParikhОценок пока нет

- 0100CT1901 Sec-23 102520202Документ120 страниц0100CT1901 Sec-23 102520202Chandra SekaranОценок пока нет

- Edison LearningДокумент62 страницыEdison LearningYork Daily Record/Sunday NewsОценок пока нет

- Price List (011) New2020 PDFДокумент3 страницыPrice List (011) New2020 PDFAyush BansalОценок пока нет

- BUK9Y53-100B DatasheetДокумент12 страницBUK9Y53-100B Datasheetisomeso21Оценок пока нет

- Installation Guide: For Packetfence Version 8.3.0Документ270 страницInstallation Guide: For Packetfence Version 8.3.0Ferjani TarekОценок пока нет

- Grand Rapids Controls LPA Checksheet AuditДокумент7 страницGrand Rapids Controls LPA Checksheet Auditalliceyew100% (3)

- Engineering Data (Design Manual) - EDTRAU342315-D - RXYQ-BYMДокумент104 страницыEngineering Data (Design Manual) - EDTRAU342315-D - RXYQ-BYMignatiusglenОценок пока нет

- User's Manual Installation Guide for Wind DisplayДокумент21 страницаUser's Manual Installation Guide for Wind DisplayVM ServicesОценок пока нет

- Diffusion of InnovationДокумент40 страницDiffusion of Innovationlali62Оценок пока нет

- Chassis (LS17) PDFДокумент10 страницChassis (LS17) PDFlasky11Оценок пока нет

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDДокумент6 страницMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaОценок пока нет

- OTC13998Документ15 страницOTC13998Raifel MoralesОценок пока нет

- Google Earth y Civil CadДокумент3 страницыGoogle Earth y Civil CadRodneyОценок пока нет