Академический Документы

Профессиональный Документы

Культура Документы

Sportswear TECH.

Загружено:

Kushagradhi DebnathАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sportswear TECH.

Загружено:

Kushagradhi DebnathАвторское право:

Доступные форматы

www.fibre2fashion.

com

EngineeredFibres&Fabrics forActiveSportswear

By:GauravAgarwal

www.fibre2fashion.com

ENGINEEREDFIBRES&FABRICSFORACTIVESPORTSWEAR

By:GauravAgarwal

Abstract:Thesportsclothingoftodayhavebecometechnicallyoriented,usinghighlyfunctional textiles for both casual and performance sportswear. The recent developments in materials for sportswear have resulted in specialized performances in different sports. In this paper an overview is given of the recent developments in fibres, yarns, fabrics for applications in active sportswear. 1.INTRODUCTION India is increasing total wealth and per capita income. The rapid spread of satellite television is globalizing the vision of the healthy lifestyle and spreading knowledge of sports and leisure wears from country to country. Due to this consumers are becoming more and more conscious for the comfort of the garments that they are wearing. Design of active sportswear is still a subject of research for many companies. As a result of this new fibre, fabrics & finishes are developedtosatisfythestringentrequirementsimposedbycontemporarysportstrends. Constantpursuitofvictoriesandrecordbreakingperformancebytoplevelprofessionalathletes, outstanding marksmanship by popular ball players and the maximum enjoyment of amateur sports activities need creative engineered sports garments. This means that the products have to be more than functional if consumers are encouraged to buy them, as they are currently demandingnewlooksandfabricswithadifferentfeeltothem. The sportswear and sport goods sector of the textile industry has not only resulted in market diversification for fibrous materials but has also contributed towards the elevation of textile science and technology to a level which starts to become in par with other hightech industrial sectors. New technological developments, more fragmented niche markets and increasingly demandingcustomerexpectationsarejustsomeofthefactorsrelentlesslydrivingthisindustrial sector. To thrive in this environment, companies are implementing radically new product developmentpractices. 2.DESIGNCONSIDERATIONSINSPORTSWEAR Design requirements of active and performancesportswear have produced designers with skills and knowledge in graphics, textiles and fashion to conceive aesthetically pleasing and ergonomically viable ranges which take advantage of the latest advances in functional and smart textiles. It is the fabrics and technology that set the trend. Incorporation of microfibres, breathable barrier fabrics, innovative stretch materials, intelligent textiles, interactive materials suchasphasechangematerialsandshapememorypolymersandwearabletechnologyasapart

www.fibre2fashion.com of the functional design system in sportswear, will become routine in the product development process. Advances in innovative high functional uncoated and coated textiles and coatings as well as the garment manufacturing technology have resulted in more sophisticated sportswear and footwear specifically designed to be used by different user categories of performance sports and outdoor leisure use. All this helps to speed the runner, keep the jogger dry and cool, streamlining the swimmer, protect the cricketer, hockey player and snowboarder, keep the football player and cyclist dry, and keep the user comfortable and warm in extreme weather conditions. 3.SPORTSWEARANDCOMFORT: In active and endurance sports, the performance of a sportswear is synonymous with its comfort characteristics. In active wear for outdoor use, the clothing should be capable of protecting the wearer from external elements such as wind, sun, rain and snow. At the same time, it should be capable of maintaining the heat balance between the excess heat produced bythewearerduetoincreasedmetabolicrateontheonehand,andthecapacityoftheclothing todissipatebodyheatandperspirationontheother. Sportswear needs to look as a whole system. If over heating is to be avoided, thermoregulation andmoisturemanagementarekeyfunctionsofclothingdesignedforuseassportswearoractive wear. The human body, its microclimate & its clothing form a mutually interactive system. The bodyand itsmicroclimateareinvariables;theclothingsystemistheonlyvariable. The human body has an operating temperature of 37C which it attempts to maintain under all circumstances. During physical activity such as in sport the body temperature rises. The body cools down again through the excretion of perspiration. Perspiration creates moisture vapor. If thiscannotbereleasedoutwardthroughmanylayersofclothingagreenhouseeffectresults. Topreventthebodytemperatureexceedingthecomfortzone,theheatmustsimultaneouslybe dissipatedoutwardly.Thehumanbodyhasnoproblemexcretinghalfaliterorevenawholeliter of perspiration per hour provided that this process is not impeded by the relative humidity of its environment & clothing. Itisclearthatclothingisthekeytobodycomfort.Comfortisdifficulttodefinesinceitcoversboth quantifiable data and subjective considerations. In general, comfort is a situation where temperature differences between body members are small with low skin humidity and the physiologicaleffortofthermalregulationreducedtominimum. Four types of Clothing comfort have been defined which are essential requirements for activesportswear.Theyare: 1. Thermophysiologicalcomfort 2. Sensorial/tactilecomfort

www.fibre2fashion.com 3. Mobility/Dexterity 4. Psychologicalcomfort This form ofcomfortmaybesaidtoexist whenthepersonisinthermalbalancei.e. when the rate of loss of heat from the body equals the rate at which it is being generated by the physiological processes. If the rate of loss of heat is insufficient, the person feels hot and the body temperature rises, heat stress eventually results. On the other hand if the rate of loss of heat is too high, the person first feels cold and the body temperature falls, causing discomfort to the person. Thus for getting thermophysiological comfort the sportswear should have suitable thermal insulation properties as well as sufficient permeability to water vapor and/or sufficientlevelofventilation. Sensorial/tactilecomfort: The sensorial comfort does not directly involve any temperature balance, but is related to the way that the person feels when clothing is worn next to skin. Wet feeling and wet cling can be a major source of sensorial discomfort in situations of profuse sweating. If the skin is wet with sweat and if the sweat is not released by the clothing then an unpleasant feeling with wetness will occur. Also the clothing which is nexttoskin will stick to body which will prevent the sports person to performproperly. While doing the various physical activities in the active sports, considerable movements of body parts occur. The sportswear must therefore have sufficient degree of mobility so that wearer can be able to move freely. Too much volume, too much weight or too much stiffness of fabric will tend to reduce the mobility and leadstodiscomfort.Theclothingshouldhavelowfluidresistanceandstretchability. The feeling of the wearer that he or she is dressed in a style/fashion means the psychological comfort. This is mainly related with aesthetic appeal. From toplevel professional sport person to amateurs, all demand psychological comfort to some extentalongwithotherthreecomforts. 4.REQUISITEFUNCTIONOFACTIVESPORTSWEAR: There are basically three types of sports players and their requirements of sportswear in termsoffunctionalandotherpropertiesaredifferent. Psychologicalcomfort Mobility: Thermophysiologicalcomfort:

www.fibre2fashion.com Top level professional primarily require functional power with aesthetic appeal as theystarveforrecordbreakingperformance. (ii) The seriously competing amateurs involved in sports club who as potential future topline performers need to have sportswear with at least minimum functional effectivenessandatareasonablecost;and (iii) Those who enjoy sports activities for its benefits in respect of health, hobbies and social contact need the material to provide a minimum physical function but they aremoreconsciousaboutcomfortandsensitivity. Therequirementsforanactivesportswearcanbroadlybeclassifiedinto: (a) Functional: For top level competition active sports wear requires super light weight, low fluid resistance, super high tenacity and stretchability. For those seeking comfort and healthy pursuits, critical features include thermal retention, UV resistance, cooling capacity, sweatabsorption,fastdrying,vapourpermeability,waterproofingetc.toproviderelaxation preventingfatigue. (b) Aesthetic: From the sensitivity or aesthetic point of view, softness, surface texture, handle,lustre,colourvariation,transparencyandcomfortinwearareimportantfactors. 5.DEVELOPMENTSINFIBRESANDTEXTILEMATERIALSFORSPORTSWEAR: Theevolutionoffibredevelopmentshasgonethroughthephasesofconventionalfibres,highly functional fibres and highperformance fibres. Polyester is the single most common fibre used for sports wear and active wear. Other fibres suitable for active wear are polyamide, polypropylene, acrylic and elastanes. Synthetic fibres can either be modified during manufacturing or be optimally blended with natural fibres to improve their thermo physiological and sensory properties. Synthetic fibres with improved UV resistance and having antimicrobial properties are also commercially available for use in sportswear. New technologies for producing microfibres have also contributed towards production of hightech sportswear. A.NEWPOLYMERSFORSPORTSWEAR: 1.PHASECHANGEMATERIAL(PCM): Phase change materials produce microcapsules full of paraffin. When, the capsules are heated, the paraffin liquidifies and heat energy is stored. When the environment cools, the paraffincrystallizesagain, releasing heat. The paraffin,which is available in different recipes with various melting points, is referred to the phasechange material, or PCM. Because the paraffin can be formulated with different melting points, the microcapsules can be designed to keep the wearer either warm or cool. The (i)

www.fibre2fashion.com warmer paraffin is suitable for skiing and other cold weather sports; the cooler waxes are good choices for biking gear, mountaineering clothes, or footwear. 2.SHAPEMEMORYPOLYMERS: Diaplex:Aspecialsuitbasedonamembraneemployingshapememorypolymerswas developed for Swedish sailor. The suit, designed employs the Diaplex smart fabric technology. Diaplex materials can be simultaneously and completely waterproof, windproof and breathable. This material can 'remember' and retain its shape, or return to a previous form. A garment made from Diaplex is able to sense changes in the surrounding environment, evaluate then intelligently, and control its responses toensurethehighestlevelofcomfort. Itsintelligenceliesintheunique wayinwhichittakesadvantage ofmicroBrownian motion (thermal vibration). MicroBrownian motion occurs within the Diaplex membrane when the temperature rises above a predetermined activation point. As a result of this motion, micropores are created in the polymer membrane which allows water vapour and body heat to escape. Because permeability increases as the temperature rises, the membrane is able to respond intelligently to changes in thewearer'senvironmentandbodytemperature. Diaplex is also unique in that the temperature at which microBrownian motion begins can be freely specified. This means that the activation point can be set to match,theenvironmentalconditionsinwhichagarmentislikelytobeworn. 3.MEMBRANETECHNOLOGY: Airvantage: Airvantage system by W.L. Gore is the first personal thermal climate management system for clothing in the world. It enableswearerstoreactasthoughtheyhadtheirown personalairconditioningsystem. The secret of the system is based on an ageold piece of wisdom air is a poor conductor of heat and therefore the best natural insulator. On the one hand trapped air protect, against the cold, on the other it keepsinexistingbodyheat. Airvantage membrane system, specially developed for the construction of permanentlyairtightandbreathablechambers,isbasedonthesamePTFEtechnology asGoreTex. Two laminates are bonded together to be airtight and breathable. The special air chambers of this garment component are adjusted using a valve. When the outside

www.fibre2fashion.com temperature changes, or when wearer becomes more or less active, the insulation layer can be regulated as required , simply by blowing air into the chambers or by allowing it to escape. In the first case, blowing air into the chambers significantly improves heat retention (thermal insulation) so that the wearer feels warmer. In the second, reducing theamountofairtrappedinthechambersmeansthatexcessbodyheatcanbereleased. Sypmpatex: Sypmpatex differs from its main competitor GoreTex in being ex tremely thin layered (70100 microns) solid polyester membrane with no micropores. It is effective in transporting perspiration moisture away from the wearer'sbodybutatthesametimeagoodbarriertowaterandwind. B.FIBRES&YARNSFORACTIVESPORTSWEAR: Developments in synthetic fibres which are tailormade have opened up enormous avenues for their use in sportswear to meet specific requirements. In active sportswear single fibre is seldom used. Mostly, specialty fibres are used in conjunction with normal fibres. Examples of suchfibresaregivenbelow: Hygra: Unitika Limited has launched Hygra, which is a sheathcore type filament yarn composed of fibre made from water absorbing polymer and nylon. The waterabsorbing polymer has a special, network structure that absorbs 35 times its own weight of water and offers quick releasing properties that the conventional water absorbingpolymercannotdo.Ontheotherhand, nylon in the core gives tensile strength and dimensional stability. Hygra also has superior antistatic properties even under low wet conditions. The main apparel applications include sportswear like athletic wear, skiwear, golfwearetc. Lumiace: Lumiace is also a product from Unitika. It is a collection of polyester filaments having different fineness (0.5 2.0 denier per filament) and irregular cross sections. Hygra LumiacecombinationinknittedfabricisverypopularintopJapaneseathletes. Dryarn: Dryarn is the new fibre from Aquafil. It is a completely recyclable polypropylene microfibre. Fabric from Dryarn is very lightweight and comfortable and used in different sports. In addition, it has a soft handle and a high thermoregulatory capacity and also dries quickly. Bacteria cannot settle on smooth surface of the fibre which avoids unpleasant odourassociatedwithdecompositionofbacteria. Killat N : Killat N from Kanebo Ltd is a nylon hollow filament. The hollow portion is about 33 per cent of the cross section of each filament due to which it gives good water absorbency and warmthretentive property. Themanufacturing technology ofKillat Nis veryinteresting.

www.fibre2fashion.com The yarn is spun as bicomponent filament yarn with soluble polyester copolymer as the core portion and nylon as the skin portion. Then by giving alkali weight loss treatment the soluble polyestercopolymerofthebicomponentfilamentwilldissolveand a large hollow portion (exceeding 30 per cent of the cross section) willbecreated. Triactor: Toyobo Co Ltd has developed Triactor, which is a perspiration absorbing/quick drying polyester filament. Polyester ishydrophobicanddoesnotabsorbmoisturebutbychangingthe filaments to Y shaped cross section Toyobo has realized quick perspiration absorbency by capillary action. The hydrophobic nature and large filament surface of polyester filaments realize quickdryingandrefreshingpropertiesatthesametime. CoolMAX: It is a tetrachannel polyester fibre with a cross section like a double scallop. This fibrewasproducedspecificallyforthesportswearmarket.Ithasimprovedwickingcapability andmoisturevaporpermeability. Drirelease: Drirelease is a wicking performance yarn developed by USbased Optimer, a company founded by a group of former Dupont scientists. This patented product is an intimate blend of 8590% hydrophobic low moistureabsorbing staple fibres such as polyester and 10 15%hydrophilicwickingstaplesuchascotton.Drireleaseisincorporatedinathleticwear,socks and underwear. Drirelease combines the wicking and soft touch properties of cotton with the nonabsorbing nature of polyester. Drirelease also incorporates a Freshguard finish. This neutralizesodorsretainedinthefabricforthelifeofthegarment. NEW Elite: Elite is the trademark for a PBT (polybutyleneterephthalate) textured yarn manufactured by Nylstar and marketed by Rhotex, Italy. After thermal treatment at the dyeing or finishing stage Elite yarn can achieve permanent elasticity with comfortable stretchpropertiesforsportswear.TheeasydyeabilityofEliteyarnwithdispersedyeat98C, makesitsuitableforblendingwithnaturalandsyntheticfibres. C.FABRICDEVELOPMENTSFORACTIVESPORTSWEAR: There has been a strong growth in development and use of high functional materials used in sportswearandoutdoorleisureclothing.Theperformancerequirementsofmanysuchproducts demand the balance of widely different properties of drape, thermal insulation, barrier to liquids, antistatic, stretch, physiological comfort etc. The research in this field over the past decade has led to the commercial developmentof a varietyof new products for high functional enduses. By designing new processes for fabric preparation and finishing, and as a result of advances in technologies for production and application of suitable polymeric membranes and surface finishes, it is now possible to successfully combine the consumer requirements of aesthetics, design and function in sportswear for different enduse applications. The fabrics for

www.fibre2fashion.com active wear and sportswear are also specially constructed in terms of the geometry, packing density and structure of the constituent fibres in yarns as well as the construction of the fabric in order to achieve the necessary dissipation of heat and moisture at high metabolic rates. Many smart doubleknitted or doublewoven fabrics have been developed for sportswear in such a way that their face closer to human skin has optimal moisture wicking and sensory propertieswhereastheouterfaceofthefabrichasoptimalmoisturedissipationbehavior. Naiva : Unitika has developed Naiva fabric by combining the Naiva yarn with a nylon microfibre. Naiva is an Eval/nylon bicomponent filament yarn. Eval is basically a copolymer resin of ethylene vinylalcohol. Naiva yarn composed of 55% Eval and 45% nylon. In the Naiva fabrics there are many nylon microloops on the surface, which are formed by making use of high thermal shrinkage property of Naiva yarn. Naiva fabric not only has good moisture permeability but also has some other positive features like lightweight, softness and has capability of secondary finishing. The fabric is very successfully used in mountaineeringwearandotheractivesportswear. Field Sensor: Field Sensor is a very popular high performance fabric from Toray, which employsa multilayerstructure thatnot onlyabsorbsperspirationquicklybutalsotransports it up to the outer layer of fabric very rapidly using principle of capillary action. It is composed of coarser denier yarn on the inside surface (in direct contact with skin) and fine denierhydrophobicpolyesteryarninameshconstructionontheoutersurfacetoaccelerate quick evaporation of sweat. The model of absorption and fast drying mechanism of field sensorisshowninfig.below

Water magic: Water magic from Kuraray also utilises the same principle for sweat absorption and quick drying as that of Naiva. Water magic is a 3layered knitted fabric of Wrap (67% polyester / 33% nylon ultra fine microfibre). Water magic has innumerable random and minute pores. These micropores speedily transportperspirationfromtheskinsidetoouterair. GoreTex: The first and probably the best known waterproof breathable fabric is GoreTex. This is a thin microporous membrane of polytetrafluroethylene (PTFE) sandwiched between two fabric layers. The polymer claimed to contain 1.4 billion tiny holes per cm. These holes are much smaller than the smallest rain drops (23

www.fibre2fashion.com gm compared with 100 pro), yet very much larger than a water vapour molecule (40 x 106 m). Entrant G II: Toray has developed a high performance waterproof breathable fabric Entrant G II. It is a microporous coating of polyurethane developed with importance given to high water pressure resistance and highmoisturepermeability. The secret of high performance of Entrant G II is in the threelayered polyurethane coating membranes including two different micro porous layers. If the layers from the top fabric side are called layer 1, layer 2 and layer 3, each layer has the followingproperties: Layer1:Foamlayerwithminisculemicroporousimproveswaterproofinganddurability; Layer2:Regularlyconfiguredmicroporousincreasesmoisturepermeability; Layer3:Poresintheresinsurfaceenhancewaterproofing.Strengtheningcoatingsurface andinhibitdewcondensation. Isofix Super: Isofix Super, developed by Kanebo, is the name applied to a coating which incorporates new processing and structural technologies by fusing antisublimation / anti migration coating techniques to special ceramics with countless number of pores. The major featuresof"IsofixSuper"otherthanwaterproof/moisturepermeablepropertyareasfollows: Anticondensation property: Once the special ceramics, which are composed of hydrophilic crystals with counters numbers of microporous, reach the supersaturated condition, they demonstrate their water absorbing power to the hilt by presenting condensation inside the garment. This water absorbing power is as high as one hundred to two hundreds times the weight of the special ceramics themselves in the coating. Dry feel: As the ceramic particles protrude from the surface of the coated resin, none of the resin ever touches the body and thus provides wear comfort without any stickyfeeling. Soft touch: Isofix Super

www.fibre2fashion.com adopts a resin which is softer than the polyurethane which is normally used in waterproof/moisturepermeablecoatings. Sportwool: It is a trade mark of The Woolmark Company. In 1994 research into the physiological benefits of wool led to the breakthrough development of Sportwool. It is a hybrid material composed of a fine Merino wool sublayer for insulation and a polyesterexteriorwhichdrawsmoistureawayfromthewoollayer tothesurface.Thewoolfibrenexttotheskinattractsperspiration vapor molecules, before they have the chance to condense into liquid,anddispersesthemintotheatmosphere. The removal of the vapor from the microclimate between the skin and fabric reduces the formation of liquid sweat leaving you drier and more comfortable. Sportwool's unique natural thermal regulation and vapor management properties cool down when it's hot and keep warm in extreme cold. So whether wearer is skiing on a cold winter morning or cycling in the heat of summer,Sportwoolisthenaturalchoicewhenwearerwantstoperformtothemaximum. 6.CONCLUSION: Sportingcultureintheworldhaschangeddramaticallyinrecentyearsfollowingtheemergence of a new generation of consumers. With the ageing population and consequent increase in leisuretimeandtravel,therewillbemoreemphasisonteamsports,leisure&individualsports. Performance apparel represents one of the fastest growing sectors of the international textile and clothing industry. Market growth is being fuelled by the emergence of new fibres, new fabricsandinnovativeprocesstechnologies. The market is also being boosted by changes in consumer lifestyles. People are spending more time on leisure activities. New hightech fabrics are being developed for a wide range of active sports such as aerobics, athletics, running, cycling, hiking, mountaineering, swimming, sailing, windsurfing, ballooning, parachuting, snowboarding, etc. More developed technologies, improved functional properties of sportswear, new fibres and fabrics are expected to come out inthenearfuturetomeetstringentexpectations. 7.REFERENCES 1. TextilesinSports,Ed.ByR.Shishoo,WoodheadPublishingLtd 2. V.K.Kothari,FibresandFabricsforActiveSportswear,AsianTextileJournal,March2003 3. AkiraYonenagaEngineeredfabricsforactivesportswear,IntlTextileBulletin,No.4,1998 4. JurgRupp,FunctionalSportswear,IntlTextileBulletin,No.4,1998 5. S C Anand & L Higgins, Textile Materials & Products for Activewear & Sportswear, Proceedings2ndInternationalConferenceofNISTI,23December2004,Delhi

www.fibre2fashion.com 6. R. Shishoo, An overview of the Recent Developments in Materials for Sportswear, Journal ofFibreBioengineering&InformaticsSociety,2008 7. www.sportwool.com 8. www.gorefabrics.com 9. www.torayentrant.com TheauthorisanAssistantManagerwithConsumerProductsDivision, BirlaCellulose,Bharuch (Guj.) ImageCourtesy:knittingindustry.com

Вам также может понравиться

- Active Sports Wear FabricДокумент7 страницActive Sports Wear Fabricsagaranju100% (1)

- Basics Sports TextilesДокумент49 страницBasics Sports Textiles20MT31 - NAAVENDHAN SОценок пока нет

- Developments in Sportswear Using Functional Fibres With Polyester FiberДокумент11 страницDevelopments in Sportswear Using Functional Fibres With Polyester FiberDUDHAYA55100% (1)

- The Jacquard Machine Analyzed and Explained: With an appendix on the preparation of jacquard cards, and practical hints to learners of jacquard designingОт EverandThe Jacquard Machine Analyzed and Explained: With an appendix on the preparation of jacquard cards, and practical hints to learners of jacquard designingОценок пока нет

- Comfort Properties of Bi-Layer Knitted Fabrics - Knitting & Hosiery - Features - The ITJ PDFДокумент12 страницComfort Properties of Bi-Layer Knitted Fabrics - Knitting & Hosiery - Features - The ITJ PDFAhmad SamerОценок пока нет

- Designing, Cutting and Grading Boot and Shoe Patterns, and Complete Manual for the Stitching RoomОт EverandDesigning, Cutting and Grading Boot and Shoe Patterns, and Complete Manual for the Stitching RoomОценок пока нет

- Sport TechДокумент4 страницыSport Techila03100% (1)

- Sportech PDFДокумент27 страницSportech PDFইমরানুল শহীদ আলভীОценок пока нет

- Fabric Defects & InspectionДокумент23 страницыFabric Defects & InspectionYogesh SharmaОценок пока нет

- Denim Jean ProductionДокумент34 страницыDenim Jean Productionsaharabid100% (2)

- SportswearДокумент5 страницSportswearsashahodgeОценок пока нет

- Fashion Forecasting in 2020 in Clothtech and SportechДокумент19 страницFashion Forecasting in 2020 in Clothtech and Sportechᗩᒸᓿᗋ ᗱᕠᓮᘘᕦОценок пока нет

- Fabric CharacteristicsДокумент41 страницаFabric CharacteristicsTesfaye MuluОценок пока нет

- Different Types of Knitted FabricsДокумент11 страницDifferent Types of Knitted FabricsDevashish BakshiОценок пока нет

- Computerized Pattern MakingДокумент18 страницComputerized Pattern MakingVaanazhaganОценок пока нет

- Men's Different Clothing Categories and BrandsДокумент74 страницыMen's Different Clothing Categories and BrandsArtist Vandana Sharma100% (1)

- Seam TypesДокумент40 страницSeam TypesGarima AgarwalОценок пока нет

- Consumption Calculation For Woven GarmentДокумент5 страницConsumption Calculation For Woven GarmentFaisal Akhter Ruhin100% (3)

- DenimДокумент11 страницDenimnidhisanjeetОценок пока нет

- Fabric NamesДокумент6 страницFabric NamesGenieve Alessandra Prescod100% (2)

- Pattern Making - Men's Trouser - Y.navinaДокумент4 страницыPattern Making - Men's Trouser - Y.navinanavina yogeshОценок пока нет

- Seam and StitchДокумент16 страницSeam and StitchYetana Wubneh100% (2)

- FinishesДокумент75 страницFinishesShubham TilaraОценок пока нет

- Manual Merchandising (New)Документ396 страницManual Merchandising (New)Muhammad Mubeen Iqbal PuriОценок пока нет

- Introduction To Apparel Industry-Unit-1Документ28 страницIntroduction To Apparel Industry-Unit-1Anubhav AgarwalОценок пока нет

- Bloomsbury Fashion Central - Sportswear, Knit, and PrintДокумент23 страницыBloomsbury Fashion Central - Sportswear, Knit, and PrintANURAG JOSEPHОценок пока нет

- 2 Textile Study Applicable To Fashion ArtДокумент143 страницы2 Textile Study Applicable To Fashion ArtRoshaniОценок пока нет

- Sizing Systems in The Apparel IndustryДокумент14 страницSizing Systems in The Apparel IndustryВалерияЧербу100% (1)

- Scap Assignment 2: Measurements and Fabric Consumption of HoodieДокумент7 страницScap Assignment 2: Measurements and Fabric Consumption of HoodieROHAN GIREESHОценок пока нет

- HTM Womenswear Current-UpdatedДокумент10 страницHTM Womenswear Current-UpdatedSujon SarkarОценок пока нет

- Applications of Nonwovens in Medical TextileДокумент17 страницApplications of Nonwovens in Medical TextileDipesh JainОценок пока нет

- Seam Classes: Superimposed SeamsДокумент15 страницSeam Classes: Superimposed SeamsP. Lakshmanakanth50% (4)

- Classification of Textiles PDFДокумент52 страницыClassification of Textiles PDFsathish_201020100% (1)

- Seamless Garment TechnologyДокумент6 страницSeamless Garment Technologyspringstar100% (2)

- Sports TextilesДокумент17 страницSports TextilesRajesh KarunakaranОценок пока нет

- Advancements in Garment Manufacturing TechnologyДокумент19 страницAdvancements in Garment Manufacturing TechnologyShanmugeshwari MuthiahОценок пока нет

- Syllabus Nift TirupurДокумент33 страницыSyllabus Nift TirupurLiyakath AliОценок пока нет

- Clothing SizesДокумент8 страницClothing SizesMoyii100% (1)

- Submitted To: Md. Emdad Sarker Lecturer Department of TextileДокумент38 страницSubmitted To: Md. Emdad Sarker Lecturer Department of TextileMd Golam Kibria100% (1)

- Tailoring BooksДокумент1 страницаTailoring Booksdctarang0% (1)

- Final Tech PackДокумент11 страницFinal Tech Packapi-464890134Оценок пока нет

- Seam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKДокумент12 страницSeam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (2)

- Operation Breakdown & Machinery Required For: Formal TrouserДокумент18 страницOperation Breakdown & Machinery Required For: Formal Trouserashishgcti8175% (8)

- Sweater Consumption CostingДокумент2 страницыSweater Consumption Costingapi-2142836790% (1)

- SMV of Different GarmentsДокумент17 страницSMV of Different GarmentsHarisha PahwaОценок пока нет

- Class Name of Stitch Available Subclass Created MachineДокумент58 страницClass Name of Stitch Available Subclass Created MachineAsm Towheed100% (8)

- Sampling and Tech PacksДокумент23 страницыSampling and Tech PacksMaham AnwarОценок пока нет

- Santoni SeamlessДокумент2 страницыSantoni SeamlessSudheer SinghОценок пока нет

- How Do Calculate The Fabric & Yarn Consumption of A Yarn Dyed T-Shirt?Документ9 страницHow Do Calculate The Fabric & Yarn Consumption of A Yarn Dyed T-Shirt?light lightОценок пока нет

- Seamless TechnologyДокумент6 страницSeamless TechnologyBéchir Azzouz100% (1)

- Woven Shirt Fabric Consumption CalculationДокумент9 страницWoven Shirt Fabric Consumption CalculationImranОценок пока нет

- Circular Knitted FabricsДокумент16 страницCircular Knitted Fabricsrdsekar7633% (3)

- Different Grading System Used in Apparel IndustryДокумент5 страницDifferent Grading System Used in Apparel Industryzain bajwaОценок пока нет

- Estimation of Thread Consumption of GarmentДокумент2 страницыEstimation of Thread Consumption of GarmentK.s. Ramesh100% (1)

- Assignment On Different Stitch and Seam Used in Knitwear ApparelДокумент30 страницAssignment On Different Stitch and Seam Used in Knitwear ApparelAnisur Rahman GeorgeОценок пока нет

- Denim WashДокумент13 страницDenim WashSundaramoorthy ManickamОценок пока нет

- Catalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationДокумент21 страницаCatalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationKushagradhi DebnathОценок пока нет

- British BS 5867 Part 2 Type B and C PDFДокумент1 страницаBritish BS 5867 Part 2 Type B and C PDFKushagradhi Debnath100% (1)

- UNIQEMA HypermerPolymericSurfactantsДокумент2 страницыUNIQEMA HypermerPolymericSurfactantsKushagradhi DebnathОценок пока нет

- Barco Projection SystemДокумент7 страницBarco Projection SystemKushagradhi DebnathОценок пока нет

- Reactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design ApproachДокумент10 страницReactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design ApproachKushagradhi DebnathОценок пока нет

- Chemours Capstone For Textiles K25183-1Документ1 страницаChemours Capstone For Textiles K25183-1Kushagradhi DebnathОценок пока нет

- The Impact of 'Zero' Coming Into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurДокумент23 страницыThe Impact of 'Zero' Coming Into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurKushagradhi DebnathОценок пока нет

- Basosoft N-Ap: Technical InformationДокумент7 страницBasosoft N-Ap: Technical InformationKushagradhi DebnathОценок пока нет

- Hydrosulfite Types: Technical InformationДокумент8 страницHydrosulfite Types: Technical InformationKushagradhi DebnathОценок пока нет

- ISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterДокумент1 страницаISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterKushagradhi DebnathОценок пока нет

- Synthesis and Application of Cationic SoДокумент5 страницSynthesis and Application of Cationic SoKushagradhi DebnathОценок пока нет

- The+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Документ1 страницаThe+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Kushagradhi DebnathОценок пока нет

- Taiwan K.K. Corp: Technical Data SheetДокумент2 страницыTaiwan K.K. Corp: Technical Data SheetKushagradhi DebnathОценок пока нет

- No Vo GAДокумент2 страницыNo Vo GAlongthОценок пока нет

- Evaluation of DetergentsДокумент14 страницEvaluation of DetergentsKushagradhi DebnathОценок пока нет

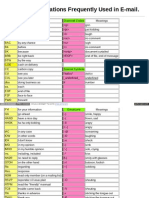

- A List of Abbreviations Frequently Used in E-Mail.: ItalicsДокумент3 страницыA List of Abbreviations Frequently Used in E-Mail.: ItalicsKushagradhi DebnathОценок пока нет

- Process Chemicals ViswaatДокумент6 страницProcess Chemicals ViswaatKushagradhi DebnathОценок пока нет

- Problems and Aspects of Natural DyesДокумент8 страницProblems and Aspects of Natural DyesKushagradhi Debnath100% (1)

- Calculation of Dyeing Recipe Calculation For Dyeing LabДокумент3 страницыCalculation of Dyeing Recipe Calculation For Dyeing LabKushagradhi DebnathОценок пока нет

- GOTS 3.0-4.0 Positive List 1Документ8 страницGOTS 3.0-4.0 Positive List 1Kushagradhi DebnathОценок пока нет

- Dwarkesh Enterprise: Properties of GREEN, VIOLET & BLUE PigmentsДокумент1 страницаDwarkesh Enterprise: Properties of GREEN, VIOLET & BLUE PigmentsKushagradhi DebnathОценок пока нет

- Phosphate EstersДокумент4 страницыPhosphate EstersKushagradhi DebnathОценок пока нет

- HeiQ Product Range 2014-03-25Документ37 страницHeiQ Product Range 2014-03-25Kushagradhi Debnath100% (1)

- Baines 1975 Ankh Belt SheathДокумент25 страницBaines 1975 Ankh Belt Sheathkingkrome999Оценок пока нет

- Supplemental Guidelines On The Delinquency Report System: (Strengthening The Disciplinary Authority of Chief of Office)Документ26 страницSupplemental Guidelines On The Delinquency Report System: (Strengthening The Disciplinary Authority of Chief of Office)Einno SnowОценок пока нет

- Storage, Stacking and Handling Practices PDFДокумент15 страницStorage, Stacking and Handling Practices PDFNgurah BuanaОценок пока нет

- Bus 685 Final ReportДокумент25 страницBus 685 Final Reportabu.sakibОценок пока нет

- Holloway Catalog (2011)Документ144 страницыHolloway Catalog (2011)sportstimenjОценок пока нет

- Hand Sewing Crossword Puzzle 921a9 6163f6b7Документ1 страницаHand Sewing Crossword Puzzle 921a9 6163f6b7api-653788186Оценок пока нет

- FST3019 Fashion-Psychology TH 1.1 50 FST3019Документ2 страницыFST3019 Fashion-Psychology TH 1.1 50 FST3019santhoshi100% (1)

- Made in Rwanda - Policy DialogueДокумент40 страницMade in Rwanda - Policy DialoguenshimiyimanaОценок пока нет

- Imc407 - Social Media ReviewДокумент16 страницImc407 - Social Media ReviewAzz IzumiОценок пока нет

- Raw Materials For Socks Making BusinessДокумент7 страницRaw Materials For Socks Making BusinessNajiya shakiraОценок пока нет

- Columbine Report Pgs 3901-4000Документ100 страницColumbine Report Pgs 3901-4000columbinefamilyrequestОценок пока нет

- OPT B1 U08 Vocab HigherДокумент1 страницаOPT B1 U08 Vocab HighermelissaОценок пока нет

- IDM - H&M - Talking PointsДокумент2 страницыIDM - H&M - Talking PointsLakshana KОценок пока нет

- Men's Suit Card InstructionsДокумент2 страницыMen's Suit Card InstructionsKirstie WatersОценок пока нет

- Blues ClothesДокумент26 страницBlues ClothesYugeshkanna VaratharajОценок пока нет

- Indian Traditional Textiles - Ajrakh PrintsДокумент2 страницыIndian Traditional Textiles - Ajrakh PrintsK. RamachandranОценок пока нет

- Answer Key Week 1Документ4 страницыAnswer Key Week 1Rd DavidОценок пока нет

- Weekend Sweater ENGLISHДокумент8 страницWeekend Sweater ENGLISHAndreea Cauș100% (6)

- Reindeer Stocking: Yarn + NotionsДокумент3 страницыReindeer Stocking: Yarn + NotionsRena VergouОценок пока нет

- Lucia The Cat DollДокумент15 страницLucia The Cat DollIlona Svobodová100% (3)

- Global Sourcing in The Textile - Jung E. Ha-Brookshire PDFДокумент854 страницыGlobal Sourcing in The Textile - Jung E. Ha-Brookshire PDFEmmanuel Tunde RennerОценок пока нет

- Qin Xiang English 342 DweДокумент18 страницQin Xiang English 342 DweDaniel Alejandro Saez100% (12)

- DenimДокумент11 страницDenimJ.SathishОценок пока нет

- Museum Quality The Rise of The Fashion ExhibitionДокумент26 страницMuseum Quality The Rise of The Fashion ExhibitionMadalina Manolache0% (1)

- Ropa Interior RomanaДокумент11 страницRopa Interior RomanaRaquel5394Оценок пока нет

- Futuro Textiles 3Документ15 страницFuturo Textiles 3yumiОценок пока нет

- Practica 1 de Ingles Tecnico 1, IndividualДокумент7 страницPractica 1 de Ingles Tecnico 1, IndividualAranilda Bautista Gonzalez100% (1)

- Doris Chan - Lacy Duster OrigДокумент6 страницDoris Chan - Lacy Duster Origtritidief100% (1)

- Rainbow English Student Book 2Документ23 страницыRainbow English Student Book 2Tânia RochaОценок пока нет

- Garment Defect ClassificationДокумент3 страницыGarment Defect ClassificationDelwin Arikatt100% (2)

- The 10 Habits of Happy Mothers: Reclaiming Our Passion, Purpose, and SanityОт EverandThe 10 Habits of Happy Mothers: Reclaiming Our Passion, Purpose, and SanityРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Wear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedОт EverandWear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedРейтинг: 5 из 5 звезд5/5 (1)

- Bulletproof Seduction: How to Be the Man That Women Really WantОт EverandBulletproof Seduction: How to Be the Man That Women Really WantРейтинг: 4.5 из 5 звезд4.5/5 (170)

- The Magic of Crystals and Gems: Unlocking the Supernatural Power of Stones (Magical Crystals, Positive Energy, Mysticism)От EverandThe Magic of Crystals and Gems: Unlocking the Supernatural Power of Stones (Magical Crystals, Positive Energy, Mysticism)Рейтинг: 4 из 5 звезд4/5 (7)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsОт EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsРейтинг: 4 из 5 звезд4/5 (5)

- DIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!От EverandDIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Рейтинг: 3.5 из 5 звезд3.5/5 (7)

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtОт EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtОценок пока нет

- Women's Work: The First 20,000 Years: Women, Cloth, and Society in Early TimesОт EverandWomen's Work: The First 20,000 Years: Women, Cloth, and Society in Early TimesРейтинг: 4.5 из 5 звезд4.5/5 (191)

- Encyclopedia of Essential Oils: The complete guide to the use of aromatic oils in aromatherapy, herbalism, health and well-being. (Text Only)От EverandEncyclopedia of Essential Oils: The complete guide to the use of aromatic oils in aromatherapy, herbalism, health and well-being. (Text Only)Рейтинг: 5 из 5 звезд5/5 (5)

- Younger Skin Starts in the Gut: 4-Week Program to Identify and Eliminate Your Skin-Aging Triggers—Gluten, Wine, Dairy, and SugarОт EverandYounger Skin Starts in the Gut: 4-Week Program to Identify and Eliminate Your Skin-Aging Triggers—Gluten, Wine, Dairy, and SugarОценок пока нет

- Rip It!: How to Deconstruct and Reconstruct the Clothes of Your DreamsОт EverandRip It!: How to Deconstruct and Reconstruct the Clothes of Your DreamsРейтинг: 3.5 из 5 звезд3.5/5 (10)

- 250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaОт Everand250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaРейтинг: 5 из 5 звезд5/5 (7)

- Skincare for Your Soul: Achieving Outer Beauty and Inner Peace with Korean SkincareОт EverandSkincare for Your Soul: Achieving Outer Beauty and Inner Peace with Korean SkincareРейтинг: 5 из 5 звезд5/5 (2)

- 50 Fat Quarter Makes: Fifty Sewing Projects Made Using Fat QuartersОт Everand50 Fat Quarter Makes: Fifty Sewing Projects Made Using Fat QuartersAme VersoРейтинг: 3.5 из 5 звезд3.5/5 (6)

- Japanese Knitting Stitch Bible: 260 Exquisite Patterns by Hitomi ShidaОт EverandJapanese Knitting Stitch Bible: 260 Exquisite Patterns by Hitomi ShidaРейтинг: 4.5 из 5 звезд4.5/5 (35)

- The Black Pullet: Science of Magical TalismanОт EverandThe Black Pullet: Science of Magical TalismanРейтинг: 4.5 из 5 звезд4.5/5 (23)

- Basic Black: 26 Edgy Essentials for the Modern WardrobeОт EverandBasic Black: 26 Edgy Essentials for the Modern WardrobeРейтинг: 4 из 5 звезд4/5 (10)

- Make Your Mind Up: My Guide to Finding Your Own Style, Life, and Motavation!От EverandMake Your Mind Up: My Guide to Finding Your Own Style, Life, and Motavation!Рейтинг: 3.5 из 5 звезд3.5/5 (391)

- The Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?От EverandThe Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?Рейтинг: 5 из 5 звезд5/5 (23)

- Fabric Manipulation: 150 Creative Sewing TechniquesОт EverandFabric Manipulation: 150 Creative Sewing TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (13)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- A Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesОт EverandA Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesРейтинг: 4.5 из 5 звезд4.5/5 (2)