Академический Документы

Профессиональный Документы

Культура Документы

Tda 7052

Загружено:

Mateus Soares Da SilvaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tda 7052

Загружено:

Mateus Soares Da SilvaАвторское право:

Доступные форматы

INTEGRATED CIRCUITS

DATA SHEET

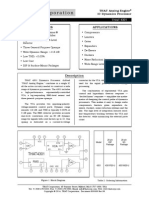

TDA7052A/AT 1 W BTL mono audio amplifier with DC volume control

Product specication File under Integrated circuits, IC01 July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

FEATURES DC volume control Few external components Mute mode Thermal protection Short-circuit proof No switch-on and off clicks Good overall stability Low power consumption Low HF radiation ESD protected on all pins QUICK REFERENCE DATA SYMBOL VP PO PARAMETERS positive supply voltage range output power TDA7052A TDA7052AT Gv IP THD maximum total voltage gain gain control range total quiescent current total harmonic distortion TDA7052A TDA7052AT ORDERING INFORMATION EXTENDED TYPE NUMBER TDA7052A TDA7052AT Notes 1. SOT97-1; 1996 September 10. 2. SOT96-1; 1996 September 10. 8 8 PACKAGE PINS DIL mini-pack PIN POSITION MATERIAL plastic plastic PO = 0.5 W PO = 0.25 W VP = 6 V; RL = RL = 8 ; VP = 6 V RL = 16 ; VP = 6 V 1.0 0.5 34.5 75 CONDITIONS MIN. 4.5 GENERAL DESCRIPTION

TDA7052A/AT

The TDA7052A/AT are mono BTL output amplifiers with DC volume control. They are designed for use in TV and monitors, but also suitable for battery-fed portable recorders and radios. Missing Current Limiter (MCL) A MCL protection circuit is built-in. The MCL circuit is activated when the difference in current between the output terminal of each amplifier exceeds 100 mA (typical 300 mA). This level of 100 mA allows for headphone applications (single-ended).

TYP.

MAX. 18 36.5 12 1 1

UNIT V W W dB dB mA % %

1.1 0.55 35.5 80 7 0.3 0.3

CODE SOT97(1) SOT96A(2)

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

VP

TDA7052A/AT

handbook, full pagewidth

1 n.c. 7

TDA7052A TDA7052AT

2 4

I + i

positive output

positive input DC volume control

I i

negative output

STABILIZER Vref

TEMPERATURE PROTECTION

MCD385 - 1

signal ground

power ground

Fig.1 Block diagram.

PINNING SYMBOL VP IN+ GND1 VC OUT+ GND2 n.c OUT 1 2 3 4 5 6 7 8 PIN DESCRIPTION positive supply voltage positive input signal ground DC volume control positive output power ground not connected negative output

VC 4

MCD384

handbook, halfpage

VP IN + GND1

1 2 3 TDA7052A TDA7052AT

8 7 6 5

OUT n.c. GND2 OUT +

Fig.2 Pin configuration.

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

FUNCTIONAL DESCRIPTION The TDA7052A/AT are mono BTL output amplifiers with DC volume control, designed for use in TV and monitors but also suitable for battery fed portable recorders and radios. In conventional DC volume circuits the control or input stage is AC coupled to the output stage via external capacitors to keep the offset voltage low. In the TDA7052A/AT the DC volume control stage is integrated into the input stage so that no coupling capacitors are required and yet a low offset voltage is maintained. At the same time the minimum supply remains low. The BTL principle offers the following advantages: Lower peak value of the supply current The frequency of the ripple on the supply voltage is twice the signal frequency.

TDA7052A/AT

Thus a reduced power supply with smaller capacitors can be used which results in cost savings. For portable applications there is a trend to decrease the supply voltage, resulting in a reduction of output power at conventional output stages. Using the BTL principle increases the output power. The maximum gain of the amplifier is fixed at 35.5 dB. The DC volume control stage has a logarithmic control characteristic. The total gain can be controlled from 35.5 dB to 44 dB. If the DC volume control voltage is below 0.3 V, the device switches to the mute mode. The amplifier is short-circuit proof to ground, VP and across the load. Also a thermal protection circuit is implemented. If the crystal temperature rises above +150 C the gain will be reduced, so the output power is reduced. Special attention is given to switch on and off clicks, low HF radiation and a good overall stability.

LIMITING VALUES In accordance with the Absolute Maximum System (IEC 134) SYMBOL VP IORM IOSM Ptot PARAMETER supply voltage range repetitive peak output current non-repetitive peak output current total power dissipation TDA7052A TDA7052AT Tamb Tstg Tvj Tsc V2 V4 operating ambient temperature range storage temperature range virtual junction temperature short-circuit time input voltage pin 2 input voltage pin 4 Tamb 25% 40 55 1.25 0.8 +85 +150 +150 1 8 8 W W C C C hr V V CONDITIONS MIN. MAX. 18 1.25 1.5 V A A UNIT

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

THERMAL RESISTANCE SYMBOL Rth j-a TDA7052A TDA7052AT Notes to the thermal resistance TDA7052A: VP = 6 V; RL = 8 . The maximum sine-wave dissipation is 0.9 W. Therefore Tamb(max) = 150 100 0.9 = 60 C. TDA7052AT: VP = 6 V; RL = 16 . The maximum sine-wave dissipation is 0.46 W. Therefore Tamb(max) = 150 155 0.46 = 78 C. PARAMETER from junction to ambient in free air 100 K/W 155 K/W

TDA7052A/AT

THERMAL RESISTANCE

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

TDA7052A/AT

CHARACTERISTICS VP = 6 V; Tamb = 25 C; f = 1 kHz; TDA7052A: RL = 8 ; TDA7052AT: RL = 16 ; unless otherwise specied (see Fig.6). SYMBOL VP IP PARAMETER positive supply voltage range total quiescent current VP = 6 V; RL = note 1 CONDITIONS MIN. 4.5 7 TYP. MAX. 18 12 UNIT V mA

Maximum gain; V4 = 1.4 V PO output power TDA7052A TDA7052AT THD total harmonic distortion TDA7052A TDA7052AT Gv VI Vno(rms) B SVRR |Voff| ZI voltage gain input signal handling noise output voltage (RMS value) bandwidth supply voltage ripple rejection DC output offset voltage input impedance (pin 2) V4 = 0.8 V; THD < 1% f = 500 kHz; note 2 1 dB note 3 PO = 0.5 W PO = 0.25 W 34.5 0.5 38 15 note 4 V4 0.3 V; VI = 600 mV 0.3 0.3 35.5 0.65 210 20 Hz to 300 kHz 46 0 20 44 20 1 1 36.5 150 25 30 dB mV k % % dB V V THD = 10% 1.0 0.5 1.1 0.55 W W

Minimum gain; V4 = 0.5 V Gv Vno(rms) VO I4 voltage gain noise output voltage (RMS value) dB V V

Mute position output voltage in mute position 30 80

DC volume control gain control range control current V4 = 0.4 V 75 60 80 70 dB A

Notes to the characteristics 1. With a load connected to the outputs the quiescent current will increase, the maximum value of this increase being equal to the DC output offset voltage dividend by RL. 2. The noise output voltage (RMS value) at f = 500 kHz is measured with RS = 0 and bandwidth = 5 kHz. 3. The ripple rejection is measured with RS = 0 and f = 100 Hz to 10 kHz. The ripple voltage of 200 mV, (RMS value) is applied to the positive supply rail. 4. The noise output voltage (RMS value) is measured with RS = 5 k unweighted.

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

TDA7052A/AT

MCD388

MCD389 - 1

handbook, halfpage

40 gain (dB) 20

handbook, halfpage

1000 Vnoise (V) 800

0 600 20 400 40 200

60

80 0 0.4 0.8 1.2 1.6 2.0 V4 (V)

0 0 0.4 0.8 1.2 1.6 V4 (V) 2.0

Fig.3 Gain control as a function of DC volume control.

Fig.4

Noise output voltage as a function of DC volume control.

MCD390 - 1

handbook, halfpage

100

I4 (A) 60

20

20

60

100 0 0.4 0.8 1.2 1.6 2.0 V4 (V)

Fig.5

Control current as a function of DC volume control.

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

APPLICATION INFORMATION

(1)

handbook, full pagewidth

TDA7052A/AT

VP = 6 V 100 nF 220 F

1 n.c. 7

TDA7052A TDA7052AT

positive input 0.47 F 2 4

I + i

R L= 8 (TDA7052A) R L = 16 (TDA7052A/AT) I i 8

RS

5 k STABILIZER Vref DC volume control TEMPERATURE PROTECTION

MCD386 - 1

This capacitor can be omitted if the 220 F electrolytic capacitor is connected close to pin 1.

ground

Fig.6 Test and application diagram.

handbook, halfpage

volume control 4

1 F

1 M

MCD387

Fig.7

Application with potentiometer as volume control; maximum gain = 30 dB.

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

PACKAGE OUTLINES DIP8: plastic dual in-line package; 8 leads (300 mil)

TDA7052A/AT

SOT97-1

D seating plane

ME

A2

A1

c Z e b1 w M (e 1) b2 5 MH

b 8

pin 1 index E

5 scale

10 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions) UNIT mm inches A max. 4.2 0.17 A1 min. 0.51 0.020 A2 max. 3.2 0.13 b 1.73 1.14 0.068 0.045 b1 0.53 0.38 0.021 0.015 b2 1.07 0.89 0.042 0.035 c 0.36 0.23 0.014 0.009 D (1) 9.8 9.2 0.39 0.36 E (1) 6.48 6.20 0.26 0.24 e 2.54 0.10 e1 7.62 0.30 L 3.60 3.05 0.14 0.12 ME 8.25 7.80 0.32 0.31 MH 10.0 8.3 0.39 0.33 w 0.254 0.01 Z (1) max. 1.15 0.045

Note 1. Plastic or metal protrusions of 0.25 mm maximum per side are not included. OUTLINE VERSION SOT97-1 REFERENCES IEC 050G01 JEDEC MO-001AN EIAJ EUROPEAN PROJECTION

ISSUE DATE 92-11-17 95-02-04

July 1994

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

TDA7052A/AT

SO8: plastic small outline package; 8 leads; body width 3.9 mm

SOT96-1

A X

c y HE v M A

Z 8 5

Q A2 A1 pin 1 index Lp 1 e bp 4 w M L detail X (A 3) A

2.5 scale

5 mm

DIMENSIONS (inch dimensions are derived from the original mm dimensions) UNIT mm inches A max. 1.75 A1 0.25 0.10 A2 1.45 1.25 A3 0.25 0.01 bp 0.49 0.36 c 0.25 0.19 D (1) 5.0 4.8 0.20 0.19 E (2) 4.0 3.8 0.16 0.15 e 1.27 HE 6.2 5.8 L 1.05 Lp 1.0 0.4 Q 0.7 0.6 v 0.25 0.01 w 0.25 0.01 y 0.1 Z (1) 0.7 0.3

0.010 0.057 0.069 0.004 0.049

0.019 0.0100 0.014 0.0075

0.244 0.039 0.028 0.050 0.041 0.228 0.016 0.024

0.028 0.004 0.012

8 0o

Notes 1. Plastic or metal protrusions of 0.15 mm maximum per side are not included. 2. Plastic or metal protrusions of 0.25 mm maximum per side are not included. OUTLINE VERSION SOT96-1 REFERENCES IEC 076E03S JEDEC MS-012AA EIAJ EUROPEAN PROJECTION

ISSUE DATE 95-02-04 97-05-22

July 1994

10

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

SOLDERING Introduction There is no soldering method that is ideal for all IC packages. Wave soldering is often preferred when through-hole and surface mounted components are mixed on one printed-circuit board. However, wave soldering is not always suitable for surface mounted ICs, or for printed-circuits with high population densities. In these situations reflow soldering is often used. This text gives a very brief insight to a complex technology. A more in-depth account of soldering ICs can be found in our IC Package Databook (order code 9398 652 90011). DIP SOLDERING BY DIPPING OR BY WAVE The maximum permissible temperature of the solder is 260 C; solder at this temperature must not be in contact with the joint for more than 5 seconds. The total contact time of successive solder waves must not exceed 5 seconds. The device may be mounted up to the seating plane, but the temperature of the plastic body must not exceed the specified maximum storage temperature (Tstg max). If the printed-circuit board has been pre-heated, forced cooling may be necessary immediately after soldering to keep the temperature within the permissible limit. REPAIRING SOLDERED JOINTS Apply a low voltage soldering iron (less than 24 V) to the lead(s) of the package, below the seating plane or not more than 2 mm above it. If the temperature of the soldering iron bit is less than 300 C it may remain in contact for up to 10 seconds. If the bit temperature is between 300 and 400 C, contact may be up to 5 seconds. SO REFLOW SOLDERING Reflow soldering techniques are suitable for all SO packages. Reflow soldering requires solder paste (a suspension of fine solder particles, flux and binding agent) to be applied to the printed-circuit board by screen printing, stencilling or pressure-syringe dispensing before package placement.

TDA7052A/AT

Several techniques exist for reflowing; for example, thermal conduction by heated belt. Dwell times vary between 50 and 300 seconds depending on heating method. Typical reflow temperatures range from 215 to 250 C. Preheating is necessary to dry the paste and evaporate the binding agent. Preheating duration: 45 minutes at 45 C. WAVE SOLDERING Wave soldering techniques can be used for all SO packages if the following conditions are observed: A double-wave (a turbulent wave with high upward pressure followed by a smooth laminar wave) soldering technique should be used. The longitudinal axis of the package footprint must be parallel to the solder flow. The package footprint must incorporate solder thieves at the downstream end. During placement and before soldering, the package must be fixed with a droplet of adhesive. The adhesive can be applied by screen printing, pin transfer or syringe dispensing. The package can be soldered after the adhesive is cured. Maximum permissible solder temperature is 260 C, and maximum duration of package immersion in solder is 10 seconds, if cooled to less than 150 C within 6 seconds. Typical dwell time is 4 seconds at 250 C. A mildly-activated flux will eliminate the need for removal of corrosive residues in most applications. REPAIRING SOLDERED JOINTS Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron (less than 24 V) applied to the flat part of the lead. Contact time must be limited to 10 seconds at up to 300 C. When using a dedicated tool, all other leads can be soldered in one operation within 2 to 5 seconds between 270 and 320 C.

July 1994

11

Philips Semiconductors

Product specication

1 W BTL mono audio amplier with DC volume control

DEFINITIONS Data sheet status Objective specication Preliminary specication Product specication Limiting values

TDA7052A/AT

This data sheet contains target or goal specications for product development. This data sheet contains preliminary data; supplementary data may be published later. This data sheet contains nal product specications.

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or at any other conditions above those given in the Characteristics sections of the specication is not implied. Exposure to limiting values for extended periods may affect device reliability. Application information Where application information is given, it is advisory and does not form part of the specication. LIFE SUPPORT APPLICATIONS These products are not designed for use in life support appliances, devices, or systems where malfunction of these products can reasonably be expected to result in personal injury. Philips customers using or selling these products for use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such improper use or sale.

July 1994

12

Вам также может понравиться

- Tda 1552 QДокумент10 страницTda 1552 QAnderson PotrikusОценок пока нет

- TDA1557QДокумент11 страницTDA1557QLuiz FernandoОценок пока нет

- Data Sheet: 1 W BTL Mono Audio AmplifierДокумент9 страницData Sheet: 1 W BTL Mono Audio AmplifierJuan Cruz PalmaОценок пока нет

- Tda 7052Документ8 страницTda 7052kunambersahajaОценок пока нет

- Data Sheet: Low Voltage Mono/stereo Power AmplifierДокумент9 страницData Sheet: Low Voltage Mono/stereo Power AmplifiergusguicorОценок пока нет

- TDA7073A DatasheetДокумент17 страницTDA7073A Datasheetsergio_741Оценок пока нет

- Tda 7052Документ8 страницTda 7052Srinath NettemОценок пока нет

- TDA1555QДокумент11 страницTDA1555QНикифор СтанојоскиОценок пока нет

- Tda 1013Документ11 страницTda 1013Marin MarinescuОценок пока нет

- Tda 1517Документ11 страницTda 1517minhchatnguyenОценок пока нет

- Tda 1308Документ17 страницTda 1308Manuel PradoОценок пока нет

- Data Sheet: 2 To 6 W Audio Power AmplifierДокумент14 страницData Sheet: 2 To 6 W Audio Power AmplifierSavio Alencar MacielОценок пока нет

- Tda 7053Документ13 страницTda 7053Fer TgОценок пока нет

- Tda 2613 QДокумент11 страницTda 2613 Qpaulmx13Оценок пока нет

- TDA7072 DatasheetДокумент11 страницTDA7072 Datasheetsergio_741Оценок пока нет

- Tda 7250Документ11 страницTda 7250Mazariegôs JJОценок пока нет

- Datasheet TDA7000 PDFДокумент10 страницDatasheet TDA7000 PDFRmsОценок пока нет

- Datasheet PDFДокумент10 страницDatasheet PDFSevillano MaycolОценок пока нет

- Data Sheet: TDA1510AQДокумент12 страницData Sheet: TDA1510AQGerardo PonceОценок пока нет

- TDA1554Q 44W Audio AmplifierДокумент11 страницTDA1554Q 44W Audio Amplifiersava7698Оценок пока нет

- Tda1013b PDFДокумент11 страницTda1013b PDFMarcelo AvilaОценок пока нет

- TDA2050 - DatasheetДокумент18 страницTDA2050 - Datasheetnwo330Оценок пока нет

- Tda 7250Документ12 страницTda 7250killer_jj100% (1)

- Tda 7497Документ8 страницTda 7497Madein ChinaОценок пока нет

- Data Sheet: 1 To 4 W Audio Power AmplifierДокумент13 страницData Sheet: 1 To 4 W Audio Power AmplifierThestrings91Оценок пока нет

- Ds Gs78lxx (F) Rev 1.0Документ9 страницDs Gs78lxx (F) Rev 1.0Juan Manuel Ibarra ZapataОценок пока нет

- TDA7233 TDA7233D: 1W Audio Amplifier With MuteДокумент7 страницTDA7233 TDA7233D: 1W Audio Amplifier With MutepempushekОценок пока нет

- TDA 1519cДокумент21 страницаTDA 1519cCris VMОценок пока нет

- 28W Hi-Fi Audio Power Amplifier With Mute / Stand-By: DescriptionДокумент11 страниц28W Hi-Fi Audio Power Amplifier With Mute / Stand-By: DescriptionbaczonifОценок пока нет

- DSДокумент13 страницDSazmanjamaatОценок пока нет

- TS921Документ16 страницTS921afsajghfdОценок пока нет

- 60 W Hi-Fi Dual Audio Driver: DescriptionДокумент12 страниц60 W Hi-Fi Dual Audio Driver: DescriptionLenin BabuОценок пока нет

- Tda 1904Документ11 страницTda 1904Adrian PérezОценок пока нет

- Tda 2030Документ11 страницTda 2030Fady HachemОценок пока нет

- 10W Car Radio Audio Amplifier: DescriptionДокумент10 страниц10W Car Radio Audio Amplifier: DescriptionLuis Arturo Leiva MonjarasОценок пока нет

- Tda 1517Документ14 страницTda 1517Cris VMОценок пока нет

- 2N4401Документ15 страниц2N4401Maurometal ZiggurathОценок пока нет

- LM 348 NДокумент6 страницLM 348 NbilarodrigoОценок пока нет

- Tda8920 2x50w Rms Class D AmplifierДокумент16 страницTda8920 2x50w Rms Class D AmplifierMarcisio Souza0% (1)

- Ta 0104 AДокумент18 страницTa 0104 AJump DownОценок пока нет

- Data Sheet: 2 X 6 W Stereo Car Radio Power AmplifierДокумент10 страницData Sheet: 2 X 6 W Stereo Car Radio Power Amplifierazzeddine_a7601Оценок пока нет

- Ba4558 PDFДокумент5 страницBa4558 PDFperro sОценок пока нет

- TDA1557QДокумент10 страницTDA1557QDaniel GureanuОценок пока нет

- Data Sheet: TDA6106QДокумент13 страницData Sheet: TDA6106Qban4444Оценок пока нет

- LM4811 Dual 105mW Headphone Amplifier With Digital Volume Control and Shutdown ModeДокумент20 страницLM4811 Dual 105mW Headphone Amplifier With Digital Volume Control and Shutdown ModeBuga BuniciОценок пока нет

- Ba4458 233498 - DS PDFДокумент6 страницBa4458 233498 - DS PDFOsman KoçakОценок пока нет

- Bu808 DatasheetДокумент8 страницBu808 Datasheetvoris115Оценок пока нет

- 2N2222Документ17 страниц2N2222Hugo LopezОценок пока нет

- BFR 91 AДокумент8 страницBFR 91 AGunnar Antonio Duran BarronОценок пока нет

- TDA7262Документ9 страницTDA7262Nelson PereiraОценок пока нет

- TDA7294Документ18 страницTDA7294frank121212Оценок пока нет

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsОт EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsОт EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsРейтинг: 3.5 из 5 звезд3.5/5 (6)

- Crowbar ProtectionДокумент1 страницаCrowbar Protectionkishan14175Оценок пока нет

- Lab # 01: Familiarization To ProteusДокумент13 страницLab # 01: Familiarization To ProteusLovely JuttОценок пока нет

- Power System Operation and Control 2 Marks by Mr.M.SureshДокумент19 страницPower System Operation and Control 2 Marks by Mr.M.SureshMr.M.SureshОценок пока нет

- TB045 - KeeLoq Manchester Encoding Receive Routines PDFДокумент12 страницTB045 - KeeLoq Manchester Encoding Receive Routines PDFpierdonneОценок пока нет

- Curtis 1243 2 Manual,: Rev. BДокумент78 страницCurtis 1243 2 Manual,: Rev. BJesus N RodriguezОценок пока нет

- MQ303AДокумент2 страницыMQ303APVPPPОценок пока нет

- "Simple Touch Alarm System" Subject: Report On Course Project OnДокумент14 страниц"Simple Touch Alarm System" Subject: Report On Course Project OnRichaОценок пока нет

- Unit-III Bipolar Junction Transistor PDFДокумент16 страницUnit-III Bipolar Junction Transistor PDFAnonymous 4F6VkOkWОценок пока нет

- Fire Alarm With Siren SoundДокумент2 страницыFire Alarm With Siren Soundmanjeet kumarОценок пока нет

- Automatic NiCd Battery Charger CircuitДокумент2 страницыAutomatic NiCd Battery Charger CircuitdewasuryantoОценок пока нет

- 19-0065 Rev 6 10/03Документ20 страниц19-0065 Rev 6 10/03dilinoxОценок пока нет

- Sulyok Et Al-2018-Energy Science & EngineeringДокумент13 страницSulyok Et Al-2018-Energy Science & Engineeringpetar2001Оценок пока нет

- An Activity Based Costing-Based A Case S-DikonversiДокумент12 страницAn Activity Based Costing-Based A Case S-DikonversiMuhammad Reza RizaldyОценок пока нет

- EC208 Analog Communication EngineeringДокумент2 страницыEC208 Analog Communication EngineeringtrismaheshОценок пока нет

- CS5532Документ50 страницCS5532Héctor LiendoОценок пока нет

- A Ferroelectric FET Based In-Memory Architecture For Multi-Precision Neural NetworksДокумент6 страницA Ferroelectric FET Based In-Memory Architecture For Multi-Precision Neural NetworksnandakishoryadavОценок пока нет

- Automating Manufacturing Systems Presentation Rev 4Документ89 страницAutomating Manufacturing Systems Presentation Rev 4tarekamininfoОценок пока нет

- Current Steering CircuitsДокумент35 страницCurrent Steering CircuitsBenazir Begam100% (1)

- Prework Questions For KI-1Документ5 страницPrework Questions For KI-1Danial SadiqОценок пока нет

- Liquid Level Indicator Using Op AmpДокумент25 страницLiquid Level Indicator Using Op AmpSontie sky walker0% (1)

- CapacitorsДокумент30 страницCapacitorsKovid BalliОценок пока нет

- DLD Lab ManualДокумент60 страницDLD Lab ManualUmesh BhadadeОценок пока нет

- HZ Series: Silicon Epitaxial Planar Zener Diode For Stabilized Power SupplyДокумент7 страницHZ Series: Silicon Epitaxial Planar Zener Diode For Stabilized Power SupplyCarlos BaezОценок пока нет

- Comparison Thyristor Vs ContactorДокумент3 страницыComparison Thyristor Vs ContactorZIPDASH0% (1)

- LM335 Temp SensorДокумент16 страницLM335 Temp SensorJuan Gil RocaОценок пока нет

- Transmisor de PresionДокумент92 страницыTransmisor de PresiongeovannycarpioОценок пока нет

- THAT 4301 DatasheetДокумент12 страницTHAT 4301 DatasheetSaverioCorОценок пока нет

- MPXV7007Документ11 страницMPXV7007Phi MacОценок пока нет

- Assignment2 - Network TheoryДокумент13 страницAssignment2 - Network TheoryMaulesh GandhiОценок пока нет

- DGCA Module-3 QuesДокумент7 страницDGCA Module-3 QuesPravin Hande100% (1)