Академический Документы

Профессиональный Документы

Культура Документы

SPO Subsea Applications v003

Загружено:

Baskar KannaiahАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SPO Subsea Applications v003

Загружено:

Baskar KannaiahАвторское право:

Доступные форматы

SPO Compact Flange

SPO-S CF : high integrity subsea ange connector

The most comprehensive range of bolted connectors

With the introduction of the 5K, 10K and 15K SPO Compact Flange standards, Vector Technology Group now offer a comprehensive range of bolted pipeline connectors for all recognised subsea piping applications. These additions to the already extensive SPO range ensure that Vector is more than capable of meeting the diverse requirements of all our clients. The SPO-S CF range offers an alternative that engineers have been waiting for and represents the ideal choice on an even greater variety of subsea applications.

What makes the SPO Compact Flange ideal for subsea piping applications?

SPO CF-S offer all of the following advantages over API flanges for your subsea piping system. High pressure flanges for subsea ASME B31.3 piping systems SPO Compact Flanges are designed to suit standard ASME B36.10M nominal pipe sizes, therefore, eliminating the necessity to incorporate tapers through the length of the flange to match bore the corresponding pipe. Flush bore - Reducing the likelihood of flow disturbance / flow irregularities whilst also offering ideal conditions for your pigging processes, a requirement of DNV-OS-F201. Exceptional fatigue characteristics - SPO Compact Flanges possess superior fatigue properties than both API and ASME flanges. Finite Element Analysis (FEA) testing confirms that the SPO compact flange fatigue properties exceed those of the weld adjoining the corresponding pipe. Static bolted pipeline connection - Loads are transferred via metal to metal contact points between the flange faces so as to completely eliminate the potential for movement between the assembled SPO Compact Flanges whilst under dynamic loading. High integrity sealing - SPO Compact Flanges incorporate two independent metal to metal sealing mechanisms. The seal ring is a non-load carrying seal which is unaffected by flanges loads, a requirement of DNV-OS-F201. Limited leakage probability - SPO Compact Flanges possess equivalent integrity to a girth welded pipe joint from a leakage probability perspective. Swivel ring flanges - SPO Compact Flanges are DNV type approval qualified and available in swivel design for all sizes listed within each pressure class. Reduced size and weight envelope - SPO Compact Flanges are both smaller and lighter than conventional API and ASME flanges, including swivel ring flanges.

SPO Compact Flanges are most commonly found on .

Subsea production flowlines Subsea gas-lift and water injection flowlines Subsea metering equipment Subsea valves, pumps and compressors Flexible and rigid risers Christmas tree equipment

Risers

SPO Compact SPO Compact FlangeFlange

Process Topside

Standard NORSOK L-005Compact Flange

Subsea

V002-03-2012

SPO Compact Flange

SPO-S CF : high integrity subsea ange connector

Differences with standard Compact Flange

SPO CF-S Standard CF

HX profile seal ring

The HX profile seal ring, a bi-directional seal ring recommended for use with SPO Compact Flanges for subsea piping applications, is an elastic seal ring which is energized by the deformation of the seal flanges towards the seal centreline. This deformation is governed by the groove and seal geometries. In addition, the seal will become pressure energized when subjected to either internal line pressure or external hyperbaric pressure. The shape and design of the HX profile seat and seal ring arrangement is ideal for flange alignment and can also compensate for flange misalignment.

sealing surfaces

The flanges are designed for NACE bolting such as A320 L7M and A453 Gr660. Standard L7 can be used and will give additional external load capacity.

Optimized geometry of transition from flange ring to flange neck in combination with a longer neck (in order to meet HISC requirements in DNV-RP-F112).

HX seal rings instead of standard seal rings.

sealing surfaces

SPO Compact Swivel Flanges

Available in all sizes within each SPO compact flange pressure class, SPO compact swivel ring flanges are designed to be at least as strong as the mating weld neck flange. SPO compact swivel ring flanges are specifically designed to withstand the gross assembly load applied when hydraulic tensioning are acting simultaneously upon each bolt-set at time of flange assembly.

Bending Moment [kNm]

Additional external load capacity for 8000psi at ambient temperature , NACE bolting A193 B7M bolts

200 180 160 140 120 100 80 60 40 20 0 0 500 1000 1500 2000

10 SPO CF 10K IX10 9 API 6A BX

Axial Load [kN]

SPO-S CF v API Class 10K weld neck flanges : Weight and dimension comparison chart

Nominal Size NPS 2 2 1/2 3 4 5 6 8 10 12 16 20 api size 1 13/16 2 1/16 2 9/16 3 1/16 4 1/16 5 1/8 7 1/16 9 11 13 5/8 16 3/4 Maximum Bore mm API SPO-S CF 46.7 55.1 53.1 64.5 65.8 73.8 78.5 90.2 103.9 110.3 131.1 140.1 180.1 187.5 229.4 232.1 280.2 264.9 347.0 344.7 426.2 439.0 API 8.0 9.8 15.4 23.9 40.4 58.0 135.4 211 337 549 655 Weight kg SPO-S CF 3.6 6.5 10.1 15.6 30.2 45.0 79.5 134.2 219.0 368 692 Saving 55 % 34 % 34 % 35 % 25 % 22 % 41 % 37 % 35 % 33 % -6 % Outside Diameter mm API SPO-S CF 187 147 200 181 232 210 270 246 316 300 357 333 480 426 552 516 654 614 768 729 871 890 Flange Thickness mm API SPO-S CF 42.2 32 43.9 38 51.3 43 58.4 50 70.4 65 79.5 79 103.1 86 124.0 95 141.2 109 168.1 135 168.1 170 Overall Length mm API SPO-S CF 107.6 80 114.3 90 129.9 100 146.6 115 174.2 144 196.6 173 247.4 209 280.5 248 319.9 290 374.4 362 352.0 454

Beside its superior performance, the SPO Compact Flange saves weight, overall length and reduces outside diameter. NOTE : following SPO-S CF sizes are also available but are not included in the table because they are not covered by API : , , 1, 1, 14, 18,22 and 24.

SPO is a trade mark of Vector AS (Norway pending other territories)

VECTOR and the Vector style are trade marks of Vector Technology Group

Вам также может понравиться

- High-Performance GM LS-Series Cylinder Head GuideОт EverandHigh-Performance GM LS-Series Cylinder Head GuideРейтинг: 4.5 из 5 звезд4.5/5 (2)

- API 6A ValveДокумент12 страницAPI 6A Valveedo_tapia_ur100% (1)

- Lifting Lug Design B 01Документ22 страницыLifting Lug Design B 01bakellyОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Standard Details For Metal Roofing & Siding: Post Frame and Residential StructuresДокумент48 страницStandard Details For Metal Roofing & Siding: Post Frame and Residential Structurespierre_oosthuizenОценок пока нет

- Catalog Mud Pump 25864Документ24 страницыCatalog Mud Pump 25864agus100% (1)

- Index: Product List SR. NOДокумент40 страницIndex: Product List SR. NOch_yustinusОценок пока нет

- CPДокумент12 страницCPthehammer2Оценок пока нет

- Hydraulic Flanges and ComponentsДокумент38 страницHydraulic Flanges and Componentsruksfarhan100% (2)

- Tandem Booster m100Документ12 страницTandem Booster m100Leonardo Alvarez100% (1)

- Control Choke Valve 9000Документ8 страницControl Choke Valve 9000sabi_shi100% (2)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- A Guide To Fall Protection in Industry R1Документ51 страницаA Guide To Fall Protection in Industry R1Nitish GunessОценок пока нет

- Apsara BorderДокумент15 страницApsara BorderskumarsrОценок пока нет

- Causes and Prevention of Cracks in BuildingДокумент34 страницыCauses and Prevention of Cracks in Buildingvatika100% (2)

- Axon-Type50u Ram BopДокумент4 страницыAxon-Type50u Ram BopMohie Khosravani0% (1)

- Fundamentals of Modern Manufacturing 6th Edition Groover Solutions ManualДокумент2 страницыFundamentals of Modern Manufacturing 6th Edition Groover Solutions Manuala36734003320% (5)

- Heat Balance DiagramДокумент10 страницHeat Balance DiagramJitendra Bhatia100% (3)

- Centurion Pump Line: Unmatched Performance and Abrasion ResistanceДокумент6 страницCenturion Pump Line: Unmatched Performance and Abrasion ResistancehenbauОценок пока нет

- Experienced Based Rules of Chemical EngineeringДокумент33 страницыExperienced Based Rules of Chemical Engineeringintania66Оценок пока нет

- 04 Manifold HydraulicsДокумент27 страниц04 Manifold Hydraulicsjoapme100% (1)

- ValvesДокумент8 страницValvespravin_2011Оценок пока нет

- Kofco Catalouge FlangeДокумент96 страницKofco Catalouge Flangeluft3744100% (4)

- Perar Trunnion Ball ValvesДокумент54 страницыPerar Trunnion Ball ValvesUday GokhaleОценок пока нет

- Air Receivers Volume CalculationДокумент98 страницAir Receivers Volume CalculationBaskar Kannaiah100% (1)

- Corrosion Ring CalculationДокумент6 страницCorrosion Ring CalculationEko Januarto0% (1)

- WKM DynaSeal 370D4 PDFДокумент40 страницWKM DynaSeal 370D4 PDFAlfredo MedinaОценок пока нет

- Hydraulic FluidДокумент4 страницыHydraulic FluidBaskar KannaiahОценок пока нет

- 01 - Fluid FlowДокумент80 страниц01 - Fluid FlowEmir KarОценок пока нет

- 05 Edge Welded BellowsДокумент13 страниц05 Edge Welded BellowsAbhishek BasakОценок пока нет

- 2017 LATBSDC CRITERIA - Final - 06 08 17 PDFДокумент72 страницы2017 LATBSDC CRITERIA - Final - 06 08 17 PDFRannie IsonОценок пока нет

- Chapter 4: Absorbers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallДокумент11 страницChapter 4: Absorbers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallBaskar KannaiahОценок пока нет

- High Performance Butterfly ValvesДокумент8 страницHigh Performance Butterfly ValvesTejas JasaniОценок пока нет

- Skid Calculation GasДокумент5 страницSkid Calculation GasBaskar KannaiahОценок пока нет

- Introduction GASKETSДокумент11 страницIntroduction GASKETSradharaman_znaОценок пока нет

- Block & Bleed Valve: High Technology Valve & Fitting SeriesДокумент20 страницBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelОценок пока нет

- Uf FloatingДокумент20 страницUf Floatingmhidayat108100% (1)

- Pump Energy Efficiency Calculation ToolДокумент8 страницPump Energy Efficiency Calculation ToolSoma NathanОценок пока нет

- Hvac Report 20140604Документ198 страницHvac Report 20140604Muhammad Yusuf FirdausОценок пока нет

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A PumpДокумент11 страницCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pumpthanh_79Оценок пока нет

- 1.hornos RotatoriosДокумент493 страницы1.hornos RotatoriosRonald100% (4)

- SPO Compact Flange Technical v02 2012Документ40 страницSPO Compact Flange Technical v02 2012Bueno8100% (2)

- Api Plan 11Документ6 страницApi Plan 11johnsaballaОценок пока нет

- Windposts and Masonry Reinforcement: For The Construction IndustryДокумент12 страницWindposts and Masonry Reinforcement: For The Construction IndustryKelvin bongОценок пока нет

- SPO Webversion HighДокумент6 страницSPO Webversion HighchadОценок пока нет

- Hydraulic Flanges & Components & Dual Seal FlangesДокумент44 страницыHydraulic Flanges & Components & Dual Seal Flangesfernandomachado1992100% (1)

- Hydraulic Flanges & Components & Dual Seal FlangesДокумент44 страницыHydraulic Flanges & Components & Dual Seal FlangesPartsGopher.comОценок пока нет

- Specification - 9110 - 201510 at Globe (Rev.03)Документ10 страницSpecification - 9110 - 201510 at Globe (Rev.03)Công PhạmОценок пока нет

- Ball Valves: For SteamДокумент8 страницBall Valves: For SteamcontorrresjulianОценок пока нет

- Serie FA Ball ValvesДокумент8 страницSerie FA Ball Valvesmetasoniko2014Оценок пока нет

- Foam ChambersДокумент4 страницыFoam ChambersIvo KovachevОценок пока нет

- VJ Flexlock BroДокумент9 страницVJ Flexlock BroAhmad ShakeelОценок пока нет

- Faslt 0020 enДокумент6 страницFaslt 0020 enshashikanth79Оценок пока нет

- Seaboard CatalogДокумент21 страницаSeaboard Catalogdmccaulley11Оценок пока нет

- SUR Seal FlyerДокумент4 страницыSUR Seal Flyersong LiОценок пока нет

- Ferulok Flareless Bite Type FittingsДокумент14 страницFerulok Flareless Bite Type FittingsPartsGopher.comОценок пока нет

- Parker MA Series PDFДокумент17 страницParker MA Series PDFhaggОценок пока нет

- Top Entry Trunnion 600 - 2500Документ20 страницTop Entry Trunnion 600 - 2500Danny PuchaОценок пока нет

- Si-704en - Id161 Valvula BolaДокумент4 страницыSi-704en - Id161 Valvula BolacarlosyanezlagosОценок пока нет

- Veljan Hydraulic CatlogueДокумент20 страницVeljan Hydraulic CatlogueRaji SuriОценок пока нет

- Gate Valve CataogueДокумент4 страницыGate Valve CataogueAditya B. RyantoОценок пока нет

- Roc-Master Swivel Ring Flange DatasheetДокумент4 страницыRoc-Master Swivel Ring Flange DatasheetlunloonОценок пока нет

- Fire DRY HydrantsДокумент4 страницыFire DRY HydrantsAbdullah RamadanОценок пока нет

- Series LF909 Specification SheetДокумент4 страницыSeries LF909 Specification SheetWattsОценок пока нет

- Spirax Sarco PDFДокумент4 страницыSpirax Sarco PDFandresaroОценок пока нет

- F 85154Документ4 страницыF 85154nazar750Оценок пока нет

- Monoflanges VariAS BlocksДокумент20 страницMonoflanges VariAS BlocksamuihОценок пока нет

- Válvula DurcoДокумент12 страницVálvula DurcoJames Henrry López EspejoОценок пока нет

- Aop ChokesДокумент12 страницAop Chokesweldsv1Оценок пока нет

- Catalog TOLCOДокумент80 страницCatalog TOLCOCostel BalasoiuОценок пока нет

- B-313 Series E-1510 Technical BrochureДокумент8 страницB-313 Series E-1510 Technical BrochureAnonymous 7xHNgoKE6eОценок пока нет

- Valve0114 PDFДокумент14 страницValve0114 PDFbinhjukiОценок пока нет

- Technical Bulletin: Valtek Mark One Control ValvesДокумент20 страницTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzОценок пока нет

- SKUM Over The Top Foam Generators OFG OFGR-0917Документ4 страницыSKUM Over The Top Foam Generators OFG OFGR-0917Lee Liang ChenОценок пока нет

- LoResCentron 2010Документ145 страницLoResCentron 2010Hendy96Оценок пока нет

- Hidrolik SilindirlerДокумент20 страницHidrolik SilindirlerEnver AtamanОценок пока нет

- Restrictive OrificeДокумент11 страницRestrictive Orificeligia hancu100% (1)

- Technip Drilling BrochureДокумент12 страницTechnip Drilling Brochurenedumaran.sОценок пока нет

- In Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkДокумент2 страницыIn Line High Flow' Insertion Type Regulators For 4" - 8" PipeworkIdehen KelvinОценок пока нет

- ButterflyДокумент24 страницыButterflyVinodh VinoОценок пока нет

- NCPWB-TR-Steel Pipe Fitting DataДокумент285 страницNCPWB-TR-Steel Pipe Fitting DataBaskar KannaiahОценок пока нет

- I2SL Fan Codes Standards 2013 Fan Codes StandardsДокумент32 страницыI2SL Fan Codes Standards 2013 Fan Codes StandardsBaskar KannaiahОценок пока нет

- Inventory Usage SampleДокумент27 страницInventory Usage SampleAnonymous lt2LFZHОценок пока нет

- Channels 0. Channels and Pipes With Frictional and Singular Pressure DropДокумент111 страницChannels 0. Channels and Pipes With Frictional and Singular Pressure DropBaskar KannaiahОценок пока нет

- 06 CompressorsДокумент16 страниц06 CompressorsmunatsiОценок пока нет

- Tri P10Документ10 страницTri P10isaac2408Оценок пока нет

- Tri P10Документ10 страницTri P10isaac2408Оценок пока нет

- Crude Oil Transfer ProДокумент3 страницыCrude Oil Transfer ProBaskar KannaiahОценок пока нет

- Drainge&Waste WaterДокумент43 страницыDrainge&Waste WatermohdnazirОценок пока нет

- Stern TubeДокумент6 страницStern TubeBaskar KannaiahОценок пока нет

- Chemical Feed Systems Basic Design Berschauer 060712Документ9 страницChemical Feed Systems Basic Design Berschauer 060712Baskar KannaiahОценок пока нет

- Equipment Data & P&id 1-10Документ10 страницEquipment Data & P&id 1-10Baskar KannaiahОценок пока нет

- Installation, Operation, and Maintenance Manual: Non-Welded Grease Duct SystemsДокумент20 страницInstallation, Operation, and Maintenance Manual: Non-Welded Grease Duct SystemsBaskar KannaiahОценок пока нет

- Fo Filling & Transfer SystДокумент1 страницаFo Filling & Transfer SystBaskar KannaiahОценок пока нет

- Pump Curve CalcДокумент6 страницPump Curve CalcBaskar KannaiahОценок пока нет

- Bunkering Procedures No 13Документ2 страницыBunkering Procedures No 13Baskar KannaiahОценок пока нет

- Bilge SystemДокумент1 страницаBilge SystemBaskar KannaiahОценок пока нет

- SealingДокумент6 страницSealingBaskar KannaiahОценок пока нет

- Load CalculationДокумент5 страницLoad CalculationBaskar Kannaiah100% (1)

- Specifications of Ajmera InfinityДокумент4 страницыSpecifications of Ajmera Infinitysrekha11Оценок пока нет

- A Solar Powered Adsorption Freezer: A Case Study For Egypt's ClimateДокумент9 страницA Solar Powered Adsorption Freezer: A Case Study For Egypt's Climateali105Оценок пока нет

- MRB Index (Minimum Requirements) : Sub Index Sub. Sub Index Description No. No. Remarks Part 1 - Purchase Order DataДокумент4 страницыMRB Index (Minimum Requirements) : Sub Index Sub. Sub Index Description No. No. Remarks Part 1 - Purchase Order Databmanojkumar16Оценок пока нет

- 50ucupv PSD enДокумент58 страниц50ucupv PSD enMohd AzharОценок пока нет

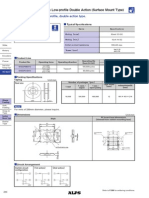

- 0.6mm Low-Profile, Double Action TypeДокумент3 страницы0.6mm Low-Profile, Double Action TypeshyhuОценок пока нет

- Polystone P Homopolymer: Technical Data SheetДокумент1 страницаPolystone P Homopolymer: Technical Data Sheetmuchamad yasinОценок пока нет

- VPAKДокумент2 страницыVPAKPingu3Оценок пока нет

- Fracture Mechanics of Delamination Buckling in Laminated CompositesДокумент20 страницFracture Mechanics of Delamination Buckling in Laminated CompositesShree BiradarОценок пока нет

- VENTURIMETERДокумент4 страницыVENTURIMETERKailash RajuОценок пока нет

- An Interface Element For The Simulation of Delamination in Unidirectional Fiber-Reinforced Composite LaminatesДокумент19 страницAn Interface Element For The Simulation of Delamination in Unidirectional Fiber-Reinforced Composite LaminatesKamal ShayedОценок пока нет

- Is 1343Документ65 страницIs 134335Оценок пока нет

- Multiple Uses of Universal Testing Machine: Iraq University College Department of Civil EngineeringДокумент31 страницаMultiple Uses of Universal Testing Machine: Iraq University College Department of Civil EngineeringAhmed NasratОценок пока нет

- CVC Thermoset BrochureДокумент28 страницCVC Thermoset BrochureMattОценок пока нет

- GE Panle BoardДокумент52 страницыGE Panle Boardchandrakanth0083396Оценок пока нет

- SUP032BR: Esp. E74104 Rev.01Документ5 страницSUP032BR: Esp. E74104 Rev.01kimanski01Оценок пока нет

- Green Leaf Exotica Apartment Brochure PDFДокумент12 страницGreen Leaf Exotica Apartment Brochure PDFbhaskar_yogendraОценок пока нет

- Sabiana FC CRCДокумент23 страницыSabiana FC CRCIgor SpasovicОценок пока нет

- HW - 05 2Документ2 страницыHW - 05 2foufou2003Оценок пока нет

- Absorber of FGD System - PPV - VEFДокумент2 страницыAbsorber of FGD System - PPV - VEFJC MexguyОценок пока нет