Академический Документы

Профессиональный Документы

Культура Документы

BS en 1057 Tube Sizes - Crane Copper Tube

Загружено:

starykltАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BS en 1057 Tube Sizes - Crane Copper Tube

Загружено:

starykltАвторское право:

Доступные форматы

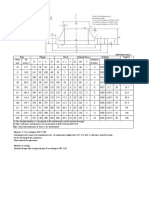

CRANE COPPER TUBE TO EN 1057

Copper and copper alloys - seamless, round copper tubes for water and gas in sanitary and heating applications

EN 1057 - TYPE Y

Size mm 6 8 10 12 15 18 22 28 35 42 54 66.7 76.1 108 Nom. Dia. (Outside) mm 6 8 10 12 15 18 22 28 35 42 54 66.7 76.1 108 Nom. Wall Thickness mm 0.8 0.8 0.8 0.8 1.0 1.0 1.2 1.2 1.5 1.5 2.0 2.0 2.0 2.5

+1

(PREVIOUSLY BS 2871 TABLE Y) Max. Working Pressures* Half Hard bar+ 188 136 106 87 87 72 69 55 54 45 47 37 33 29 bar = 0.1N/mm = 10 5 N/m Hard bar+ 223 161 126 104 104 85 84 65 65 54 56 45 39 34 Annealed bar+ 144 105 82 67 67 55 53 42 41 34 36 28 25 22

*Based on designated temper at 65C

Usage: Underground w orks and heav y duty requirements including hot and cold w ater supply, gas reticulation, sanitary plumbing, heating and general engineering.

ADDED TOUGHNESS & DURABILITY

EN 1057 - TYPE X

Size mm 6 8 10 12 15 18 22 28 35 42 54 66.7 76.1 108 133 159 Nom. Dia. (Outside) mm 6 8 10 12 15 18 22 28 35 42 54 66.7 76.1 108 133 159 Nom. Wall Thickness mm 0.6 0.6 0.6 0.6 0.7 0.8 0.9 0.9 1.2 1.2 1.2 1.2 1.5 1.5 1.5 2.0

+1

(PREVIOUSLY BS 2871 TABLE X) Max. Working Pressures* Half Hard bar+ 133 97 77 63 58 56 51 40 42 35 27 20 24 17 14 15 bar = 0.1N/mm = 10 5 N/m Hard bar+ 161 118 93 76 71 67 62 48 51 43 33 27 29 20 17 18 Annealed bar+ 102 75 59 48 45 43 39 31 33 27 21 17 18 13 10 12

*Based on designated temper at 65C

Usage: Abov e groundserv ices including drinking w ater supply, hot and cold w ater systems, sanitation, central heating and other general purpose applications.

ECONOMICAL AND STRONG

EN 1057 - TYPE Z

Size mm 6 8 10 12 15 Nom. Dia. (Outside) mm 6 8 10 12 15 Nom. Wall Thickness mm 0.5 0.5 0.5 0.5 0.5

(PREVIOUSLY BS 2871 TABLE X) Max. Working Pressures* bar+ 113 98 78 64 50

15 18 22 28 35 42 54 66.7 76.1 108 133 159

15 18 22 28 35 42 54 66.7 76.3 108 133 159.5

0.5 0.6 0.6 0.6 0.7 0.8 0.9 1.0 1.2 1.2 1.5 1.5

+

50 50 41 32 30 28 25 20 19 17 16 15 1 bar = 0.1N/mm = 10 5 N/m

*Based on material in hard drawn condition at 65C

Usage: Abov e groundserv ices including drinking w ater supply, hot and cold w ater systems, sanitation, central heating and other general purpose applications.

LOW COST UTILITY RANGE

MECHANICAL PROPERTIES OF TUBE TO EN 1057

Temper R220 Annealed R250 Half Hard R250 Half Hard R290 Hard Nom. Dia. (Outside) 6 to 54mm 6 to 66.7mm 6 to 159mm 6 to 267mm MPa* 220 250 250 290 Minimum Elongation 40% 30% # 20% # 3% Hardness** 40 to 70 75 to 100 75 to 100 100 min

# Note: Elongations for half hard tubes depend on the ratio of outside diameter to wall thickness. * MPa: Minimum tensile strength ** Hardness HV/5 indicative

Return to Tube Sizing index...

2014, Crane Enfield Metals Pty Ltd. A ll Rights Reserv ed. Priv acy Policy | Disclaimer

A Nice

site.

Вам также может понравиться

- @@@ BS en 1057 Tube Sizes - Crane Copper TubeДокумент2 страницы@@@ BS en 1057 Tube Sizes - Crane Copper TubestarykltОценок пока нет

- 10 1092Документ39 страниц10 1092ThinkProgressОценок пока нет

- Fittings Din11852 Din11850Документ14 страницFittings Din11852 Din11850dingobk1Оценок пока нет

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityДокумент5 страницMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhОценок пока нет

- Din 2616 PDFДокумент2 страницыDin 2616 PDFALEKSANDARОценок пока нет

- Din en 10216-2Документ2 страницыDin en 10216-2vishal.nitham100% (1)

- Din 2616 PDFДокумент2 страницыDin 2616 PDFTahresОценок пока нет

- Conical Seat Spherical Washer Is 4297Документ6 страницConical Seat Spherical Washer Is 4297Rajasekaran Murugan0% (1)

- Din 3357-4-1981Документ5 страницDin 3357-4-1981олегОценок пока нет

- Din 6798 AДокумент3 страницыDin 6798 ADuong BachОценок пока нет

- 2814 01jan08t51626Документ20 страниц2814 01jan08t51626Philip_8300% (1)

- 1LUB000001-BLE InstallationManual Dry 201402Документ24 страницы1LUB000001-BLE InstallationManual Dry 201402Anonymous mcCJYBoОценок пока нет

- DIN 2076 vs. ASTM A 877Документ1 страницаDIN 2076 vs. ASTM A 877tobypadfieldОценок пока нет

- RJR PMMTДокумент16 страницRJR PMMTArun PrasadОценок пока нет

- Stainless Steel Food-Industry Tubes: Seamless & WeldedДокумент8 страницStainless Steel Food-Industry Tubes: Seamless & WeldedspiratubeОценок пока нет

- Din 15207Документ2 страницыDin 15207damodarvajjaОценок пока нет

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoДокумент2 страницыAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987Оценок пока нет

- DIN 2527-1972, Blank FlangesДокумент6 страницDIN 2527-1972, Blank FlangesalfredopinillosОценок пока нет

- Pins and KeysДокумент12 страницPins and KeysSam GillilandОценок пока нет

- 1 2312 PDFДокумент4 страницы1 2312 PDFFrancisco CarrascoОценок пока нет

- SC470-P Four Inch STUB Cyclone 2016Документ2 страницыSC470-P Four Inch STUB Cyclone 2016Tobias De Somer100% (1)

- Hollow Steel Catalog PDFДокумент44 страницыHollow Steel Catalog PDFaiyubi2Оценок пока нет

- Iso 4783-2Документ12 страницIso 4783-2Retract11Оценок пока нет

- Din 976-1 1995Документ6 страницDin 976-1 1995Charmaine DrafkeОценок пока нет

- E91 202006 20orifice 20plate 20 - 20doschДокумент6 страницE91 202006 20orifice 20plate 20 - 20doschiaft100% (1)

- Waste Heat Recovery Vinay ShuklaДокумент31 страницаWaste Heat Recovery Vinay ShuklaVnyОценок пока нет

- Cables CSA Norma CanadienseДокумент98 страницCables CSA Norma CanadienseJesús EstévezОценок пока нет

- 4 Steel Rod Bar Wire For Cold Heading and Cold Extrusion - Del Conds Q and T SteelsДокумент22 страницы4 Steel Rod Bar Wire For Cold Heading and Cold Extrusion - Del Conds Q and T SteelsDiana MurzacОценок пока нет

- Parallel Key Calculation According To DIN 6892Документ21 страницаParallel Key Calculation According To DIN 6892zahirshah1436923Оценок пока нет

- CuZn39pb3 - DIN 12164Документ1 страницаCuZn39pb3 - DIN 12164Bruno FaveroОценок пока нет

- Mil 12560 Armor PlateДокумент39 страницMil 12560 Armor Plategman5900Оценок пока нет

- 06 Eurocodes Steel Workshop WALDДокумент136 страниц06 Eurocodes Steel Workshop WALDFrancisco RojasОценок пока нет

- Stainless Steel Sightglass Din 28120 28121Документ4 страницыStainless Steel Sightglass Din 28120 28121Thoa Tran VanОценок пока нет

- Metric Thread - Extended Thread Size RangeДокумент19 страницMetric Thread - Extended Thread Size RangeNatashaAggarwalОценок пока нет

- Old and New DINДокумент6 страницOld and New DINDianaОценок пока нет

- Metric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityДокумент5 страницMetric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityJaganОценок пока нет

- Din 2616 PDFДокумент2 страницыDin 2616 PDFmiguelfpintoОценок пока нет

- Round Washers SN 808: July 2000Документ1 страницаRound Washers SN 808: July 2000Maurício Duarte de AndradeОценок пока нет

- Din 2577Документ2 страницыDin 2577zaharievОценок пока нет

- ErmetoДокумент14 страницErmetoJavier VespaОценок пока нет

- Din Flange Din 2627: (Dimensions in MM.)Документ12 страницDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönОценок пока нет

- 1.4404 enДокумент5 страниц1.4404 enyraju88Оценок пока нет

- Al Busbar 6060 DatasheetДокумент1 страницаAl Busbar 6060 DatasheetpiirsaluОценок пока нет

- AVK Gate Valve HandwheelДокумент2 страницыAVK Gate Valve HandwheelQubit SizedОценок пока нет

- MIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsДокумент47 страницMIL-STD-193L Painting Procedures and Marking For Vehicles, Construction Equipment, Material Handling Equipment, and Spare PartsCemalОценок пока нет

- PV Syst Report - 15KWp Roof Top Solar PV PlantДокумент8 страницPV Syst Report - 15KWp Roof Top Solar PV PlantstalineleОценок пока нет

- Circlip Data PDFДокумент6 страницCirclip Data PDFRay FaiersОценок пока нет

- Din 470 PDFДокумент6 страницDin 470 PDFLuciano FontesОценок пока нет

- BS en 1412-2016Документ12 страницBS en 1412-2016S TОценок пока нет

- GB T 699 1988 Quality Carbon Structural SteelsДокумент17 страницGB T 699 1988 Quality Carbon Structural SteelsPHUONGОценок пока нет

- 1DIN 6921-10.9 Hex Flange Bo.Документ2 страницы1DIN 6921-10.9 Hex Flange Bo.Sunil BaliОценок пока нет

- Uni 663 Grade Fe55 1 Tubes PDFДокумент1 страницаUni 663 Grade Fe55 1 Tubes PDFMitul MehtaОценок пока нет

- Fittings - DIN 2616: VL Code 731Документ2 страницыFittings - DIN 2616: VL Code 731RatheeshОценок пока нет

- Requirements For Seismic Qualification of HVACR EquipmentДокумент32 страницыRequirements For Seismic Qualification of HVACR Equipmentabhishek yadavОценок пока нет

- 1390-1997 Cup Head Bolts With ISO Metric Coarse Pitch ThreadsДокумент19 страниц1390-1997 Cup Head Bolts With ISO Metric Coarse Pitch ThreadsSean LiongОценок пока нет

- Ejector Simulation PaperДокумент11 страницEjector Simulation PaperRavi RanjanОценок пока нет

- BS en 1057 Tube Sizes - Crane Copper TubeДокумент2 страницыBS en 1057 Tube Sizes - Crane Copper TubeΣπίθας ΣπιθαμήОценок пока нет

- Mueller Black Label en 1057Документ2 страницыMueller Black Label en 1057Maria Emeren Mercado Baba100% (1)

- Thyssenkrupp Materials International: Material Data SheetДокумент4 страницыThyssenkrupp Materials International: Material Data SheetjaseerkannothОценок пока нет

- Uow009699 Building Elements Commissioning StandardДокумент28 страницUow009699 Building Elements Commissioning StandardstarykltОценок пока нет

- Uow009694 Hydraulic Services Design StandardsДокумент37 страницUow009694 Hydraulic Services Design StandardsstarykltОценок пока нет

- Aqua 1Документ324 страницыAqua 1staryklt100% (1)

- Power System Sizing Form: G G G GДокумент4 страницыPower System Sizing Form: G G G GstarykltОценок пока нет

- Ts Join GuideДокумент1 страницаTs Join GuidestarykltОценок пока нет

- Glossary of Home Construction Terms - HCM-04759Документ15 страницGlossary of Home Construction Terms - HCM-04759starykltОценок пока нет

- Residential Electric Service InstallationДокумент56 страницResidential Electric Service InstallationJ Hevesi100% (1)

- 7123AF Aquatherm Fusiotherm Hot & Cold Water System 2010Документ9 страниц7123AF Aquatherm Fusiotherm Hot & Cold Water System 2010starykltОценок пока нет

- Enclosed Shower BaysetДокумент2 страницыEnclosed Shower BaysetstarykltОценок пока нет

- Guide To Concrete RepairДокумент168 страницGuide To Concrete Repairhansen_zinck4751100% (11)

- Floor Waste Installation OverviewДокумент2 страницыFloor Waste Installation OverviewstarykltОценок пока нет

- 0621 SIKA Waterproofing - Wet AreasДокумент12 страниц0621 SIKA Waterproofing - Wet Areasstaryklt100% (1)

- Appendix 07 - Deliverables - Detailed SubmissionДокумент10 страницAppendix 07 - Deliverables - Detailed SubmissionstarykltОценок пока нет

- 0 - Mains Water Pipe SizingДокумент4 страницы0 - Mains Water Pipe SizingstarykltОценок пока нет

- Ceramic Tilles Installation ManualДокумент16 страницCeramic Tilles Installation ManualstarykltОценок пока нет

- @@@ Geothermal-WellsДокумент44 страницы@@@ Geothermal-WellsstarykltОценок пока нет

- MEN System of EarthningДокумент6 страницMEN System of EarthningstarykltОценок пока нет

- Specification For Stop ValvesДокумент9 страницSpecification For Stop ValvesstarykltОценок пока нет

- Bbse3006 1011 05-Waterside01Документ60 страницBbse3006 1011 05-Waterside01starykltОценок пока нет

- Bbse3006 1011 05-Waterside01Документ60 страницBbse3006 1011 05-Waterside01starykltОценок пока нет

- Mebs6000 1011 01 Cold & Flush WaterДокумент70 страницMebs6000 1011 01 Cold & Flush Waterstaryklt100% (1)

- Ostrich Farming (FARM To PLATE) FinalДокумент8 страницOstrich Farming (FARM To PLATE) FinalMuhammad BilalОценок пока нет

- Physics Question Bank 2 2012-2013Документ12 страницPhysics Question Bank 2 2012-2013Hany ElGezawy100% (1)

- Yellow FeverДокумент1 страницаYellow FeverajithpakОценок пока нет

- ACLS Review TestДокумент5 страницACLS Review Testtostc60% (5)

- 12 Physics Current Electricity Test 05 AnswerДокумент2 страницы12 Physics Current Electricity Test 05 AnswerphultushiblsОценок пока нет

- Vehicle Search ProceduresДокумент13 страницVehicle Search Proceduressanjuan_97Оценок пока нет

- CR1610Документ2 страницыCR1610Eulides RomeroОценок пока нет

- Presented By: Abhishek Sambhav FMS ROLL-02Документ25 страницPresented By: Abhishek Sambhav FMS ROLL-02Varun MehrotraОценок пока нет

- Drag DivergenceДокумент1 страницаDrag DivergenceBijin ChadayanОценок пока нет

- This ForДокумент2 страницыThis ForChapter 11 DocketsОценок пока нет

- Formwork DesignДокумент2 страницыFormwork DesignBilal Ahmed Barbhuiya67% (3)

- Karan Nangia Resume 1 1Документ2 страницыKaran Nangia Resume 1 1Vaibhav ZawarОценок пока нет

- Speed Acceleration WorksheetДокумент2 страницыSpeed Acceleration WorksheetPei JingОценок пока нет

- EE6511Документ1 страницаEE6511suprobhatОценок пока нет

- Ibo 06Документ4 страницыIbo 06Bhavna SinghalОценок пока нет

- Compensation & Reward Strategy: By:-Deepak Angrish Dheeraj Kokil Manisha Rahul Tejyan Prabhat TomarДокумент13 страницCompensation & Reward Strategy: By:-Deepak Angrish Dheeraj Kokil Manisha Rahul Tejyan Prabhat TomarangrishdeepakОценок пока нет

- CEMA Safety Poster SetДокумент9 страницCEMA Safety Poster Settinesh_vohraОценок пока нет

- HMДокумент2 страницыHMgangrukaОценок пока нет

- Sizing Capacitor Banks Power Factor CorrectionДокумент21 страницаSizing Capacitor Banks Power Factor CorrectiongauravatiwariОценок пока нет

- Exam 2 ReviewДокумент3 страницыExam 2 Reviewdhruv1117Оценок пока нет

- Role of Community Radio As A Means of Social MobilizationДокумент8 страницRole of Community Radio As A Means of Social MobilizationAhm Bazlur RahmanОценок пока нет

- Scope of MBA in Rural Management in Banking & FinanceДокумент1 страницаScope of MBA in Rural Management in Banking & FinanceThe IIHMR UniversityОценок пока нет

- D63ssw10-Das-001 - Ssw40 Data SheetДокумент5 страницD63ssw10-Das-001 - Ssw40 Data SheetPrejit RadhakrishnaОценок пока нет

- Global Chaser-Semen IndonesiaДокумент8 страницGlobal Chaser-Semen Indonesiayudhie_7Оценок пока нет

- Karnataka Second PUC Business Studies Question PaperДокумент2 страницыKarnataka Second PUC Business Studies Question PaperSaifulla Baig75% (4)

- Atomic Absorption SpectrometerДокумент16 страницAtomic Absorption SpectrometerJaga JayОценок пока нет

- Tron Time Delay Fuse 500vДокумент1 страницаTron Time Delay Fuse 500valexjoelОценок пока нет

- Industrial Combustion AnalyzerДокумент2 страницыIndustrial Combustion AnalyzerjeffchengОценок пока нет

- Test AnswersДокумент3 страницыTest AnswersAjay Abraham AnathanamОценок пока нет

- Assignment 1 (Total 70 Points) Due Time: October 16, 2014, 11pmДокумент2 страницыAssignment 1 (Total 70 Points) Due Time: October 16, 2014, 11pmravalmeghalОценок пока нет