Академический Документы

Профессиональный Документы

Культура Документы

Exxonmobil Olefins Process Description

Загружено:

amiramirimehrАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Exxonmobil Olefins Process Description

Загружено:

amiramirimehrАвторское право:

Доступные форматы

SECTION 2 PROJECT DESCRIPTION

2.1 Project Description

The proposed project includes construction of eight (8) new steam cracking furnaces and recovery equipment. The major pieces of recovery equipment include a quench tower, caustic wash facilities, a process gas compressor, a sour water stripper, a wet air oxidation unit, a deethanizer, an ethylene/ethane (C2) splitter, and a demethanizer. Bottoms product from the new quench tower and deethanizer will be routed to the existing base plant. In addition, a new cooling tower and a new flare system will be constructed. Existing utilities (such as plant air, electric, marginal steam product) will support the proposed project as needed. A duct burner will be installed in existing Train 5. Figures 2-1 through 2-4 show the basic process flow of the proposed project. As built configurations may differ without impact to the GHG emissions and/or controls. The emissions from the proposed project will be controlled using the following control technologies: ultra low NOx burners and Selective Catalytic Reduction (SCR) units on the proposed furnaces, cyclonic separators on the proposed decoking drums, drift eliminators on the cooling tower, and staged flare system to control off gas streams. 2.2 Detailed Project Description

The new facilities will process ethane to produce ethylene and other products. The ethane recovered from the process is recycled to the feed stream. A process flow sequence is shown on the block flow diagram, Figure 2-1. The proposed project will contain typical process equipment including vessels, drums, exchangers, rotating equipment, pipe and piping components, utilities, instrumentation including analyzers, and chemical injection facilities. Design capacity is included in Appendix A and the operating schedule is included in Table 7-1 of this application for each of the proposed sources. 2.2.1 Furnace Section

The unit will operate by firing the furnace section, consisting of eight steam cracking furnaces, continuously (EPNs: XXAF01-ST through XXHF01-ST). The furnace design is proprietary and is equipped with ultra low NOx burners and SCR systems to control NOx emissions. The furnaces will crack fresh ethane that is combined with recycled ethane. Steam is introduced as part of the process. The furnace outlet stream is cooled in the Quench Tower. The furnaces will fire imported natural gas or a blended fuel gas that consists of imported natural gas and tail gas. Tail gas is a recycle stream resulting from an initial separation of methane and hydrogen during the chilling step within the Demethanizer System. The composition of blended fuel gas will vary and will depend on current hydrogen production and disposition.

Sage Environmental Consulting, L.P. Revised November 2012

2-1

ExxonMobil Baytown Olefins Plant Ethylene Expansion Project GHG Permit Application

2.2.1.1.1

Decoking

In the cracking operation, coke (molecular carbon) gradually builds on the inside walls of the furnace tubes. This layer of coke impedes heat transfer and must be removed while the furnace is offline through a steam/air decoke operation. The coke is removed from the walls of the furnace tubes through oxidation and spalling. The spalled coke fines are disengaged from the furnace effluent in the decoke drum. Particulate matter emissions are controlled through cyclonic separators at the decoke drum vent which releases to atmosphere (EPNs: XXAB-DEC through XXGH-DEC). Figures 2-2 and 2-3 provides a comparison of the on-line furnace operation versus the decoke furnace operation. 2.2.2 Quench Tower

The combined furnace effluent flows into the Quench Tower where it is cooled with quench water. The majority of the dilution steam and some of the heavier hydrocarbons are condensed and exit the tower bottoms. Cooled cracked gases from the tower overhead are caustic scrubbed and compressed. Pyrolysis water in the Quench Tower contains trace amounts of hydrogen sulfide, organic acids, phenols, and some heavy hydrocarbons through direct contact with the process gas. A stripper removes these hydrocarbons from the quench (pyrolysis) water stream that will be used for dilution steam. The heavier hydrocarbons removed from quench water stream are sent to the base plant for recovery. Some process water is removed from the circulating dilution steam and is processed in water treatment facilities. 2.2.3 Recovery Section

The processing steps within the Recovery Section consist of process gas compression, ammonia removal, caustic scrubbing, and feed drying; deethanizing and acetylene conversion; feed chilling and demethanizing; and ethylene recovery. Refrigeration required for the heat removal in low temperature fractionation is provided by refrigeration systems. 2.2.3.1 Caustic Wash and Compression Caustic Water Wash Towers are located between compressor stages, where carbon dioxide (CO2) and hydrogen sulfide (H2S) are removed in stages of caustic scrubbing. Spent caustic resulting from the caustic scrubbing of the Quench Tower overhead is oxidized in a Wet Air Oxidation Unit prior to neutralization with sulfuric acid and introduction to the wastewater treatment system. Gases from the Wet Air Oxidation Unit are combusted to minimize VOC emissions. The duty of the process gas compressors is to transfer low pressure gas from the Quench Tower overhead stream to a higher pressure disposition. This process allows the gas to move through the Recovery Section for separation. Once washed and compressed, the Quench Tower overhead stream is dried.

Sage Environmental Consulting, L.P. Revised November 2012

2-2

ExxonMobil Baytown Olefins Plant Ethylene Expansion Project GHG Permit Application

2.2.3.2 Deethanizer and Acetylene Converter The Deethanizer separates the hydrocarbons with two or less carbon atoms from heavier hydrocarbons. The overhead stream is sent to the Acetylene Converters where acetylene is converted to ethylene and ethane. If the Acetylene Converter requires regeneration online, the gases from the Acetylene Converter regeneration are minimal and are directed to a new Acetylene Converter Regeneration Vent (EPN: ACETCONVXX). The Deethanizer bottoms product, hydrocarbons with more than two carbon atoms, is sent to the BOP Depropanizer in the existing plant facilities. The heavier products from the new facilities such as propylene, propane, 1,3-butadiene, isoprene, pyrolysis gasoline, and benzene are recovered along with the same products from the existing facilities. 2.2.3.3 Demethanizer System The objective of the Demethanizer System is to separate ethylene from lighter components. The Demethanizer Chilling Train and Demethanizer accomplish this separation through progressively colder temperature levels and distillation. A tail gas stream consisting of methane and hydrogen is produced from the Demethanizer system. This stream can be further processed to purify and recover the commercial value of the hydrogen. If this disposition is unavailable, the tail gas may be routed to the fuel gas system. 2.2.3.4 Ethylene Recovery Ethylene and ethane are fractionated in the C2 Splitter to produce the ethylene product. The residual ethane is recycled to the steam cracking furnaces where it is mixed with fresh feed. 2.2.4 Cooling Tower

A new cooling tower (EPN: BOPXXCT) will be constructed to provide process heat removal and supply cooling water to the proposed project. This cooling tower will be a multi-cell, induced draft, counter-flow type cooling tower. No increase in GHG emissions are being requested from the proposed cooling tower. 2.2.5 Flare System

A new flare system (EPNs: FLAREXX1 and FLAREXX2) will be designed to provide safe control of gases vented from the proposed project. This system will be equipped with a totalizing flow meter and an on-line analyzer to speciate the hydrocarbons in the flare gases, including Highly Reactive Volatile Organic Compounds (HRVOCs). 2.2.6 Wastewater Collection and Treatment System

The proposed project will operate a system to collect process wastewater, separate hydrocarbons from the water and segregate the streams in storage tanks. The wastewater

Sage Environmental Consulting, L.P. Revised November 2012

2-3

ExxonMobil Baytown Olefins Plant Ethylene Expansion Project GHG Permit Application

will be further processed in an existing treatment system. The treated water will then be discharged to an approved outfall location. 2.2.7 Storage Tanks

Several new storage tanks will be constructed for the proposed project. These tanks will be ancillary to the process and will store materials such as slop oil, diesel fuel, wastewater, ammonia, compressor wash oil, lube oil, caustic, spent caustic, sulfuric acid, methanol, various additives, and bleach. Some tanks will be routed to control. No increase in GHG emissions are being requested from the proposed storage tanks with atmospheric vents. 2.2.8 Engines Backup Generators

2.2.8.1.1

The proposed project includes three backup generators, estimated at three (3) megawatt total. Each unit is powered by a diesel engine (EPNs: DIESELXX01-DIESELXX03) and there is one diesel tank associated with each backup generator. The normal operation of the generators is to test for proper operation weekly, in the event it needs to be used in an emergency or backup situation. 2.2.8.1.2 Firewater Booster Pumps

The proposed project will provide two booster pumps for the existing firewater system. These pumps will be powered by two diesel engines (EPNs: DIESELXXFW1 and DIESELXXFW2). The normal operation of the booster pump and engine is to test for proper operation weekly, in the event it needs to be used in an emergency or backup situation. 2.3 Planned Maintenance, Start-Up, and Shutdown Activities

The emissions represented in this application reflect the planned maintenance, start up and shut down (MSS) activities requested to be authorized in this new permit application action. Planned MSS activities and associated emissions including equipment degassing/opening, vacuum trucks, frac tanks, and consumables are described below. Planned MSS activities with associated GHG emissions are emitted from the flare and are therefore represented in flare emissions. 2.3.1 Equipment Openings

Equipment is cleared throughout the year in preparation for maintenance activities. GHG emissions are generated when the cleared vapors are controlled by the flare system. No GHG emissions are proposed from opening the equipment to atmosphere. 2.3.2 Furnace Start-Up

Planned MSS emissions from the proposed furnaces are due to the SCR warm-up during

Sage Environmental Consulting, L.P. Revised November 2012

2-4

ExxonMobil Baytown Olefins Plant Ethylene Expansion Project GHG Permit Application

start up. This operation is intermittent and infrequent and is not expected to result in increased GHG emissions compared to normal operation. 2.3.3 Consumables

Small, generally disposable items termed consumables will be included as planned MSS activities for the proposed project; however, no increase in GHG emissions are being requested from the planned MSS activities due to consumables. 2.3.4 Vacuum Trucks

A vacuum truck operates by reducing the pressure on its tank prior to or during pickup of materials and venting released vapors through the vacuum pump and sometimes to a control device. Vacuum trucks are utilized at BOP on a daily basis to transfer materials from one container/vessel to another or from a container/vessel into a closed drain system, usually for purposes of routine maintenance such as: removing the contents of a tank prior to degassing, washing, and/or changing service of the tank; removing water or solids buildup; or collecting materials for treatment in waste/wastewater management units. No increase in GHG emissions are being requested from vacuum truck operations. 2.3.5 Frac Tanks

Frac tank is a generic term for small portable tanks of 500 barrels or less that are used as a repository for cleared/dewatered equipment. The tanks temporarily hold material so that it can be tested prior to reinsertion into the process or treatment in a wastewater treatment unit. Ancillary equipment from fugitives, deoiling/dewatering devices, and waste containers are included with this source. No increase in GHG emissions are being requested from the planned MSS activities due to frac tanks. 2.3.6 Flare System

The flare system is used to control emissions from planned MSS activities related to equipment clearing and startup and shutdown activities.

Sage Environmental Consulting, L.P. Revised November 2012

2-5

ExxonMobil Baytown Olefins Plant Ethylene Expansion Project GHG Permit Application

Вам также может понравиться

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОт EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОценок пока нет

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- Propylene-Propane - Howat Swift - McCabe ThieleДокумент19 страницPropylene-Propane - Howat Swift - McCabe ThieleFred FaberОценок пока нет

- 1 s2.0 S1226086X14001221 MainДокумент6 страниц1 s2.0 S1226086X14001221 MainJorge Rodriguez HerreraОценок пока нет

- Modeling and Simulation of Steam CrackersДокумент6 страницModeling and Simulation of Steam CrackersFathan FathullahОценок пока нет

- T2091 100 PDFДокумент10 страницT2091 100 PDFRICKY ECHANOОценок пока нет

- Preflash DrumДокумент27 страницPreflash DrumGarry David100% (1)

- Hydrotreating - UOP - A Honeywell CompanyДокумент59 страницHydrotreating - UOP - A Honeywell CompanySamОценок пока нет

- Simulation and Performance Analysis of Propane Propylene SplitterДокумент4 страницыSimulation and Performance Analysis of Propane Propylene SplitterAnonymous UY9QffОценок пока нет

- Self-Optimizing Control of A Gas Oil HydrodesulfurizationДокумент167 страницSelf-Optimizing Control of A Gas Oil Hydrodesulfurizationvu anh ducОценок пока нет

- Base Aromatics Production Processes: P A R T 2Документ12 страницBase Aromatics Production Processes: P A R T 2Bharavi K SОценок пока нет

- Catalytic: Reactivities, Networks, Kinetics High-Pressure HydroprocessingДокумент38 страницCatalytic: Reactivities, Networks, Kinetics High-Pressure HydroprocessingEdgar ZitroОценок пока нет

- Dme BДокумент8 страницDme Bdewi xiaОценок пока нет

- UniSim Design Clean Fuels PPKG User GuideДокумент54 страницыUniSim Design Clean Fuels PPKG User Guideapi-3750488Оценок пока нет

- (Petroleum) - UOP Fluid Catalytic Cracking UnitДокумент25 страниц(Petroleum) - UOP Fluid Catalytic Cracking UnitSölangs QüntellaОценок пока нет

- Critical Variable in Catalytic Reforming and Unit Monitoring Best PracticesДокумент18 страницCritical Variable in Catalytic Reforming and Unit Monitoring Best Practicesbakhtyar21Оценок пока нет

- Assay BachaqueroДокумент12 страницAssay BachaqueroGinis MrcОценок пока нет

- A Study On Tolling of Feed in Olefin Plant Lead To Reduction in Production Cost PDFДокумент18 страницA Study On Tolling of Feed in Olefin Plant Lead To Reduction in Production Cost PDFIbrahim100% (1)

- Aromatics Upgrading Technologies: Ihs ChemicalДокумент9 страницAromatics Upgrading Technologies: Ihs ChemicalLêĐứcTiếnОценок пока нет

- Aspen Utilities - Refinery EngineersДокумент72 страницыAspen Utilities - Refinery EngineersUrcan GeorgianaОценок пока нет

- Convert Bottom-Of-The-Barrel Into Diesel and Light OlefinsДокумент5 страницConvert Bottom-Of-The-Barrel Into Diesel and Light OlefinsAmjad HaniОценок пока нет

- Iocl Section 1 - Process SpecficationДокумент73 страницыIocl Section 1 - Process SpecficationYogi173Оценок пока нет

- Chapter 3Документ14 страницChapter 3Larry Jampong100% (1)

- Ethylene Plant Analysis PDFДокумент8 страницEthylene Plant Analysis PDFtotpityiОценок пока нет

- Pce-II Unit-I & II 1Документ84 страницыPce-II Unit-I & II 1Pavan SatishОценок пока нет

- ECAT Analysis GuideДокумент12 страницECAT Analysis GuideElder RuizОценок пока нет

- Comparison of Approaches To Determine Hydrogen Consumption During Catalytic Hydrotreating of Oil Fractions PDFДокумент9 страницComparison of Approaches To Determine Hydrogen Consumption During Catalytic Hydrotreating of Oil Fractions PDFNoheilly Vásquez100% (1)

- Muñoz Et Al. Comparison of Correlations For Estimating Product Yields From Delayed CokingДокумент12 страницMuñoz Et Al. Comparison of Correlations For Estimating Product Yields From Delayed CokingSergioDanielContreras100% (1)

- Propane Dehydrogenation in Modified Membrane Porous ReactorДокумент7 страницPropane Dehydrogenation in Modified Membrane Porous ReactorNoezran AzwarОценок пока нет

- Fractionation and Absorption For The Process Man PDFДокумент70 страницFractionation and Absorption For The Process Man PDFWilliam SandersОценок пока нет

- Process Simulation of Solvent Deasphalting Plants With PROIIДокумент29 страницProcess Simulation of Solvent Deasphalting Plants With PROIIstudyendless100% (2)

- Filling The Propylene Gap On Purpose TechnologiesДокумент12 страницFilling The Propylene Gap On Purpose Technologiesvajidqc100% (1)

- KLM Refining Technical Rev 3Документ6 страницKLM Refining Technical Rev 3Muhammad Abdul RaufОценок пока нет

- Project 6 AmmoniaДокумент10 страницProject 6 AmmoniaAhmed AliОценок пока нет

- Conversion of Methanol To Light Olefins On Sapo-34 Kinetic Modeling and Reactor DesignДокумент167 страницConversion of Methanol To Light Olefins On Sapo-34 Kinetic Modeling and Reactor DesignHassan BahaaОценок пока нет

- RP153E Toc PDFДокумент12 страницRP153E Toc PDFAshwani KumarОценок пока нет

- Choosing A Selective Hydrogenation SystemДокумент9 страницChoosing A Selective Hydrogenation SystemrizaherОценок пока нет

- Integration Naphtha DearomatizationДокумент4 страницыIntegration Naphtha Dearomatizationfanoos10000Оценок пока нет

- Amine Expert Company PDFДокумент2 страницыAmine Expert Company PDFWajid NizamiОценок пока нет

- Alpha OlefinsДокумент3 страницыAlpha OlefinsAnkit ModiОценок пока нет

- Eliminating Inert Entry For CatalystДокумент2 страницыEliminating Inert Entry For CatalystAndri SaputraОценок пока нет

- Waste ReductionДокумент108 страницWaste ReductionJust Semsem100% (1)

- Hydroprocessing: Hydrocracking & HydrotreatingДокумент45 страницHydroprocessing: Hydrocracking & HydrotreatingRobin ZwartОценок пока нет

- Future Coils For Ethylene FurnacesДокумент2 страницыFuture Coils For Ethylene FurnacesAli DarvishiОценок пока нет

- Case Study Naphtha Cracker ProjectДокумент4 страницыCase Study Naphtha Cracker ProjectErica LindseyОценок пока нет

- Refining-Petrochemical Integration-FCC Gasoline To PetrochemicalsДокумент4 страницыRefining-Petrochemical Integration-FCC Gasoline To PetrochemicalsKwangsjungОценок пока нет

- Aromatics PDFДокумент24 страницыAromatics PDFGerardo RiosОценок пока нет

- 2 - TDVS GopalkrishnaДокумент61 страница2 - TDVS GopalkrishnaManav GaneshОценок пока нет

- FYDP Final Report G13 PDFДокумент30 страницFYDP Final Report G13 PDFJeanette Hong May Hurn0% (1)

- HSFCCДокумент22 страницыHSFCCdonald55555100% (1)

- Nicholas Oligomerization PDFДокумент16 страницNicholas Oligomerization PDFTanase DianaОценок пока нет

- Heurtey Petrochem: Coker Furnace Run LengthДокумент24 страницыHeurtey Petrochem: Coker Furnace Run LengthFayaz MohammedОценок пока нет

- GPA08 PaperДокумент9 страницGPA08 PaperhicherkОценок пока нет

- Lecture2 (Petrochemical)Документ12 страницLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- Pyrolysis Furnace Rev 1 PDFДокумент11 страницPyrolysis Furnace Rev 1 PDFKmajdianОценок пока нет

- Condensate StabilizerДокумент16 страницCondensate Stabilizern73686861Оценок пока нет

- AGR OptimizationДокумент43 страницыAGR Optimizationinara amatullahОценок пока нет

- PRT RelianceДокумент26 страницPRT Relianceficky_iitdОценок пока нет

- Fluid Catalytic CrackingДокумент16 страницFluid Catalytic CrackingArief Maulana IlhamОценок пока нет

- Shot CokeДокумент9 страницShot CokeaminОценок пока нет

- 01 Introduction HAMYARWPДокумент12 страниц01 Introduction HAMYARWPamiramirimehrОценок пока нет

- 010526Документ6 страниц010526amiramirimehrОценок пока нет

- HP Spent CausticДокумент4 страницыHP Spent CausticamiramirimehrОценок пока нет

- SPYRO DescrДокумент2 страницыSPYRO DescramiramirimehrОценок пока нет

- Physical Property MethodsДокумент10 страницPhysical Property MethodsamiramirimehrОценок пока нет

- Physical Property MethodsДокумент10 страницPhysical Property MethodsamiramirimehrОценок пока нет

- Don't Gamble With Physical Properties For SimulationsДокумент12 страницDon't Gamble With Physical Properties For Simulationslaiping_lum100% (1)

- RA Series-Installation & Connection Manual Arc WeldingДокумент48 страницRA Series-Installation & Connection Manual Arc WeldingsunhuynhОценок пока нет

- A. E. Beck (Auth.) - Physical Principles of Exploration Methods - An Introductory Text For Geology and Geophysics Students (1981, Macmillan Education UK)Документ240 страницA. E. Beck (Auth.) - Physical Principles of Exploration Methods - An Introductory Text For Geology and Geophysics Students (1981, Macmillan Education UK)EdilberОценок пока нет

- EE 465 Lecture 8Документ25 страницEE 465 Lecture 8hshjxcbzОценок пока нет

- EMOSFET Nchannel 2N4351Документ1 страницаEMOSFET Nchannel 2N4351Pradina Kiky WasibagnoОценок пока нет

- Frantech - India InvestmentДокумент3 страницыFrantech - India InvestmentSrinivas Tanneru100% (1)

- SB Ibl P CBL Submersible Power CableДокумент23 страницыSB Ibl P CBL Submersible Power CableMuhammad ShahrukhОценок пока нет

- Alternative Propulsion For Automobiles by Cornel StanДокумент348 страницAlternative Propulsion For Automobiles by Cornel StanThuận Vũ Đình100% (1)

- 30gt 34siДокумент28 страниц30gt 34sijosealfredojlОценок пока нет

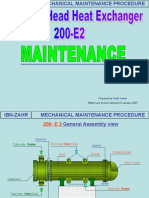

- 200 E 2 Floating Head Heat Exchanger MaintenanceДокумент16 страниц200 E 2 Floating Head Heat Exchanger Maintenancesubha50% (2)

- Depletion of Natural ResourcesДокумент3 страницыDepletion of Natural ResourcesViraj SadekarОценок пока нет

- Chapter 4 Psychomentry, Humidification and DehumidificationДокумент14 страницChapter 4 Psychomentry, Humidification and DehumidificationNurshaqina SufianОценок пока нет

- Model Answer Summer 2016Документ22 страницыModel Answer Summer 2016DiyaNegi0% (1)

- A Perfect FitДокумент6 страницA Perfect Fitmostafagoly1358Оценок пока нет

- Review of Related Studies (Solar Panel) : Charger - BODY FULL PDFДокумент2 страницыReview of Related Studies (Solar Panel) : Charger - BODY FULL PDFMatti NoОценок пока нет

- Register of Licences and Permits For Electric Power Undertakings PDFДокумент20 страницRegister of Licences and Permits For Electric Power Undertakings PDFNyasclemОценок пока нет

- ME303 7 Head Loss 2 BranchedДокумент39 страницME303 7 Head Loss 2 BranchedtoshugoОценок пока нет

- Alkyl Halides - Organic Chemistry-1Документ17 страницAlkyl Halides - Organic Chemistry-1Defaults rulezОценок пока нет

- EXPT. 1 Common Laboratory OperationsДокумент8 страницEXPT. 1 Common Laboratory Operationsjazzmin dulceОценок пока нет

- Inkohärente Lichtquellen: Christian WenningДокумент15 страницInkohärente Lichtquellen: Christian Wenningkummetha vanithaОценок пока нет

- C776-06 (2011) Standard Specification For Sintered Uranium Dioxide PelletsДокумент4 страницыC776-06 (2011) Standard Specification For Sintered Uranium Dioxide PelletsAndré BerninzonОценок пока нет

- Resolver Vs EncoderДокумент7 страницResolver Vs EncoderAmirtha swamy.nОценок пока нет

- Book Abstracts Book RedДокумент207 страницBook Abstracts Book Redankabe100% (1)

- Control Systems Viva VoiceДокумент10 страницControl Systems Viva VoiceSunil MotepalliОценок пока нет

- Building Services - Hvac NotesДокумент29 страницBuilding Services - Hvac NotesGayathriKanagarajОценок пока нет

- Cobar 1540 Ross Garling Hydraulic MiningДокумент26 страницCobar 1540 Ross Garling Hydraulic MiningAbyzhar AlpasyahОценок пока нет

- T H MorayOscTubeДокумент9 страницT H MorayOscTuberocism01100% (1)

- Lab Report 3 (I)Документ5 страницLab Report 3 (I)Kinit KinitОценок пока нет

- Physics Past Paper (June 2005)Документ11 страницPhysics Past Paper (June 2005)Jotham Omoregie80% (5)

- Kawasaki FH451V-FH721V 2003 Service Manual PDFДокумент153 страницыKawasaki FH451V-FH721V 2003 Service Manual PDFBrianCookОценок пока нет

- Fuel Tank TestДокумент1 страницаFuel Tank TestIvan RuedaОценок пока нет