Академический Документы

Профессиональный Документы

Культура Документы

CDM PROJECT DESIGN DOCUMENT FORM

Загружено:

nangkarak8201Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CDM PROJECT DESIGN DOCUMENT FORM

Загружено:

nangkarak8201Авторское право:

Доступные форматы

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

CLEAN DEVELOPMENT MECHANISM PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) Version 03 - in effect as of: 22 December 2006 CONTENTS A. B. C. D. E. General description of the small scale project activity Application of a baseline and monitoring methodology Duration of the project activity / crediting period Environmental impacts Stakeholders comments Annexes Annex 1: Contact information on participants in the proposed small scale project activity Annex 2: Information regarding public funding Annex 3: Baseline information Annex 4: Monitoring Information

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Revision history of this document

Version Number 01 02

Date 21 January 2003 8 July 2005

Description and reason of revision Initial adoption The Board agreed to revise the CDM SSC PDD to reflect guidance and clarifications provided by the Board since version 01 of this document. As a consequence, the guidelines for completing CDM SSC PDD have been revised accordingly to version 2. The latest version can be found at <http://cdm.unfccc.int/Reference/Documents>. The Board agreed to revise the CDM project design document for small-scale activities (CDM-SSC-PDD), taking into account CDM-PDD and CDM-NM.

03

22 December 2006

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

SECTION A. General description of small-scale project activity A.1 Title of the small-scale project activity:

8MW Cirompang Mini Hydro Power Plants at Bungbulang, Garut, Indonesia. Version : 3.1 Date : 29/08/2012

A.2.

Description of the small-scale project activity:

The project activity hereinafter referred to as Project is a new 8 MW run -of-river hydroelectric power plant being developed by PT. Tirta Gemah Ripah (TGR) in Garut district, West Java Province, Indonesia. The purpose of the project activity is generation of clean hydroelectric power and delivery to Jamali Grid. The project will be constructed on Cirompang River. The project activity is run-off river project which is taking place in the existing reservoir. The PP has received approval to use the water for power generation. There will be no modification done by PP in existing reservoir for use of water for power generation. The project is expected to generate net electricity of 47471 MWh/year and expected to bring about GHG emission reductions of approximately 33,847 tCO2e annually. Hence project activity would contribute to reduction of CO2 emissions that in the absence of the project activity would have otherwise happened by gird connected fossil fuel plants. The project complies with the sustainable development criterias of the host country in the following manner: Environment: The project activity is a run-of-river hydroelectric power plant. It is a well established technology which utilizes water for energy generation without depleting it or impacting the natural environment. Since the project activity generates electricity from renewable source, it avoids emission such as SOx , NOx and other particulates matter which would have been emitted from the fossil fuel fired plants. Social: Project will aid development of social infrastructure in the region such as roads and water supply. Project will create job opportunities during the construction and operation stage. Economy: Project activity will create new jobs both skilled and unskilled for local population. This increase in employment will stimulate local economy. Technology: The project will contribute to development of technological capacity building in the country as the project will be implemented with local engineers as well as local labour who will work on the construction. A.3. Project participants:

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Name of Party involved (*) ((host) indicates a host Party)

Sweden

Private and/or public entity(ies) Project participants (*) (as applicable) Nordic Environment Finance Corporation NEFCO in its capacity as Fund Manager to the NEFCO Carbon Fund (NeCF) Public Entity

Kindly indicate if the party involved wishes to be considered as project participant (yes/no) No

Indonesia (Host)

PT. Tirta Gemah Ripah (Public No Entity) (*) In accordance with the CDM modalities and procedures, at the time of making the CDM-PDD public at the stage of validation, a Party involved may or may not have provided its approval. At the time of requesting registration, the approval by the Party(ies) involved is required. The carbon purchaser is the Nordic Environment Finance Corporation NEFCO in its capacity as Fund Manager to the NEFCO Carbon Fund (NeCF) NEFCO Carbon Fund (NeCF) NEFCO, the Nordic Environment Finance Corporation, is a multilateral risk capital institution financing environmental projects in Central and Eastern Europe, with an emphasis on the Russian Federation and Ukraine. Its purpose is to facilitate the implementation of environmentally beneficial projects in the neighbouring region, with transboundary effects that also benefit the Nordic region. Today, NEFCO manages funds in an aggregate of approximately 470 million. NEFCO is located in Helsinki, Finland. The NEFCO Carbon Fund (NeCF) was established as a Public Private Partnership in April 2008, to provide financial assistance to projects by purchasing emission reduction credits from projects under the JI and CDM mechanisms. The NEFCO Carbon Fund (NeCF) has the Danish Energy Agency, DONG Energy, Eesti Energia, the Industrialization Fund for Developing Countries (Denmark), Ministries of Environment and Foreign Affairs of Finland, Etel-Pohjanmaan Voima Oy (Finland), Kymppivoima Oy (Finland), GDF Suez, the Norwegian Finance Ministry and NEFCO itself, as participants in the fund. The total available resources are ca. 165 million. NEFCO is the Fund Manager of the NeCF, and has been authorized by the governments investing in the NeCF to participate on their behalf in actions leading to the generation, transfer and acquisition of CERs under Article 12 of the Kyoto Protocol

A.4.

Technical description of the small-scale project activity: A.4.1. Location of the small-scale project activity: A.4.1.1. Host Party(ies):

Country: Indonesia

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

A.4.1.2. Province: West Java A.4.1.3.

Region/State/Province etc.:

City/Town/Community etc:

Village: Cihikeu and Bungbulang Sub District: Bungbulang District: Garut A.4.1.4. Details of physical location, including information allowing the unique identification of this small-scale project activity : The geographical coordinates of the project site are o o Dam : North Latitude: -7.4505 , East Longitude: +107.6093 Power House : North Latitude: -7.4762 , East Longitude: +107.6122

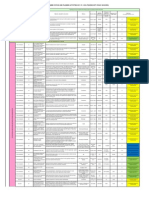

.The physical location of plant site is depicted in the map below:

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Project location Figure 1: Location planned in River Cirompang in Countryside Cihikeu & Bubbulang, District Gaurt A.4.2. Type and category(ies) and technology/measure of the small-scale project activity: According to the Appendix B of the simplified modalities and procedures for small-scale CDM project activities, project activity falls under the Type I Renewable Energy Projects. The project activity exports the generated electricity to the grid and falls in the category I. D -Grid Connected Renewable Electricity Generation. Following Table details the same : Term Description Type Type I, Renewable Energy Projects Category D, Grid Connected Renewable Electricity Generation Technology/Measure Renewable energy generation units (hydro) that supply electricity to a regional grid. Technology Description: The project is a runofriver Hydroelectric power plant on Cirompang river with a total installed capacity of 8MW consisting of 4 X 2MW turbines and a net projected output of 47, 471 MWh annually. The electricity generated will be transmitted to the Jamali grid via 20 kV transmission line. The main construction structures of the project consist of: Channel Intake / Weir

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

The water in the river will be diverted by the weir through an opening in the river side (the `intake') into an open channel. Line Carrier (headrace) It will channel water from the canal intake (Intake) towards sand trap. Sand Trap The water drawn from the river usually carries suspension of small particles. This sediment consists of hard abrasive materials such as sand which can cause significant damage and rapid wear to turbine runners. To remove this material the water flow will be slowed down in settling basins so that the silt particles will settle on the basin floor. Head Pond/Forebay Tank This head pond is not a storage area, it is meant to flood a sufficient area to regulate water current into Penstock. Penstock The penstock is like a pipe to convey water from the head pond to the powerhouse. Power House Here all mechanical equipment such as turbines and generators as well as electrical equipment such as panels and controllers will be housed. Turbine and Generator Four 2 MW pelton turbines will be installed. When water flows into the turbine, it turns the blades in the turbine which spins the generators shaft. Generator will convert the mechanical energy from the turning shaft into electrical energy. The characteristics of the Turbine used in the project are presented in Table 1 below. Table 1: Key Turbine Characteristics Item Parameter Type Efficiency at Peak Type/value/Unit Pelton 75%

Efficiency at Design Flow 75% Turbines Turbine Speed Manufacturer Technology Generator Key characteristics: Parameter Unit 1000 m3/s Jyoti Ltd , Vadodara, India Pelton

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Number Type Rated capacity Rated frequency Rated power factor

4 Synchronous, vertical axis, 3 phases 2000 kW 50 Hz 0.8

Transmission Lines The power generated will be transmitted to the Grid via 20 KV transmission lines. The Table 2 below highlights Project key Technical Design data and parameters Table 2: Key Technical Design Data and Parameters

Design Data /Parameters Total Installed Capacity

Unit MW

Quantity 8 2 8760 68.77 142

Installed Capacity of each MW Unit Annual Operating hours hours Capacity Factor Gross Head % m

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Figure 2: Typical Scheme of run-off river system In case of emergency, the diesel generators will be used. Technology transfer and know-how The installation and commissioning services are from Indonesia only. The technology employed by the project proponent does not result in GHG emissions and the project does not cause any negative impacts on the environment. The technology used does not pose any threat to the environment in comparison to fossil fuel-fired power plants. Therefore the technology is environmentally safe and sound. A.4.3 Estimated amount of emission reductions over the chosen crediting period: Estimation of annual emission reductions in tonnes of CO2e 33,847 33,847 33,847 33,847 33,847 33,847

Year Year 1 (01/03/2013- 28/02/2014) Year 2 (01/03/2014-28/02/2015) Year 3 (01/03/2015 -29/02/2016) Year 4 (01/03/2016 28/02/2017) Year 5 (01/03/2017 28/02/2018) Year 6 (01/03/2018 28/02/2019)

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Year 7 (01/03/2019 29/02/2020) Year 8 (01/03/2020 28/02/2021) Year 9 (01/03/2021 28/02/2022) Year 10 (01/03/2022 28/02/2023) Total estimated reductions (tonnes of CO2e) Total number of crediting years Annual average of the estimated reductions over the crediting period (tCO2e) A.4.4. Public funding of the small-scale project activity:

33,847 33,847 33,847 33,847 338,470 10 33,847

The project will not receive any public funding from Parties included in Annex I of the UNFCCC. A.4.5. Confirmation that the small-scale project activity is not a debundled component of a large scale project activity: According to paragraph 2 of Appendix C1 of the Simplified Modalities and Procedures for Small-Scale CDM project Activities, the following results into debundling of large CDM project: A proposed small-scale project activity shall be deemed to be a debundled component of a large project activity if there is a registered small-scale CDM project activity or an application to register another small-scale CDM project activity: With the same project participants; In the same project category and technology/measure; Registered within the previous 2 years; and Whose project boundary is within 1 km of the project boundary of the proposed small-scale activity at the closest point. The project activity is not a de-bundled component of a large project activity as there is no small scale CDM project activity or an application to register another small-scale CDM project activity by Project Proponent (PP) in the same project category and technology in the last two years within 1 km of the project boundary of the proposed small scale project activity.

SECTION B. Application of a baseline and monitoring methodology B.1. Title and reference of the approved baseline and monitoring methodology applied to the small-scale project activity: The project activity uses the following approved baseline and monitoring methodology available at the UNFCC website2is a small scale project activity and conforms to Appendix B of the simplified modalities and procedures for small-scale CDM project activities.

1

http://cdm.unfccc.int/EB/Meetings/007/eb7ra07.pdf

10

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Title Grid connected renewable electricity generation Guidance on the Assessment of Investment Analysis Guideline to small-scale CDM Methodologies (Indicative Simplified Baseline and Monitoring Methodologies for selected Small Scale CDM Project Activity Categories) Tool to calculate the emission Factor for an electricity system Tool to calculate project or leakage CO2 emission from fossil fuel consumption

Reference AMS-I D EB 62 Annex 5 EB 61 Annex 21

Version Version 17 Version 5 Version 17

EB 63 Annex 19 EB 41, Annex 11

Version 2.2.1 Version 2

B.2

Justification of the choice of the project category:

Applicability of AMS I. D: The project activity utilizes the hydro power for electricity generation, which falls into the category of renewable energy. The capacity of the proposed project activity is 8 MW which is below 15 MW, the eligibility limit of 15 MW for a small-scale CDM project activity applies only to the renewable component. The project activity is in line with the approved methodology AMS. I. D Version 17; specific features of proposed project and applicability of methodology are discussed below: Applicability Criteria with AMS-I.D. 1 This methodology comprises renewable energy generation units, such as photovoltaic, hydro, tidal/wave, wind, geothermal and renewable biomass:3 (a) (b) Supplying electricity to a national or a regional grid; or Supplying electricity to an identified consumer facility via national/regional grid through a contractual arrangement such as wheeling. Project Applicability The project activity involves a renewable energy generation unit specifically a hydro power unit that displaces electricity from Jamali Grid, an electricity distribution system supplied by fossil-fuel fired generating units. Thus the project activity complies with the applicability criteria.

http://cdm.unfccc.int/methodologies/DB/RSCTZ8SKT4F7N1CFDXCSA7BDQ7FU1X

Refer to EB 23, annex 18 or the definition of renewable biomass.

11

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Illustration of respective situations under which each of the methodology (i.e. AMS-I.D, AMS-I.F and AMS-I.A4) applies is included in Table 2. Project type AMS- AMS- AMSI.A I.D I.F 1 Project supplies electricity to a national/regional grid 2 Project displaces grid electricity consumption (e.g. grid import) and/or captive fossil fuel electricity generation at the user end ( excess electricity may be supplied to a grid) 3 Project supplies electricity to an identified consumer facility via national/regional grid (through a contractual arrangement such as wheeling) 4 Project supplies electricity to a mini grid5 system where in the baseline all generators use exclusively fuel oil and/or diesel fuel 5 Project supplies electricity to household users (included in the project boundary) located in off grid areas This methodology is applicable to project activities that (a) install a new power plant at a site where there was no renewable energy power plant operating prior to the implementation of the project activity (Greenfield plant); (b) involve a capacity addition6; (c) involve a retrofit7 of (an)

The project supplies electricity to Jamali grid. The grid is owned by PT Perusahaan Listrik Negara (PLN), a state owned electricity company of Indonesia. Thus the project complies with the applicability criteria of AMS I.D

The project activity shall install a new power plant at a site where there was no renewable energy power plant operating prior to the implementation of the project

AMS-I.D Grid connected renewable electricity generation, AMS -I.F Renewable electricity generation for captive use and mini-grid and AMS-I.A Electricity generation by the user The sum of installed capacities of all generators connected to the mini-grid is equal to or less than 15 MW.

5 6

A capacity addition is an increase in the installed power generation capacity of an existing power plant through: (i) the installation of a new power plant besides the existing power plant/units, or (ii) the installation of new power units, additional to the existing power plant/units. The existing power plant/units continue to operate after the implementation of the project activity.

7

Retrofit (or Rehabilitation or Refurbishment). It involves an investment to repair or modify an existing power plant/unit, with the purpose to increase the efficiency, performance or power generation capacity of the plant, without adding new power plants or units, or to resume the operation of closed (mothballed) power plants. A retrofit

12

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

existing plant(s); or (d) involve a replacement8 of (an) existing plant(s).

Hydro power plants with reservoirs that satisfy at least one of the following conditions are eligible to apply this methodology: The project activity is implemented in an existing reservoir with no change in the volume of reservoir; The project activity is implemented in an existing reservoir, where the volume of reservoir is increased and the power density of the project activity, as per definitions given in the Project Emissions section, is greater than 4 W/m2; The project activity results in new reservoirs and the power density of the power plant, as per definitions given in the Project Emissions section, is greater than 4 W/m2.

activity (Greenfield plant). Thus the Project Activity complies with the applicability criteria (a) The project activity is a run offriver and it is implemented in an existing reservoir. There will be no change in the volume of the reservoir. So the proposed project activity is implemented in the existing reservoir with no change in the volume of reservoir. Hence this condition is applicable to the project activity.

If the new unit has both renewable and non-renewable components (e.g., a wind/diesel unit), the eligibility limit of 15 MW for a small-scale CDM project activity applies only to the renewable component. If the new unit co-fires fossil fuel9, the capacity of the entire unit shall not exceed the limit of 15 MW.

Combined heat and power (co-generation) systems are not eligible under this category.

In the case of project activities that involve the addition of renewable energy generation units at an existing renewable power generation facility, the added capacity of the units

The project activity has no non renewable component and has 100% renewable component (Hydro). The capacity of the proposed project is 8 MW which is lower than 15 MW, limit set for small scale project activity. Hence this condition is applicable. There is no Combined heat and power (co-generation) in the project activity. Thus the project activity complies with the applicability criteria. The project activity does not that involve the addition of renewable energy generation units at an existing renewable power

restores the installed power generation capacity to or above its original level. Retrofits shall only include measures that involve capital investments and not regular maintenance or housekeeping measures.

8

Replacement. It involves investment in a new power plant or unit that replaces one or several existing unit(s) at the existing power plant. The installed capacity of the new plant or unit is equal to or higher than the plant or unit that was replaced.

9

A co-fired system uses both fossil and renewable fuels.

13

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

added by the project should be lower than 15 MW and should be physically distinct10 from the existing units. In the case of retrofit or replacement, to qualify as a smallscale project, the total output of the retrofitted or replacement unit shall not exceed the limit of 15 MW.

generation facility. Hence this condition is not applicable to the project activity. The project activity does not seek to any retrofit or replacement. Hence this condition is not applicable to the project activity.

Summary: It can be concluded based from the above discussion that the project activity meets the applicability criteria of approved small scale methodologies AMS I.D B.3. Description of the project boundary:

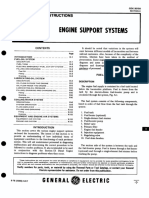

According to the paragraph 9 of the small scale methodology AMS-I.D. Version 17 The spatial extent of the project boundary includes the project power plant and all power plants connected physically to the electricity system11 that the CDM project power plant is connected to. For the project activity, the generated electricity of the project will be delivered to the Jamali Grid, and the auxiliary internal power consumption of hydropower plants is also contained in the project boundary. Also in case of emergency, the diesel generators will be used and it comes under project boundary. A general schematic view of the boundaries is shown in figure below.

10

Physically distinct units are those that are capable of generating electricity without the operation of existing units, and that do not directly affect the mechanical, thermal, or electrical characteristics of the existing facility. For example, the addition of a steam turbine to an existing combustion turbine to create a combined cycle unit would not be considered physically distinct.

11

Refer to the latest approved version of the Tool to calculate the emission factor for an electricity system for definition of an electricity system.

14

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Existing reservoir

Tunnel

Penstock

Power house

Diesel Generator (In case of emergency, it will be used)

Transformer CO2 emission from diesel generator Jamali Grid

Project boundary

Table 3 below Summary of gases and sources included in the project boundary, and justification explanation where gases and sources are not included: Scenario Baseline scenario Source Gas Included/ Excluded Included Excluded Justification/Explanation Main Emission Source. Not Significant. Excluded for simplification and conservativeness.

Electricity CO2 Delivered to the N2O grid by the

15

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Project activity

project activity CH4 that otherwise would have been generated by the operation of grid connected power plants and by the addition of new generation sources. Emissions CO2 associated with N2O the operation of the project CH4

Excluded

Not Significant. Excluded for simplification and conservativeness.

Included Excluded Excluded

Emission from the diesel generator. Not Significant. Excluded for simplification and conservativeness. Not Significant. Excluded for simplification and conservativeness.

B.4.

Description of baseline and its development:

Baseline Scenario: As per applicable methodology AMS I. D version 17, EB 61 paragraph 10 : the baseline scenario is that the electricity delivered to the grid by the project activity would have otherwise been generated by the operation of grid-connected power plants and by the addition of new generation sources into the grid. Hence in the project scenario the electricity delivered to the Jamali grid by the project activity would have otherwise been generated by the operation of grid connected power plants and by the addition of new generation sources into the grid. Data used to determine the baseline emissions: The Emission Factor is calculated in a transparent and conservative manner as follows: A combined margin (CM), consisting of the combination of operating margin (OM) and build margin (BM) according to the procedures prescribed in the Tool to calculate the Emission Factor for an electricity system, version 2.2.1, EB 63 Annex 19. The Directorate General Electricity and Energy Utilization (DJLPE, Direktorat Jenderal Listrik dan Pemanfaatan Energi), a government institution has issued an official baseline emission factor for the Jamali grid which is available from. http://pasarkarbon.dnpi.go.id/web/index.php/komnasmpb/read/20/faktor-emisi-jaringan-listrik-jawamadura-bali-jamali-2010-.html The calculation method opted for expost grid emission factor is as per Tool to calculate the Emission Factor for an electricity system, version 2.2.1, EB 63 Annex 19 is presented in Annex 3 of the PDD.

16

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

The parameters considered in the baseline calculation as presented in table below: Parameter EGBL,y EFgrid,CM,y Unit Description Source of data to be used Electricity meter As published by Host Country DNA As published by Host Country DNA As published by Host Country DNA

EFgrid,BM,y

MWh Net electricity supplied to the grid tCO2/MWh Combined margin CO2 emission factor for grid connected power generation in year y tCO2/MWh Build margin CO2 emission factor for grid connected power generation in year tCO2/MWh Operating margin CO2 emission factor for grid connected power generation in year

EFgrid,OM,y

B.5. Description of how the anthropogenic emissions of GHG by sources are reduced below those that would have occurred in the absence of the registered small-scale CDM project activity: The project activity is additional as per the options provided under Non-binding best practice examples to demonstrate additionality for SSC project activities. According to the Non-binding best practice examples to demonstrate additionality for SSC project activities (EB 35, Annex 34): a. Project participants shall provide an explanation to show that the project activity would not have occurred anyway due to at least one of the following barriers: Investment barrier: a financially more viable alternative to the project activity would have led to higher emissions; b. Access-to-finance barrier: the project activity could not access appropriate capital without consideration of the CDM revenues c. Technological barrier: a less technologically advanced alternative to the project activity involves lower risks due to the performance uncertainty or low market share of the new technology adopted for the project activity and so would have led to higher emissions d. Barrier due to prevailing practice: prevailing practice or existing regulatory or policy requirements would have led to implementation of a technology with higher emissions e. Other barriers: without the project activity, for another specific reason identified by the project participant, such as institutional barriers or limited information, managerial resources, organizational capacity, financial resources, or capacity to absorb new technologies, emissions would have been higher. Among the multiple barriers identified in the implementation of the project activity, the investment barrier analysis is used to demonstrate the financial non-viability of the project activity in a conservative and transparent manner. The project activity involves high investment cost. The returns generated from the project activity are low and hence the CDM funds are considered essential for improving the returns generated from the project. Investment barrier

17

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

The investment barrier has been demonstrated in accordance with the Non-binding best practice examples to demonstrate additionality for SSC project activities provided by CDM EB in its 35th Meeting (Annex 34), which states under investment barrier, Best practice examples include but are not limited to, the application of investment comparison analysis using a relevant financial indicator, application of a benchmark analysis or a simple cost analysis (where CDM is the only revenue stream such as end-use energy efficiency). From the above three best practice options under Investment Barrier, the project proponent has chosen to demonstrate additionality using benchmark analysis because the baseline scenario for the project activity is be the electricity import from Jamali grid, for which no investment is required by the Project Participant. Hence, benchmark approach is best suited approach for PP. This is based on the reference to the Guidance 19 of Annex 5 of EB 62, "The benchmark approach is therefore suited to circumstances where the baseline does not require investment or is outside the direct control of the project developer, i.e. cases where the choice of the developer is to invest or not to invest ." This analysis has been selected and conducted in accordance with the Guidance on the Assessment of Investment Analysis (Version 05) (EB-62, Annex 5). As per the guidance, the most suitable financial indicator for the project activity is determined to be the project IRR Selection of Benchmark: In accordance with the EB Guidance on the assessment of investment analysis (EB-62, Annex 05) Local commercial lending rates or weighted average costs of capital (WACC) are appropriate benchmarks for a project IRR. In line with the Guidelines on the Assessment of Investment Analysis, EB62 - Weighted average cost of capital (WACC) is an appropriate benchmark for project IRR. Steps to calculate WACC are detailed below: WACC = E *Re + D*Rd*(1-Tc) V V where: WACC: Weighted average cost of capital (%) E/V : Percentage of financing that is equity (%). D/V: Percentage of financing that is by debt (%). Re : Cost of equity Rd: Cost of debt Tc: Tax rate Cost of equity is calculated using CAPM Model as detailed below: Re = krf + Rp * where: krf : Risk free rate Rp : Market Risk Premium : Beta of industry Applicable data used to calculate WACC at the time of decision making is listed in table below:

18

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Parameter E/V

Value 30%

Source Based on the FSR which provides the typical debt/equity finance structure observed in the hydro power sector of Indonesia, which is line with the para 18 of the Guidance on the Assessment of Investment Analysis, Version 05, EB 62, Annex 5 Based on the FSR which provides the typical debt/equity finance structure observed in the hydro power sector of Indonesia, which is line with the para 18 of the Guidance on the Assessment of Investment Analysis, Version 05, EB 62, Annex 5. Calculated based on the formula : Re = krf + Rp * Based on the Feasibility Study Report which provides the lending rate observed for debt financing which is in line with the Guidance on the Assessment of Investment Analysis, Version 05, EB 62, Annex 5. Government Regulation No.17, Year 2000, Clausal No.17, which is in line with the Guidance on the Assessment of Investment Analysis, Version 05, EB 62, Annex 5. http://www.idx.co.id/Portals/0/StaticData/Publication/BondBook/ FileDownload/INDONESIA%20BOND%20MARKET%20DIRE CTORY%202011.pdf Bonds published in the year 2010 which have a maturity period of 10 or more which is in line with the Guidance on the Assessment of Investment Analysis, Version 05, EB 62, Annex 5. Calculated (Market return krf). The market return is calculated based on the Jakarta Composite Index (JCI). The krf is calculated as explained above, which are in line with the Guidance on the Assessment of Investment Analysis, Version 05, EB 62, Annex 5. Calculated. http://www.stern.nyu.edu/~adamodar/pc/archives/totalbeta09.xls The beta value for electrical utility central of 0.95 (The unlevered beta) is chosen in the benchmark evaluation. The unlevered beta value is then levered with the D/E ratio 70:30 and the tax rate 28% to get the levered beta 2.56. using the formula BL=BU*(1+(1-Tc)*(D/E)) BL = Levered beta ; BU =Unlevered beta Tc= Tax rate D/E = Debt: Equity ratio Calculated based on the formula WACC = E/V *Re + D/V*Rd*(1-Tc)

D/V

70%

Re Rd

53.96% 13.00%

Tc

28%

krf

8.71%

Rp

17.69%

2.56

WACC

22.74%

Beta:

19

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

The Beta value has been calculated based on sector information as compiled by a finance professor of Stern School of Business, New York University. Due to the lack of publicly available information in the host country, the project participant chose the Beta of the electricity generating companies listed in the website. The beta value for electrical utility central of 0.95 (The unlevered beta) is chosen in the benchmark evaluation. This electrical utility (central) has minimum beta value, compared to other two listed electrical utility and this is conservative. The unlevered beta value is then levered with the D/E ratio 70:30 and the tax rate 28% to get the levered beta 2.56. Debt: Equity ratio: As per para 18 of the Guidance on the Assessment of Investment Analysis, Version 05, EB 62, Annex 5, If the benchmark is based on parameters that are standard in the market, then the typical debt/equity finance structure observed in the sector of the country should be used.. In line with guideline, PP has considered Debt: Equity ratio of 70:30 based on the FSR which provides the typical debt/equity finance structure observed in the hydro power sector of Indonesia and the same is considered in the benchmark evaluation of the project activity. Market return: The market return is calculated based on the Jakarta Composite Index (JCI) and was used in the Capital Asset Pricing Model (CAPM) to calculate the cost of equity. The compounded return for the market is calculated over a time period of 5 years (Dec 2005- Dec 2010) to determine the market return. Risk free return: The risk free rate is determined as an average of 3 government bond rates from Indonesia issued for a period of more than 10 years and published in the year 2010. The risk free rate is the rate of return on an asset that is theoretically free of any risk. When doing investment analysis on longer term projects or valuation, the risk free rate should be the long term government bond rate (Estimating Risk Free Rates by Dr. Aswath Damodaran of Stern School of Business, New York University page 6)12. Hence bonds having a maturity period of 10 years or more are considered for risk free rate calculation. Project IRR (which is post tax ) is calculated based on following information: Parameter Installed Capacity Total Investment Annual O& M cost Annual Net electricity exported to grid Electricity Tariff

12

Value 8 139757 3257 47,471 656

Unit MW IDR(million) IDR(million) MWh IDR

Source Feasibility Study Report Feasibility Study Report Feasibility Study Report Calculated Feasibility Study Report

http://jft-newspaper.aub.edu.lb/reserve/data/fina306-ai-project-reading/riskfree.pdf

20

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Income tax

28

Project Lifetime

20

years

Indonesia Government Regulation No.17 Year 2000, clausal No.17 Feasibility Study report

Using above data Project IRR without CDM is calculated as below: Project IRR Without CDM Value 14.51% Benchmark (WACC) 22.74%

Above table shows that Post tax Project IRR without CDM is below the benchmark. The CDM revenue helps improve the project IRR significantly. Sensitivity Analysis: Sub-step 2d: Sensitivity analysis As per paragraph 20 of Guidelines on the assessment of investment analysis (EB 62, Annex 5); Only variables, including the initial investment cost, that constitute more than 20% of either total project costs or total project revenues should be subjected to reasonable variation (all parameters varied need not necessarily be subjected to both negative and positive variations of the same magnitude), and the results of this variation should be presented in the PDD and be reproducible in the associated spreadsheets. Where a DOE considers that a variable which constitute less than 20% has a material impact on the analysis they shall raise a corrective action request to include this variable in the sensitivity analysis. As per para 21 of the Guidelines on the assessment of investment analysis (EB 62, Annex 5); The DOE should assess in detail whether the range of variations is reasonable in the project context. Past trends may be a guide to determine the reasonable range. As a general point of departure variations in the sensitivity analysis should at least cover a range of +10% and 10%, unless this is not deemed appropriate in the context of the specific project circumstances. In cases where a scenario will result in the project activity passing the benchmark or becoming the most financially attractive alternative the DOE shall provide an assessment of the probability of the occurrence of this scenario in comparison to the likelihood of the assumptions in the presented investment analysis, taking into consideration correlations between the variables as well as the specific socio-economic and policy context of the project activity. In line with the above guidance para 20 and 21 of EB62, Annex 5, following critical parameters have been identified for conducting the Sensitivity analysis: Plant load Factor (PLF) which constitutes 22% of total project cost Operation and Maintenance cost which constitutes 18% of total project revenue. Tariff rate which constitutes 22% of total project cost Total project cost.

In line with paragraph 21 of EB62, annex 5, all the above parameters have been varied by at least 10%. The results of the sensitivity analysis are reflected below:

21

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Particulars IRR with variation in project investment IRR with variation in tariff IRR with variation in PLF IRR with variation in O&M expenses Plant load factor:

IRR with varied parameters (%) -10.00% 0.00% 10.00% 16.13% 14.51% 13.15% 12.76% 14.51% 16.19% 12.76% 14.51% 16.19% 14.76% 14.51% 14.27%

The Project IRR crosses the benchmark at PLF of 104.46 % which is not a likely to happen. The capacity factor determined in the FSR according to historical hydrological data from 1997 to 2006 shows a value lesser than 104.46%. Hence achieving a PLF value of 104.46% is not possible. Operation and Maintenance cost: The Project IRR crosses the benchmark when O&M cost is decreased to -9588 Million IDR. However, such a situation is not possible as O&M cost usually increases year on year basis. There will not be a situation of decrease in O & M cost. Hence, such a scenario of decreasing of -9588 Million IDR is not possible. Tariff rate: The Project IRR crosses the benchmark at tariff of 996 IDR/kWh which is not realistic, as the PP signed long term power purchase agreement for the period of 15 years at the rate of 656 IDR/kWh. As per PPA Article 10, para 1, page 14 the tariff rate is as per the data by Minister of Energy and Mineral Resources No. 31 of 2009, which is fixed for 15 years (as per article 3 para 1,page 7) from the date of commissioning of the project. & Article 3, Para 2 page 7, states that The life of the agreement referred to in paragraph (1) of this Article 3, may extended the lifetime of power plant with the written approval of THE PARTIES the lifetime of the project can be extended over to 15 years which is mentioned in para 1 by the parties PP and PLN with the written approval. Hence the PP may extend the PPA after 15 years and so the tariff may also be remains same. Thus the situation is not likely to happen. Project cost: The Project IRR crosses the benchmark when the project cost is decreased to 87828 Million IDR. However it is not possible as PP has already placed purchase orders for 80% of the total project cost. Hence such a situation is not possible. Conclusion: Thus, the financial analysis shows that the project activity is not the most financially attractive, and the sensitivity analysis shows that it is unlikely to be financially attractive compared to the benchmark under reasonable variations of the relevant parameters. Early Consideration of CDM:

22

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

As per the Guidelines on the Demonstration and Assessment of Prior Consideration of the CDM13, version 04, EB 62 (Annex13) , For Project activities with a start date on or after August 2008 the project participant must inform a Host party DNA and the UNFCCC Secretariat in writing of the commencement of the project activity and of their intension to seek CDM Status. Such Notification must be made within six months of the project activity starting date The start date for the project activity is 04/08/2011 when the EPC contract for the project activity was signed. The prior CDM consideration notification was sent to UNFCCC and Host party DNA on 09th March 2011 and 8th March 2011 respectively. The same is reflected on UNFCCC website. This confirms that the project proponent has seriously considered CDM benefits for the proposed project activity. The chronology of the events is presented below: S.No 1 2 3 4 Events Board decision to processs the clearance for the 8 MW project activity PPA between PT. PLN (Persero) and PT. Tirta Gemah Ripah for Mini Hydro Power Plant Total Capacity 2000 kW. Investment Approval from the Regent of Garut for Cirompang Mini Hydro Power Plant with capacity 8.000 kW. Recommendation on Cirompang MHPs Use of Land Allocation Permit, from the Office of Housing, Spatial Planning, and Settlements, Garut regency. Recommendation letter document of Environmental Management Effort & Environmental Monitoring Effort for Cirompang MHP 8 MW construction. Feasibility study report Board resolution to undertake the project activity under CDM CDM Advisory services agreement between PP and consultant. CDM prior intimation to UNFCCC and DNA Date 23rd June 2010 28th June 2010 23rd July 2010 26th July 2010

2nd Sep 2010.

6 7 8 9

10 11 12

13

Stakeholder consultation meeting EPC contract between PT. Hutama Karya (Persero) and PT. Tirta Gemah Ripah The Agreement between PT. TGR with GP3A Daerah Irigasi Cirompang (affiliation of farmers using Cirompang water) regarding the Use of Dams, Irrigation Channels, and Tunnels for the Cirompang Mini Hydro Power Investment Project. PPA between PT. PLN (Persero) and PT. Tirta Gemah Ripah for Mini Hydro Power Plant Total Capacity 8000 kW

Nov 2010 10th Dec 2010 2nd March 2011 To UNFCCC - 9th March 2011 To DNA 8th March 2011 15th April 2011 4th Aug 2011 11th Aug 2011

21st Nov 2011

13

http://cdm.unfccc.int/Reference/Guidclarif/reg/reg_guid04.pdf

23

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

B.6.

Emission reductions: B.6.1. Explanation of methodological choices:

Baseline Emissions As per paragraph 11 of the methodology AMS-I.D., Version 17, the baseline emissions are calculated as the product of electrical energy baseline EGBL, y expressed in MWh of electricity produced by the renewable generating unit multiplied by the grid emission factor.

BE y EGBL, y * EFCO2 ,grid , y

Where:

BE y

EGBL , y

Baseline Emissions in year y (t CO2)

Quantity of net electricity supplied to the grid as a result of the implementation of the CDM project activity in year y (MWh)

EFCO2, grid , y

CO2 emission factor of the grid in year y (t CO2/MWh)

The Emission Factor is calculated in a transparent and conservative manner as follows: A combined margin (CM), consisting of the combination of operating margin (OM) and build margin (BM) according to the procedures prescribed in the Tool to calculate the Emission Factor for an electricity system, version 2.2.1, EB 63 Annex 19. The Directorate General Electricity and Energy Utilization (DJLPE, Direktorat Jenderal Listrik dan Pemanfaatan Energi), a government institution has issued an official baseline emission factor for the Jamali grid which is available from. http://pasarkarbon.dnpi.go.id/web/index.php/komnasmpb/read/20/faktor-emisi-jaringan-listrik-jawamadura-bali-jamali-2010-.html The calculation method opted for expost grid emission factor is as per Tool to calculate the Emission Factor for an electricity system, version 2.2.1, EB 63 Annex 19 is presented in Annex 3 of the PDD. Project Emissions: As per paragraph 20 of approved methodology AMS-I.D. (Version-17, EB- 61), emissions from water reservoir of hydro power plants qualify as project emissions. The project emission for the project activity will be PEy = PEHP,y + PEFF,y Where:

24

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

PEHP,y - Emission from reservoir: PEFF,y - Emission from fossil fuel consumption in year y. It is the emission from diesel generator which will be used in emergency purposes and it is calculated by Tool to calculate project or leakage CO2 emission from fossil fuel consumption. PEHP,y - Emission from reservoir: The proposed project activity is implemented in the existing reservoir with no change in the volume of reservoir. Therefore, project activity not shall account for CH4 and CO2 emissions from the reservoir. So PEHP,y = 0. PEFF,y - Emission from diesel generator backup: The project emission includes the proponent of emission from diesel generator which will be used in emergency purposes and it is calculated by Tool to calculate project or leakage CO2 emission from fossil fuel consumption. The following formula is applied according to the Tool to calculate project or leakage CO 2 emission from fossil fuel consumption: Emission from the operation of a backup system in process j during the year y is calculated as follows: PEFC,j,y = FCi,j y Where: PEFC,j,y FCi,j y Are the CO2 emissions from fossil fuel combustion in process j during the year y Is the quantity of fuel type i combusted in process j during the year y (mass or volume unit/year)

COEF

i,y

COEFi,y = NCVi,y EFCO2,i,y

COEFi,y Is the CO2 emission coefficient of fuel type i in year y (tCO2/mass or volume unit) NCVi,y EFCO2,i,y i PEy = 0. Leakage Emissions: As per paragraph 22 of the approved methodology AMS-I.D. (Version-17, EB-61), if the energy generating equipment is transferred from another activity, leakage is to be considered. The leakage emissions may be considered as zero as no such equipment shall be transferred from another project activity. Hence LEy = 0 Emission Reductions Is the weighted average net calorific value of the fuel type i in year y Is the weighted average CO2 emission factor of fuel type i in year y (tCO2/GJ) Are the fuel types combusted in process j during the year y

25

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

As per paragraph 23 of the approved methodology AMS-I.D. (Version-17, EB-61), Emission reductions are calculated as follows:

ER y BE y PE y LE y

Where:

ERy

BE y PE y

Emission reductions in year y (tCO2/y) Baseline Emissions in year y (tCO2/y) Project emissions in year y (tCO2/y) Leakage emissions in year y (tCO2/y) B.6.2. Data and parameters that are available at validation:

LE y

Data / Parameter: Data unit: Description: Source of data used: Value applied: Justification of the choice of data or description of measurement methods and procedures actually applied : Any comment: Data / Parameter: Data unit: Description: Source of data used: Value applied: Justification of the choice of data or description of measurement methods and procedures actually applied : Any comment: B.6.3

Grid Emission Factor tCO2e/MWh CO2 emission factor of the grid in year y Emission Factor for Jamali Grid 0.713 The value is published by host country DNA

The value is expost and hence it is to be monitored during the crediting period Installed Capacity of the project activity MW The installed capacity of the project activity Feasibility Study report 8

The data is from Feasibility Study Report.

NA

Ex-ante calculation of emission reductions:

Ex- ante emissions are calculated as defined in section 6.1 as given below: Baseline emissions (BE,y):

26

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

As per paragraph 11 of the methodology AMS-I.D, Version 17, the baseline emissions are the product of electrical energy baseline EGBL, y expressed in MWh of electricity produced by the renewable generating unit multiplied by the grid emission factor.

BE y EGBL, y * EFCO2 ,grid , y

Where:

BE y

= Baseline Emissions in year y; tCO2e = Quantity of net electricity supplied to the grid as a result of the implementation of the CDM project activity in year y (MWh) = CO2 emission factor of the grid in year y (tCO2e/MWh) Units MW Nos MW Hours % MWh % MWh MWh tCO2e/MWh tCO2e/year Value 2 4 8 8760 68.77 48194 1.5 723 47471 0.713 33,847 Remarks FSR FSR Calculated FSR FSR Calculated FSR Calculated Calculated Calculated Calculated

EGBL, y

EFCO2 , grid , y

Parameter Capacity of each turbine Number of turbines Total installed capacity Total number of hours of operation annually Plant load factor Gross energy generation Auxiliary consumption Net energy generation from the project activity Grid emission factor Baseline emissions Project Emissions (PEy)

The project emission includes the proponent of emission from diesel generator which will be used in emergency purposes and it is calculated by Tool to calculate project or leakage CO2 emission from fossil fuel consumption. The following formula is applied according to the Tool to calculate project or leakage CO 2 emission from fossil fuel consumption: Emission from the operation of a backup system in process j during the year y is calculated as follows: PEFC,j,y = FCi,j y Where:

COEF

i,y

COEFi,y = NCVi,y EFCO2,i,y

27

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Particular Quantity of diesel consumption in the project activity

Unit Litres/annum

Value 0

Net Calorific Value of diesel

TJ/tonne

0.0433

Emission factor of diesel

tCO2/TJ

74.8

Density of diesel Project emission consumption of diesel Hence PEy = 0 Leakage Emissions (LEy) LEy = 0 Emission Reduction ERy, = BEy PEy LEy, = 33,847 0 0 = 33,847 B.6.4 due to

T/litre

0.8439*1 0^-3 0

Remarks Diesel will be consumed only for emergency cases 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 2, Chapter 1, Table 1.2, The upper limit value has been used. 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 2, Chapter 1, Table 1.4. The upper limit value has been used. http://v-c-s.org/sites/v-cs.org/files/15.%20EFFC%20fossil%20fuels.pdf Calculated

tCO2e/annum

Summary of the ex-ante estimation of emission reductions: Estimation of project activity emissions (tonnes of CO2e) 0 0 Estimation of baseline emissions (tonnes of CO2e) 33,847 33,847 Estimation of leakage (tonnes of CO2e) 0 0 Estimation of overall emission reductions (tonnes of CO2e) 33,847 33,847

Year

Year1 (01/03/201328/02/2014) Year 2 (01/03/201428/02/2015)

28

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Year 3 (01/03/2015 29/02/2016) Year 4 (01/03/2016 28/02/2017) Year 5 (01/03/2017 28/02/2018) Year 6 (01/03/2018 28/02/2019) Year 7 (01/03/2019 29/02/2020) Year 8 (01/03/2020 28/02/2021) Year 9 (01/03/2021 28/02/2022) Year 10 (01/03/2022 28/02/2023)

0 0 0 0 0 0 0 0

33,847 33,847 33,847 33,847 33,847 33,847 33,847 33,847

0 0 0 0 0 0 0 0

33,847 33,847 33,847 33,847 33,847 33,847 33,847 33,847

Total Emission Reductions (tCO2e)

B.7

338,470

338,470

Application of a monitoring methodology and description of the monitoring plan: B.7.1 Data and parameters monitored: EGfacility,y= EGBL,y MWh/year Quantity of net electricity supplied to the grid in year y Onsite measurement by Project Developer 47,471 Electricity will be measured with an electricity meter and will be recorded on a monthly basis by Project Developer with the use of Energy Meter (s). Measured : Continuously Recorded : Monthly The meter(s) will be subject to maintenance and calibration according to standard set by PLN. On site staff will receive training in CDM monitoring and the maintenance requirements of the electricity meters. Data measured by the meter(s) will be cross checked using electricity sales receipts. The accuracy (class 0.2) of the measurement will be ensured through annually calibration by a qualified party. Data will be archived at least for two years after the end of the crediting period,

Data / Parameter: Data unit: Description: Source of data to be used: Value of data Description of measurement methods and procedures to be applied: QA/QC procedures to be applied:

Any comment:

29

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

or the last issuance of CERs, whichever occurs later. Data / Parameter: Data unit: Description: Source of data to be used: Value of data Description of measurement methods and procedures to be applied: QA/QC procedures to be applied: Any comment:

EFCO2, grid , y

tCO2e/MWh CO2 emission factor of the grid in year y Emission Factor for Jamali Grid. 0.713 The value is published by the host country DNA. However, the calculation procedure is provided in Annex 3

The data is a published data by host country DNA. Hence QA/QC procedure is not applicable. Data will be archived at least for two years after the end of the crediting period, or the last issuance of CERs, whichever occurs later.

Data / Parameter: Data unit: Description: Source of data to be used: Value of data applied for the purpose of calculating expected emission reductions in section B.6 Description of measurement methods and procedures to be applied: QA/QC procedures to be applied: Any comment:

FCi , y

Litres/annum Quantity of fossil fuel consumption(diesel) in project activity in a year Log book maintained to record onsite consumption of diesel. -

The data will be monitored continuously and aggregated monthly.

The diesel consumption quantities can be cross-checked with the records of the quantity of diesel purchased from the invoices. The data will be archived electronically and the archived data will be kept for 2 years beyond the Crediting Period.

Data / Parameter: Data unit: Description: Source of data to be used: Value of data applied

NCVi , y

TJ/tonne Net calorific value of the fossil fuel (i) (diesel) combusted in the project activity during the year y. 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 2,Chapter 1, Table 1.2 0.0433

30

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

for the purpose of calculating expected emission reductions in section B.6 Description of measurement methods and procedures to be applied: QA/QC procedures to be applied: Any comment:

The net calorific value of diesel has been sourced from IPCC 2006 default value at the upper limit of the uncertainty at a 95% confidence interval and any future revision of the IPCC guidelines will be taken into account in determining the same. Project participants have no control on the parameter. Hence, No QA/QC procedures are applicable. The data will be archived electronically and the archived data will be kept for 2 years beyond the Crediting Period.

Data / Parameter: Data unit: Description: Source of data to be used: Value of data applied for the purpose of calculating expected emission reductions in section B.6 Description of measurement methods and procedures to be applied: QA/QC procedures to be applied: Any comment:

diesel

T/Litres Density of fossil fuel diesel combusted in the project activity http://v-c-s.org/sites/v-c-s.org/files/15.%20E-FFC%20fossil%20fuels.pdf 0.8439*10^-3

The value of the density of the diesel has been taken based on regional values available.

Not applicable. The data will be archived electronically and the archived data will be kept for 2 years beyond the Crediting Period.

B.7.2

Description of the monitoring plan:

Parties involved in monitoring This section details the steps taken to monitor the greenhouse gas emissions reductions on a regular basis. The Monitoring set up for this project has been developed to ensure that from the start, the Project is well organised in terms of the collection and archiving of complete and reliable data.

31

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

The monitoring of this type of project consists of metering the electricity generated by the renewable technology. Below is the description of monitoring procedures for data measurement, quality assurance and quality control. PLN, as the state-owned company that own the Grid to which the Project Developer send its electricity to, is responsible in maintaining the electricity generation in the Grid as well as the system of metering to measure the transferred electricity into the Grid. The monitoring plan of the project will follow PLN system on measuring the electricity sent to the Grid. Metering of Electricity Supplied to the Grid The main electricity meter for establishing the electricity delivered to the grid will be installed at the project site using a Metering System that is approved by PLN. This electricity meter provides the main data for CER measurement, thus it will be the key part of the verification process. To check the amount of electricity delivered to the grid, official data will be used. In case of emergency purposes, the diesel generators will be used. Quality Control and Quality Assurance Quality control and quality assurance procedures will guarantee the quality of data collected. The electricity meter(s) will undergo periodic calibration once in a year throughout the lifetime of the Project Activity. Inspection will also be done as requested by PLN subject to manufacturer standards. Moreover, meter(s) are maintained by qualified spare parts. Documents of these procedures will be available during the verification. Data Collection and Archiving: The monthly data of electricity generation is collected in electronic form. However, the data in electronic form is archived throughout the life time of the project. The electricity records are maintained regularly by the team at the site. The archived data will be kept for 2 years beyond the Crediting Period. The following chart shows the data flow for the monitored data for the project acticity.

32

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

President PT TGR

CDM Manager

Power plant Manager

Power plant operators

Power plant Shift In charge The table below shows the roles and responsibilities and the information flow for the project activity data. Personnel Power plant Shift Incharge Responsiblity Monitoring the plant parameters including the monitoring parameters as described in the PDD. Collecting the data recorded in log sheets of respective sections and prepares the consolidated report on electricity generation. Responsible for the overall plant performance and electricity generation of the power plant. Cross check and sign the daily plant operation reports regularly. Should look after the periodical tests of the monitoring equipments as per the monitoring plan. Responsible for the storage and archiving of information in good condition. Responsible for the total monitoring plan. Examining the reports generated by Power

Power plant Operators

Power plant Manager

33

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

CDM Manager

President PT TGR

Plant operators with reference to the monthly electricity generated; net electricity exported to grid and annual emission reduction calculations as per the monitoring plan. Responsible for overall CDM activities and proper monitoring of data as mentioned in monitoring plan. He will be reporting to Director to look after the CDM validation / verification process for the project activity. President will review the reports regularly and take necessary corrective action conforming to CDM.

Emergency procedures: A back up meter will be installed in the power house and equipped with UPS (Uninterruptible Power Supply). In the situation of the main meter has problem, the back up meter will maintain the metering process. To ensure that the data is recorded correctly, the shift engineer will read the meter in power house and record it in the log book. B.8 Date of completion of the application of the baseline and monitoring methodology and the name of the responsible person(s)/entity(ies) Date of completion of the application of the baseline and monitoring methodology: 14/07/2011 Name of the entity determine the baseline: Mr.Johan Romadhon, CEO, PT Tirta Gemah Ripah. PT. Tirta Gemah Ripah. (Project Participant as mentioned in Annex 1) SECTION C. Duration of the project activity / crediting period C.1 Duration of the project activity: C.1.1. Starting date of the project activity: 04/08/2011 (Signing of EPC contract).

C.1.2. Expected operational lifetime of the project activity:

20 years

34

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

C.2

Choice of the crediting period and related information:

Project Activity will use Fixed Crediting Period. C.2.1. Renewable crediting period C.2.1.1. NA C.2.1.2. NA C.2.2. Fixed crediting period: C.2.2.1. Starting date: Length of the first crediting period: Starting date of the first crediting period:

01/03/2013 or registration date. (Whichever occurs later) C.2.2.2. 10 years SECTION D. Environmental impacts D.1. If required by the host Party, documentation on the analysis of the environmental impacts of the project activity: Based on the letter issued by the Department of Mining and Energy ,Directorate General of Electricity and Energy Development, the project activity does not required to have an Environment Impact Assessment (AMDAL) however it is still required to submit an Environment Management (UKL) and Environment Planning(UPL) Procedure to be approved and fulfilled. The same has been approved for the project activity by Badan Pengelolaan Lingkungan Hidup, Pemerintaah Kabupaten Garut (Local Government Environment Department) .The project activity will also need to comply with the procedure by submitting a periodic report. Table 5: Summary of Environment Management Procedure Findings

Activity Pre-construction Impacts Parameters Environmental Efforts Management

Length:

35

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Field Survey

Public Perception

Normal daily activities (does not cause fears and anxieties among the residents)

Socializing development community,

the project

PLTMH to the

Land Procurement and Acquisition Construction Workforce Recruitment and Layoffs

Public Perception

Appropriate reimbursement (of the lands owned by the residents) Mutual agreements with local agencies (lands owned by Perhutani)

Discussion and coordination to set the reimbursement price for land acquisition. Discussion and coordination with local agencies associated with the use of lands owned by the residents. Prioritizing the local workforce in recruitment Inform the workers that the jobs for construction period will be temporary (during construction period) Prioritizing the local workforce in recruitment Providing the appropriate and adequate wages The logging will be carried out selectively (only as necessary) The arrangement of execution time (not during rains) Digging of pile will be carried out as necessary and carefully. Digging and hoarding will be carried out as necessary and carefully Activities will not be conducted during heavy rainfalls period Constructing a landslide retainer, especially in places with high risk of landslide Planting vegetations to strengthen the cliff, this eventually is expected to prevent landslide. Digging and hoarding will be carried out as necessary and carefully Activities will not be conducted during heavy rainfalls period Constructing a landslide retainer, especially in places with high risk of landslide Planting vegetations to strengthen the cliff, this eventually is expected to prevent landslide.

Public Perception

Complaints of the residents The number of workers recruited from local residents Complaints of the residents

Job Opportunities Increased Income Degradation of Water Quality and disturbance to water biota

The number of workers recruited from local residents Wage satisfaction Water quality standard (PP. no 82 Year 2001 or West-Java Governor Decision no. 38/1991 )

Land Clearing and Maturation

Loss of vegetations

The magnitude of lost vegetations (area of cleared space) Complaints from the residents about the risk of landslide Disturbance to environmental function and stability.

Landslide

Construction of Main Facilities and Infrastructure

Landslide and Degradation of water quality

Complaints from the residents about the risk of landslide Disturbance to environmental function and stability.

Perception and Complaints of

36

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

the Community (to the installation of transmission network) Operations Recruitment Workers of Job opportunities

The willingness of residents to allow electrical poles installed in their land No request for reimbursement.

Inform the residents about the benefits of transmission network installations.

The number of workers recruited from local residents

Prioritizing the local workforce in recruitment. Inform them that the jobs for construction period will be temporary and limited to a few workers. Providing adequate and appropriate wages to the workers. Optimizing the operations

Increased Income Operations and Management of Pembangkit Listrik Tenaga Mikro Hidro (PLTMH) and Maintenance of PLTMH facilities Facilities provided to the community (electricity) Nuisance

Adequate wages and satisfaction with the wage earned Addition of Electrical Capacity

Noise Standards (kepMenLH No Kep48/MenLH/11/1996) Landslide Complaints from the residents about the risk of landslide. Disturbance to environmental function and stability.

Placing the turbine in closed space

Constructing a landslide retainer, especially in places with high risk of landslide Planting vegetations to strengthen the cliff, this eventually is expected to prevent landslide. Inviting community participation in managing PLTMH Coordinating with local authorities and agencies in managing PLTMH If the mud precipitates in the tranquilizing pool, it will not be thrown directly to the river, but removed from the pool to other area. The clearance of water entering the turbine (by installing trash trapper/trap). Keeping the hygiene Conducting reforestation in the open activity locations due to PLTMH development activities Developing clear work instructions which are obeyed by all workers. Installing warning/notification

Public perceptions

Satisfaction of community

Improvement of Water Quality

Quality standards of River Water (PP no. 82 Year 2001 or West-Java Governor Decision No.38/1991). Success of reforestation.

Accidents and Safety Issues

Number of Reported Accidents

37

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Environmental Security

board. Creating boundary or setting up fences for important and accidentprone facilities. Providing the workers with personal protective equipment and first aid kit. Number of disturbances to the PLTMH facilities. Disruptions of the forest areas surrounding the location. Coordinating with local agencies. Keeping the environmental securities together with the community and local government agencies. Organizing community development activities in Bungbuland and Cihikeu villages.

New Business Opportunities (because the availability of electricity)

Improvement of local economy

D.2. If environmental impacts are considered significant by the project participants or the host Party, please provide conclusions and all references to support documentation of an environmental impact assessment undertaken in accordance with the procedures as required by the host Party: The project is expected to deliver an overall positive sustainable impact and development on the local and global environment All negative environmental impacts are subjected to observation and management as described above. SECTION E. Stakeholders comments E.1. Brief description how comments by local stakeholders have been invited and compiled:

The project developer conducted a stakeholders consultation meeting at their project site with the local village people residing in and around the vicinity of this project activity in order to view the concerns of the local stakeholders and their opinion about the proposed project activity on 15/04/2011. Some of the key local stakeholders were also invited by an invitation letter14. The local population and regulatory authorities participated in that meeting. An advertisement was also published to inform local people regarding the project activity in daily newspaper i.e. Radar Garut on 4 April 2011. Mr. Herman Rachmat (General Manager TGR) briefed the attendees about the project and the agenda of the stakeholder meeting and introduced the global warming and the climate change. Mr.Yulianto (Project Director TGR) introduced the company/project to the audience and also presented a brief overview of the hydro power business. After this brief introduction of company, climate change, Kyoto Protocol and CDM, he explained to the attendees the purpose of the stakeholder consultation meeting as to seek the concern, opinion and suggestion of the stakeholders.

14

Copy of invitation letters shall be provided at the time of validation

38

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Subsequently, project promoter invited the stakeholders to ask for their queries and suggestions. The questions and responses to their query are given in the next section.

E.2.

Summary of the comments received:

People participated with great enthusiasm and raised a few questions, which were answered to in an appropriate manner by the project developer. Summary of these comments is given as follows; Mr.Ayi Saripudin (Cibungbulang Head of Sub-districts Secretary) Opening Statement: We would like to thank PT. Gemah Ripah for its contribution to the Bungbulang Sub-district by developing the Cirompang Mini Hydro Power Plant (MHPP), hereafter referred as MHPP. We also fully support the CDM project, a global/international scale program, which allows us to contribute to save the environment. Mr.Burhanudin Apip (Head of Local Environmental Management Council) Opening Statement: We support the development of Cirompang MHPP, because Garut Regency still lacks electricity. In addition, 18500 houses in our regency are still not connected to the electrical network. Therefore, we support the development of Cirompang MHPP. Mr. M.Mahfudin (GP3A of Mitra Cai) Question: We fully support the development of Cirompang MHPP and CDM proposal, and according to the agreement between TGR and Mitra Cai, we hope that the rice fields will continue to be irrigated and we hope that TGR will conduct reforestation in the area surrounding the project location. Answer: TGR will neither destroy the existing channels nor use the old tunnels, but we will construct new channels and tunnels. Therefore, the irrigation will not be disturbed during the construction period. In accordance to the agreement between TGR Mitra Cai, the water will be prioritized to irrigate the rice fields up to 800 L/seconds, and the rest will be allocated to MMPH. Mr. Ridwan Taufik (Sabareuma Environmental Activist) We support the Development of Cirompang MMPH, because it represents clean, environmentally friendly energy.What are the advantages of CDM to the community and environment? Answers: To supply the electricity to Garut Regency To preserve the environment because PLTM is free of pollution. To provide jobs to the members of Bungbulang community according to their skill set. To assist in increasing the CSR activities to the community surrounding the project. Mr.Tjahya (Head of Intellegence, Bungbulang Police Department) In principle, we support the continuation of the Cirompang MHPP project.We request a coordination between TGR, Muspika of the Sub-district, and police department for the safety and continuity of the

39

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

project. The police department is ready to help the project in preventing any provocation, in order to aid safe and continuous development of PLTMH. Mr. Aos Suryana (Water and Mining Resources Agency) At the location of Cirompang irrigation grounds belonging to SDAP, above the bridge to be exact, there is an area of around 2-3 Hectares, which can be utilized for reforestation. We hope that from the CDM project, the TGR can participate in restoring the area for greener purposes The meeting was concluded with vote of thanks by Mr. Herman Rachmat from TGR. In general, all participants in the forum supported the implementation of proposed project. E.3. Report on how due account was taken of any comments received:

No negative comments have been received on the Project.

40

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Annex 1 CONTACT INFORMATION ON PARTICIPANTS IN THE PROJECT ACTIVITY Organisation: Street/P.O.Box: Building: City: State/Region: Postal code: Country: Phone: Fax: E-mail: URL: Represented by: Title: Salutation: Last name: Middle name: First name: Department: Phone (direct): Fax (direct): Mobile: Personal e-mail: Nordic Environment Finance Corporation NEFCO in its capacity as Fund Manager to the NEFCO Carbon Fund (NeCF) Fabianinkatu 34, P.O. Box 249 Helsinki FI-00171 Finland +358 10 6180 644 +358 9 630 976 www.nefco.org/cff Ash Sharma Vice President, Head, Carbon Finance and Funds Unit Mr. Sharma Ash + 358 10 6180 644 +358 9 630 976 +358 10 6180 644 ash.sharma@nefco.fi

Organization: Street/P.O.Box: Building: City: State/Region: Postfix/ZIP: Country: Telephone: FAX: E-Mail: URL: Represented by: Title: Salutation: Last Name:

PT. Tirta Gemah Ripah Jl. Tubagus Ismail Depan No. IA Bandung West Java 40134 Indonesia +62-222535852/+62-8112209514 +62-222535851 Mr Johan Romadhon CEO Mr Romadhon

41

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Middle Name: First Name: Department: Mobile: Direct FAX: Direct tel: Personal E-Mail:

Johan +62-8112209514 +62-222535851 +62-222535852/+62-8112209514 tgr.jabar@gmail.com

42

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board

Annex 2 INFORMATION REGARDING PUBLIC FUNDING No public funding is involved in this project activity

43

PROJECT DESIGN DOCUMENT FORM (CDM-SSC-PDD) - Version 03

CDM Executive Board