Академический Документы

Профессиональный Документы

Культура Документы

CH 08

Загружено:

Ingi Abdel Aziz SragИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CH 08

Загружено:

Ingi Abdel Aziz SragАвторское право:

Доступные форматы

Chapter 8

Deformation and Strengthening Mechanisms

QUESTIONS AND PROBLEMS

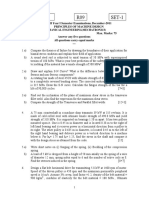

Basic Concepts Characteristics of Dislocations W8.1 Is it possible for two screw dislocations of opposite sign to annihilate each other? Explain your answer. W8.2 For each of edge, screw, and mixed dislocations, cite the relationship between the direction of the applied shear stress and the direction of dislocation line motion. Slip Systems W8.3 (a) Define a slip system. (b) Do all metals have the same slip system? Why or why not? W8.4 One slip system for the HCP crystal structure is {0001} 1120 . In a manner similar to Figure 8.6b, sketch a {0001}-type plane for the HCP structure and, using arrows, indicate

three different 1120 helpful.

slip directions within this plane. You might find Figure 3.24

W8.5 (a) In the manner of Equations 8.1a, 8.1b, and 8.1c, specify the Burgers vector for the

simple cubic crystal structure. Its unit cell is shown in Figure 3.42. Also, simple cubic is the crystal structure for the edge dislocation of Figure 5.8, and for its motion as presented in Figure 8.1. You may also want to consult the answer to Concept Check 8.1.

(b) On the basis of Equation 8.13, formulate an expression for the magnitude of the

Burgers vector, |b|, for simple cubic.

Slip in Single Crystals W8.6 Sometimes cos cos in Equation 8.2 is termed the Schmid factor. Determine the

magnitude of the Schmid factor for an FCC single crystal oriented with its [120] direction parallel to the loading axis.

W8.7 A single crystal of zinc is oriented for a tensile test such that its slip plane normal makes

an angle of 65 with the tensile axis. Three possible slip directions make angles of 30, 48, and 78 with the same tensile axis.

(a) Which of these three slip directions is most favored? (b) If plastic deformation begins at a tensile stress of 2.5 MPa (355 psi), determine the

critical resolved shear stress for zinc.

W8.8 For crystals having cubic symmetry, generate a spreadsheet that will allow the user to

determine the angle between two crystallographic directions, given their directional indices.

W8.9 A single crystal of a metal that has the FCC crystal structure is oriented such that a tensile

stress is applied parallel to the [100] direction. If the critical resolved shear stress for this material is 0.5 MPa, calculate the magnitude(s) of applied stress(es) necessary to cause slip to occur on the (111) plane in each of the [1 1 0], [10 1] and [0 11] directions.

W8.10 Consider a single crystal of some hypothetical metal that has the BCC crystal structure

and is oriented such that a tensile stress is applied along a [121] direction. If slip occurs on a (101) plane and in a [111] direction, compute the stress at which the crystal yields if its critical resolved shear stress is 2.4 MPa.

Deformation by Twinning W8.11 List four major differences between deformation by twinning and deformation by slip

relative to mechanism, conditions of occurrence, and final result.

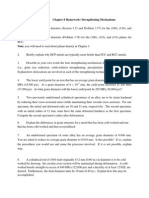

Strengthening by Grain Size Reduction W8.12 Describe in your own words the three strengthening mechanisms discussed in this chapter

(i.e., grain size reduction, solid-solution strengthening, and strain hardening). Be sure to explain how dislocations are involved in each of the strengthening techniques.

W8.13 The lower yield point for an iron that has an average grain diameter of 1 102 mm is

230 MPa (33,000 psi). At a grain diameter of 6 103 mm, the yield point increases to 275 MPa (40,000 psi). At what grain diameter will the lower yield point be 310 MPa (45,000 psi)?

Solid-Solution Strengthening W8.14 In the manner of Figures 8.17b and 8.18b, indicate the location in the vicinity of an edge

dislocation at which an interstitial impurity atom would be expected to be situated. Now briefly explain in terms of lattice strains why it would be situated at this position.

Strain Hardening W8.15 (a) Show, for a tensile test, that

%CW = 100 + 1

if there is no change in specimen volume during the deformation process (i.e., A0l0 =

Adld). (b) Using the result of part (a), compute the percent cold work experienced by naval brass

(for which the stressstrain behavior is shown in Figure 7.12) when a stress of 415 MPa (60,000 psi) is applied.

W8.16 Two previously undeformed specimens of the same metal are to be plastically deformed

by reducing their cross-sectional areas. One has a circular cross section, and the other is rectangular; during deformation the circular cross section is to remain circular, and the rectangular is to remain as such. Their original and deformed dimensions are as follows:

Circular (diameter, mm) Rectangular (mm)

Original dimensions Deformed dimensions

18.0 15.9

20 50 13.7 55.1

Which of these specimens will be the hardest after plastic deformation, and why?

W8.17 (a) What is the approximate ductility (%EL) of a brass that has a yield strength of 345

MPa (50,000 psi)?

(b) What is the approximate Brinell hardness of a 1040 steel having a yield strength of

620 MPa (90,000 psi)?

Recovery Recrystallization Grain Growth W8.18 Briefly cite the differences between recovery and recrystallization processes. W8.19 Explain the differences in grain structure for a metal that has been cold worked and one

that has been cold worked and then recrystallized.

W8.20 (a) What is the driving force for recrystallization? (b) For grain growth? W8.21 (a) From Figure 8.25, compute the length of time required for the average grain diameter

to increase from 0.03 to 0.3 mm at 600C for this brass material.

(b) Repeat the calculation at 700C. W8.22 An undeformed specimen of some alloy has an average grain diameter of 0.050 mm. You

are asked to reduce its average grain diameter to 0.020 mm. Is this possible? If so, explain the procedures you would use and name the processes involved. If it is not possible, explain why.

Crystalline Ceramics (Deformation Mechanisms for Ceramic Materials) W8.23 Cite one reason why ceramic materials are, in general, harder yet more brittle than

metals.

Factors That Influence the Mechanical Properties of Semicrystalline Polymers (Deformation of Elastomers) W8.24 Briefly explain how each of the following influences the tensile modulus of a

semicrystalline polymer and why:

(a) Molecular weight

(b) Degree of crystallinity (c) Deformation by drawing (d) Annealing of an undeformed material (f) Annealing of a drawn material W8.25 Normal butane and isobutane have boiling temperatures of 0.5 and 12.3C (31.1 and

9.9F), respectively. Briefly explain this behavior on the basis of their molecular structures, as presented in Section 4.2.

W8.26 The tensile strength and number-average molecular weight for two polyethylene

materials are as follows:

Tensile Strength (MPa) Number-Average Molecular Weight (g/mol)

90 180

20,000 40,000

Estimate the number-average molecular weight that is required to give a tensile strength of 140 MPa.

W8.27 For each of the following pairs of polymers, do the following: (1) state whether or not it

is possible to decide whether one polymer has a higher tensile strength than the other; (2) if this is possible, note which has the higher tensile strength and then cite the reason(s) for your choice; and (3) if it is not possible to decide, then state why.

(a) Linear and isotactic poly(vinyl chloride) with a weight-average molecular weight of

100,000 g/mol; branched and atactic poly(vinyl chloride) having a weight-average molecular weight of 75,000 g/mol

(b) Graft acrylonitrile-butadiene copolymer with 10% of possible sites crosslinked;

alternating acrylonitrile-butadiene copolymer with 5% of possible sites crosslinked

(c) Network polyester; lightly branched polytetrafluoroethylene W8.28 Would you expect the tensile strength of polychlorotrifluoroethylene to be greater than,

the same as, or less than that of a polytetrafluoroethylene specimen having the same molecular weight and degree of crystallinity? Why?

W8.29 List the two molecular characteristics that are essential for elastomers. W8.30 Which of the following would you expect to be elastomers and which thermosetting

polymers at room temperature? Justify each choice.

(a) Phenol-formaldehyde (b) Lightly crosslinked polyisoprene having a glass-transition temperature of 60C (

76F)

W8.31 Compute the weight percent sulfur that must be added to completely crosslink an

alternating acrylonitrile-butadiene copolymer, assuming that four sulfur atoms participate in each crosslink.

W8.32 For the vulcanization of polyisoprene, compute the weight percent of sulfur that must be

added to ensure that 10% of possible sites will be crosslinked; assume that, on the average, 3.5 sulfur atoms are associated with each crosslink.

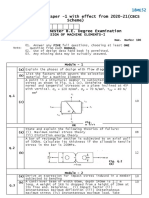

DESIGN PROBLEMS

Strain Hardening Recrystallization W8.D1 Determine whether or not it is possible to cold work brass so as to give a minimum

Brinell hardness of 150, and at the same time have a ductility of at least 20%EL. Justify your decision.

W8.D2 It is necessary to select a metal alloy for an application that requires a yield strength of at

least 310 MPa (45,000 psi) while maintaining a minimum ductility (%EL) of 27%. If the metal may be cold worked, decide which of the following are candidates: copper, brass, and a 1040 steel. Why?

W8.D3 A cylindrical rod of brass originally 10.2 mm (0.40 in.) in diameter is to be cold worked

by drawing; the circular cross section will be maintained during deformation. A coldworked yield strength in excess of 380 MPa (55,000 psi) and a ductility of at least 15%EL are desired. Furthermore, the final diameter must be 7.6 mm (0.30 in.). Explain how this may be accomplished.

Вам также может понравиться

- HW #7Документ4 страницыHW #7c_sierra34Оценок пока нет

- Prolemario 2Документ4 страницыProlemario 2Emiliano LozanoОценок пока нет

- CH 07Документ12 страницCH 07Madeline NgoОценок пока нет

- Materials 1 Exam: Phase Diagrams, Microstructure and PropertiesДокумент4 страницыMaterials 1 Exam: Phase Diagrams, Microstructure and Propertiesshauno9997Оценок пока нет

- 3094 HW ECBДокумент2 страницы3094 HW ECBradarskiОценок пока нет

- Mechanics of Solids Exam QuestionsДокумент10 страницMechanics of Solids Exam QuestionsNandu Sreekumar SОценок пока нет

- GEEN 3024 Practice Exam 2Документ12 страницGEEN 3024 Practice Exam 2ChristinaОценок пока нет

- dmm1 PDFДокумент9 страницdmm1 PDFmohan_rapaka6095Оценок пока нет

- Ashok Dmm1Документ4 страницыAshok Dmm1Praveen KumarОценок пока нет

- Mechanics of SolidsДокумент8 страницMechanics of SolidsKhaista RahmanОценок пока нет

- Gujarat Technological UniversityДокумент7 страницGujarat Technological Universitythe grayОценок пока нет

- Assignment No. 1 Materials Science and MetallurgyДокумент2 страницыAssignment No. 1 Materials Science and MetallurgySamruddhi MirganeОценок пока нет

- MME291 TermFinalQues 09-15Документ20 страницMME291 TermFinalQues 09-15behind mirrorОценок пока нет

- Tutorial Questions For Part 1Документ5 страницTutorial Questions For Part 1Ng Yan XiongОценок пока нет

- Be Winter 2022Документ3 страницыBe Winter 2022Karan SheladiyaОценок пока нет

- PMD ModelДокумент8 страницPMD ModelDamodara SatyaDeva MadhukarОценок пока нет

- Home Assignment 5Документ2 страницыHome Assignment 5SantoshОценок пока нет

- BG1005 Materials Sciences_ Homework #1Документ4 страницыBG1005 Materials Sciences_ Homework #1blueworld_918094Оценок пока нет

- 7 4Документ8 страниц7 4Izwan HassanОценок пока нет

- MCEN30017 Tutorial 2Документ3 страницыMCEN30017 Tutorial 2vsanthanamОценок пока нет

- ENGINEERING MATERIALS ASSIGNMENTДокумент3 страницыENGINEERING MATERIALS ASSIGNMENTHussain AliОценок пока нет

- Design of Machine Elements Exam QuestionsДокумент8 страницDesign of Machine Elements Exam Questionsslv_prasaadОценок пока нет

- Machine Members Design AssignmentДокумент13 страницMachine Members Design AssignmentHafiz Mahar28Оценок пока нет

- DESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperДокумент8 страницDESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperelimelekОценок пока нет

- IFS Mechanical Engineering 2015 Part 1Документ4 страницыIFS Mechanical Engineering 2015 Part 1Saurabh BhardwajОценок пока нет

- Gujarat Technological UniversityДокумент4 страницыGujarat Technological Universitythe grayОценок пока нет

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsОт EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsОценок пока нет

- Machine Design MCQsДокумент10 страницMachine Design MCQssureshm_raj5434Оценок пока нет

- No of Pages Course Code:: Fig.1 Fig 2Документ4 страницыNo of Pages Course Code:: Fig.1 Fig 2CRAZY PIANO PLAYERОценок пока нет

- 2018 April CE201-D - Ktu QbankДокумент2 страницы2018 April CE201-D - Ktu Qbanklakshmi dileepОценок пока нет

- Dme Question BankДокумент4 страницыDme Question BankRavi Patil100% (1)

- DESIGN OF MACHINE ELEMENTS Question PaperДокумент4 страницыDESIGN OF MACHINE ELEMENTS Question PaperL RevathiОценок пока нет

- MSE 227 Chapter 8 HWДокумент1 страницаMSE 227 Chapter 8 HWjosewilliam85Оценок пока нет

- GTU BE-SEMESTER-VII Machine Design Exam QuestionsДокумент2 страницыGTU BE-SEMESTER-VII Machine Design Exam QuestionsNILESH SUTHARОценок пока нет

- Dme Gtu PaperДокумент5 страницDme Gtu PaperManav HnОценок пока нет

- MECH 390 - PRACTICE 1 - FALL 2011Документ5 страницMECH 390 - PRACTICE 1 - FALL 2011Abeer AlnaqbiОценок пока нет

- Gujarat Technological UniversityДокумент3 страницыGujarat Technological UniversityHarshit PatelОценок пока нет

- 2014 2015 S2 KNJ1433 AssignmentДокумент3 страницы2014 2015 S2 KNJ1433 AssignmentFiq DenОценок пока нет

- Design of Machine Elements IДокумент8 страницDesign of Machine Elements Imesab100Оценок пока нет

- Mech4005y 5 2010 2Документ4 страницыMech4005y 5 2010 2Balgo BalgobinОценок пока нет

- B.Tech Exam Design of Machine Members QuestionsДокумент8 страницB.Tech Exam Design of Machine Members Questionsprk74Оценок пока нет

- Taller 3 - Propiedades MecánicasДокумент2 страницыTaller 3 - Propiedades MecánicasJuan Pablo Rinc�n Ru�zОценок пока нет

- DME-I Model Paper-3 2Документ3 страницыDME-I Model Paper-3 2Srinivas KosuriОценок пока нет

- Assignment 1 E FДокумент2 страницыAssignment 1 E FSudhananda MallickОценок пока нет

- GTU BE Semester IV Machine Design & Industrial Drafting ExamДокумент3 страницыGTU BE Semester IV Machine Design & Industrial Drafting ExamhukОценок пока нет

- 08 r05310305 Design of Machine Members IДокумент9 страниц08 r05310305 Design of Machine Members IKrupanandareddyYarragudiОценок пока нет

- 3-1 DMM1 (Nov 2009 Regular)Документ9 страниц3-1 DMM1 (Nov 2009 Regular)micmechОценок пока нет

- Mechanics of Solids exam questionsДокумент10 страницMechanics of Solids exam questionsgalehОценок пока нет

- 9A14503 Principles of Machine DesignДокумент8 страниц9A14503 Principles of Machine DesignsivabharathamurthyОценок пока нет

- Dmm1 Mar2007Документ8 страницDmm1 Mar2007prk74Оценок пока нет

- Assignment 1 Mech 321 Properties and Failure of Materials Jan 2009Документ2 страницыAssignment 1 Mech 321 Properties and Failure of Materials Jan 2009DSGОценок пока нет

- BF1113 Assignment 2Документ2 страницыBF1113 Assignment 2sanasieОценок пока нет

- Model Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationДокумент10 страницModel Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationSharath KotegarОценок пока нет

- Rr312404 Design of Machine ElementsДокумент9 страницRr312404 Design of Machine ElementsSrinivasa Rao GОценок пока нет

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsДокумент5 страницMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SОценок пока нет

- Question Bank - DMEДокумент6 страницQuestion Bank - DMEBdhdhshОценок пока нет

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОт EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОценок пока нет

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapОт EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieОценок пока нет

- Pohlak 1Документ4 страницыPohlak 1Ingi Abdel Aziz SragОценок пока нет

- PresentaciónASCAMM STA2009Документ23 страницыPresentaciónASCAMM STA2009Ingi Abdel Aziz SragОценок пока нет

- Marc PaperДокумент8 страницMarc PaperIngi Abdel Aziz SragОценок пока нет

- HP Personal Media Drive User's GuideДокумент16 страницHP Personal Media Drive User's GuidemaderaziОценок пока нет

- N V Reddy - BakДокумент5 страницN V Reddy - BakIngi Abdel Aziz SragОценок пока нет

- APICS CPIM Study Notes DSP ModuleДокумент16 страницAPICS CPIM Study Notes DSP Modulecwh927100% (5)

- Dieless FormingДокумент1 страницаDieless FormingIngi Abdel Aziz SragОценок пока нет

- Negative Aluminium SheetsДокумент5 страницNegative Aluminium SheetsCarlos ArenasОценок пока нет

- EP0970764B1Документ52 страницыEP0970764B1Ingi Abdel Aziz SragОценок пока нет

- N V Reddy - BakДокумент5 страницN V Reddy - BakIngi Abdel Aziz SragОценок пока нет

- 20 Simple Tips To Be Happy Now PDFДокумент11 страниц20 Simple Tips To Be Happy Now PDFLaura OtiОценок пока нет

- Sales Forecasting Using ExcelДокумент1 страницаSales Forecasting Using ExcelIngi Abdel Aziz SragОценок пока нет

- APICS CPIM Study Notes MPR ModuleДокумент17 страницAPICS CPIM Study Notes MPR Modulecwh92770% (10)

- ROI Calculation:: Calculating Return-On Investment Kenneth H. Silber, Ph.D. Version 4.0 - 04/03/02Документ4 страницыROI Calculation:: Calculating Return-On Investment Kenneth H. Silber, Ph.D. Version 4.0 - 04/03/02zeeshanshani1118Оценок пока нет

- Cpim Online Materials You Will NeedДокумент2 страницыCpim Online Materials You Will NeedIngi Abdel Aziz SragОценок пока нет

- Cpim-Apics MCQ BookletДокумент143 страницыCpim-Apics MCQ BookletSmart SarimОценок пока нет

- CPIM MPR Sample TestДокумент16 страницCPIM MPR Sample Testdia198450% (2)

- InstructionsДокумент1 страницаInstructionsIngi Abdel Aziz SragОценок пока нет

- Cpim-Apics MCQ BookletДокумент143 страницыCpim-Apics MCQ BookletSmart SarimОценок пока нет

- 5 Years Marketing PlanДокумент58 страниц5 Years Marketing PlanhawwacoОценок пока нет

- Fe 70900Документ3 страницыFe 70900Ingi Abdel Aziz SragОценок пока нет

- VentureGrip 400 MSDSДокумент8 страницVentureGrip 400 MSDSIngi Abdel Aziz SragОценок пока нет

- U.S. Adhesives Industry-Current Structure and Future GrowthДокумент8 страницU.S. Adhesives Industry-Current Structure and Future GrowthIngi Abdel Aziz SragОценок пока нет

- Design Guide For PET Bottle Recyclability 31 March 2011Документ38 страницDesign Guide For PET Bottle Recyclability 31 March 2011Виктор Парамонов50% (2)

- TFC Global Challenge 2014 Stu Flyer PRF09Документ2 страницыTFC Global Challenge 2014 Stu Flyer PRF09jehana_bethОценок пока нет

- Sheet (1) : Eng.A.Sobhi & Eng - Abd-ElrahmanДокумент1 страницаSheet (1) : Eng.A.Sobhi & Eng - Abd-ElrahmanIngi Abdel Aziz SragОценок пока нет

- 36 - 4 - New York - 08-91 - 1618Документ8 страниц36 - 4 - New York - 08-91 - 1618Ingi Abdel Aziz SragОценок пока нет

- Inferior ProductsДокумент40 страницInferior ProductsIngi Abdel Aziz SragОценок пока нет

- Sample Interview Questions With Suggested Ways of Answering: Research The CompanyДокумент2 страницыSample Interview Questions With Suggested Ways of Answering: Research The CompanyIngi Abdel Aziz SragОценок пока нет

- Fair - #039 14 Internship BookletДокумент27 страницFair - #039 14 Internship BookletIngi Abdel Aziz SragОценок пока нет

- D257272 1200 FDD 002 R1 PDFДокумент420 страницD257272 1200 FDD 002 R1 PDFTap Toan100% (1)

- Module 4-Answer KeyДокумент100 страницModule 4-Answer KeyAna Marie Suganob82% (22)

- English Skills BookДокумент49 страницEnglish Skills BookAngela SpadeОценок пока нет

- HU675FE ManualДокумент44 страницыHU675FE ManualMar VeroОценок пока нет

- Manual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFДокумент106 страницManual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDante Renee Mendoza DelgadoОценок пока нет

- Product Catalog 2016Документ84 страницыProduct Catalog 2016Sauro GordiniОценок пока нет

- Week 6Документ7 страницWeek 6Nguyễn HoàngОценок пока нет

- HP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityДокумент65 страницHP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityAlexandru BotnariОценок пока нет

- Youth, Time and Social Movements ExploredДокумент10 страницYouth, Time and Social Movements Exploredviva_bourdieu100% (1)

- Philippine College of Northwestern Luzon Bachelor of Science in Business AdministrationДокумент7 страницPhilippine College of Northwestern Luzon Bachelor of Science in Business Administrationzackwayne100% (1)

- Mechanical Questions & AnswersДокумент161 страницаMechanical Questions & AnswersTobaОценок пока нет

- Interna Medicine RheumatologyДокумент15 страницInterna Medicine RheumatologyHidayah13Оценок пока нет

- Application Programming InterfaceДокумент12 страницApplication Programming InterfacesorinproiecteОценок пока нет

- Lec 10 - MQueues and Shared Memory PDFДокумент57 страницLec 10 - MQueues and Shared Memory PDFUchiha ItachiОценок пока нет

- Nqs PLP E-Newsletter No68Документ5 страницNqs PLP E-Newsletter No68api-243291083Оценок пока нет

- STERNOL Specification ToolДокумент15 страницSTERNOL Specification ToolMahdyZargarОценок пока нет

- Seminar #22 Vocabury For Speaking PracticeДокумент7 страницSeminar #22 Vocabury For Speaking PracticeOyun-erdene ErdenebilegОценок пока нет

- Bethany Getz ResumeДокумент2 страницыBethany Getz Resumeapi-256325830Оценок пока нет

- Av1 OnДокумент7 страницAv1 OnLê Hà Thanh TrúcОценок пока нет

- Motivations for Leaving Public Accounting FirmsДокумент33 страницыMotivations for Leaving Public Accounting Firmsran0786Оценок пока нет

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Документ28 страницMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palОценок пока нет

- Raychem Price ListДокумент48 страницRaychem Price ListramshivvermaОценок пока нет

- Trove Research Carbon Credit Demand Supply and Prices 1 June 2021Документ51 страницаTrove Research Carbon Credit Demand Supply and Prices 1 June 2021Ceren ArkancanОценок пока нет

- Principles of Cost Accounting 1Документ6 страницPrinciples of Cost Accounting 1Alimamy KamaraОценок пока нет

- VNC Function Operation InstructionДокумент11 страницVNC Function Operation InstructionArnaldo OliveiraОценок пока нет

- Genre Worksheet 03 PDFДокумент2 страницыGenre Worksheet 03 PDFmelissaОценок пока нет

- Maximizing modular learning opportunities through innovation and collaborationДокумент2 страницыMaximizing modular learning opportunities through innovation and collaborationNIMFA SEPARAОценок пока нет

- Mark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'Документ5 страницMark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'bhaskkarОценок пока нет

- BSC6900 UMTS V900R011C00SPC700 Parameter ReferenceДокумент1 010 страницBSC6900 UMTS V900R011C00SPC700 Parameter Referenceronnie_smgОценок пока нет

- Ch. 7 - Audit Reports CA Study NotesДокумент3 страницыCh. 7 - Audit Reports CA Study NotesUnpredictable TalentОценок пока нет