Академический Документы

Профессиональный Документы

Культура Документы

Aspen Plus Dynamics Datasheet

Загружено:

atsomech132206Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aspen Plus Dynamics Datasheet

Загружено:

atsomech132206Авторское право:

Доступные форматы

Aspen Plus Dynamics

Dynamic simulation and optimization of chemical processes

Aspen Plus Dynamics extends Aspen Plus steady-state models into dynamic process models, enabling design and verification of process control schemes, safety studies, relief-valve sizing, failure analysis, and development of startup, shutdown, rate-change, and grade transition policies.

Improve Collaboration and Understanding of Plant Behavior

The process industries are faced with an increasingly competitive environment and ever-changing market conditions. Productivity and profitability can be maximized by reducing the time to market for new products, improving the yield and quality of products, and operating the plant more safely and efficiently. The key to realizing such results is enabling process engineers, control engineers, and process operations to work together. Aspen Plus Dynamics provides a common platform that can be applied across the plant lifecycle, from conceptual design and commissioning to operation and process revamps. Companies are able to meet tighter product specifications through improved understanding of plant operability issues, ensure faster and safer plant start-ups, and avoid unplanned downtimesresulting in maximum plant availability and productivity.

Reported Benefits

$15 million saved through improved start-up procedures $10 million saved capital cost by avoiding over-design of relief systems 15% capacity increase in a sold-out plant through improved operability Improved safety through better operational procedures, enhanced control system design, and proper relief-valve sizing Better design decisions through detailed analysis of the trade-offs between process operability and process integration A Methyl Amines process was converted from a steady-state model to Aspen Plus Dynamics. In this case a step change in the ammonia feed and the corresponding response at different parts of the process is evaluated.

Key Technical Features

Easy conversion of steady-state Aspen Plus models into dynamic models Compatible with Aspen Custom Modeler, enabling custom user-defined unit operations within Aspen Plus Dynamics Best-in-class physical properties through integration with Aspen Properties Optimization and estimation tools enabling parameter fitting, data reconciliation, and steady-state and dynamic process optimization Equation-oriented architecture allowing fast and robust simulation of complex, highly integrated processes Flexible Task Language to define transition schemes or to simulate equipment failures Library of equipment models including rigorous reactive distillation with hydraulics and a full set of pressure relief models Library of control models to simulate process control systems including links to Aspen DMCplus and Simulink Choice of flow-driven or pressure-driven simulation for quick, high-performance simulation or rigorous, high-fidelity simulation

Added Value of Integration

Aspen Plus Dynamics is tightly integrated with other aspenONE Engineering solutions: Aspen Model Runner is an execution environment that can be used to run process models exported from Aspen Plus Dynamics. Use Aspen Model Runner to protect intellectual property inside the models and to reduce deployment costs. Aspen Polymers extends Aspen Plus Dynamics with a complete set of polymer thermodynamics methods and data, polymerization reaction models, and extensions to the equipment models to track polymer properties. Aspen Simulation Workbook enables easy development of Microsoft Excel-based user interfaces to Aspen Plus Dynamics, making it easy to deploy your dynamic models to a wider range of users in the plant.

Worldwide Headquarters Empower Your Company to Succeed

aspenONE Engineering is an integrated lifecycle solutionfrom conceptual design through plant startup and operations supportenabling you to model, build, and operate safer, more efficient and more competitive process plants. AspenTechs Engineering Professional Services helps ensure that your project achieves its maximum potential by leveraging our unparalleled industry expertise to design, analyze, debottleneck, and improve plant performance. Combined with our world-class 24/7 technical support service, flexible training options, including online training from within the software, proprietary search engine to locate and re-use models and data, and local language product availability, AspenTech provides the resources to enable your company to meet and exceed its business objectives. Aspen Technology, Inc. 200 Wheeler Road Burlington, MA 01803 United States phone: +17812216400 fax: +17812216410 info@aspentech.com

Regional Headquarters

Houston, TX | USA phone: +12815841000

About AspenTech

AspenTech is a leading supplier of software that optimizes process manufacturingfor energy, chemicals, pharmaceuticals, engineering and construction, and other industries that manufacture and produce products from a chemical process. With integrated aspenONE solutions, process manufacturers can implement best practices for optimizing their engineering, manufacturing, and supply chain operations. As a result, AspenTech customers are better able to increase capacity, improve margins, reduce costs, and become more energy efficient. To see how the worlds leading process manufacturers rely on AspenTech to achieve their operational excellence goals, visit www.aspentech.com.

2012 Aspen Technology, Inc. AspenTech, aspenONE, the Aspen leaf logo, OPTIMIZE, and the 7 Best Practices of Engineering Excellence are trademarks of Aspen Technology, Inc. All rights reserved. All other trademarks are property of their respective owners. 11-1403-0412

So Paulo | Brazil phone: +551134436261 Reading | United Kingdom phone: +44(0)1189226400 Singapore | Republic of Singapore phone: +6563953900 Manama | Bahrain phone: +97317503000 For a complete list of offices, please visit www.aspentech.com/locations

Вам также может понравиться

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- Aspen Polymers Ds D PDFДокумент2 страницыAspen Polymers Ds D PDFMasagus Sapta RyandaОценок пока нет

- Aspen Polymers DatasheetДокумент2 страницыAspen Polymers DatasheetSyed Ubaid AliОценок пока нет

- The Data Industry: The Business and Economics of Information and Big DataОт EverandThe Data Industry: The Business and Economics of Information and Big DataОценок пока нет

- Aspen PIMS BrochureДокумент4 страницыAspen PIMS BrochureckwabiОценок пока нет

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979От EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonОценок пока нет

- 1732 15 Aspen APC WebДокумент8 страниц1732 15 Aspen APC WebAlberto Fonseca UribeОценок пока нет

- Week#2 - Olefins Plant - Annotated PDFДокумент42 страницыWeek#2 - Olefins Plant - Annotated PDFAgus WahyudhiОценок пока нет

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsОт EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsОценок пока нет

- Predict Distillation Tray Efficiency: Reactions and SeparationsДокумент7 страницPredict Distillation Tray Efficiency: Reactions and SeparationsJohn AnthoniОценок пока нет

- Understand Thermodynamics To Improve Process Simulations: Computational MethodsДокумент6 страницUnderstand Thermodynamics To Improve Process Simulations: Computational MethodsAxel SantínОценок пока нет

- Supply Chain Optimisn B K DattaДокумент33 страницыSupply Chain Optimisn B K DattamelgeorgeОценок пока нет

- Benefits of The NIST Thermo Data Engine in AspenONE EngineeringДокумент12 страницBenefits of The NIST Thermo Data Engine in AspenONE EngineeringMohammed MorsyОценок пока нет

- KBC Viewpoint Optimization Programs Mar18 - USДокумент12 страницKBC Viewpoint Optimization Programs Mar18 - USjunk multiОценок пока нет

- Use of Dynamic Simulation To ConvergeДокумент8 страницUse of Dynamic Simulation To ConvergeneftОценок пока нет

- ENG Simulations Improve Refining Margins - Final PresentationДокумент31 страницаENG Simulations Improve Refining Margins - Final PresentationElimar RojasОценок пока нет

- CPE666 - Chapter 4 PDFДокумент71 страницаCPE666 - Chapter 4 PDFbruce bartonОценок пока нет

- Aspen Petroleum Supply Chain: Installation GuideДокумент70 страницAspen Petroleum Supply Chain: Installation GuideYves-donald MakoumbouОценок пока нет

- Multi-Objective Optimization of An Industrial Crude Distillation Unit Using The Elitist Nondominated PDFДокумент13 страницMulti-Objective Optimization of An Industrial Crude Distillation Unit Using The Elitist Nondominated PDFBahar MeschiОценок пока нет

- CV of Chemical EngineerДокумент3 страницыCV of Chemical EngineerAmol JdvОценок пока нет

- Presentation AirДокумент19 страницPresentation AirMohd JamalОценок пока нет

- Lec SimulationДокумент80 страницLec SimulationDr Tajammal MunirОценок пока нет

- Advanced Process Control Delivers Significant Economic Savings for Alumina PlantsДокумент6 страницAdvanced Process Control Delivers Significant Economic Savings for Alumina PlantscbqucbquОценок пока нет

- APC Boosts Polypropylene OperationДокумент6 страницAPC Boosts Polypropylene OperationJuan AlejandroОценок пока нет

- Modeling and Simulation of Steam CrackersДокумент6 страницModeling and Simulation of Steam CrackersFathan FathullahОценок пока нет

- Tutorial 12 ASPEN PLUS Sensitivity Analysis and Transport PropertiesДокумент14 страницTutorial 12 ASPEN PLUS Sensitivity Analysis and Transport PropertiesramsrivatsanОценок пока нет

- BPCL Supply Chain PDFДокумент33 страницыBPCL Supply Chain PDFNavodyuti DasОценок пока нет

- Real-Time Optimization of AcetaldehydeДокумент10 страницReal-Time Optimization of AcetaldehydeSadiq BashaОценок пока нет

- Recycle Structure of the FlowsheetДокумент53 страницыRecycle Structure of the FlowsheetInnekeОценок пока нет

- AT-07338-BRO-Aspen GDOT brochure-OLEFINS-2021-1112Документ7 страницAT-07338-BRO-Aspen GDOT brochure-OLEFINS-2021-1112Zeeshan AlamОценок пока нет

- Seperation Model EquationДокумент130 страницSeperation Model EquationHans WurstОценок пока нет

- Jay H Lee - MPC Lecture NotesДокумент137 страницJay H Lee - MPC Lecture NotesVnomiksОценок пока нет

- CHE 4170 Design Project HYSYSДокумент16 страницCHE 4170 Design Project HYSYSPhan NeeОценок пока нет

- Sematech APCДокумент20 страницSematech APCMark YamayoshiОценок пока нет

- Unisim Operations PIN R400Документ4 страницыUnisim Operations PIN R400asamad54Оценок пока нет

- Chemengmagaugust 2014Документ76 страницChemengmagaugust 2014makwana1Оценок пока нет

- 12 ConceptualDesignDistillationColumnsДокумент26 страниц12 ConceptualDesignDistillationColumnscryovikasОценок пока нет

- Dynamics Split 1Документ100 страницDynamics Split 1chantran90Оценок пока нет

- Reactions and Separations Simulations: 3 Key IssuesДокумент7 страницReactions and Separations Simulations: 3 Key Issuesken910076100% (1)

- (Petrochemicals Industries) Lecture 2 and 3Документ82 страницы(Petrochemicals Industries) Lecture 2 and 3Abdelhai YehiaОценок пока нет

- Polyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Документ8 страницPolyethylene Terephthalate (PET) : A Comprehensive Review: What Is PET Plastic?Ahmad Shah 8999Оценок пока нет

- Dynamic Analysis of Cyclohexane Production With Aspen HYSYS® V8.0Документ0 страницDynamic Analysis of Cyclohexane Production With Aspen HYSYS® V8.0udokasОценок пока нет

- Advanced Process Control Quick and Easy Energy SavingДокумент3 страницыAdvanced Process Control Quick and Easy Energy SavingRobert MontoyaОценок пока нет

- UAE University College of Engineering Training and Graduation Project UnitДокумент100 страницUAE University College of Engineering Training and Graduation Project UnitPortia ShilengeОценок пока нет

- Aspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACДокумент13 страницAspen Plus Tutorial 5 Preparing and Configuring A Distillation Column Using RADFRACRavi Kant TripathiОценок пока нет

- Repsol - Use of Simulation For HDS UnitДокумент16 страницRepsol - Use of Simulation For HDS UnitHoracio RodriguezОценок пока нет

- AspenHYSYSDynModeling2006 RefДокумент226 страницAspenHYSYSDynModeling2006 RefIndra Kurniawan WijayaОценок пока нет

- Aspen Utilities - Refinery EngineersДокумент72 страницыAspen Utilities - Refinery EngineersUrcan GeorgianaОценок пока нет

- Pinch Analysis of Heat Exchanger Networks in The Crude Distillation Unit of Port-Harcourt RefineryДокумент10 страницPinch Analysis of Heat Exchanger Networks in The Crude Distillation Unit of Port-Harcourt RefineryAdriana WagnerОценок пока нет

- Managing APC Software With VirtualДокумент35 страницManaging APC Software With VirtualJuan AlejandroОценок пока нет

- Lecture 1 - Intro To Process SimulationДокумент48 страницLecture 1 - Intro To Process SimulationSJ ChuaОценок пока нет

- Profit Controller RMPCT OverviewДокумент4 страницыProfit Controller RMPCT OverviewEnrique Cerna VillalobosОценок пока нет

- Simulating visbreaker columnДокумент11 страницSimulating visbreaker columnkataria200784Оценок пока нет

- Process Engineering Services: Feasibility Studies and Conceptual DesignДокумент18 страницProcess Engineering Services: Feasibility Studies and Conceptual DesignDuy TùngОценок пока нет

- Chemical Bandwidth ReportДокумент40 страницChemical Bandwidth ReportterumistarОценок пока нет

- KBCДокумент15 страницKBCMauricio Huerta JaraОценок пока нет

- DMC PlusДокумент156 страницDMC Plusedo7474Оценок пока нет

- AspenProcessEconAnalyzerV9 0 UsrДокумент506 страницAspenProcessEconAnalyzerV9 0 UsrivanОценок пока нет

- Hydrocarbon Bio-Jet Fuel From Bioconversion of Poplar Biomass. Techno-Economic Assessment PDFДокумент16 страницHydrocarbon Bio-Jet Fuel From Bioconversion of Poplar Biomass. Techno-Economic Assessment PDFatsomech132206Оценок пока нет

- Biomass Pyrolysis: Comments On Some Sources of Confusions in The Definitions of Temperatures and Heating RatesДокумент13 страницBiomass Pyrolysis: Comments On Some Sources of Confusions in The Definitions of Temperatures and Heating Ratesatsomech132206Оценок пока нет

- Hydrodeoxygenation of Phenolic Model Compounds Over Mos Catalysts With Different StructuresДокумент7 страницHydrodeoxygenation of Phenolic Model Compounds Over Mos Catalysts With Different Structuresatsomech132206Оценок пока нет

- Development of A Condenser For Marine Florae Pyrolysis ReactorДокумент156 страницDevelopment of A Condenser For Marine Florae Pyrolysis ReactorRichard Jess Chan100% (2)

- Desimo GravatasДокумент9 страницDesimo GravatasΚωνσταντίνος ΑποστολόπουλοςОценок пока нет

- Aspen Plus IGCC ModelДокумент19 страницAspen Plus IGCC ModelSampath AttuluriОценок пока нет

- Status Review On Membrane Systems For Hydrogen SeparationДокумент29 страницStatus Review On Membrane Systems For Hydrogen SeparationZoran_Velinov100% (1)

- DVC6200Документ4 страницыDVC6200Jesus BolivarОценок пока нет

- Power Generation SystemДокумент72 страницыPower Generation SystemAbshir Mohamed HajjiОценок пока нет

- RECYCLED ASPHALTДокумент27 страницRECYCLED ASPHALTwillypraviantoОценок пока нет

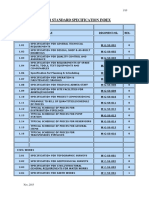

- Water Standard Specification Index As On Dec 2015Документ10 страницWater Standard Specification Index As On Dec 2015afp15060% (1)

- TriPac EVOLUTION 55711-19-OPДокумент52 страницыTriPac EVOLUTION 55711-19-OPRodrigo Hernandez100% (1)

- Solar Refrigerator SpecsДокумент4 страницыSolar Refrigerator SpecsFaisal Bin FaheemОценок пока нет

- Optical Properties of MaterialДокумент63 страницыOptical Properties of MaterialNoviОценок пока нет

- TMX53DC 1607 121 (Drawings Electric)Документ13 страницTMX53DC 1607 121 (Drawings Electric)ChristianОценок пока нет

- APC Back-Ups 350Документ2 страницыAPC Back-Ups 350Justin EndacottОценок пока нет

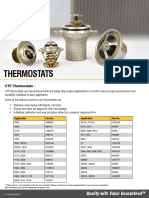

- TERMOSTATOSДокумент1 страницаTERMOSTATOSSERGIOEDWARDOОценок пока нет

- Site Effect Evaluation Using Spectral Ratios With Only One StationДокумент15 страницSite Effect Evaluation Using Spectral Ratios With Only One StationJavier MtОценок пока нет

- Chilled Water Pipe Insulation Method StatementДокумент2 страницыChilled Water Pipe Insulation Method StatementGündoğdu Akın75% (4)

- 1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshДокумент65 страниц1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshbenonОценок пока нет

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Документ5 страницCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723Оценок пока нет

- V. Ganapathy On Calculation of Flue Gas DensityДокумент2 страницыV. Ganapathy On Calculation of Flue Gas DensityRi KoОценок пока нет

- LT AB Cable GTPsДокумент3 страницыLT AB Cable GTPsnishant sainiОценок пока нет

- Syllabus of Diploma in Electrical EngineeringДокумент17 страницSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- United States Patent (10) Patent No.: US 8,106,570 B2Документ20 страницUnited States Patent (10) Patent No.: US 8,106,570 B2zahra sdeghiniaОценок пока нет

- Ceiling Mounted Chilled Water UnitДокумент2 страницыCeiling Mounted Chilled Water UnitPrinces Katherine VergaraОценок пока нет

- 2007 Bachu Etal CO2 Storage Capacity EstimationДокумент14 страниц2007 Bachu Etal CO2 Storage Capacity EstimationArindam Obzi GuptaОценок пока нет

- Type 316 Stainless Steel Properties & ApplicationsДокумент3 страницыType 316 Stainless Steel Properties & Applicationsh4josephОценок пока нет

- 947 SampleДокумент6 страниц947 SamplesarveshkdahiyaОценок пока нет

- GD 511a-1 Parts ManualДокумент275 страницGD 511a-1 Parts ManualMachinery Club100% (4)

- SGMF Hose BunkeringДокумент15 страницSGMF Hose BunkeringFilipОценок пока нет

- Furnace Incident During DecokingДокумент9 страницFurnace Incident During DecokingMohamed Sayed AbdoОценок пока нет

- Cwi QuestionsДокумент6 страницCwi QuestionsGokul Thangam75% (4)

- Production Range: EUROPIPE. The World Trusts UsДокумент8 страницProduction Range: EUROPIPE. The World Trusts UsIslam-Lotfi Hadj-ArabОценок пока нет

- O359h MilДокумент90 страницO359h MilNisar AhmedОценок пока нет

- 937 Letter AttchamentДокумент8 страниц937 Letter AttchamentNeeta RautelaОценок пока нет

- New Tutorial 2 Solution On ThermodynamicsДокумент7 страницNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadОценок пока нет

- Sully: The Untold Story Behind the Miracle on the HudsonОт EverandSully: The Untold Story Behind the Miracle on the HudsonРейтинг: 4 из 5 звезд4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldОт EverandThe Fabric of Civilization: How Textiles Made the WorldРейтинг: 4.5 из 5 звезд4.5/5 (57)

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1395)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОт EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОценок пока нет

- The Weather Machine: A Journey Inside the ForecastОт EverandThe Weather Machine: A Journey Inside the ForecastРейтинг: 3.5 из 5 звезд3.5/5 (31)

- Hero Found: The Greatest POW Escape of the Vietnam WarОт EverandHero Found: The Greatest POW Escape of the Vietnam WarРейтинг: 4 из 5 звезд4/5 (19)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestОт EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestРейтинг: 4 из 5 звезд4/5 (28)

- The End of Craving: Recovering the Lost Wisdom of Eating WellОт EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellРейтинг: 4.5 из 5 звезд4.5/5 (80)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980От Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Рейтинг: 4 из 5 звезд4/5 (21)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (241)

- The Future of Geography: How the Competition in Space Will Change Our WorldОт EverandThe Future of Geography: How the Competition in Space Will Change Our WorldРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureОт EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureРейтинг: 5 из 5 звезд5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceОт EverandPale Blue Dot: A Vision of the Human Future in SpaceРейтинг: 4.5 из 5 звезд4.5/5 (586)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsОт EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsОценок пока нет

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseОт EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseРейтинг: 3.5 из 5 звезд3.5/5 (12)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesОт EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesОценок пока нет

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (50)

- Reality+: Virtual Worlds and the Problems of PhilosophyОт EverandReality+: Virtual Worlds and the Problems of PhilosophyРейтинг: 4 из 5 звезд4/5 (24)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationОт EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationРейтинг: 4.5 из 5 звезд4.5/5 (46)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterОт EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterРейтинг: 5 из 5 звезд5/5 (3)

- Fallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldОт EverandFallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldРейтинг: 4.5 из 5 звезд4.5/5 (82)

- The Path Between the Seas: The Creation of the Panama Canal, 1870-1914От EverandThe Path Between the Seas: The Creation of the Panama Canal, 1870-1914Рейтинг: 4.5 из 5 звезд4.5/5 (124)