Академический Документы

Профессиональный Документы

Культура Документы

Conservanti - Artic Vechi

Загружено:

Violeta GrigorasАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Conservanti - Artic Vechi

Загружено:

Violeta GrigorasАвторское право:

Доступные форматы

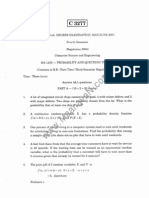

J. Soc.Cosmet. Chem.

23 703-720(1972)

1972 Society of Cosmetic Chemists of GreatBritain

Preservatives for pharmaceuticals

H. S. BEAN*

Presentedon 29th September1971 in London, at the Symposiumon 'Microbial control', organized by the Pharmaceutical Society of Great Britain and the Societyof CosmeticChemists of Great Britain.

Synopsis--Examinationof the literature strongly indicates that PRESERVATIVE activity should be biocidal rather than biostatic and underlines the necessityof establishingSTANDARDS for preservative activity, such standardsto include requirementsfor the rate of kill or time to sterilizespecified standardinfectionsin a productand a specification for the capacity of the preservative to deal with successive infectionsof the product. The chemical availability of a preservativein a product may alter during STORAGE as a result of absorptionby the package,in-useinfection,or changein storagetemperatureand the microbiological significance of the lossmay be estimatedfrom a knowledgeof the concentration exponentand/or temperaturecoefficient of the preservative. The preservativeactivity of a substance may be markedly influencedby product environment, the more complexthe product the greaterthe number of factorsinfluencingthe activity with the resultthat the preservative activity of a simpleAQUEOUS SOLUTION can usually be stated with greater confidence than that of an EMULSION. Nevertheless, with the aid of mathematicalmodels and a knowledgeof the appropriate parametersit is often possibleto predict the activity of a fluid containingSURFACE ACTIVE AGENTS or an emulsified preparationwith acceptable accuracy.

For severaldecades pharmacists have been aware of the need to protecttheir products against microbialcontamination but it is onlyduring the last one or perhaps two decades that serious thoughthasbeenapplied to the science of preservation. A searchthroughpharmaceutical compendia and texts revealsvery few 'traditional'preservatives includingethyl alcoholat a concentration of not lessthan 20o, chloroformat 0.25o, sucrose at 67o and benzoic acid at 0.1o. That they are still usedis testimony to their effectiveness but

*Department of Pharmacy,Chelsea Collegeof Science and Technology,London, S.W.3.

703

704

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

severe limitationsin their applicabilityrestricttheir use in modernproducts.Alcohol was traditionallythe preservative of tincturesand other galenicals the useof whichhasrapidly declined. Chloroformhasbeenused both as a flavouring agentand preservative in extemporaneously prepared oral preparations with shortstorage life. It is volatileand readilylost from suchpreparations and is now losingfavour because of possible toxicity. Syrups are still in vogue but temperaturecycling during storagecan producea surfacelayer deficientin sucrose and deficientin antimicrobial activity. Indeed, recommendations to includepreservatives in syrups(1) focusattentionon possible failures in the useof syrupasa preservative. The physico-chemical properties of benzoicacid placesevere restriction on its use. It has only moderate water-solubility(ca 0.28) but high lipid solubility,for effectiveness must be employed at about half-saturation concentration which, as will be shown later, detracts from its usefulness and

hasa pKa of 4.2 whichreallyrestricts its employment to acidicpreparations. Several reports (2-5) have indicated the widespreadnature of contamination in pharmaceuticals and stressed the necessity of controllingit Unfortunately,exceptfor sterileproductswhich are outsidethe purviewof this survey, there are no universallyrecognizedstandardsof what constitutes an acceptable numberof micro-organisms in a product,theeffectiveness of a preservation or evenmethods of determining preservative activity. Let it be first established that the writer stronglysupports the hypothesis that preservationmust never be a substitutefor good manufacturing practice which can lead to a substantiallyreduced number of microorganisms in a productat completionof manufacture.It is rather a safeguard either to destroyor inhibit the growth of those organisms which cannotbe eliminatedby goodmanufacturing practiceor which gain access to the product during use. Hitherto, the effectiveness of preservation has usuallybeen assessed by a so-called challenge test.Theseinvolveinoculatinga productwith known organisms andincubating perhaps for manymonths. The prolonged storage or incubation is a confession of the recognition of the possibility of failure of the preservative effectively to fulfil its role and a number of containers are put on storage in an attemptto quantifythe probabilityof failure.The testis really a measure of the ability of contaminating organisms to destroy the product.I submitthat more desirable would be a performance test--a measure of the ability of the productto destroy invading organisms. Such a test wouldbe more positive, more rapidly performed and possibly more easilydefinable by regulatorybodies.

PRESERVATIVESFOR PHARMACEUTICALS

705

REQUIREMENTSOF PRESERVATIVES

'What constitutessatisfactory preservation?' is a question that has been askedby many and indeedwas the subjectof a paper presented in 1958(6). The inclusionin a productof a bacteriostatic concentration of a preservative has often beenregarded as adequate and many examples can be found of recommended concentrations of preservatives beingat the level indicated in testsfor minimum inhibitory concentrations. One does not

have to seek far for the reason. It is that because the fundamental meta-

bolismof all cellsis essentially similar,a compound which shows marked toxicityto microbialcellsis likely to showat leastsometoxicityto human cells,depending upon the mode of application.This philosophy, though understandable, doesnot necessarily make for adequatepreservation. As far as the preservation of ophthalmicsolutions is concerned a very definite shift in attitude is detectable. Crompton (7) originally suggested that ophthalmicsolutions shouldincorporate a bacteriostatic and indeed reconunended 0.005o chlorhexidine which is certainlybacteriostatic rather than bactericidal (7). He later declared(8) that relianceon bacteriostatics can be hazardous and maintainedthat ophthalmicsolutions shouldcontain a quickly acting bactericide,and Williams and Boehm (9) criticizedthe Solutionfor Eye Drops (B.P.C. 1959) on the groundsthat it was not bactericidal. Perhaps the most categorical statement is due to Kohn, Gershenfeld and Barr (10) who believethat any substance having a sterilizing time greaterthan 1 h is too slow-acting for use as a preservative in ophthalmicsolutions.I am happy to observe that the preservatives currently recommended by the British Pharmaceutical Codex for eye drops appearin most situations to meet this requirement and furthermore they do so without there having been criticisms of their use on the groundsof toxicity or irritancy. There are, however,exceptions to this generalstatement. For example,Ridley (11) found 0.0045/0 phenylmercuric nitrate to be necessary in eye drops to ensurefreedomfrom contamination;a concentration four times that recommendedby the Codex.

There is nothing like the weight of authoritativeadvicefor products other than ophthalmicsolutions but it is instructive to consider what are regardedas adequatepreservatives by several pharmacopoeias (Table I). Of thepreservatives shown thereis agreement onlyon therecommended concentration for phenol.In the caseof cresolthe specified concentrations rangefrom 0.30 to 0.50o and since the concentration exponent for cresol is about six the activity of the more concentrated solutionis about (1.66)6

706

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

Table I

Some preservatives recommended by pharmacopoeias

Pharmacopoeia

French Pharm.

Preservative

B.P.

Codex

U.S.P.

Helv.

Phenol Cresol Chlorocresol Organomercurial Methylparaben

0.5 0.3 % 0.1 o 0.001% --

0.5 o 0.3 % 0.3 % ---

0.5 0.5 % -0.1% --

-0.3 o 0.2 % -O.1%

or 20 timesthat of the weaker. For chlorocresol, the concentration rangeis 0.1-0.3 and the most concentratedwill have an activity about 30 or 725 timesthat of the weakest.What is clear is that pharmacopoeias reflect the uncertainty of precisely what constitutes an adequate preservative. If the activities of the variouspreservatives recommended by any single

pharmacopoeia is examined an equallywidevariationis obvious (TableIi), thoseof the British Pharmacopoeia rangingfrom about 10 min to 10 h.

Table II

The activities of preservatives recommendedby the British Pharmacopoeia

Time to kill

Preservative

Chlorocresol Cresol

%w/v

0.1 0.3

10a ml-1

E. coli 10 min 30 min

Phenylmercuric NO a

Phenol

0.001

0.5

2 h*

10 h

*Using thioglycolate recovery medium.

The only point common to all pharmacopoeias and all preservatives recommended by them is that they are bactericidalrather than bacteriostaticand evenmarkedlybactericidal with the possible exception of 0.1o methylparahydroxybenzoate. It is interesting to note that a workingparty report (12) recentlypublished by the Societyof CosmeticChemists of Great Britain recommends that cosmetic productsshouldbe selfsterilizing. It is my belief that the most satisfactory requirement to date is that of the U.S.P. XVIII (13) which requires that a satisfactorilypreserved ophthalmicsolutionwill reducethe viable count of any contamination to 0.1}/oof the originaland not permit any subsequent multiplication of the survivorsduring a 7 day period of the 28 day test period. The latter clause is all important.Dr Waltersand I (14) found,aslong ag a 1)55,

PRESERVATIVES

FOR

PHARMACEUTICALS

707

that the last survivorsin any initially bactericidalsolutionmay multiply, utilizing as nutrient the purinesand pyrimidinesreleasedby dead and/or dying cells. Severalreports of similar observations have sincebeen published(15-17) showing that the multiplication is not peculiarto the useof any one preservative and suggesting that it may occurgenerally with preservativeshaving high intrinsic activity and therefore used in low concentration.The phenomenon has, to my knowledge,neverbeenassociated with preservatives used at concentrations of 0.lo or higher, unlessthe productprovidedconsiderable nutrient. Although I believe the U.S.P. requirement to be basicallysatisfactory ! would be even happier if the required mortality level was increasedto 100o (admittedlya difficultconditionto demonstrate in practice)and the latter requirementassociated with a maximum time limit--perhaps 3 h because this represents the approximate interval at which glaucoma patients apply their ophthalmic drops. Again, pharmacopoeial preservativeswould often meet this requirementand it thereforerepresents the type of standard whichcouldbe imposed.

ACTIVITY AND CAPACITY OF PRESERVATIVES

Having postulatedpossiblerequirements for preservatives a selection has to be made of a possible compound.A usefulguide seems to be that if a saturatedaqueoussolution of the candidate-compound fails to sterilize an inoculum of about 108 ml- vegetative organismswithin 10 min, it is unlikely to prove suitable. Phenol, cresol, chlorocresolbenzalkonium, chloride and chlorhexidine acetate amongst others would meet this re-

quirement, chloroxylenol, benzylchlorophenol and the parabens wouldnot. The first group have relatively high water solubility and relatively low intrinsic activity. Again, the acceptable compoundsare recognizedby the pharmaceutical compendia, the unacceptable usuallyare not. The concentration of the chosencompoundto producethe required activity is next determined,particular considerationbeing given to the probability of the preservedsolution being able to maintain its activity againsta heavyinfectionor evena succession of infections.The destruction of organismsby preservatives involvesa chemicalor physicalreaction betweenthe micro-organismand the preservativeresultingin a loss of preservative to the cellsfrom the solution,the heavierthe infectionthe greater the loss of preservative from the solution.The more active preservatives are used in lowest concentration and it is these that suffer the

708

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

greatest depletion{,Table III) and greatest lossof activity.Phenylmercuric nitrate0.001}/owill sterilize an inoculumof 10aml- Pseudomonas aeruginosa

in 10 min, 105 ml 4 in 25 min and l0 s ml - in 180 min. Solutions which suffera marked lossof activity as the level of infectionis increased or when they are subjected to a succession of infectionsmay be described aspossess-

ingoor (antimicrobial) capacity and thosewhichsufferlittle lossof activity havegoodcapacityand are obviouslypreferable.

Table III

Lossin activityof preservative solutions after infectionby 109E. coli ml-x

Preservative

Phenol coefficient

Initial concn of

solution

Proportion of preservative

Initial sterilization

time for

Sterilization time of

residual

(Yoo w/v)

Phenol 1 1.0

removed by cells()

0.5

E. coli (rain)

10

solution (rain)

10

m-Cresol Chlorocresol

2 12

0.33 0.08

0.6 2.5

10 10

10 11.5

Benzylchlorophenol

160

0.006

33.0

10

115.0

ABSORPTION OF PRESERVATIVES BY CONTAINERS

Preservatives are also liable to be removed from solutionsthrough absorption by plastics containers or rubberclosures of glass containers. In general, the lesswater-soluble and more lipid-soluble preservatives tend to be more solublein organicphases and are absorbed to a greaterextentby containers and their closures. Thus, phenol is not absorbedto any great extent but chlorocresol may suffer considerable depletionand phenylmercuric nitrate may suffer almost complete removal by rubber caps (Table IV), but because of its low concentration exponent the lossof preservative activity may be lessserious than in the caseof chlorocresol.

Table IV

Loss of preservativethrough absorptioninto rubber caps

Initial Preservative Concentration Loss as Increase

concentration (% w/v)

after absorption (%)

0.39 0.21

percentage of initial concentration

22 30

in time for residual concentration

to sterilize

Phenol Cresol

0.5 0.3

x 4.5 x 8.5

Chlorocresol

0.1

0.04

60

x 250

Phenylmercuric NO a

0.001

0.00005

95

x 42

PRESERVATIVES

FOR

PHARMACEUTICALS

709

As an exampleof absorptionby plastics,Hamdi (18) has shownthat cellulose acetateabsorbs 23 mg g- phenolfrom a 0.1o solution,suggesting a plastics/water partitioncoefficient of about30 and 19 mg g- chlorocresol from a 0.025o solution,indicatinga partition coefficient of about 475. Thesefiguresindicatethat the lossof chlorocresol into a plastics container is more likely seriously to reducethe activity of a preservative than is the lossof phenol.

KINETICS OF PRESERVATIVES

When bacteriaare introducedinto a solutionof preservative the rate at which they die can for practicalpurposes (there are theoreticalobjections) be represented by the first-order reactionequation

-dN dt

- KN

(I)

where N is the number of viable organismsm1-1 at time t and K is the death-rate constant. Integrating the equation between viable number No ml4 at time t =0 and viable number N ml- at time t and convertingto commonlogarithms,equation I becomes

2.303 No

K -

log

N-

and the reaction may be represented by Fig. 1. Any reduction in the

15 -

104

I0

.9

--K

o IC)

t0

20

30

40

50

60

Time ( rain )

iue 1. Typical representation of the death of mim-oganisms

710

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

concentration of the preservative will increase the time needed to reachany

specified mortalityleveland reduce the slopeof the line in Fig. 1. Converselyany increase in concentration will reducethe time and increase the slope.

The practicalworkeris likely to be concerned about the increase in time needed to reachthe 99.9}/0 mortalitylevel specified by U.S.P. XVIII for ophthalmic solutions resulting from a known concentration of preservative being absorbedby the container.This increase in time can be calculated from a knowledge of the concentration exponentof the preservative and

log K- log K. log C- log Ca

or

(C )n K =K-

wheren -- concentration exponentof preservative K = death rate constantat concentrationC

K. = death rate constant at concentration Now, at concentration C

2.303 100

K- t

and at concentration

2.303

1g 0.1

100

K.- t. log0.1

where t -- time to reachspecified mortalitylevelat concentration C t. = time to reachspecified mortality levelat concentration Ca

EquationH indicates that if the concentration of a preservative is plottedagainst the time takento reachsomespecified level of mortality, such as99.9 or even100 or sterility, a straight lineresults with a slope numerically equalto n, theconcentration exponent (Fig.2). Thus,whenthe concentration exponent hasonce beendetermined for a named preservative it can be of greatpracticalvalue and the writer regards it as the most useful parameter of a preservative. Preservatives belonging to a particular chemicalgroup have approximately the sameconcentration exponent,

PRESERVATIVES

FOR

PHARMACEUTICALS

711

Log conch preservahve

Figure 2. The concentration exponentof a preservative.

someexamples beingshownin Table V and Table VI shows the theoretical change in activitywith change in concentration for the preservative groups listed in Table V, and indicatesthat losses of preservatives of the order of 10o may be of no significance and that even lossesof up to 50 of

Table V

Concentrationexponents of somecommonlyusedpreservatives

Preservative n Preservative n

Organomercurials Formaldehyde Quaternaries

0.5 1.0 1.0

Table VI

Chlorhexidine Parabens Phenolics

2.0 2.5 6.0

Relationship betweenconcentrationexponent, changein concentration' and changein activity

Increase in killing time for concentration loss of:

Concentration

exponent

0.5 1.0 2.0 2.5 6.0

50 %

x x x x 1.4 2 4 5.6

40

x x x 1.3 1.66 3.55

20 %

x x x x x 1.11 1.25 1.56 1.75 3.8 x x x

10 %

1.05 1.11 1.23 1.30 1.90

x 2.75 x20.9

x x

x64

712

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

organomercurials and quaternaries may not be of practicalimportancebut 50o lossof a phenoliccanbe very serious. Thus, when considering the loss of preservative from a solution,through no matter what cause,it is not sufficient to statethe weightlost or percentage lost, but it is imperative that this information be linked with the concentrationexponentbecauseit is the lossof activity and not the lossin weightthat is of concern. Preservativeactivity is influenced by temperature, the higher the ambient temperaturethe more active is the preservative. It is usual to relatepreservative temperature to the death-rate constant by the expression

0(50: - 50x ) - K. Ki

where 0 = temperature coefficient of the preservative Kx = death-rateconstantat temperatureTx K,. = death-rateconstantat temperatureT1 and sinceby equation (II)

Kx K2 tz tl

(Ill)

0(50,50) - tx

(IV)

Thus, if the temperaturecoefficient of a preservative is known the change in sterilizationtime may be calculatedfor a stated temperaturechange. Unfortunately, temperaturecoefficients vary accordingto the temperature rangeoverwhichthey are measured and the testorganism (19, 20). For the sakeof an example,a representative 0xfor phenolover the temperature range 10-20 would be 5.0 (0=5-1.175C -) which meansthat at 20 a solutionof phenolwouldkill E. coli five timesas fast as at l0 . It is sometimes usefulto be able to predict the effecton preservative activityof changing both the concentration and the temperature of a preservative.If from equation(II) is abstracted

C1n

re-arrangedas

Clntl = Cs":

and this is combinedwith equation (IV) re-arrangedas

tl = t2 0(50:-501)

PRESERVATIVES

FOR

PHARMACEUTICALS

713

we have Cxtx = C.,,t. 0(v:- Vl)

which is an equationincorporating all the terms necessary to predict the effecton extinctiontime of changing both concentration and temperature. To illustratethe useof the equation,a multipledoseinjectioncontained at the time of manufacture 0.1o chlorocresol whichprovidedan approximate sterilization time for an infection of vegetativecells of 10 min at 25C.After severalmonthsstorageand as a result of absorption by the closure the chlorocresol concentration in the solutionhad fallen to 0.04o. If the container wasstored in a cupboard at 10 the activityof the solution wouldhavefallenas a resultof both the drop in concentration and drop in temperature. A newestimate of the sterilization timewouldbe provided by

Cxntl 0(':-

tz=

---

C2 n

(0.1) x 10 x (0.04)0

= 27 470 min.

Suchan interminabletime may be without real meaningbut it indicates

a change from a solution possessing considerable preservative activityto one virtually devoid of preservative activity--a potentially dangerous

solution.

INFLUENCE OF FORMULATION

The formulationof a productmay substantially modify the chemical and biological availability of an included preservative and thereby modify the activity of the preservative. The major formulationfactorsaffecting activity are pH, complexation with emulgents or dispersing agentsand partitioning of the preservative between the components of an emulsified

product.

Whilst pH is by no meansunimportantas a factor influencing preservative activity, there havebeenvery few systematic and comprehensive studies of the problem and it is very difficultto quantifybecause changes in pH may modify the ionizationof chemical groupings on the bacterial surface, produceionizationof the preservative and influence partitioning of the preservative between the productand the microbialcell and all three factors may interact. In very generalterms there is evidencethat a rise in the pH of solutionof a quaternaryproduces increased uptake of the quaternaryleadingto enhanced antimicrobialactivity (21). On the other

714

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

hand thereis ampleevidence that a risein the pH of a solutionof a phenolic or an organicacid reduces cellularuptakeand activity(22, 23). Much more readily quantifiableis the effectof nonionicsurfactants on the activity of preservatives.Kostenbauder and others (24-26) have assumedthat interaction betweensurfactants and phenolicsor organic acidsinvolves complexation and a reductionin the concentration of 'free' preservative, the latter largely but not necessarily completelycontrolling the activity of the system. The amount of preservative bound to the surfactant is directly related to the concentrationof surfactant,the relationship beingrepresentable by the equation

R = SC+I

whereR = ratio of total/free preservative

C -- constant

$ = surfactant

concentration.

The constantC has a unique value for each surfactant-preservative pair and increases in value as the lipid solubilityof the preservative increases (Fig. 3). R is the factor by which the total concentration of preservative

40-

3o

2O

I0

12

Cetommcrogolconch (% w/v)

Figure 3. The binding of phenolicsto Cetomacrogol(27). A, phenol; B, cresol; C, chlorocresol.

PRESERVATIVES FOR PHARMACEUTICALS

715

must be increasedfor a gven surfactant concentrationto maintain a specified concentration free in the water. Eventhe simplest emulsion contains oil, water and emulgent the latter beingpartially adsorbed at the o/w interfaces but the majority of it being dispersed throughoutthe water phase as emulgentmicelies.A preservative incorporatedin an emulsionis distributedbetweenall three components or phases and the influence of eachof the phases on preservative availabilityand activityis mosteasilyunderstood by considering simplified models.The influenceof the emulgentin the water on preservative availability has alreadybeen considered. If now the oil and water phasesare considered without referenceto the emulgent,the preservativewill be distributedbetweenthe two phases so that

Co

Cw-K?v

whereCo = concentration of preservative in the oil at equilibrium Cw = concentration of preservative in the water at equilibrium Kw = oil/water partition coefficient,a constant at a specified temperature for any oil, water preservative mixture. An enormous rangeof valuesfor oil/waterpartition coefficients is recorded (28, 29) somevaluesfor the parabens beingshownin Table VII and having

Table VII

Oil/water partitioncoefficients for parabens (25)

Partition coefficient

Compound

Liquid paraffin/water

0.02 0.50 3.0

Soya oil/water

7.5

Methyl hydroxybenzoate Propyl hydroxybenzoate Butyl hydroxybenzoate

80.0 280.0

a range of 14 000. The coefficients can be usedin the equationbelow (30) for calculationof the way in which the relationship of the total concentration of paraben in the oil/watermixtureto the concentration in the water depends on the proportionof oil and water (Table VIII).

Cw- c(o

Koo+I

whereC = total concentration of preservative Cw = concentration of preservative in the water

0 = oil' water ratio.

716

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

Table VIII

Influenceof proportionof oil on the concentration of methylparaben in the water of an oil/water mixture

Preservative concentration in water

Total preservative

Oil:

water ratio

concentration Oil phase

in oil/water

Kw

0.11

0.25

0.43

0.66

1.00

mixture

10 20

w/v oil phase

30 40 50

Methyl paraben Liquid paraffin 0.1 (S.G. 0.85) 0.02 Methyl paraben Liquid paraffi 0.2% (S.G. 0.85) 0.02 Methyl paraben 0.2 Soya oil 80.0

0.11

0.22

0.027

0.12

0.24

0.012

0.14

0.24

0.008

0.16

0.24

0.006

0.20

0.24

0.005

In liquid paraffin/water mixtures the concentration of methylparaben

in the water is always higher than the total concentrationin the mixture

and increases as the proportionof oil is increased until water saturation (0.24o w/v) is reached. With vegetable oils the water concentration is so far belowthe total concentration that the aqueous phase is virtuallydevoid

of activity andtheconcentration fallsastheproportion of oil isincreased.

The samegeneralpicture is obtainedwith many preservatives no matter

what the vegetableoil. The inclusionof an emulgent in the system resultsin a redistribution of the preservative betweenthe total aqueousphase and the oil, the con-

centration in the total aqueous now beingcalculated usingthe equation

C. = C(0 +1) K0+I

whereCa = concentration of preservative in the total aqueous phase K = oil/aqueous phasepartitioncoefficient. Becausethe preservative in the water is partly associated with the

emulgent,the concentration free in the water is Cw = c^/J whichcan be shown(31) to be equivalent to

Cw = 00+R)

C(0+l)

(v)

a moregenerally useful expression because Kw ,the trueoil/water partition

PRESERVATIVES FOR PHARMACEUTICALS

717

coefficient, is constantfor any oil/preservative/water mixture, whereasK

falls astheconcentration of emulgent isincreased.

If it is now assumed that the liquid paraffin/watermixturesof Table VIII are emulsified by the inclusionof 5.0o Polysorbate 80 the concentration of methyl parabenfree in the water can now be recalculated (Table IJO usingequation (V) the appropriate valueof R being4.5.

Table IX

Influence of proportion of oil on the concentrationof methylparabenfree in the water of liquid paraffin/wateremulsions emulsifiedwith 5 % Polysorbate 80

Preservative concentration in water Oil:

Total

o

water ratio

0.43 0.66 1.00

preservative

concentration in emulsion

Oil phase

Kw

0.11

0.25

% w/v oil phase

10 20 30 40 50

Methyl paraben Liquid paraffin 0.1% (S.G. 0.85) Methyl paraben Liquid paraffin 0.2 % (S.G. 0.85)

0.02

0.025

0.027

0.032

0.037

0.044

0.02

0.05

0.055

0.063

0.074

0.088

Because in the emulsions the concentrations of methyl parabenin the wateraresofar belowthoserequired for preservation thetotal concentration would have to be increased. If it is accepted that 0.2o is requiredin the water, the total concentrations that would be required in the emulsions containing10, 20, 30, 40 and 50o oil would be 0.81, 0.72, 0.67, 0.54 and 0.47o respectively, which can be shown experimentally to producean activityin the emulsion approximately equivalent to that produced by 0.2o methyl parabenin water. The writer hasendeavoured to showthat oncethe requiredactivity of a preservative in a producthas been established, it can be maintainedin

spite of predictable losses for the solution provided certain basic parameters of the preservative are known. Even in products which are more complex than an aqueoussolutionit is often possible to quantify changes in the chemical availabilityof a preservative with changes in formulationand to modifyeitherthe total concentration of preservative to meetthe availability requirements or substitute anotherpreservative with more satisfactory

718

JOURNAL OF THE SOCIETY OF COSMETIC CHEMISTS

characteristics. That is, provided the parametersof preservatives are adequately quantified it is possible to elevate preservation from a hit-andmissstrategy to a more precise science.

(Received: 15th June 1971)

REFERENCES

(1) Lord, C. F. and Husa, W. J. Antimolding agentsfor syrups.J. Am. Pharm. Assoc.Sci. Ed. 43 438 (1954). (2) Report by the Royal Swedish Medical Board into microbiological contamination of medicalpreparations (1956). (3) Report of Working Party of National Health Service Laboratories, Denmark. Dansk. Tidsskr.Farm. 42 1, 50, 71,125, 257 (1967).

(4) World Health Organization.Microbiologicalcontamination of non-sterile drugs. Working paper WHO/Pharm./69.433 (1969). (5) Dony, J. Condition microbiologiquedu mdicament non sterile. XIX Journespharmaceutiques Franfaises,25 (1969). (6) Sykes, G. The basis for 'sufficientof a suitable bacteriostatic'in injections. J. Pharm. Pharmacol.10 Suppl. 4OT (1958). (7) Crompton,D. O. Ophthalmicprescribing. Austral.J. Pharm. 1020 (1962). (8) Crompton, D. O. Sterility of eye medicaments. Lanceti 41 (1964). (9) Williams, R. and Boehm, E. E. Sterility of eye medicaments. Lancet ii 790 (1963). (10) Kohn, S. R., Gershenfeld, L. and Barr, M. Effectiveness of antibacterialagentspresently employedin ophthalmicpreparationsas preservatives againstPseudomonas aeruginosa. J. Pharm. Sci. 52 967 (1963). (11) Ridley, F. Sterile drops and lotions in ophthalmicpractice.Brit. J. Ophthal.42 641 (1968). (12) Hygienic manufactureand preservation of toiletriesand cosmetics. J. $oc. Cosmet.Chem. 21 719 (1970). (13) U.S. Pharmacopoeia XVIII. p. 845. Antimicrobialagents--effectiveness. (1970)(Bethesda,

Md).

(14) Bean, H. S. and Walters, V. The viability of Escherichia coli in aqueoussolutionsof benzylchlorophenol. J. Pharm. Pharmacol. 7 661 (1955). (15) Brown, M. R. W. and Garrett, E. R. Kinetics and mechanisms of action of antibioticson micro-organisms. J. Pharm. Sci. 53 179 (1964). (16) Garrett,E. R. and Brown,M. R. W. The actionof tetracycline and chloramphenicol alone and in admixtureon the growthof E. coli.J. Pharm. Pharmacol. 15, 185T (1963). (17) Bean, H. S. andFarrell,R. Thepersistence of Pseuabmonas aeruginosa in aqueous solutions of phenols.J. Pharm. Pharmacol.19 Suppl. 183S(1967). (18) Hamdi, F. J. Studies in the interactionof somephenolswith plastics.M.Phil. Thesis, University of London (1968). (19) Tilley, F. W. An experimental studyof the influence of temperature on the bactericidal activities of alcohols and phenols. J. Bacteriol. 43 521 (1942). (20) Cohen,B. Effectof temperature and hydrogen-ion concentration uponviabilityof E. coli and Ebethella typhiin water. J. Bacteriol.7 183 (1922). (21) Salton,M. R. J. The actionof lyticagents on the surface structures of the bacterial cell.

Proceedings of the Second International Congress on Surface Activity274 (1957).(Butter-

worth, London). (22) Lundy, H. W. The effectof saltsupon the germicidal action of phenoland secamyltricresol. J. Bacteriol. 35 633 (1938). (23) Oka, S. Studies on transfer of antiseptics to microbes and their toxiceffect. Bull. Agr. Chem.Soc. Japan24 59 (1960). (24) Patel,N. K. and Kostenbauder, H. B. Interactionof preservatives with macromolecules I. J. Am. Pharm. Assoc.Sci. Ed. 47 289 (1958). (25) Pisano,F. D. and Kostenbauder, H. B. Interactionof preservatives with macromolecules II. J. Am. Pharm. Assoc.Sci. Ed. 48 310 (1959). (26) Miyawaki,G. M., Patel,N. K. and Kostenbauder, H. B. Interaction of preservatives with macromolecules III. J. Am. Pharm. Assoc.$ci. Ed. 48 315 (1959). on the influence of a surface activeagenton the activityof some (27) Sheikh,A. W. Studies

preservatives. Ph.D. Thesis, University of London(1971).

PRESERVATIVES FOR PHARMACEUTICALS

719

(28) Hibbott, H. W. and Monks, J. Preservation of emulsions--p-hydroxybenzoicester partition coefficient. J. $oc. Cosmet.Chem.12 2 (1961). (29) Bean, H. W., Heman-Ackah, S. M. and Thomas, J. The activity of antibacterials in twophasesystems. J. $oc. Cosmet.Chem.16 15 (1965). (30) Bean, H. S. and Heman-Ackah, S. M. Influence of oil: water ratio on the activity of some bactericides against Escherichia cell in liquid paraffin and water dispersions. J. Pharm. Pharmacol.16 Suppl. 58T (1964). (31) Bean, H. S., Kenning, G. H. and Malcolm, S. A. A model for the influence of emulsion formulation on the activity of phenolicpreservatives. J. Pharm. Pharmacol.21 Suppl. 173S(1969).

DISCUSSION

MR. R. J. MCBRIDE: It is good to seeyou advocating 100K mortality level within a fixed time limit as a standardfor a preservative suitablefor usein preservingophthalmic solutions.We believethat the time period of 3 h is too slow, however, especiallyfor multidosesolutionsusedin eye clinics,and we prefer the time of 1 h, suggested by Kohn et al (10). Our own work hasshownthat this 1 h sterilizationtime can be achieved against high inocula of Pseudomonas aeruginosa in preserved fluorescein sodium, pilocarpine hydrochloride, atropine sulphate, physostigmine sulphate, or salicylate and sodium bicarbonateophthalmic solutions.

TE LECTURER: I supposefor ophthalmic solutionsit is a questionof toxicity; I really do not know the optimal time. I would make the point that if you do not get 100o mortality you are liable to have subsequent multiplication.For injectionswe have been obtainingsterilizationtimes < 1 h by incorporating0.1 chlorocresol, and there have been no criticisms. It was only when we had 0.1 chlorocresol which did produce roughly a 10 min kill in ophthalmicsolutions,that the problem of toxicity arose; we now know that this was due to an unfortunate use in ophthalmic surgery. The major problemis one of toxicityrather than producingsterility.

DR. R. M. E. RICHARDS: The useof mixtures of antibacterial agentsfor the preserva-

tion of pharmaceuticals has not often been reported in the literature. Nevertheless mixturesof antibacterialagentsare in frequent usein commercialpreparations.According to Remington(32) they now accountfor almost50o of the preservative systems in commerciallyavailable ophthalmic solutionsproduced in the U.S.A. Remington also predictsthe increaseof the use of mixtures of antibacterialsin extemparaneous compounding. Would you please comment on the parameters to be observed in choosing a mixture of antibacterialsin pharmaceuticalpreservation.

THE LECTURER: AS far as I see, the advantagesare that a mixture broadens the spectrum of micro-organisms whichmay le dealt with and it may increase the capacity of the preservative system.For example,if one usesshall we say, two of the parabens-methylparaben,propylparaben,the probabilityis that with the moreactivecompound (propylparabort) thecell-aqueous phase partitioncoefficient will bein fayourof muchof the propylcompound goinginto the cell,leavingthe system deficient in activity.If one would also include the methyl compoundthis would tend to increasethe capacity. There are great theoreticaldifficulties in handlingthesemixturesof preservatives--if theywork, usethem.I think the reason that solittle hasappeared in the literatureis the (32) Remington, P. J. Pharmaceutical scieaces 14th edn. 1570(1970) (Mack Publishing Co..

Easton, Pennsylvania).

720

JOURNALOF THE SOCIETY OF COSMETIC CHEMISTS

difficultyof predictingpreciselywhat they will do. Garratt and Brown (33) wereable to producea very simplekineticexplanation;if you try to applythat to mostantibacterials it just doesnot work. One can get a long way with mixtureswithin onechemical class. For example,if you are goingto mix phenol and if you like chloroxylenol, and if you know the activities of the separatecompoundsand their concentrationexponents,you can get a long way towardscalculating with reasonable accuracy(q-50o) precisely what the activityof the mixture will be. For mixturesof differentclasses of compounds, for examplephenylethyl alcoholtogetherwith a parabenor similar,heavenonly knows where the mathematics goes.It is not only a questionof mixture of the preservatives; I think Richardsand McBride (34) made this point. If you have two preservatives in an ophthalmicsolutionyou have three components in the system. Now attopine and, I think, pilocarpine will tendto enhance theactivityof manyof these preservatives whereas

fluorescein will actimtroposite direction. Until we havemuchmoreknowledge it is

thus very difficult to predicf Wrhat theactivity ofa product willbe. MR.G. Scs: I wonder w}iIher Remington (32) means a real 505/0 in theterms of

mixtures inwhich we think oft::! .,. orwhether alarge proportion ofthat 505/0 isnot

groupsof homologues of the paralSL,hich can be calledmixtures. DR. R. M. E. RicH^v,r>s: The 505/0do not includethe parabens--theseare all kinds of combinations of antibacterials probably with differentmodesof actionand sometimes

used at quite strangeconcentrations.

TH Lc'ruv,v,: Many insulinscontain a mixture of preservatives and, I think, this mixtureis not alwaysthere for preservative reasons alone, e.g. theremay be analgesic

reasons.

(33) Garrett, E. R. and Brown,M. R. W. The actionof tetracydine and chloranphenicol alone and in admixtureon the growthof E. cell. J. Pharm. Pharmaol. 15 185T (1963). (34) Richards,R. M. E. and McBride,R. J. The preservation of ophthalmic solutions with antibacterial combinations. J. Pharm.Pharrnaol. 23 Suppl.235S(1971).

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- AFM13 Preface Solutions ManualДокумент5 страницAFM13 Preface Solutions ManualArshad33% (3)

- John Deere 772d 6wd GraderДокумент6 страницJohn Deere 772d 6wd GraderyaserattiaОценок пока нет

- Section 1 Atoms, Molecules and StoichiometryДокумент27 страницSection 1 Atoms, Molecules and Stoichiometryapi-3734333100% (2)

- Homework Lesson 6-10Документ9 страницHomework Lesson 6-10Valerie YenshawОценок пока нет

- Manual LDM5 U enДокумент3 страницыManual LDM5 U enLuizAugustoMedeirosОценок пока нет

- IyerpptДокумент35 страницIyerpptVioleta Grigoras100% (1)

- Principles and Practice of Cleaning in PlaceДокумент41 страницаPrinciples and Practice of Cleaning in PlaceVioleta GrigorasОценок пока нет

- Method for preparing anhydrous iron chloridesДокумент4 страницыMethod for preparing anhydrous iron chloridesVioleta GrigorasОценок пока нет

- The Determination of Caffeine by High PerformanceДокумент3 страницыThe Determination of Caffeine by High PerformanceVioleta GrigorasОценок пока нет

- Quality - Manual Conwin CorporationДокумент75 страницQuality - Manual Conwin CorporationJohnОценок пока нет

- Caffeine HPLC EssayДокумент5 страницCaffeine HPLC EssayIvan TaufikОценок пока нет

- Aspirin Resistance in Cardiovascular Disease A ReviewДокумент10 страницAspirin Resistance in Cardiovascular Disease A ReviewVioleta GrigorasОценок пока нет

- 25 Pi 006 3 Recommendation On Validation Master PlanДокумент29 страниц25 Pi 006 3 Recommendation On Validation Master PlancarbouОценок пока нет

- Aspirin Esterase Activity - Evidence For Skewed Distribution inДокумент5 страницAspirin Esterase Activity - Evidence For Skewed Distribution inVioleta GrigorasОценок пока нет

- Aspirin Resistance in Cardiovascular Disease A ReviewДокумент10 страницAspirin Resistance in Cardiovascular Disease A ReviewVioleta GrigorasОценок пока нет

- S Determination of Caffeine in BeveragesДокумент5 страницS Determination of Caffeine in BeveragesVioleta Grigoras100% (1)

- Asymmetric SynthesisДокумент89 страницAsymmetric SynthesisVioleta GrigorasОценок пока нет

- HPLC Analysis Determines Caffeine Levels in SodaДокумент5 страницHPLC Analysis Determines Caffeine Levels in SodaVioleta GrigorasОценок пока нет

- The Determination of Caffeine by High PerformanceДокумент3 страницыThe Determination of Caffeine by High PerformanceVioleta GrigorasОценок пока нет

- Conservanti WC500003388Документ10 страницConservanti WC500003388Violeta GrigorasОценок пока нет

- Efficacy of antimicrobial preservationДокумент2 страницыEfficacy of antimicrobial preservationVioleta GrigorasОценок пока нет

- Conservanti WC500003388Документ10 страницConservanti WC500003388Violeta GrigorasОценок пока нет

- Packaging of Pharmaceutical ProductsДокумент91 страницаPackaging of Pharmaceutical ProductsclaireОценок пока нет

- DSR Final 4-18 (JOG ES HBS W Track Changes) - FinalДокумент20 страницDSR Final 4-18 (JOG ES HBS W Track Changes) - FinalVioleta GrigorasОценок пока нет

- Science and Research ReportДокумент8 страницScience and Research ReportVioleta GrigorasОценок пока нет

- Smart Drugs For Cognitive Enhancement: Ethical and Pragmatic Considerations in The Era of Cosmetic NeurologyДокумент6 страницSmart Drugs For Cognitive Enhancement: Ethical and Pragmatic Considerations in The Era of Cosmetic Neurologyt_barronОценок пока нет

- Chemical Engineering & Technology Volume 24 Issue 2 2001 [Doi 10.1002%2F1521-4125%28200102%2924%3A2-173%3A%3Aaid-Ceat173-3.0.Co%3B2-g] a. M. Dehkordi; T. Kaghazchi; M. Sohrabi -- Application of an Air-Operated ImpingiДокумент7 страницChemical Engineering & Technology Volume 24 Issue 2 2001 [Doi 10.1002%2F1521-4125%28200102%2924%3A2-173%3A%3Aaid-Ceat173-3.0.Co%3B2-g] a. M. Dehkordi; T. Kaghazchi; M. Sohrabi -- Application of an Air-Operated ImpingiVioleta GrigorasОценок пока нет

- 03 030708e Caffeine AnhydrousДокумент12 страниц03 030708e Caffeine AnhydrousVioleta GrigorasОценок пока нет

- Chemical Engineering & Technology Volume 24 Issue 5 2001 [Doi 10.1002%2F1521-4125%28200105%2924%3A5-470%3A%3Aaid-Ceat470-3.0.Co%3B2-4] W. Mickler -- Separation of Heavy Metals From Landfill Leachate by Reactive LiquidДокумент6 страницChemical Engineering & Technology Volume 24 Issue 5 2001 [Doi 10.1002%2F1521-4125%28200105%2924%3A5-470%3A%3Aaid-Ceat470-3.0.Co%3B2-4] W. Mickler -- Separation of Heavy Metals From Landfill Leachate by Reactive LiquidVioleta GrigorasОценок пока нет

- Cosmetic Microbiology FinalДокумент18 страницCosmetic Microbiology FinalZara KhanОценок пока нет

- Cosmetics Legisl Metd For AnalДокумент200 страницCosmetics Legisl Metd For AnalVioleta Grigoras100% (1)

- Chemical Engineering & Technology Volume 24 Issue 5 2001 [Doi 10.1002%2F1521-4125%28200105%2924%3A5-470%3A%3Aaid-Ceat470-3.0.Co%3B2-4] W. Mickler -- Separation of Heavy Metals From Landfill Leachate by Reactive LiquidДокумент6 страницChemical Engineering & Technology Volume 24 Issue 5 2001 [Doi 10.1002%2F1521-4125%28200105%2924%3A5-470%3A%3Aaid-Ceat470-3.0.Co%3B2-4] W. Mickler -- Separation of Heavy Metals From Landfill Leachate by Reactive LiquidVioleta GrigorasОценок пока нет

- R.A. Heacock - The Chemistry of Adrenochrome and Related CompoundsДокумент57 страницR.A. Heacock - The Chemistry of Adrenochrome and Related CompoundsGummyCola100% (1)

- On-Line Pretreatment and Determination of Parabens in CosmeticДокумент7 страницOn-Line Pretreatment and Determination of Parabens in CosmeticVioleta GrigorasОценок пока нет

- Ultra-Low-Power Wireless Systems - Energy-Efficient Radios For The Internet of Things PDFДокумент11 страницUltra-Low-Power Wireless Systems - Energy-Efficient Radios For The Internet of Things PDFnhatvpОценок пока нет

- WWW Mathworks inДокумент7 страницWWW Mathworks inRagini SharmaОценок пока нет

- Vesda Arrange Fire Alarm SystemДокумент1 страницаVesda Arrange Fire Alarm SystemGaurav Kumar SharmaОценок пока нет

- Tomescu PDFДокумент353 страницыTomescu PDFLuís Farias100% (3)

- Modern Scoring BRASS Manual1Документ25 страницModern Scoring BRASS Manual1Pepe ChorrasОценок пока нет

- EL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENДокумент4 страницыEL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENfederico4thОценок пока нет

- Carbolite CWF1313 004 - 3216Документ44 страницыCarbolite CWF1313 004 - 3216dev-nullОценок пока нет

- ACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinДокумент658 страницACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinluizamgoОценок пока нет

- AAL1 and Segmentation and Reassembly LayerДокумент18 страницAAL1 and Segmentation and Reassembly Layeroureducation.inОценок пока нет

- Area Under The CurveДокумент3 страницыArea Under The CurveReyland DumlaoОценок пока нет

- Transformer X - R CalculationДокумент2 страницыTransformer X - R CalculationTharindu WimalasekaraОценок пока нет

- Liquefaction AnalysisДокумент16 страницLiquefaction AnalysisKristi Engineering Services Pvt. Ltd.Оценок пока нет

- Smart AntennasДокумент40 страницSmart AntennasMeeraОценок пока нет

- Application of Nitrous Oxide in AutomobilesДокумент26 страницApplication of Nitrous Oxide in AutomobilesMohammed NuhmanОценок пока нет

- Caractéristique Dell Latitude E7250Документ3 страницыCaractéristique Dell Latitude E7250Milandou Ahmed TresorОценок пока нет

- Problems On Heat Transfer ConductionДокумент3 страницыProblems On Heat Transfer ConductionGenerale, Rey marck C.Оценок пока нет

- Technical manual for Felt Compulsion mountain bike suspension systemДокумент15 страницTechnical manual for Felt Compulsion mountain bike suspension systemDiogo SilvaОценок пока нет

- PQT MJ07Документ6 страницPQT MJ07Raguraman BalajiОценок пока нет

- HW 11Документ7 страницHW 11Devendraa MuniandyОценок пока нет

- Understand The Standardization Protocol For Iot Understand The Concepts of Web of Things. Understand The Concepts of Cloud of Things With Understand The Basic Concepts of Aspect OrientedДокумент2 страницыUnderstand The Standardization Protocol For Iot Understand The Concepts of Web of Things. Understand The Concepts of Cloud of Things With Understand The Basic Concepts of Aspect OrientedShanthi GanesanОценок пока нет

- IgE Level Effect of Phyllanthus Acidus Leaf ExtractДокумент5 страницIgE Level Effect of Phyllanthus Acidus Leaf Extractkhatami muhammadОценок пока нет

- Process Bus and Sampled Values Based ApplicationsДокумент49 страницProcess Bus and Sampled Values Based ApplicationsMarco TrovóОценок пока нет

- Mech Vi Non Traditional Machining (10me665) NotesДокумент45 страницMech Vi Non Traditional Machining (10me665) Notesnikhil0% (1)

- Maa 2.8 ExponentsДокумент12 страницMaa 2.8 ExponentsMuborakОценок пока нет

![Chemical Engineering & Technology Volume 24 Issue 2 2001 [Doi 10.1002%2F1521-4125%28200102%2924%3A2-173%3A%3Aaid-Ceat173-3.0.Co%3B2-g] a. M. Dehkordi; T. Kaghazchi; M. Sohrabi -- Application of an Air-Operated Impingi](https://imgv2-1-f.scribdassets.com/img/document/212315304/149x198/a6a28e660e/1394741544?v=1)

![Chemical Engineering & Technology Volume 24 Issue 5 2001 [Doi 10.1002%2F1521-4125%28200105%2924%3A5-470%3A%3Aaid-Ceat470-3.0.Co%3B2-4] W. Mickler -- Separation of Heavy Metals From Landfill Leachate by Reactive Liquid](https://imgv2-2-f.scribdassets.com/img/document/212315079/149x198/1102ed5286/1394741540?v=1)