Академический Документы

Профессиональный Документы

Культура Документы

Booster Vapor-Compression Refrigerating Systems

Загружено:

Luis CarlosАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Booster Vapor-Compression Refrigerating Systems

Загружено:

Luis CarlosАвторское право:

Доступные форматы

Purdue University

Purdue e-Pubs

International Refrigeration and Air Conditioning

Conference

School of Mechanical Engineering

2010

Booster Vapor-Compression Refrigerating

Systems

Dmytro Buyadgie

Wilson Ltd

Vitaliy Sechenyh

Wilson Ltd

Sergii Nichenko

Wilson Ltd

This document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact epubs@purdue.edu for

additional information.

Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at https://engineering.purdue.edu/

Herrick/Events/orderlit.html

Buyadgie, Dmytro; Sechenyh, Vitaliy; and Nichenko, Sergii, "Booster Vapor-Compression Refrigerating Systems" (2010).

International Refrigeration and Air Conditioning Conference. Paper 1062.

http://docs.lib.purdue.edu/iracc/1062

, Page 1

International ReIrigeration and Air Conditioning ConIerence at Purdue, July 12-15, 2010

Booster Vapor-Compression Refrigerating Systems

Dmytro BUYADGIE

1

, Vitaliy SECHENYH

*1,2

, Sergii NICHENKO

1,2

1

Wilson Ltd,

Odessa, Ukraine

tel.: 380 48 7343010, Iax: 380 48 7342010,

e-mail: oIIicewilson-ukraine.com

2

Odessa State Academy oI ReIrigeration,

Odessa, Ukraine

tel.: 380 48 7232220, Iax: 380 48 7231145

e-mail: adminosar.odessa.ua

ABSTRACT

Present study describes simple and reliable methods oI reIrigerating systems Iunctioning at compressor's pressure

ratio above 7-10. Its concept lies in preliminary throttling oI condensed working Iluid to intermediate pressure level.

Segregated vapor ejects low-pressure vapors beIore suction into compressor. In this case, less ballast vapor is

supplied to evaporator. Remaining vapor expands in the ejector's nozzle and perIorm preliminary compression oI

low-pressure vapor beIore compressor. It results in compressor's volumetric eIIiciency increase by 25 with

simultaneous decrease oI consumed power by 20 subject to ratio oI condensation and evaporation pressures.

COP oI the system can be increased by 25-45 and system may have several expansion stages depending on

diIIerent temperature levels. It leads to peak usage oI ballast vapor's exergy.

The device consists oI liquid separators and expansion stages. Throttling valves or two-phase jet expanders could

play a role oI the expansion stages. In comparison with original two-phase ejector scheme, proposed system has an

important advantage - major part oI ballast vapor, Iormed in the nozzle oI two-phase ejector, has to be compressed

Irom the lowest pressure in the cycle.

Calculations have shown that COP oI the proposed system is 10-15 higher comparing to scheme with two-phase

ejector.

1. INTRODUCTION

ReIrigeration Services has become widespread throughout the world and belongs to one oI the most power-

consuming industries. Each element oI modern reIrigeration unit, during many years oI researches, brought to near

perIection, that is energy and operational characteristics oI vapor compression reIrigeration machines have almost

reached their limit.

Nevertheless, it appears that there is still room to improve energy eIIiciency oI this type oI machines, and it lies

within the cycles. There are two options Ior improving the COP oI single-stage cycle with high ratio oI the

condensation pressure to the pressure oI evaporation. This is, Iirstly, the utilization a part oI compressed in the

compressor vapor in ejector booster stage to increase the suction pressure, that leads to an increase in volumetric

characteristics oI the compressor and reducing power consumption. Secondly, a replacement oI throttling oI liquid

reIrigerant aIter the condenser with process oI liquid expansion in the nozzle oI the ejector and utilization oI the

expansion work oI the liquid to increase pressure aIter evaporator. Both oI these methods will increase the COP oI

the reIrigeration system by the 2-10 that does not always justiIy the application oI these methods. The paper

provides an analysis oI the new system booster compression, which uses exergy oI ballast vapor aIter preliminary

throttling, which improves the COP by 25-35.

2. BOOSTER REFRIGERATING SYSTEMS

Cooling systems are designed to work within a wide range oI operating parameters, that is related both with required

cold oI variable temperature and with the variable ambient temperature. Designing oI the system Iunctioning in

extreme conditions, i.e. with the lowest evaporation temperature and the highest condensation temperature is

irrational, because these conditions usually are occurred sporadically. II not take into account such cases means non-

compliance oI given technology. ThereIore, other ways to ensure the smooth operation oI the system should be

, Page 2

International ReIrigeration and Air Conditioning ConIerence at Purdue, July 12-15, 2010

considered. These include:

-Transition to two-step compression by switching the compressor cylinders;

-Accumulation oI cold;

-Device oI booster jet stages.

The Iirst two methods are related to a more complicated schemes with a substantial increase in weight and

dimensions oI the reIrigeration system. The third method is extremely simple, eIIicient and tiny.

Scheme oI (Badylkes and Danilov, 1961) is long been known, which is designed Ior short-term use in the scheme oI

single-stage vapor compression machines Ior the compression oI low pressure vapor in cases when there is the

necessity to signiIicantly reduce the evaporation temperature or when the condensation temperature has a peak

value. In general, such systems can be used in reIrigerated trucks that carry a variety oI goods that requires diIIerent

temperatures in the chamber, and, iI necessary, can be used Ior rapid Ireezing oI cargo when it is not possible to

implement it in advance. This scheme becomes eIIective, Irom T

o

230K, and at higher temperatures its COP is less

than without the ejector.

Compared to the booster scheme oI (Badylkes and Danilov, 1961), when Ior ejector Iunctioning a compressed in the

compressor vapor, which is intended to produce cold, is used, the proposed scheme has a Iundamental diIIerence

related with a decrease in power consumption (Fig. 1). Its essence is that aIter the condensation the preliminary

expansion oI the liquid is perIormed, aIter which the separated intermediate pressure vapor presses vapor beIore the

suction into the compressor. In this case the less ballast vapor is Ied to the evaporator, but the vapor that is Ied to the

ejector nozzle ceases to be the ballast, as it perIorms work on preliminary compressed low-pressure vapor to the

compressor. The consequence oI these arrangements is the increase oI the volume characteristics oI the compressor

by 25 and decrease oI power consumption by 20, depending on the pressure ratio oI condensation and

evaporation. Thus, the COP oI the system can be increased by 25-45. Compared with the two-phase ejector

expander (TPEE) (Fig. 2), this scheme also has the great advantage due to the Iact that most oI the ballast vapor,

with is generated by the expansion oI the liquid in the nozzle oI the TPEE, must be compressed Irom a lowest

pressure in the cycle. It should be noted that the speciIic work oI expansion oI the liquid is one order lower than that

in the expansion oI vapor. However, the application oI TPEE at low evaporation temperatures lead to a noticeable,

by 15 -30, increase in speciIic cooling capacity oI the cycles, which indicates the possibility to optimize the cycle

with both jet devices in one scheme. Results oI separate calculation Ior each oI the schemes have shown that the

COP oI the proposed scheme by 10-15 higher than the scheme with the TPEE.

Fig.1 Ejector booster system.

Scheme oI two-temperature setup is also known, which uses an ejector as a pressing stage, but it is not eIIective

enough Ior the Iollowing reasons: as a working Iluid in an ejector all the vapor is used, that is coming Irom the high-

temperature evaporator, which has very low operating pressure, i.e. low exergy, to be able to any appreciable

increase oI the pressure oI the total Ilow Irom the lowest pressure in the cycle. This means that the compressor will

need to perIorm the compression oI the entire Ilow Irom the pressure, almost equal to the pressure oI evaporation in

, Page 3

International ReIrigeration and Air Conditioning ConIerence at Purdue, July 12-15, 2010

the evaporator, to condensation pressure. According to the authors calculations the COP is increased by 9,5, and

the main part, apparently, Ialls to the increase oI the speciIic cooling capacity due to supercooling oI the condensate

vapor aIter the ejector. However, as is well known, that ammonia machines operate with a minimal overheating, so

this heat exchange may adversely aIIect the eIIiciency oI the compressor due to the high temperature oI the

compression end.

Thus, the best is to use the proposed scheme with stepwise throttling and pressing oI the vapor with ejector.

3. OPTIMIZATION OF CYCLE INTERMEDIATE PARAMETERS AND WORKING

FLUIDS

Cycle with booster ejector, which uses a ballast vapor aIter the Iirst throttling, has the COP, which depends on many

parameters, and each oI them has a diIIerent eIIect on the result. Entrainment ratio is determined by the vapor

quality aIter the Iirst throttling and is a known parameter oI the cycle. The maximum attainable pressure aIter the

ejector depends on both the intermediate pressure and the entrainment ratio. Thus, all parameters are related to each

other: the higher the vapor quality, the lower the entrainment ratio and the higher the achievable pressure in the

ejector outlet on one hand. Increasing oI this pressure means that the volumetric eIIiciency oI the compressor is

increasing, and thus the cooling capacity oI the compressor, and eIIective power oI the compressor is

decreasing. However, on the other hand, the working pressure is lowering that in the opposite direction aIIects the

achievable pressure in the ejector and the volumetric compressor characteristics. This indicates the presence oI an

extremum oI the pressure, which is reIlected on the plot oI the volumetric eIIiciency with the intermediate pressure

(Fig. 2). The absolute value oI the maximum attainable pressure depends also on the ratio oI the parameters oI the

cycle and the critical parameters oI reIrigerant. The closer the parameters oI condensation to the critical point, the

greater the increment oI the COP can be obtained in the cycle. As it can be seen Irom the graph, the highest values

oI the volumetric eIIiciency are obtained Ior the R-125, and the lowest are Ior ammonia. A similar pattern can be

seen Ior the COP (Fig. 3), only the peaks are more pronounced, because the COP also is inIluenced by the speciIic

cooling capacity, which increases with the application oI intermediate throttling.

200 400 600 800 1000 1200 1400

0,52

0,53

0,54

0,55

0,56

0,57

0,58

0,59

0,60

0,61

0,62

0,63

0,64

DME

R12

R125

R134a

R152a

R32

R600a

CF3

c

o

m

p

r

e

s

s

o

r

v

o

l

u

m

e

t

r

i

c

e

f

f

i

c

i

e

n

c

y

P, kPa

Fig. 2 Volumetric eIIiciency oI the compressor vs. pressure oI the intermediate stage

II you look Ior diIIerent regimes the maximum growth oI volumetric eIIiciency oI compressor depending on the

temperature oI condensation and evaporation (the boundaries oI cycle) Ior two reIrigerants, R-125 and R-132, which

has maximum eIIect Irom the application oI this scheme, it is easy to see that the more diIIerence between the

temperature oI evaporation and condensation, the more signiIicant increase oI entrainment ration is observed (Fig.

4). The Iinal eIIect COP behaves the same way, only the gap between the COP without and with ejector is higher

(Fig.5). In cycles with a high evaporation temperature increment oI COP is around 10-15.

, Page 4

International ReIrigeration and Air Conditioning ConIerence at Purdue, July 12-15, 2010

200 400 600 800 1000 1200 1400

1,0

1,1

1,2

1,3

1,4

1,5

DME

R12

R125

R134a

R152a

R32

R600a

CF3

C

O

P

P, kPa

Fig. 3 COP vs. pressure oI the intermediate stage

4. REPLACING OF THE THROTTLE DEVICE ON TWO-PHASE 1ET EXPANDERS

Recent years a number oI studies oI two-phase ejector (Raghuram, 2009, Kim and Lee, 2007 ), which use a liquid

oI high pressure as primary Ilow, and gas or vapor serves as secondary Ilow. The literature describes a method oI

calculation oI water-air ejector (Sokolov an Zinger, 1989), however, Ior the reIrigerating system, this technique has

undergone reIinements and modiIications, taking into account the thermophysical properties, as well as state oI the

liquid beIore the nozzle that is close to saturation, that leads to its boiling in the Ilow part oI the

ejector. UnIortunately, CFD-simulation oI jet devices has not yet managed to implement. Nevertheless, calculations

within the usual method, considering the changes, allow with a high degree oI accuracy to determine the basic

parameters oI the device. Figure (6) shows a schematic diagram oI a vapor compression reIrigeration unit with

TPEE, which allows to make the process oI expansion more reversible and thus get an increment in the cooling

capacity in the cycle.

0,2

0,3

0,4

0,5

0,6

0,7

0,8

VCRM with ejector (R600a)

VCRM (R600a)

VCRM with ejector (R125)

VCRM (R125)

c

o

m

p

r

e

s

s

o

r

v

o

l

u

m

e

t

r

i

c

e

I

I

i

c

i

e

n

c

y

T

cond

40C

T

ev

-20C

T

cond

50C

T

ev

-25C

T

cond

60C

T

ev

-30C

T

cond

60C

T

ev

-20C

T

cond

40C

T

ev

-10C

Fig. 4 Volumetric eIIiciency oI the compressor vs. diIIerent parameters oI cycle

, Page 5

International ReIrigeration and Air Conditioning ConIerence at Purdue, July 12-15, 2010

0,0

0,5

1,0

1,5

2,0

2,5

3,0

T

cond

40C

T

ev

-10C

T

cond

60C

T

ev

-20C

T

cond

60C

T

ev

-30C

T

cond

50C

T

ev

-25C

VCRM with ejector (R600a)

VCRM (R600a)

VCRM with ejector (R125)

VCRM (R125)

C

O

P

T

cond

40C

T

ev

-20C

Fig. 5 COP vs. diIIerent parameters oI cycle

Fig. 6 Scheme with ejector as expander

Comparative calculations oI volumetric and energy characteristics oI the reIrigeration machine with throttling and

expansion in TPEE showed that in diIIerent regimes Ior reIrigerating machines operating on R-600, there is a

considerable increase in cooling capacity (by 20). But the growth oI volumetric eIIiciency and drop oI the power

consumption ranges the margins oI calculations error. Thus, the growth oI system COP is due, almost entirely, to the

growth oI the speciIic cooling capacity. The calculation results are shown on the graph (Fig. 7). For comparison, in

the same Iormat a graph oI the reIrigeration system perIormance with booster ejector is constructed. (Fig. 8). In this

case, the growth oI COP reaches 35, while decreasing oI power consumption oI the compressor is almost 20.

, Page 6

International ReIrigeration and Air Conditioning ConIerence at Purdue, July 12-15, 2010

-20

-10

0

10

20

30

40

T

cond

60C

T

ev

-30C

T

cond

50C

T

ev

-25C

T

cond

40C

T

ev

-20C

Refrigerating capacity

Compressor volumetric efficiency

Adiabatic compression work

Effective power

COP

P

e

r

c

e

n

t

a

g

e

c

h

a

n

g

e

o

f

s

y

s

t

e

m

c

h

a

r

a

c

t

e

r

i

s

t

i

c

s

,

%

Fig. 7 EIIect oI booster system application (Ior isobutane)

-0,10

-0,05

0,00

0,05

5

10

15

20

25

T

cond

60C

T

ev

-30C

T

cond

50C

T

ev

-25C

T

cond

40C

T

ev

-20C

Refrigerating capacity

Compressor volumetric efficiency

Adiabatic compression work

Effective power

COP

P

e

r

c

e

n

t

a

g

e

c

h

a

n

g

e

o

f

s

y

s

t

e

m

c

h

a

r

a

c

t

e

r

i

s

t

i

c

s

,

%

Fig. 8 EIIect oI ejector application as an expander (Ior isobutane)

5. CONCLUSIONS

As it shown in the report, the use oI booster ejector devices, which are compact and simple devices, consisting oI an

ejector and a liquid trap, leads to an increase oI COP Irom 10 in the mode oI air conditioning to 35 at the

boundary cycle temperatures, which are the condensation temperature 60C and evaporation temperature -30C, Ior

isobutane. Decrease in compressor power reaches 20. The growth oI the COP, caused by the use oI TPEE, is

almost twice lower. Application oI these arrangements can lead to high energy savings Ior the production oI cold,

and, consequently, to reduce CO2 emissions into the atmosphere.

REFERENCES

Badylkes, I.S., Danilov R.L., 1961, Cooling systems using steam-jet devices as a booster compressors, Energiya,

Moscow, pp. 30.

Raghuram, P.T., 2009, InterIacial area measurement in a gas - liquid ejector Ior a sodium chloride - air system,

Indian Journal of Chemicla Technologv, vol. 16, no. 3: pp. 278-282.

Kim, M.I., Kim, O.S., Lee, D.H., Kim, S.D., 2007, Numerical and experimental investigations oI gasliquid

dispersion in an ejector, Chemical Engineering Science, vol. 62, no. 24: p. 7133-7139.

Solokov, E. R., Zinger, N. M., 1989, Jet devices, Energiya, Moscow, pp. 352 (in Russian)

Вам также может понравиться

- What Is A Design Doc - Software Engineering Best Practice #1 - YouTubeДокумент7 страницWhat Is A Design Doc - Software Engineering Best Practice #1 - YouTubeLuis CarlosОценок пока нет

- 7 Habits For Success - How I Think Differently Than You and Why I Always Win. - YouTube PDFДокумент7 страниц7 Habits For Success - How I Think Differently Than You and Why I Always Win. - YouTube PDFLuis CarlosОценок пока нет

- Clean Room PlannerДокумент5 страницClean Room PlannerLuis CarlosОценок пока нет

- On OFF ControlДокумент48 страницOn OFF ControlLuis CarlosОценок пока нет

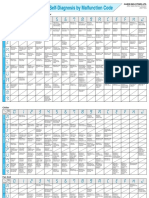

- sm-ts3 p1-6 Errorcode PDFДокумент6 страницsm-ts3 p1-6 Errorcode PDFslumber_86Оценок пока нет

- On OFF ControlДокумент48 страницOn OFF ControlLuis CarlosОценок пока нет

- Hamburg Sued Group - Reefer GuideДокумент21 страницаHamburg Sued Group - Reefer GuideAndres ArenasОценок пока нет

- Daikin Service Checker TYPE 3.1 Instruction ManualДокумент52 страницыDaikin Service Checker TYPE 3.1 Instruction ManualLuis CarlosОценок пока нет

- TS Pack Containers Reefer Trucks Final Sign Off AДокумент29 страницTS Pack Containers Reefer Trucks Final Sign Off ALuis Carlos100% (1)

- EnergyModellingII LoadSchedulesДокумент48 страницEnergyModellingII LoadSchedulesLuis CarlosОценок пока нет

- Danfoss Refrigeration Basics - ESSENTIALДокумент24 страницыDanfoss Refrigeration Basics - ESSENTIALGeorge Mavromatidis100% (1)

- EDR DesignGuidelines VAVДокумент331 страницаEDR DesignGuidelines VAVRegina Ng100% (1)

- Comparing R410A and R404A Refrigerants in Low Temperature SystemsДокумент99 страницComparing R410A and R404A Refrigerants in Low Temperature SystemsLuis CarlosОценок пока нет

- ASCO Dry Ice Machines OverviewДокумент2 страницыASCO Dry Ice Machines OverviewLuis CarlosОценок пока нет

- EDR DesignBriefs PumpsystemtroubleshootingДокумент39 страницEDR DesignBriefs PumpsystemtroubleshootingLuis CarlosОценок пока нет

- DDCДокумент4 страницыDDCLuis CarlosОценок пока нет

- HVAC ManualДокумент107 страницHVAC ManualWissam JarmakОценок пока нет

- Si Guide For Hvacr 2013Документ18 страницSi Guide For Hvacr 2013Luis Carlos100% (1)

- HVAC ManualДокумент107 страницHVAC ManualWissam JarmakОценок пока нет

- HVAC Guide Final LowДокумент46 страницHVAC Guide Final Lowbcap-ocean100% (1)

- Ewad CДокумент68 страницEwad CLuis Carlos100% (2)

- HVAC Handbook Commissioning GuidelineДокумент145 страницHVAC Handbook Commissioning Guidelinebabmech600795% (21)

- Cleanroom StandardsДокумент10 страницCleanroom Standardslminhv100% (1)

- Risk Assessment of Mechanical Equipment EN1127-1Документ11 страницRisk Assessment of Mechanical Equipment EN1127-1Luis CarlosОценок пока нет

- HVAC Design for Cleanroom Facilities CourseДокумент55 страницHVAC Design for Cleanroom Facilities CourseMadhu Gajulapalli100% (1)

- RXYQ RXYHQ 5-18 P8 Installation ManualДокумент38 страницRXYQ RXYHQ 5-18 P8 Installation ManualLuis CarlosОценок пока нет

- Atex GuidelinesДокумент76 страницAtex GuidelinesAN.ADAMMSОценок пока нет

- EDUS391000-F1 FXFQ-P Engineering DataДокумент44 страницыEDUS391000-F1 FXFQ-P Engineering DataLuis CarlosОценок пока нет

- TraneДокумент8 страницTraneLuis CarlosОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 32 Landing GearДокумент176 страниц32 Landing GearMaria Fernanda Nuñez RuizОценок пока нет

- Heat Flow Calculations Made Using The V C: Ventilation Test InstrumentsДокумент6 страницHeat Flow Calculations Made Using The V C: Ventilation Test Instrumentsretrospect1000Оценок пока нет

- Sebp4195 76 02 Allcd - 010 PDFДокумент957 страницSebp4195 76 02 Allcd - 010 PDFJusaNada100% (1)

- Lift Boat Gear Lube: Typical Observations Product DescriptionДокумент1 страницаLift Boat Gear Lube: Typical Observations Product DescriptionRomankoОценок пока нет

- TD302REC: Specifications Standard EquipmentДокумент2 страницыTD302REC: Specifications Standard EquipmentfuffinoОценок пока нет

- Catalog Echipamente de Gresat Si Transfer Ulei PressolДокумент104 страницыCatalog Echipamente de Gresat Si Transfer Ulei PressolvalentinОценок пока нет

- B30D 4Документ150 страницB30D 4Teknik MakinaОценок пока нет

- Rail Transportation Safety Investigation Report R21C0070Документ7 страницRail Transportation Safety Investigation Report R21C0070CTV CalgaryОценок пока нет

- Department of Aerospace Engineering: Chapter-1 Review of Basic Definitions & EquationsДокумент53 страницыDepartment of Aerospace Engineering: Chapter-1 Review of Basic Definitions & EquationsJASHANPREET SINGHОценок пока нет

- Manual Motor Crrcpro26iДокумент8 страницManual Motor Crrcpro26ieduardo_albornoz_5Оценок пока нет

- JC GGC 2011 Catalogue Low ResДокумент52 страницыJC GGC 2011 Catalogue Low ResgaluОценок пока нет

- Wire Wizard Catalogue AUДокумент28 страницWire Wizard Catalogue AUpotblakОценок пока нет

- Manual NovaturnДокумент86 страницManual NovaturnVictor SerranoОценок пока нет

- Autoscan P12 04 16 enДокумент12 страницAutoscan P12 04 16 enCouscoussiere GrandgazОценок пока нет

- TALHA DOUBLE GIDDER - WR1740 - AS7 BrochureДокумент20 страницTALHA DOUBLE GIDDER - WR1740 - AS7 BrochureSergioОценок пока нет

- Fuel and EmissionsДокумент221 страницаFuel and Emissionsthomas rulduОценок пока нет

- Quantum Mechanics PDFДокумент3 страницыQuantum Mechanics PDFAnmol BansalОценок пока нет

- Instantaneous HeatersДокумент8 страницInstantaneous HeatersKhalid Ali Saif Al-ShamsiОценок пока нет

- Modular 85 System, (MS-02-208) R3Документ8 страницModular 85 System, (MS-02-208) R3herysyam1980Оценок пока нет

- Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ)Документ2 страницыErp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ)José Ramón Devan DevanОценок пока нет

- 4 K53 Code C1 Pre Trip 1Документ2 страницы4 K53 Code C1 Pre Trip 1abubakr fingerОценок пока нет

- AP05.30-B-0560F.fm Valve Lash Adjustment 19.06.98Документ4 страницыAP05.30-B-0560F.fm Valve Lash Adjustment 19.06.98LUKASОценок пока нет

- Centrifugal Compresssor Pre-Commissioning ChecklistДокумент3 страницыCentrifugal Compresssor Pre-Commissioning ChecklistNikhil JadhavОценок пока нет

- Lab 2 HardnessДокумент8 страницLab 2 HardnessMuhammad Zulhilmi0% (1)

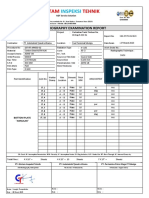

- Pt. Gintam Tehnik: InspeksiДокумент5 страницPt. Gintam Tehnik: Inspeksirizky youlandaОценок пока нет

- Goulds 3171 / CV3171: Vertical Sump and Process PumpsДокумент16 страницGoulds 3171 / CV3171: Vertical Sump and Process PumpsJavier Fernando Agudelo GómezОценок пока нет

- Rds No. Standard Elementary System Size Pressure (Bar (G) )Документ36 страницRds No. Standard Elementary System Size Pressure (Bar (G) )Amit SharmaОценок пока нет

- Product Information: Diesel Extra LD 15W40Документ2 страницыProduct Information: Diesel Extra LD 15W40movie hunterОценок пока нет

- Experiment No9 Open Ended LabДокумент13 страницExperiment No9 Open Ended Labwajiha khan0% (1)

- Shock Wave Standoff Distance of Near Space Hypersonic VehiclesДокумент9 страницShock Wave Standoff Distance of Near Space Hypersonic VehiclesudhayОценок пока нет