Академический Документы

Профессиональный Документы

Культура Документы

2009 SDPlate 2.2-1 Reinforced Elastic Bearing

Загружено:

Kangho WonАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2009 SDPlate 2.2-1 Reinforced Elastic Bearing

Загружено:

Kangho WonАвторское право:

Доступные форматы

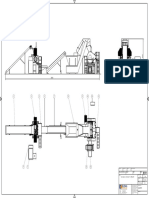

(N-1) layers of" Thick steel sheets (See "BEARING TABLE)" D/2

D/2 (N-1) layers of Bottom Flange " Thick steel sheets Factory Vulcanization Required

D { Girder

C/2

STATE

FEDERAL PROJECT NO.

SHEET

TOTAL SHEETS

N. J.

C/2

Steel Load |

STRUCTURE NO.

D D/2

Weld Size "W" " (Min.)

{ Girder D/2 Steel Load Plate (Lm x Wm) Steel Load Plate (Lm x Wm) T2

Weld size "W"

Sole Plate Required Sole Plate

Factory Vulcanization

Bottom Flange End of Girder

(Lm x Wm)

STRUCTURE NAME

Bottom flange

N Layers. For

" Min. (Typ.) " Cov. (Typ.) T2 " (Min.)

** **

"N" Layers.

Concrete Bearing For thickness see "BEARING TABLE" Masonry Plate T1

NOTE TO DESIGNER:

H

Thickness See

"BEARING TABLE".

T3

T4

THIS SHEET IS NOT TO BE PLACED INTO THE CONTRACT SET

" Cov. (Typ.)

" (Min.)

OF PLANS AS IS. HOWEVER, INDIVIDUAL DETAILS MAY BE

T1 p Dia. Pin, Tight Fit, rigidly attached to Masonry |

Surface

UTILIZED FOR SHOP DRAWING REVIEW. OTHER SUITABLE

Masonry Plate

Sole |

DETAILS, AS PUBLISHED BY OTHERS AND THAT MEET OVERALL

Masonry Plate

Concrete Bearing Surface

ELEVATION

ELEVATION

EZ | ET

{ Bearing

DESIGN CRITERIA STATED HEREIN, MAY BE USED.

ET

1"

Masonry

EZ

SECTION B-B

Rectangular Elastomeric Bearing Pad & Steel Rectangular Elastomeric

GENERAL NOTES:

1"

Bearing Pad & Load plate

Lm/2

Masonry |

Load |

1. Elastomeric Bearings shall be designed in conformance with the AASHTO LRFD Bridge Design

Specifications, with current interims, as modified by Section 3 of the NJDOT Design Manual for Bridges

and Structures, and the NJDOT Standard Specifications for Road and Bridge Construction with

m(Typ.) { Brg. Lm/2 2. { Brg.

current Supplemental Specifications, as modified by the Special Provisions.

Fm

Lm

Tapered sole plates may be required when the bottom of the beam and the top of the bearings are

not parallel to each other. A tapered sole plate shall be placed between the beam and the external

Lm/2

Fm Lm

Pin Dia.

(See "BEARING Lm/2 TABLE") EL { Girder

load plate if either of the following conditions exist:

a. Longitudinal grade of the bottom flange is one percent or more.

EL

{ Girder

b. The required taper is " or more.

1"

Wm/2 Wm

Wm/2

3. The top of pedestals shall be level.

1"

Wm/2 ET EZ

Wm/2

Gm

4.

Indicate the maximum design reactions ( DL + LL ) at the supports.

Wm Gm

T 5.

The continuous weld connecting the load plate to the sole plate shall be allowed to cool after

PLAN

each pass. However the temperature of the steel adjacent to the elastomer shall not exceed

200^ F Temperature shall be controlled by the welding procedure.

FIXED BEARINGS

PLAN

6.

The size of weld (W) shall be determined by the designer. Minimum weld size shall be ".

EXPANSION BEARINGS

C Rounded End

Elastomeric Layer

7. Anchor Bolt shall be threaded as shown in "ANCHOR BOLT DETAIL FOR ALL BEARINGS".

Steel Load Plate End of

C/2 C/2

The nut shall be tightened to the satisfaction of the Engineer and the Anchor Bolt tip shall be

removed " above the top of the nut. Anchor Bolts, Plates, Washer Plates and Nuts shall

Girder Bottom Sole |

Masonry Plate 1" min. pin press fit or

" thick

steel sheets equally spaced 8.

conform to the requirements of NJDOT Standard Specifications for Road and Bridge Construction.

flange

This drawing represents straight simple span bridge structure. For clarity purposes no lateral

Pin bonded to surrounding Elastomer

Concrete Bearing

bracings are shown.

H masonry |. (No Welding

" Stl Load |

T4 T3 threaded full depth into

9. All anchor bolts shall be cast-in-place.

Surface

Allowed)

(Lm x Wm) This portion of bolt shall 10. be removed after nut has

If the design indicates that there will be no tension under any loading condition, the plate and

PIN DETAIL FOR FIXED BEARINGS

Masonry Plate

nuts are not required.

{ Bearing

Fit, rigidly attached

P Dia. Pin, Tight

been tightened to the satisfaction of the Engineer.

" Expansion Bearing - " Thick Washer Heavy Hex Nut (ASTM A563)

11. The furnishing of Reinforced Elastomeric Bearings shall conform to the provisions of Subsection

503.08 of the Standard Specifications.

to Masonry |

SECTION A-A

Plate (AASHTO M270 Galvanized) For length (Awp) and width (Bwp) see "BEARING TABLE"

Fixed Bearing - Washer (ASTM F436 Masonry P L plain-Galvanized) for Anchor Bolt Awp

12. The Designer shall reference the criteria of Subsection 1.24.20 of the Bridges and Structures

Design Manual for submission of final plans.

Bearings shall be placed on a bearing pad.

Expansion/Fixed Bearing { Girder fully threaded H.S. Anchor Concrete Bearing Surface

Am

{ Slot "

EL

Edge of Bolt (A449 Galvanized) For bolt diameter see 6" in "BEARING TABLE". Expansion Bearing - { of slot in Masonry Plate. For slot size see "TYPICAL SLOTTED HOLE DETAIL" Bm

Fixed Bearing - { of Heavy Hex Nut (ASTM A563) shall be tightened to the m Diameter hole in Masonry Plate for Anchor Bolt. (See

Masonry |

*

Bwp "BEARING TABLE" for m)

The note should be modified to reflect

applicable year and updated Specifications.

" thick Washer Plate.

(N-1) layers of " Thick steel plates Sole Plate

Flat-Head Screw Pin Plate Typ. Load Plate

For hole diameter, (

s)

see "BEARING TABLE".

**

satisfaction of the Engineer.

For hole diameter ( s)

Manufacturer shall provide the weld size

(minimum size of weld shall be ").

Slotted hole shall be filled

"

Heavy Hex Nut (ASTM A563) with full thread engagement.

see "BEARING TABLE" Anchor Plate (4" X" X 4" AASHTO M270 Galvanized)

with concrete grout material

and covered with washer

plate after bearing is set

in its final position.

N Layers. Typ.

Concrete Bearing Surface Masonry Plate

TYPICAL SLOTTED HOLE DETAIL

ANCHOR BOLT DETAIL FOR ALL BEARINGS

BDC04MB-01

MASONRY PLATE

STANDARD DRAWING PLATE 2.2-1

( FOR EXPANSION BEARINGS ONLY )

NEW JERSEY DEPARTMENT OF TRANSPORTATION

ELEVATION

FIX LOCATION MAX. DESIGN QUANTITY SHAPE

ELASTOMERIC BEARING TABLE

ITEM NO. EXP.

REQUIRED REACTION

BUREAU OF STRUCTURAL ENGINEERING

ONE WAY ELASTOMER LAYERS LOAD | LONG. THICKNESS Wm N Lm MOVEMENT THICKNESS (IN) LAYERS (IN) (IN) (IN)

*

FACTOR (KIPS)

MASONRY |

T1 T2 (IN) (IN) Fm (IN)

BRG. ANCHOR BOLTS WELD SIZEWASHER | Gm (IN)

Am Bm

SOLE PLATE E (IN)

(IN)

T

LL W/O

E (IN)

Ez

m (IN) (IN)

(IN)

BOLTS

DL+SDL

W Awp

s HOLE DIA.

P PIN

Bwp (IN)

(IN) PER BRG. (IN)

D (IN) (IN)

(IN)

T3

T4

IMP

(KIPS)

FOR PIN (IN)

DIA.

(IN)

(IN)

(KIPS)

(IN)

(IN)

REINFORCED ELASTOMERIC BEARING

JOB NO.

CONTROL SECTION

DES. BY DWN.

BY

: ROUTE

CHK.

BY

SECTION :

EST.

CHK. BY

BDC04MB-01

MUNICIPALITY

COUNTY

BY SPECS.

BY

*

IN CHARGE OF

One way longitudinal movement is the maximum movement (Expansion or Contraction) of the Superstructure when bearings are set at 68^ F. This includes 1" of tolerance.

When the bearings are to be set at temperatures other than 68^, reference AASHTO LRFD Bridge Design Specifications, Articles 3.12.2.1 and 3.12.2.2 for guidance for setting temperatures and bearing movement.

SCALE :

NONE

BRIDGE

SHEET NO.

OF

file=

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- Presidential Regulation No 56 Year 2011 (English Version)Документ19 страницPresidential Regulation No 56 Year 2011 (English Version)mcneil_scribdОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- Aashto LRFD Bridge Design Specifications: SI Units 4th Edition 2007Документ9 страницAashto LRFD Bridge Design Specifications: SI Units 4th Edition 2007Kangho WonОценок пока нет

- 상주~영천 고속도로 민간투자사업 (제7공구) Aashto 98 Asd Design MethodДокумент10 страниц상주~영천 고속도로 민간투자사업 (제7공구) Aashto 98 Asd Design MethodKangho Won100% (1)

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- Tech Civil01Документ130 страницTech Civil01Kangho WonОценок пока нет

- 단면 IДокумент10 страниц단면 IKangho WonОценок пока нет

- AASHTO BEAMS Standard DimentionsДокумент16 страницAASHTO BEAMS Standard Dimentionsjedidestroyer100% (1)

- 2014.04.21 City LoacationДокумент1 страница2014.04.21 City LoacationKangho WonОценок пока нет

- Temperature Gradient For Concrete 20120126 (BS)Документ39 страницTemperature Gradient For Concrete 20120126 (BS)Kangho WonОценок пока нет

- LRFD Design Example Nº1. Prestressed Prescast Concrete Beam Bridge Design (MATLAB)Документ347 страницLRFD Design Example Nº1. Prestressed Prescast Concrete Beam Bridge Design (MATLAB)rapaigОценок пока нет

- Appendix FДокумент8 страницAppendix FKangho WonОценок пока нет

- Rigid Pavement Design: 29.1.1 Modulus of Sub-Grade ReactionДокумент9 страницRigid Pavement Design: 29.1.1 Modulus of Sub-Grade Reactionnageshkumarcs100% (1)

- AASHTO BEAMS Standard DimentionsДокумент16 страницAASHTO BEAMS Standard Dimentionsjedidestroyer100% (1)

- Box GirderДокумент148 страницBox GirderJohn Wong100% (2)

- Section 4: Structural Analysis and EvaluationДокумент32 страницыSection 4: Structural Analysis and EvaluationKangho WonОценок пока нет

- Cover Appendix K2 20120907Документ1 страницаCover Appendix K2 20120907Kangho WonОценок пока нет

- Appendix FДокумент8 страницAppendix FKangho WonОценок пока нет

- Adjacent Precast Concrete Box Beam BridgesДокумент86 страницAdjacent Precast Concrete Box Beam BridgesSudathipTangwongchai100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- ZSXMB Moni ViewerДокумент38 страницZSXMB Moni ViewerAnil ChauhanОценок пока нет

- ADVANTAGES AND DISADVANTAGES OF 5TH GENRATION sLANGUAGESДокумент4 страницыADVANTAGES AND DISADVANTAGES OF 5TH GENRATION sLANGUAGESKaren NguyenОценок пока нет

- Covered In: Mapping The PMP® Exam Content Outline To The Course ContentДокумент8 страницCovered In: Mapping The PMP® Exam Content Outline To The Course ContentMoEllitheyОценок пока нет

- Sicc Ac CP 01 Snttc1aДокумент15 страницSicc Ac CP 01 Snttc1aEnrique Campos CannavaroОценок пока нет

- Nomex 414Документ4 страницыNomex 414alex696Оценок пока нет

- Hepworth - DrainДокумент144 страницыHepworth - DrainAmal ChandraОценок пока нет

- Training Report at Rail Coach Factory RCF PDFДокумент27 страницTraining Report at Rail Coach Factory RCF PDFYogendra Kumar92% (12)

- RM QAFA Training DocumentДокумент27 страницRM QAFA Training Documentស្រី ស្រស់Оценок пока нет

- TE040 Test Script APДокумент28 страницTE040 Test Script APumamahesh_jv100% (1)

- Biznet Inspire Apr2011Документ23 страницыBiznet Inspire Apr2011GoyobodОценок пока нет

- EX200 Red Hat Certified System Administrator (RHCSA) Exam - 112016Документ17 страницEX200 Red Hat Certified System Administrator (RHCSA) Exam - 112016Aumi KhanОценок пока нет

- Wco Working BodiesДокумент1 страницаWco Working BodiesJose BustamanteОценок пока нет

- Technical Regulation For Machinery Safety - Part 1: Portable And/or Hand-Oriented MachinesДокумент53 страницыTechnical Regulation For Machinery Safety - Part 1: Portable And/or Hand-Oriented MachinesEyad OsОценок пока нет

- SSL Matrix2 Owners ManualДокумент170 страницSSL Matrix2 Owners ManualOmu AntenaОценок пока нет

- CoC 100850996CRT-001i PDFДокумент1 страницаCoC 100850996CRT-001i PDFAnderson Joel Navarro YarlequeОценок пока нет

- Electrocraft PMDC CatalogДокумент42 страницыElectrocraft PMDC CatalogElectromateОценок пока нет

- Introduction To HTML Grade 9Документ23 страницыIntroduction To HTML Grade 9fredОценок пока нет

- SANS 941 (Colour)Документ13 страницSANS 941 (Colour)ByronОценок пока нет

- 09.5 - MOE 1998 Draft Noise Guidelines For Landfill Sites (For Haul Route Analysis)Документ6 страниц09.5 - MOE 1998 Draft Noise Guidelines For Landfill Sites (For Haul Route Analysis)NewfsterОценок пока нет

- Tyre Plant C / SC1412T + MPR160T: Title: 1: 50 A3Документ3 страницыTyre Plant C / SC1412T + MPR160T: Title: 1: 50 A3asciacion hermandad HispanocolombianaОценок пока нет

- LogДокумент132 страницыLogjamesОценок пока нет

- @@D@-@ @@d@-@/na20d@-@: Cp1e-E Cp1e-NДокумент44 страницы@@D@-@ @@d@-@/na20d@-@: Cp1e-E Cp1e-NEDEVALDOОценок пока нет

- Ethernet IP Via 1761 NET ENI To SLC503Документ21 страницаEthernet IP Via 1761 NET ENI To SLC503benito1Оценок пока нет

- Notam VviДокумент18 страницNotam Vvicaoap3847Оценок пока нет

- UGF7945 Calero Ncalero SQL Plan Baselines Oow2014Документ69 страницUGF7945 Calero Ncalero SQL Plan Baselines Oow2014girglОценок пока нет

- Etos® Ed - TDДокумент12 страницEtos® Ed - TDVibhav MehtaОценок пока нет

- REVISED TEACHER-EVALUATION TOOL (Edited)Документ8 страницREVISED TEACHER-EVALUATION TOOL (Edited)Jee En BeeОценок пока нет

- HAL 102 - LabДокумент43 страницыHAL 102 - LabSyrd MdeОценок пока нет

- Standardization Ensures Safe Power Transformer UseДокумент30 страницStandardization Ensures Safe Power Transformer UseEL MONADY MohammedОценок пока нет