Академический Документы

Профессиональный Документы

Культура Документы

FiatMultipla WhatToDoWhenAWheelBoltShears FittingNewFrontHubFlange&Amp OrBearing

Загружено:

a1037699Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FiatMultipla WhatToDoWhenAWheelBoltShears FittingNewFrontHubFlange&Amp OrBearing

Загружено:

a1037699Авторское право:

Доступные форматы

FiatMultipla_WhatToDoWhenAWheelBoltShears&FittingNewHubFlange&OrBearing This article starts by considering your options when you shear off a wheel bolt, but then

goes on to describe how to replace a front and rear hub and bearing, or just the front bearing and could be read just for that. I had the misfortune to have two wheel bolts shear off on my front nearside wheel hub and though I hoped to just remove the broken stubs I ended up replacing the front hub flange and the wheel bearing. There are several preventative or remedial routes. I hope this article helps anyone with a sheared bolt or needing to replace a wheel bearing! Preventative With hindsight I should have used my M ! .!" tap to clean out the holes in the flange which were tight when last I did a wheel change though eased by #omma #opper $ase on the threads, but having delegated the wheel fitting to my son who doesn%t know his own strength he managed to shear one bolt about ! or & mm from the end but didn%t know he had and when I checked his tightening I managed to shear the second bolt flush with the flange! It is worth buying a M ! .!" tap 'my Irwin tap cost (!.)) on ebay incl delivery* and a tube of #omma #opper $ase '(&.+, Wilco-irect* which can also be used on the brake pads.

Re e!ial .hearing bolts are a common occurrence irrespective of vehicle and my M/T garage mechanic said they usually use a MI0 welder to build up a raised heap on the stub and then weld on a nut. 1roblem with that is that if your welding eyes aren%t too good you might weld the stub to the flange and make it even harder to remove! It is a possible route. ! I have read that you can use an old screwdriver and hammer to turn them off on the grounds that it was the being to tight that caused them to break under tension rather than the thread being too tight, but it would only work I suspect if the bolts had been easy to wind in by hand. & 2ou could drill out the centre and use a screw e3tractor with a ratchet, see pic. That was my first try. 4nfortunately they were too tight and the hardened screw e3tractor sheared off flush 'I should have used the largest one*. I couldn%t therefore use remedy +, though when the correct drill bit arrived it made short work of the shorter stub for which the thread cleaned up well using the M ! tap as in second pic.

+ With more hindsight I could have just drilled the bolt ends out and cleaned up the threads. 5or this you would have had to have the foresight to have the correct drill bit which for M ! .!" pitch is !)67+8 or 9.)"mm 'preferably 9.)mm*. It would be worth having these drill bits in reserve as none of them are going to be available locally. I bought three on ebay for a total of (!.): incl p;p but they took ! days to arrive! It is important that you first make a concentric pilot indentation with a smaller sharp drill bit, perhaps an :mm one. 5inish off with the M ! .!" tap which you should also have in readiness! This option would cost the princely sum of about (+ and be a very <uick solution! " =uy a new front hub flange on the grounds that they only cost ( 9."9, but you will find as I did that you will also need a new bearing! >ear hub flanges come with the embedded bearing and cost more. ?inks provided later. Front"#lange

Option"$"woul!"be" %"re&o en!e!"one"#or"both"#ront"an!"rear"hubs"i#"%our"bearing"is"soun!'" 5or front wheels just drill through the hole with the disc in place. ?ikewise for the rear wheel case with rear discs, but if you have rear drum brakes you will probably need to first remove the drum so that the swarfe can be removed. Front"wheel"hub I always look to see if I can do a job with fewer steps than recommended but this time I was in part defeated so the following says what you should do. I had thought that the front hub flange and bearing would be as easy to remove as a rear hub but I had overlooked that you can%t just use a hub remover on the front a3le because it just pushes the splined driveshaft back out of the hub, whereas the rear one is a fi3ed stub a3le and allows the hub to be pushed off instead! The front bearing slides into the knuckle from the inside and the stub of the flange slides into the bearing from the outside which is why they are available separately. It isn%t <uite as simple as that because obviously both contacts have to be tight enough so that the outer bearing shell does not rotate in the steering knuckle and the flange doesn%t rotate inside the inner bearing shell. 'The driveshaft splines make the hub turn but the inner part of the bearing must still turn with the hub.* They have to be an @interference fit% but in reality they are an absolute pain to separate! /nce I knew that it is impossible to remove the hub flange without knackering the bearing I resigned myself to replacing what had been a good bearing. I went hard at it with a "kg slide hammer but the flange just wouldn%t budgeA .o just go for the easy way which is to remove the steering knuckle and take it to a friendly garage with the new bearing and #Bclip and in my case a new hub flange and ask them to use their hydraulic press to first remove the flange and then press out the old bearing and fit the new one. They charged me ( 9 which seeing how hard it was to do even with the correct e<uipment was very reasonable. The flange is pressed outwards, but the bearing is pressed out towards the inside after removing a #Bclip behind the bearing. The new bearing is pressed in until it meets a flange in the knuckle.

The following before and after pictures show the knuckle with the bearing, #Bclip and flange in position. The C=. sensor will enter at about 9 o%clock. Ct the bottom of the first pic you can see where a flat screwdriver can be tapped in to open the jaws of the ball joint enough to separate the knuckle and the ball on the wishbone.

If the bearing splits in two when the flange is pressed out under the 9 ton hydraulic pressure you have to use a hammer and cold chisel to move the bit left on the stub of the flange hub a few millmetres so that you can get the jaws of a hub puller behind it. Note("The"new"bearing"&o es"with"a"new")*&lip"an!"hub"nut' Note(""The"bearings"#or"ABS"an!"non"ABS"hubs"are"!i##erent"+see"lin,"below-'"."ha!"to"tell"the" garage"whi&h"wa%"the"bearing"has"to"go"in"the"hub/""The" agneti&"ring"si!e"is"towar!s"the"insi!e" but"it"isn0t"labelle!'"".t"is"!ar,"brown1gol!"in"&olour"while"the"other"si!e"is"steel'"" Note"i#"the%"get"it"wrong"%ou"will"have"to"bu%"another"bearing"as"it"will"be"!a age!"when"it"is" re ove!' 2ou could install the bearing and its #Bclip and then the flange using a block of hardwood and a hammer.

On&e"the"new"bearing"has"been"presse!"in"the"&ir&lip"is"positione!"in"the"groove"as"in"the"earlier" pi&ture2"with"the"gap"stra!!ling"the"ABS"sensor"whi&h"&o es"through"a"hole"in"the",nu&,le' Others have mentioned having problems with ABS brakes and it has been suggested that this might have been because there were cracks in the magnetic ring on the bearing. I couldnt crack my old one though I dont know what is inside the cover!

Se3uen&e"o#"steps"to"re ove"the"steering",nu&,le'"" Note("4se"lots"o#"WD$5"or"Plus6as"when"!is antling' ?oosen the wheel bolts ! 4se a hammer and old screwdriver or punch to raise the indented parts of the hub nut where they have been hammered into the slots in the end of the driveshaft.

& >emove the hub nut using a thinBwall &7mm socket. 2ou need one with an outside diameter of +)mm. /thers will not fit inside the the centre boss in the flange. + Dack up the car and remove the wheel. " ?oosen but do not yet remove the two bolts holding the knuckle to the shock absorber strut. ?oosen the two wheel locating pins.

7 If your Multipla has C=. brakes remove the 9mm bolt on the sensor and carefully disconnect the sensor from the knuckle. 4se lots of W-+9 and swivel rotate it by its metal bracket a little at a time 'by up to &9 degrees*.

) >emove the bolt and nut holding the swivel ball to the bottom of the knuckle. C screwdriver will help you separate the ball joint from the knuckle. The second pic shows how the bolt secures the ball joint.

: -isconnect the tieBrod end from the knuckle.

, >emove the two caliper pins. To do this, first prise out the plastic plugs and use a )mm allen key to unscrew the pins. 1ut #opper $ase on pin shaft when reassembling.

9 >emove the antiBs<ueal spring from the caliper. '1ic shows this after the caliper has been slid away and supported.*

.lide off the caliper and pads and support the caliper so that the rubber hyraulic pipe is not in tension.

! >emove the two wheel locating pins and remove the disc. .ee &

& Ct this point I removed the two bolts holding the caliper carrier, but I suspect that may not be necessary if you can remove the disk without. If you do have to remove them also remove the 9mm bolt holding the stone guard on. '=olt is shown top right in the second picture.*

+ >emoving the two bolts holding the knuckle on the shock absorber strut should allow you to disengage the splined driveshaft and to remove the knuckle. EoteF In my case the drive shaft wouldn%t slide out and I chose to remove the si3 "mm allen keyB headed bolts on the inner driveshaft flange and then use a hub puller to force the driveshaft out. Cvoid doing this if you can as you could use a hub puller once the knuckle has been disconnected. I later had to spend &9 minutes cleaning up the splines on the driveshaft so that it would readily slide into the new flange. I have not had this problem before. Eote the use of the lug on the strut to avoid the heads of the allen bolts being damaged by not having the wrench in line.

Reasse bl% >eassembly is straightforward. #lean the caliper jaws and the brake pad ends and use #opper $ase antiBseiGe grease on their meeting faces.

4se the new hub nut supplied with the bearing. >efit the wheel and tighten the hub nut to )9Em H 7! degrees. I did this twice to take up any slack. >emove the wheel and use a hammer and cold chisel to depress the edge of the hub nut into the grooves in the driveshaft, rotating the hub to bring them to the top. .ome people use ?octite on the shaft thread as well.

Rear"Hub"an!"Bearing These are much easier to replace than the front ones. If you have rear disc brakes you have to remove the hub nut and use a hub puller to force the hub and bearing off the fi3ed stub a3le. If you have rear drum brakes you first have to remove the drum to get access to the same hub. There is a separate article on removing the rear drums that shows how to use two bolts to force it off. The rear flange and bearing comes as a unit again in two forms, C=. and nonBC=.. The same hubs ae used for disc and drum brakes. .hop+1arts have the separate front hub flange and the bearing, and the rear hub flange with bearing on .pecial /ffers.

httpF66www.shop+parts.co.uk6InameJstore;opJ>esults;categoryJ ,;secondaryJ&:;optsJ79;btnKiew1roductsJ.earch

So&,ets"an!"spanners"nee!e!"an!"Tor3ue"settings("&he&,"these"values"#or"%oursel# Lub nutF &7mm thin wall socket +)mm/)9Em H 7!degrees #aliper pinsF )mm allen !+Em #aliper #arrier =racket 'if needed*F =olt ,mm 9"Em Mnuckle to .hock Cbsorber .trutF bolt "mm, nut )mm )9Em .teering =all jointF bolt )mm, nut )mm )9Em TieBrod endF nut )mm +9Em Wheel ?ocating6-isc 5i3ing pinsF !mm !Em C=. sensorF 9mm bolt )Em -riveshaft bolts 'if needed*F "mm allen +9Em

Вам также может понравиться

- Service Manual HeidenHain TNC 360Документ157 страницService Manual HeidenHain TNC 360a1037699100% (1)

- Secure FTP SeminarДокумент7 страницSecure FTP Seminara1037699Оценок пока нет

- Wind Turbines - I. Al-BahadlyДокумент664 страницыWind Turbines - I. Al-Bahadlykevin_leigh_1Оценок пока нет

- How To Run Diesel Particulate Filter Regen and ResetДокумент1 страницаHow To Run Diesel Particulate Filter Regen and Reseta1037699Оценок пока нет

- JTD105 SX With and Without A MAFДокумент2 страницыJTD105 SX With and Without A MAFa1037699Оценок пока нет

- Cambelt and Water Pump Change MultiplaДокумент12 страницCambelt and Water Pump Change Multiplaa1037699Оценок пока нет

- Airmasssensoron JTDДокумент1 страницаAirmasssensoron JTDa1037699Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Grapple Releasing SpearДокумент7 страницGrapple Releasing SpearALEX MAKANGAОценок пока нет

- Service Clark Transmission 18000Документ74 страницыService Clark Transmission 18000Paul Jhon Solis huariОценок пока нет

- Data Part-1Документ18 страницData Part-1Mau MaunuОценок пока нет

- Drilling MachineДокумент6 страницDrilling MachineAnand BalajiОценок пока нет

- Section 1 Section 1: General InformationДокумент1 страницаSection 1 Section 1: General InformationPalincas Alin FelixОценок пока нет

- Harga Special: CoretДокумент3 страницыHarga Special: CoretAbim GondrongОценок пока нет

- Principles of Machine Shop Practices RSTДокумент34 страницыPrinciples of Machine Shop Practices RSTJoel Kelly Cangrehilla MabaoОценок пока нет

- Toyo Thread Cutting AttachmentДокумент12 страницToyo Thread Cutting Attachmentiril anwarОценок пока нет

- ECODAN Talpyklos Su 200 L Boileriu Jungimo Schema PDFДокумент1 страницаECODAN Talpyklos Su 200 L Boileriu Jungimo Schema PDFTomas GeneviciusОценок пока нет

- John Deere 7720 COMBINE WITH 224 RIGID PLATFORM Parts Catalog-91-120Документ30 страницJohn Deere 7720 COMBINE WITH 224 RIGID PLATFORM Parts Catalog-91-120Retro Animados0% (1)

- Instrument Hookup Drawing OF LEVEL SWITCHДокумент1 страницаInstrument Hookup Drawing OF LEVEL SWITCHEdafe DicksonОценок пока нет

- China GPZ Bearings CatalogueДокумент272 страницыChina GPZ Bearings CatalogueAlanYuОценок пока нет

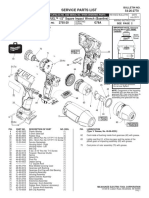

- 2755 22 (G78A) Milwaukee PBДокумент2 страницы2755 22 (G78A) Milwaukee PBZeckОценок пока нет

- Kx6 SeriesДокумент216 страницKx6 SeriesThang TranОценок пока нет

- PCB Drill ChartДокумент4 страницыPCB Drill ChartSougata DasОценок пока нет

- Bosch Table Saw Gts 10 XC Professional Manual 93459Документ390 страницBosch Table Saw Gts 10 XC Professional Manual 93459Marijan HorvatОценок пока нет

- Witnessed Factory Acceptance ReportДокумент4 страницыWitnessed Factory Acceptance ReportKarna Satish KumarОценок пока нет

- Air CooledДокумент34 страницыAir Coolededward m. limenОценок пока нет

- ListДокумент1 страницаListrigoberto otinianoОценок пока нет

- 2008 Sacksafoam II Model 5598 ManualДокумент27 страниц2008 Sacksafoam II Model 5598 ManualRicardo GalindoОценок пока нет

- Mercedes Benz CAN 44.30Документ93 страницыMercedes Benz CAN 44.30SaasiОценок пока нет

- Victaulic Pl2015 MainДокумент241 страницаVictaulic Pl2015 MainTevton JackОценок пока нет

- Furuno GMDSS Installation Manual PDFДокумент64 страницыFuruno GMDSS Installation Manual PDFEric PskdОценок пока нет

- Service Report: Nature of ProblemДокумент2 страницыService Report: Nature of Problemjherson gravidesОценок пока нет

- Shimano Sienna 10SN4000FDДокумент2 страницыShimano Sienna 10SN4000FDDanielОценок пока нет

- Adaptor Otg: NO Description Stok Harga (Per PCS)Документ10 страницAdaptor Otg: NO Description Stok Harga (Per PCS)MARSELO MELKYОценок пока нет

- Replacement Filling ValveДокумент11 страницReplacement Filling ValveYASSIR DINHAZОценок пока нет

- Service Training Parker PV Series 42Документ39 страницService Training Parker PV Series 42Javier PeñaОценок пока нет

- 477-8344 Adapter Gp-Fast Fill FuelДокумент4 страницы477-8344 Adapter Gp-Fast Fill FuelAnderson Oliveira SilvaОценок пока нет

- TAB-0000IN01-03-0-Cable ListДокумент7 страницTAB-0000IN01-03-0-Cable ListRaka PriaОценок пока нет