Академический Документы

Профессиональный Документы

Культура Документы

Conformal Cooling

Загружено:

gpiprototype.comИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Conformal Cooling

Загружено:

gpiprototype.comАвторское право:

Доступные форматы

Any shape. Anytime. Anywhere.

Whitepaper

Optimised mould temperature

control procedure using DMLS

Siegfried Mayer (EOS GmbH)

Courtesy of Fennel GmbH & Co. KG

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich

Phone +49 89 893 36-0, Fax +49 89 893 36-285, www.eos.info

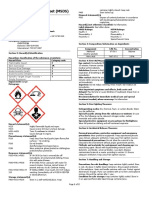

Whitepaper Optimizing mould temperature control for better products

1. Introduction

EOSINT M systems produce solid metal parts by locally melting metal powder with a focused

laser beam layer by layer. This automatically creates the final geometry from 3D CAD data.

This method is called Direct Metal Laser-Sintering (DMLS). Depending on the material used

and process parameters applied, this method allows for a wide range of part properties.

Producing layer by layer allows for manufacturing highly complex geometries directly

from electronic data with unique freedoms of design. DMLS can make EDM and milling

obsolete in many cases, especially with complex part geometries where slides, inserts or

other tool components with complex characteristics are required.

Since 1995, tooling has been the major application for EOSINT M technology. This appli-

cation, called DirectTool, allows the manufacturing of tooling inserts and components in

a timely manner, due to a tight process chain (Rapid Tooling). By continuously improving

the technology and through the market introduction of the EOS maraging steel MS1 (which

meets the high requirements of tool making for serial production), other applications such

as series tooling and die casting became possible. On top of the value of short turn-around

times additional value was created by the unique geometric freedom of design: “Advanced

tooling”.

One of the relevant “Advanced tooling” applications is the integration of conformal cooling Figure 1

channels. This helps to improve both the quality and economics of injection moulded Conventional heating/cooling

parts. Today tools produced by EOSINT M are used to produce millions of parts in injection channels (left), Conformal heating/

moulding operations or many thousand metal parts in die casting. cooling channels with DMLS (right)

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 2

Whitepaper Optimizing mould temperature control for better products

2. DMLS allows for almost any shape in heating/cooling channels

and thus improves effectiveness of cooling

Conformal cooling with DMLS helps achieving these improvements and advantages:

» �In terms of tool geometry

• Routing options for cooling channels are almost infinite. This makes it possible to create

an ideal cooling channel in a well defined distance to the cavity. A conventional drilled

cooling mechanism can not achieve this (Figure 1).

• Cooling channel cross sections can take almost any shape (e. g. oval vs. round) (Figures

7, 8). Turbulence of the coolant (the desired high Reynolds number) within the system can

thus be controlled by actively choosing different cross sections and by switching between

different cross sections. As a consequence, turbulence inside of the coolant is generated,

close to cavity along the whole path of the channels. A bended path should improve in

most of the cases this effect.

• Changing cross sections or forking the cooling channel can easily be done without

splitting up the form (Figure 8). This allows for additional heat/cooling advantages in areas

that cannot be reached by conventional methods.

» �Quality in the process of injection moulding

• A more effective mould temperature control system saves time and costs in the process

of injection moulding

• Quality of injection moulded parts is improved by better control of the injection

moulding process. Warping and sink marks are minimized by evenly cooling out the plastic

melt thus minimizing internal stress. Scrap rates are reduced or eliminated. Avoiding

internal stresses helps to produce better parts with the same amount of required material.

Certain geometries are only possible to manufacture at required quality standards with

conformal cooling.

• Even combined systems with separated cooling and heating channels are possible

or the split between main systems (for the control of the global temperature) and specific

systems (for the handling of close to cavity critical temperatures) can be performed with

DMLS. This opens up potential for future applications.

» Process costs

• Heating/cooling at critical parts inside the tool, which cannot – or only hardly - be

reached by conventional methods, becomes feasible (e. g. long and lean cores, areas

around hot-runners or small sliders). Using special copper heat conductors or other

complex measures becomes obsolete.

• If necessary, it is possible to undercool mould cavities, thus reaching optimal cycle times

by minimizing cool down times in tooling cavities.

• An evened out temperature level can help to improve tool life time. This becomes

relevant especially in die casting tools that are exposed to extreme temperature variations.

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 3

Whitepaper Optimizing mould temperature control for better products

Conventional cooling has the following drawbacks:

» �The distance from cavity to cooling channel differs as only straight line drilling channels

are possible (Figure 2) and as a consequence the heat dissipation cannot take place

uniformly in the material. This results in …

• Uneven temperature levels on the cavity surface.

• Uneven cooling-down processes resulting in internal stresses and thus negative impact

on part quality (warpage).

• Actively influencing cooling-down processes inside the melt can often not be achieved.

• On top clogging of dead drilling ends creates areas with zero flow velocity thus

facilitating dirt agglomeration. The drilling procedure itself is not without certain risks: in

case of deep drilling there is always a danger to hit ejector holes (wandering drill), or the drill

can even break. As a consequence, the whole mould insert could get unusable.

Figure 2

Conventional tooling mould

temperature control. An uneven

energy conductance is obvious in

these cases. In the dead areas in

front of the threaded plug that are

not passed through (marked green),

dirt deposits accumulate, which leads

to a steady decline of the general

flow (unnecessary pressure loss)

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 4

Whitepaper Optimizing mould temperature control for better products

3. Case studies[1]

Maximum value created by DirectTool is optimizing cooling channels thus conditioning

tooling temperature, which enables an uniform temperature level for the mould. This

temperature level is influenceable in order to achieve on the one hand a lower tempera-

ture for quicker cooling or higher temperature for better product surface quality on the

other hand. Therefore it has to be decided in every single case between the advantages of a

reduced cycle time (=> process speed) and the moulded part quality (=>scrap rate because

of warpage, better surfaces). This compromise has to be taken over into the tool and

mould temperature control system design and the right choice. Conventional cooling

channels are drilled into a tool. This limits design to straight lines, easily accessible by a

drill. Tooling cavities can pose limits to position and routing of conventional cooling

channels. With DMLS cooling channels can be positioned freely. Cross sections can be

optimized to mould temperature control requirements.

Studies and examples have shown the benefits of optimized cooling. Theoretical and Figure 3

practical research by PEP - Pôle Européen de la Plasturgie, Oyonnax Cedex achieved a drop Electric cover

in tooling temperature by 20°C thus reducing cycle time by 20 seconds. LBC- LaserBear- Left: Conventionally

beitungsCenter, Kornwestheim reduced cycle times by up to 60 % in one case and reduced drilled cooling channels

scrap rates from 50 % to zero by optimizing tooling temperature with DirectTool. Middle: Optimized

conformal cooling

The project shown in Figure 4 avoided warpage in spherical injection moulded parts. The Right: Simulated temperature

product, a give-away golf ball to be produced in large quantities at low costs, required distribution within tool

blow moulding extruded PP combined with the injection of an elastomer. An additional Courtesy of PEP, Legrand

technical benefit could be easily integrated, thanks to DMLS: usually the main challenge

with this kind of form is about the venting of the tool which can, in the worst case, lead

to deformed golf balls. The solution of this problem was the integration of venting

channels with almost invisible openings towards the cavity. Thanks to the opportune choice

of the process parameters it was possible to achieve two main objectvives: on the one hand

the pressure can escape and on the other hand the channels do not clog up.

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 5

Whitepaper Optimizing mould temperature control for better products

As can be seen, the volume of the cavities could be minimized which helped reducing Figure 4

building time and thus costs of the DMLS tool. Eight cavities were combined making up Golf Ball blow-mould

for a four cavity tool, producing more than20 million golf balls. Building the tool only took Left: Conformal cooling

50 hours. The conformal cooling channels increased the productivity by 20 %. Middle: Venting channels (Green)

Right: DirectTool cavity

Figure 5 shows three examples for the usage of conformal cooling channels. Figure 5a Courtesy: Es-Tec, DemoCenter

shows a tool for blow-moulding PE bottles. Cycle-time and productivity of this type of tool

are limited by the time it takes to cool down the bottle necks as wall-thickness reaches

a maximum there. In this case-study small DirectTool inserts with conformal cooling

channels were built and integrated into a conventionally manufactured tool in order to

extract the heat from these parts more quickly. The inserts reduced cycle times from 15

down to 9 seconds. This enables a 75 % increase in productivity for a 4 bottle blow mould

without sacrificing on quality.

Figure 5b shows a cooling pin for cooling an injection point, which is a classical hot spot.

Conformal cooling in this case reduces cycle times by two thirds. 5c depicts a core with

spiral conformal cooling channels inside the dome. By conventionally milling the lower

part of the tool and limiting DMLS to the part with conformal cooling, costs were reduced.

0.3mm machining allowance was added for finish-machining of the outer surface.

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 6

Whitepaper Optimizing mould temperature control for better products

Figure 5

Cooled tooling inserts.

(a) left: for bottle necks in a blow mould

(b) middle: core for cooling a gating point

(c) right: hybrid core containing

conformal cooling channel built

on top of a machined base.

Courtesy of SIG Blowtec,

Es-Tec, DemoCenter, LBC

4. Designing DMLS mould temperature control systems

Design recommendations for the layout of heating/cooling channels with DMLS are the

same as the ones given for conventional designed channels: they are both based on the

plastic recrystallization and heat conductivity theories[2], with the necessary adaptations to

conformal mould temperature control systems on the one hand and the advantages of DMLS

on the other hand (for example the possibility to change the cross section along the channel

path). The ultimate objective is the creation of a mould temperature control system, which

enables a constant and adapted temperature level for the material, during the running injection

moulding process (observe recommendations of the material manufacturer), on each point of

the moulding surface. In order to achieve this result, the channel diameter should be chosen

depending on the distance between the heating/cooling channel and the cavity. Provided

that the design for the moulded part is correct, the product can recrystallize uniformly and Figure 6

efficiently in the mould after the injection phase, which improves the quality (no internal optimal design of a three

residual stress means warp-free product with longer life cycle) and reduces the cycle time. dimensional channel system

Wall thickness Hole Centerline Distance

of molded diameter distance between

product (in mm) between holes center of holes

(in mm) and cavity

b a c

0-2 4-8 2-3xb 1.5 - 2 x b

2-4 8 - 12 2-3xb 1.5 - 2 x b

4-6 12 - 14 2-3xb 1.5 - 2 x b

According to experience, the optimal diameter should be chosen between 4-12 mm

(depending on the design of the product). These values are preferred values, to be used

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 7

Whitepaper Optimizing mould temperature control for better products

in ideal cases, as in practice sometimes tool inserts are too slim to make it possible to

follow exactly this rule (for example a closely placed pair of ejector pins, thin walls etc.).

In case of such complex geometrical conditions it can be necessary to design much smaller

diameters, for example when eliminating a hot spot. DMLS can build channels down to

1 mm diameter, but it should be taken into consideration that such fine channels can only

be put into service with specially treated fluids in order to avoid clogging. Simulation soft-

ware helps to find the right layout in such critical cases.

Figure 7

With DMLS it’s possible to vary the

channel cross section shape of the

manufactured tool inserts: additionally

to circular ones, the designer can

choose complex other shapes. The

feasibility criterion supposes a cross

section, which is self supporting. This

means the angle of overhanging areas

should be above 40° to horizontal.

On the last picture the cooling

performance can be increased due

to the ribbed shape and the higher

expected turbulence in the channel

(higher Reynolds number).

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 8

Whitepaper Optimizing mould temperature control for better products

Figure 8

the freedom to change the

cross-section shape enables the DMLS

user to implement new solutions:

in this illustrated case, the preferred

design does not require a new channel

layout. In this example two ejectors

are bypassed in the space between

without pushing the remaining wall

thickness to a critical limit. Absolute

condition: the cross section area along

the channel has to be kept constant,

to avoid flow braking effects.

5. Conclusions

DMLS opens new frontiers for the implementation of very efficient heat/cooling systems

and also offers the designer extended possibilities for the manufacturing of high perfor-

mance tools – without having to consider the many limitations which characterize the

conventional process. The real additional challenge for the integration of this kind of system

is to be found in the first steps of the project, that is to find the correct design of the

channels. The manufacturing process of the mould inserts is not influenced by the

complexity of the chosen cooling solution because the DMLS system simply builds the

channels at the same time, without having any major impact regarding the jobtime. In

view of all the advantages such systems offer, it is not justifiable to do without them in the

injection moulding production, considering the fact that the main part of the costs in large

scale serial production occurs at this stage. In order to reach the maximum efficiency in

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 9

Whitepaper Optimizing mould temperature control for better products

service (and in order to foresee the effect during the mould design) the use of adequate

simulation software and respectively analysis software (based on the control volume

FEM) is highly recommendable. According to the current level of knowledge, there is no

analysis software which is able to simulate three dimensional heating/cooling systems

with different channel cross section shapes. But considering the complexity of the mould

temperature control requirements, the results of simulations made with the approximation

of the channels to a circular shape should be sufficient for a first approximation.

References

[1] Mike Shellabear, Joseph Weilhammer: Tooling Applications with EOSINT M.

In: EOS Whitepaper, Krailling, September 2007.

[2] Olaf Zöllner, Optimised mould temperature control.

In: ATI 1104 d (Application Technology Information),

Plastics Business Group, Bayer AG, Leverkusen, 31.01.1999.

About the author

Siegfried Mayer started at EOS in 2000 as application engineer. He

has more than 14 years experience in the tooling sector and has been

responsible, since the beginning for tooling and moulding customers

and for the tooling application area.

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich, www.eos.info 10

EOS GmbH Electro Optical Systems, Robert-Stirling-Ring 1, D-82152 Krailling/Munich

Phone +49 89 893 36-0, Fax +49 89 893 36-285, www.eos.info

Вам также может понравиться

- Conformal Cooling For Plastics Injection MouldingДокумент5 страницConformal Cooling For Plastics Injection MouldingAlberto ConzОценок пока нет

- Conformal CoolingДокумент19 страницConformal CoolingskumaranspОценок пока нет

- Peti, FerenczДокумент7 страницPeti, FerenczFajar FadhilaОценок пока нет

- 2001 - Problems of Accuracy Control in Cold FormingДокумент6 страниц2001 - Problems of Accuracy Control in Cold FormingNguyen Hoang DungОценок пока нет

- Effective Control of Warping During Injection Molding: Ming-Shyan Huang, Shih-Chih Nian, and Chih-Yang WuДокумент4 страницыEffective Control of Warping During Injection Molding: Ming-Shyan Huang, Shih-Chih Nian, and Chih-Yang WuPrabhath SanjayaОценок пока нет

- Design and Optimisation of Conformal Cooling Channels in Injection Moulding ToolsДокумент8 страницDesign and Optimisation of Conformal Cooling Channels in Injection Moulding ToolsEbd RahmanОценок пока нет

- Automation Automotive Engineering 3DP Electron: Heating MethodsДокумент10 страницAutomation Automotive Engineering 3DP Electron: Heating MethodsDavision ProiectОценок пока нет

- Isothermal ForgingДокумент10 страницIsothermal ForgingGaurav VermaОценок пока нет

- Simulation of Thermo-Mechanical Forming Process With LS-DYNAДокумент8 страницSimulation of Thermo-Mechanical Forming Process With LS-DYNAPeter ZubarikОценок пока нет

- 3D Printing of Core and Cavity InsertsДокумент15 страниц3D Printing of Core and Cavity InsertsSushmaОценок пока нет

- An Experimental Investigation of The Cooling and Heating Performance of A Gravity Die Casting Mold With Conformal Cooling ChannelsДокумент13 страницAn Experimental Investigation of The Cooling and Heating Performance of A Gravity Die Casting Mold With Conformal Cooling ChannelsVictor RodriguesОценок пока нет

- Forging Final PDFДокумент6 страницForging Final PDFShubham SemwalОценок пока нет

- Finite Element Modeling of High Speed Machining Processes: Arno Behrens, Bert WesthoffДокумент6 страницFinite Element Modeling of High Speed Machining Processes: Arno Behrens, Bert WesthoffGatyo GatevОценок пока нет

- Optimized Mold Temperature ControlДокумент50 страницOptimized Mold Temperature ControlSüleymanŞentürkОценок пока нет

- Simultaneous Cold and Hot Forging in A Single ...Документ4 страницыSimultaneous Cold and Hot Forging in A Single ...Mustafa Mert SAMLIОценок пока нет

- Computer Simulation of Induction HeatingДокумент4 страницыComputer Simulation of Induction HeatingvertauldОценок пока нет

- 2008-Electric Hot Incremental Forming - A Novel Technique FanДокумент5 страниц2008-Electric Hot Incremental Forming - A Novel Technique FanKaradam PatelОценок пока нет

- 5 - Hoffmann, 2007 - Design of Hot Stamping Tools With Cooling SystemДокумент4 страницы5 - Hoffmann, 2007 - Design of Hot Stamping Tools With Cooling SystemCaio GrisottoОценок пока нет

- Finite Element Analysis On Temperature Distribution of Turning ProcessДокумент6 страницFinite Element Analysis On Temperature Distribution of Turning ProcessIJMERОценок пока нет

- Temperature Measurement When High Speed Machining Hardened Mould/die SteelДокумент9 страницTemperature Measurement When High Speed Machining Hardened Mould/die Steelkuba DefaruОценок пока нет

- Whitt 2019Документ5 страницWhitt 2019tahmid orvilleОценок пока нет

- Extruder Melt Temperature Control With F PDFДокумент6 страницExtruder Melt Temperature Control With F PDFAutogreder100% (1)

- Scheithauer2018 Article AdditiveManufacturingOfCeramicДокумент7 страницScheithauer2018 Article AdditiveManufacturingOfCeramicBethiza CamposОценок пока нет

- Compensation For Tool Deformation and Expansion inДокумент9 страницCompensation For Tool Deformation and Expansion inSangHak LeeОценок пока нет

- Waseem IntrДокумент9 страницWaseem IntrDarshan R GorpadeОценок пока нет

- Design and Simulation of Conformal Cooling For A Die-Casting Mold InsertДокумент6 страницDesign and Simulation of Conformal Cooling For A Die-Casting Mold InsertVictor RodriguesОценок пока нет

- Comparison Between Dry and Wet Machining of Stainless Steel N. I. Galanis, D. E. Manolakos, N. M. VaxevanidisДокумент8 страницComparison Between Dry and Wet Machining of Stainless Steel N. I. Galanis, D. E. Manolakos, N. M. VaxevanidisaeroprinceОценок пока нет

- Deform PaperДокумент14 страницDeform PaperSample RajОценок пока нет

- Failure Analysis of Tube and Shell Heat ExchangerДокумент5 страницFailure Analysis of Tube and Shell Heat ExchangerIJRASETPublicationsОценок пока нет

- Cryogenic Treatment and Cryogenic Cooling in Die Sink Electric Discharge Machining Process: An Experimental Set UpДокумент5 страницCryogenic Treatment and Cryogenic Cooling in Die Sink Electric Discharge Machining Process: An Experimental Set UpDarshan AachaОценок пока нет

- A Simulation Study of Conformal Cooling Channels in Plastic InjectionДокумент6 страницA Simulation Study of Conformal Cooling Channels in Plastic InjectionMustafa ÇalışkanОценок пока нет

- Specifying A SolenoidДокумент2 страницыSpecifying A SolenoidfadhlidzilОценок пока нет

- Hot Rolling ThesisДокумент8 страницHot Rolling ThesisClaire Webber100% (1)

- Thermal Exchange Effects On Steel Thixoforming ProcessesДокумент12 страницThermal Exchange Effects On Steel Thixoforming ProcessesAldo HernándezОценок пока нет

- Ime 3Документ11 страницIme 3pavan06mceОценок пока нет

- Design Optimization of Hot Forming Tools by Numerical Thermal AnalysisДокумент18 страницDesign Optimization of Hot Forming Tools by Numerical Thermal AnalysisvishalОценок пока нет

- Thermal PasteДокумент3 страницыThermal PastejuarezcruzОценок пока нет

- Investigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachДокумент6 страницInvestigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachPujara ManishОценок пока нет

- Design For Six Sigma in Electronics CoolingДокумент4 страницыDesign For Six Sigma in Electronics CoolingAllan Graver ChristensenОценок пока нет

- 2018 03 HP Induction Thoughts PDFДокумент3 страницы2018 03 HP Induction Thoughts PDFHuh ggОценок пока нет

- Cycle Time Reduction in Injection Molding ProcessДокумент9 страницCycle Time Reduction in Injection Molding ProcessPFE100% (1)

- A Model Research For Prototype Warp Deformation in The FDM ProcessДокумент10 страницA Model Research For Prototype Warp Deformation in The FDM ProcessyaellОценок пока нет

- Research and SolutionДокумент3 страницыResearch and SolutionMidi RiyantoОценок пока нет

- High PressureДокумент9 страницHigh PressureAlin StrachinescuОценок пока нет

- Irjet V6i1176Документ10 страницIrjet V6i1176Sam SamОценок пока нет

- 57 - Isijint 2016 679Документ8 страниц57 - Isijint 2016 679H. LEOCADIOОценок пока нет

- Metallic Additive ManufacturingДокумент61 страницаMetallic Additive Manufacturingashok gadewalОценок пока нет

- Potential of Thermography For The Monitoring of DED-Arc ProcessesДокумент9 страницPotential of Thermography For The Monitoring of DED-Arc ProcessesengineeringОценок пока нет

- Hot RunnerДокумент20 страницHot RunnerbasuОценок пока нет

- 422ME-3 Production Engineering-3 Lab - Manual: Processing of Polymer Materials and Application of 3D PrintingДокумент10 страниц422ME-3 Production Engineering-3 Lab - Manual: Processing of Polymer Materials and Application of 3D PrintingSyed KhaleelullahОценок пока нет

- CFD Analysis in A Heat Sink For Cooling Of-LibreДокумент11 страницCFD Analysis in A Heat Sink For Cooling Of-LibreVedant DubeyОценок пока нет

- Cirp Annals - Manufacturing Technology: D. Biermann (2), I. IovkovДокумент4 страницыCirp Annals - Manufacturing Technology: D. Biermann (2), I. Iovkovbchnb gcnnjОценок пока нет

- Applied Thermal Engineering 2Документ10 страницApplied Thermal Engineering 2dima2000Оценок пока нет

- A Comparison Between Direct and Indirect Laser Sintering of MetalsДокумент6 страницA Comparison Between Direct and Indirect Laser Sintering of MetalsYaswanth BhatrajuОценок пока нет

- DPR - RPT by EDMДокумент11 страницDPR - RPT by EDMswapnil pandeОценок пока нет

- Mould Cooling SystemДокумент15 страницMould Cooling SystemIqbal FauziОценок пока нет

- Ultrasonic Inspection of Pipeline Split-TeesДокумент8 страницUltrasonic Inspection of Pipeline Split-TeesEhab SaadОценок пока нет

- Design and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesОт EverandDesign and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesОценок пока нет

- CoCr MP1 M270 Material Data SheetДокумент6 страницCoCr MP1 M270 Material Data Sheetgpiprototype.comОценок пока нет

- SS-PH1-M270 Material Data SheetДокумент5 страницSS-PH1-M270 Material Data Sheetgpiprototype.comОценок пока нет

- Ma Raging Steel MS1 Material Data SheetДокумент4 страницыMa Raging Steel MS1 Material Data Sheetgpiprototype.comОценок пока нет

- M Materials enДокумент58 страницM Materials engpiprototype.comОценок пока нет

- GPI Prototype TrifoldДокумент2 страницыGPI Prototype Trifoldgpiprototype.comОценок пока нет

- E500V 3D Printer LetterДокумент2 страницыE500V 3D Printer Lettergpiprototype.comОценок пока нет

- DM20 M270 Material Data SheetДокумент4 страницыDM20 M270 Material Data Sheetgpiprototype.comОценок пока нет

- Rigid 84 Shore D Polyurethane Casting SystemДокумент2 страницыRigid 84 Shore D Polyurethane Casting Systemgpiprototype.comОценок пока нет

- Accesorios de Carga CROSBYДокумент52 страницыAccesorios de Carga CROSBYRodolfo AlboresОценок пока нет

- Lied Mann 2017Документ8 страницLied Mann 2017Chandra SekarОценок пока нет

- Nutrient Recovery From Wastewater Stream PDFДокумент10 страницNutrient Recovery From Wastewater Stream PDFPedro RipaceОценок пока нет

- Tappi Extrution Coating and LaminatingДокумент26 страницTappi Extrution Coating and LaminatingKhương HuỳnhОценок пока нет

- Chapter 6 Thermodynamics: The First Law: Systems, States, and Energy (Sections 6.1-6.8)Документ12 страницChapter 6 Thermodynamics: The First Law: Systems, States, and Energy (Sections 6.1-6.8)MostafaRock100% (2)

- B Pharma-1 PDFДокумент2 страницыB Pharma-1 PDFHIMANSHU YADAVОценок пока нет

- Boq 153501Документ28 страницBoq 153501kamakhyaguri pwdОценок пока нет

- Protein Sample Preparation & QuantificationДокумент19 страницProtein Sample Preparation & QuantificationKurdianto MSiОценок пока нет

- Analytical ChemistryДокумент79 страницAnalytical ChemistryDipeshBardoliaОценок пока нет

- The Calorific Value of A Fuel Is TheДокумент4 страницыThe Calorific Value of A Fuel Is TheRana PrathapОценок пока нет

- Principles of Soil Science Exercise Manual: Mark W. BowenДокумент70 страницPrinciples of Soil Science Exercise Manual: Mark W. BowenDominic ImperialeОценок пока нет

- Installation Manual For Bifacial PV M OduleДокумент20 страницInstallation Manual For Bifacial PV M OdulejosepablohgОценок пока нет

- Chapter 13 Oil Based MudsДокумент65 страницChapter 13 Oil Based Mudsمحمد أحمد عبداللطيفОценок пока нет

- Sika PDS E Intraplast ZДокумент2 страницыSika PDS E Intraplast Zlwin_oo2435100% (1)

- Chapter 13 - Normalization Tutorial: Branchno Branchaddress TelnosДокумент2 страницыChapter 13 - Normalization Tutorial: Branchno Branchaddress TelnosMoms Diva Diva DivaОценок пока нет

- Engineering Vol 56 1893-10-06Документ33 страницыEngineering Vol 56 1893-10-06ian_newОценок пока нет

- Arcelormittal Pressure VesselДокумент10 страницArcelormittal Pressure VesselkokopirokoОценок пока нет

- Iwcf NotesДокумент81 страницаIwcf NotesShraddhanand More100% (1)

- Nital EtchДокумент2 страницыNital EtchJohn GeddesОценок пока нет

- 1027 Application GuidelineДокумент6 страниц1027 Application GuidelineJORGEALEXERОценок пока нет

- Cambridge International Advanced Subsidiary and Advanced Level in Chemistry (9701)Документ18 страницCambridge International Advanced Subsidiary and Advanced Level in Chemistry (9701)GregОценок пока нет

- MDI Synonyms, Acronyms, and CAS Registry Numbers: November 2001, Diisocyanates PanelДокумент4 страницыMDI Synonyms, Acronyms, and CAS Registry Numbers: November 2001, Diisocyanates Panelnur34Оценок пока нет

- Group #4: September 25, 2019Документ5 страницGroup #4: September 25, 2019MIKAYLA ELAINE P. DELA CRUZОценок пока нет

- Hydrolysis Testing MethodsДокумент3 страницыHydrolysis Testing Methodsmdipu5_948971128Оценок пока нет

- Lecture Notes Materials and Ecological EngineeringДокумент463 страницыLecture Notes Materials and Ecological EngineeringInhake AutechreОценок пока нет

- Effects of Three Different Dietary Binders On Juvenile Sea CucumberДокумент8 страницEffects of Three Different Dietary Binders On Juvenile Sea CucumberEnrique MartinezОценок пока нет

- Environmental Permitting Guidance The Solvent Emissions DirectiveДокумент44 страницыEnvironmental Permitting Guidance The Solvent Emissions Directiveultimet1Оценок пока нет

- Aluminium Silicate - WikipediaДокумент2 страницыAluminium Silicate - Wikipediamovie hunterОценок пока нет

- Module 1Документ15 страницModule 1venugopal_aeroОценок пока нет

- Composite Materials: Cris Arnold Materials Research Centre J.c.arnold@swansea - Ac.ukДокумент30 страницComposite Materials: Cris Arnold Materials Research Centre J.c.arnold@swansea - Ac.ukMazin MohammedОценок пока нет