Академический Документы

Профессиональный Документы

Культура Документы

Asme PCC

Загружено:

ajaysharma_1009Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Asme PCC

Загружено:

ajaysharma_1009Авторское право:

Доступные форматы

ASME PCC-2 Repair of Pressure Equipment and Piping

1. Butt-Welded Insert Plates in Pressure Components

DESCRIPTION The repair of pressure components by butt-welded insert plates involves the replacement of pressure boundary material in a pressure component with an insert plate attached by full penetration butt welds.

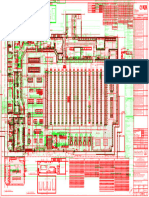

DESIGN Insert plates and welds should be of the same material as the existing pressure component, or of another material that has at least equal notch toughness and allowable stress, Rectangular and square insert plates shall have corners rounded to a radius 13 mm (12 in.) thick up to 25 mm (1 in.) 75 mm (3 in.) or a larger. Over 25 mm (1 in.) thick 150 mm (6 in.) or a larger. Less than 13 mm (12 in.) thick may have smaller corner radii. (Normally 1 inch or greater) Minimum Size of Insert Plates. ( non-postweld heat-treated). lesser of 12t or 380 mm (15 in.) (where t is the thickness of the parent material). Flush Insert Plate (With or Without Nozzle/Manway) With Its Butt Weld Intersecting Existing Butt Weld in Shells or Heads NOTES: (1) Existing butt weld in vessel shell or head. (Fig. 2 shows butt weld in a cylindrical shell.) (2) Thirty deg minimum angle.

(3) Full RT or UT, or MT or PT both sides of existing butt weld, 100 mm (4 in.) min. each side of intersection with insert plate. (4) Insert plate butt weld. Full RT or UT, or MT or PT both sides of weld. (5) For nonpostweld heat-treated carbon and low alloy steel nozzle/manway assemblies, 150 mm (6 in.) minimum between the toe of the nozzle fillet weld and the nearest edge of the insert plate butt weld (see para. 3.8).

Intersecting "Doghouse" Type Insert Plate Butt Weld (With or Without Nozzle/Manway) With Shell Butt Weld in Vessel Shells and Heads NOTES: (1) Existing butt weld in vessel shell or head. (Fig. 3 shows butt weld in a cylindrical shell.) (2) Length of cut in shell butt weld, 150 mm (6 in.) minimum on each side of intersecting insert plate butt weld. (3) Insert plate butt weld. (4) Cut existing shell butt weld to 150 mm (6 in.) minimum on each side of intersecting insert plate butt weld and bevel edges (or arc gouge edges) to the desired edge bevels. Reweld after completion of insert plate butt weld. Full RT or UT, or MT or PT both sides of new weld. (5) For nonpostweld heat-treated carbon and low alloy steel nozzle/manway assemblies, 150 mm (6 in.) minimum between the toe of the nozzle fillet weld and the nearest edge of the insert plate butt weld (see para. 3.8).

FABRICATION One-Sided Welds. For flush inserts in pipe or tube or other pressure components that do not allow two-sidedwelding, gas tungsten arcwelding, or another welding process that provides an acceptable weld on the opposite side should be used for the initial pass joining the insert to the pipe wall.

Weld Spacing Between Nonintersecting Adjacent Butt Welds in Carbon Steel and Low Alloy Steel Pressure Components 4.3.1 Minimum Spacing Between Non-Postweld Heat-Treated Butt Welds. Non-postweld heat-treated butt welds around the periphery of insert plates shall be spaced no closer to existing non-postweld heattreated butt welds or reinforcing plate attachment welds than (a) for tw 13 mm (12 in.), 150 mm (6 in.) (b) for tw > 13 mm (12 in.), the greater of 250 mm (10 in.) and 8tw where tw p thickness of the thicker of the two adjacent butt welds, mm (in.) 4.3.2 Alternative Spacing Between Non-Postweld Heat-Treated ButtWelds. The spacing between adjacent non-postweld heat-treated carbon and low alloy steel

butt welds may be reduced to the lesser of 8tw or 200mm (8 in.) for tw 40 mm (112 in.), provided both butt welds are ground smooth, 100% RT or UT examined and 100% MT or PT examined after completion of welding in areas where the spacing between the adjacent butt welds is less than that specified in para. 4.3.1. As an alternative, the root pass and the weld, after half of the groove is filled, may be either 100% MT or PT examined in place of the 100% RT or UT examination requirement above. The butt welds with thicknesses less than 13 mm (12 in.) need only be MT or PT examined. See para. 5.1. 4.3.3 Spacing Betwen Stress-Relieved Butt Welds. The spacing between the adjacent butt welds shall be not less than 2tw if the first butt weld has been

EXAMINATION OF WELDS 5.1 Insert Plate Welds All insert plate welds to the existing pressure component in pressure vessels shall be examined by radiographic (RT) or ultrasonic (UT) examination methods to the extent required by the applicable code of construction or post-construction code for the pressure component. Where UT is used, examination of the root pass by either magnetic particle (MT) or liquid-penetrant (PT) methods is recommended. The procedures, personnel qualifications, and acceptance criteria shall be in accordance with the applicable code of construction or the

applicable post-construction code. 5.2 Finished Welded Surfaces Unless 100% RT or UT examination is required, all finished welded surfaces shall be examined by magnetic particle (MT) or liquid-penetrant (PT) methods. Examination by the MT or PT methods is recommended for the root pass of single-groove welds and for the backgouge of double-groove welds. No crack-like indications, incomplete fusion, or incomplete penetration are permissible. Additional Examination Requirements for Carbon and Low Alloy Steels 5.4.1 Rectangular and Square Insert Plates. For rectangular or square insert plates, the welds around the rounded corners, as a minimum, shall be either spot RT or UT examined. As an alternative, the root pass, the weld after half of the groove is filled, and the completed weld shall be either MT or PT examined. 5.4.2 Closely Spaced and Intersecting Welds. See paras. 4.3 and 4.4 for additional examination requirements for closely spaced welds and intersecting welds.

5.4.1 Rectangular and Square Insert Plates. For rectangular or square insert plates, the welds around the rounded corners, as a minimum, shall be either spot RT or UT examined. As an alternative, the root pass, the weld after half of the groove is filled, and the completed

weld shall be either MT or PT examined. 5.4.2 Closely Spaced and Intersecting Welds. See paras. 4.3 and 4.4 for additional examination requirements for closely spaced welds and intersecting welds.

Вам также может понравиться

- API 570 Open BookДокумент9 страницAPI 570 Open BookMusa ÇelikОценок пока нет

- API 570 - Asme B31.3 Q&AДокумент29 страницAPI 570 - Asme B31.3 Q&AShaalan Ali100% (1)

- API 570 - Close Book Mockup Exam FinalДокумент19 страницAPI 570 - Close Book Mockup Exam Finaljasminnee80% (10)

- API 570 - CL Book 111122112010 R0... Mockup 3Документ18 страницAPI 570 - CL Book 111122112010 R0... Mockup 3patvinderОценок пока нет

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationДокумент8 страницAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinОценок пока нет

- 510 Open Exam B. Rev7Документ15 страниц510 Open Exam B. Rev7yrdna nawaiteosОценок пока нет

- API 570 ExamДокумент33 страницыAPI 570 ExammedhichemguesmiОценок пока нет

- API 570 - Close Book Mockup Exam FinalДокумент19 страницAPI 570 - Close Book Mockup Exam FinalHajarath AliОценок пока нет

- API 570 Final Exam Open Book Questions 24Документ11 страницAPI 570 Final Exam Open Book Questions 24Ravindra S. Jivani100% (5)

- BAY.t-510 Open Prac Exam #3Документ14 страницBAY.t-510 Open Prac Exam #3Karim MamdouhОценок пока нет

- Api 510 Q&a-2Документ32 страницыApi 510 Q&a-2Mohammed ShakilОценок пока нет

- API 570 - Mockup CB - Paper 2Документ16 страницAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- A) 1.7 To 4.0 B) 2.55 To 3.9 C) 2.0 To 4.0 D) None of TheseДокумент17 страницA) 1.7 To 4.0 B) 2.55 To 3.9 C) 2.0 To 4.0 D) None of TheseAshish Patel100% (1)

- 11.API 574 Practive QnsДокумент6 страниц11.API 574 Practive QnsvamsikrishnaОценок пока нет

- API 570 Daily ExamДокумент3 страницыAPI 570 Daily Examalouis100% (1)

- The Location Markers Required by ASME V Are Required To Appear As Radiographic ImagesДокумент6 страницThe Location Markers Required by ASME V Are Required To Appear As Radiographic ImagesSadiq KhattakОценок пока нет

- 1 API 653 Memories March 2014 ExamДокумент16 страниц1 API 653 Memories March 2014 ExammajidОценок пока нет

- Code Sec.: PD C Se P Y C D Set Xcrxyrs C DДокумент1 страницаCode Sec.: PD C Se P Y C D Set Xcrxyrs C DsubhaОценок пока нет

- 15 API 570 - Open Book Mockup Exam FinalДокумент12 страниц15 API 570 - Open Book Mockup Exam FinalMichael Albuquerque100% (1)

- API 510 Certification Exam Study Plan PDFДокумент3 страницыAPI 510 Certification Exam Study Plan PDFJayeshОценок пока нет

- API 572 Study Guide: Practice QuestionsДокумент10 страницAPI 572 Study Guide: Practice QuestionsRizwan Nazir100% (1)

- Closed Book Api 572-A (55-65) - 2Документ11 страницClosed Book Api 572-A (55-65) - 2slxanto100% (1)

- API 510 Petrosync Course PDFДокумент301 страницаAPI 510 Petrosync Course PDFAkramKassis100% (1)

- API 510 QUIZ No.4Документ5 страницAPI 510 QUIZ No.4Hatem RagabОценок пока нет

- API 510 Section 8 QuizДокумент17 страницAPI 510 Section 8 Quizamalhaj2013Оценок пока нет

- Centre To Centre Tolerance For BoltingДокумент50 страницCentre To Centre Tolerance For BoltingSm JawedОценок пока нет

- API 570 - Daily Exam 5C API-571-577 Questions - PSJДокумент4 страницыAPI 570 - Daily Exam 5C API-571-577 Questions - PSJKrishna Moorthy50% (2)

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsДокумент6 страницAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiОценок пока нет

- 177538089-API-570-Final-Exam-Questions - REALIZARДокумент26 страниц177538089-API-570-Final-Exam-Questions - REALIZARALe Infinito100% (1)

- API 510 Case Study - 7Документ2 страницыAPI 510 Case Study - 7Khaled FatnassiОценок пока нет

- API 570 Questions 13Документ4 страницыAPI 570 Questions 13Ravindra S. JivaniОценок пока нет

- Api 570 Quiz-2Документ34 страницыApi 570 Quiz-2jacquesmayol0% (1)

- API-570 SAMPLE Closed Book ExamДокумент12 страницAPI-570 SAMPLE Closed Book ExamuttamОценок пока нет

- Pressure Vessel Dimension InspectionДокумент3 страницыPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- Asme Questions and Answers Part - IiДокумент6 страницAsme Questions and Answers Part - IiAshwani Dogra100% (1)

- Flange Surface Inspection CriteriaДокумент1 страницаFlange Surface Inspection CriteriaOscarОценок пока нет

- API 578 Mock QuestionДокумент4 страницыAPI 578 Mock QuestionsheikmoinОценок пока нет

- API 570 Exam 574 QuizДокумент3 страницыAPI 570 Exam 574 Quizessnelson100% (2)

- API 510 Data Sheets - QuizletДокумент1 страницаAPI 510 Data Sheets - Quizletads_1203Оценок пока нет

- 02 API 570 Points To RecallДокумент6 страниц02 API 570 Points To RecallMohammedBujairОценок пока нет

- API 653 - Section 650 Flash Card - 36 QuestionsДокумент5 страницAPI 653 - Section 650 Flash Card - 36 QuestionsdanielbellaОценок пока нет

- API RP 572 QuizДокумент17 страницAPI RP 572 Quizamalhaj2013Оценок пока нет

- Practice Questions For API RP 577Документ10 страницPractice Questions For API RP 577vamsikrishnaОценок пока нет

- 13) Api 510 Day 5Документ50 страниц13) Api 510 Day 5hamed100% (1)

- Pages From API 570 All Closed BookДокумент18 страницPages From API 570 All Closed Bookkumar50% (2)

- API 510.jan 2022open ClosedДокумент3 страницыAPI 510.jan 2022open ClosedChiheb KaanicheОценок пока нет

- API 653 Examination Sample ItemsДокумент3 страницыAPI 653 Examination Sample ItemsAbdelhakim MaghnoujОценок пока нет

- Casti CourseДокумент43 страницыCasti CoursekazumiyutoriОценок пока нет

- Final Examination #1: Open Book Questions (1 50)Документ29 страницFinal Examination #1: Open Book Questions (1 50)kiho sung100% (1)

- API 510 TestДокумент3 страницыAPI 510 Testshabbir626Оценок пока нет

- Module 5-AДокумент9 страницModule 5-Adash1991Оценок пока нет

- Shear Load CalculationДокумент8 страницShear Load Calculationvinny1978Оценок пока нет

- ChecklistДокумент61 страницаChecklistjhunkujha11Оценок пока нет

- 510 y Asme PCC-2 Insert PlatesДокумент3 страницы510 y Asme PCC-2 Insert PlatesJuan Jose Espinoza BarandiaranОценок пока нет

- Types - Elstomeric BearingsДокумент4 страницыTypes - Elstomeric BearingsdsanandaОценок пока нет

- PipelineДокумент3 страницыPipelineKrystle FlowersОценок пока нет

- Standard HFRW PDFДокумент3 страницыStandard HFRW PDFGuidoColomboОценок пока нет

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionДокумент12 страницSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717Оценок пока нет

- Metallurgy For Non Metallurgist - Module-1Документ61 страницаMetallurgy For Non Metallurgist - Module-1ajaysharma_1009Оценок пока нет

- Sample Question Bank - MetallurgyДокумент4 страницыSample Question Bank - Metallurgyajaysharma_1009Оценок пока нет

- Metallurgy For Non Metallurgist - Module-2Документ65 страницMetallurgy For Non Metallurgist - Module-2ajaysharma_1009Оценок пока нет

- Technical HandbookДокумент44 страницыTechnical Handbookajaysharma_1009Оценок пока нет

- Technical HandbookДокумент44 страницыTechnical Handbookajaysharma_1009Оценок пока нет

- Dec 2021 - 936 - BOK - FinalДокумент3 страницыDec 2021 - 936 - BOK - FinalKumarОценок пока нет

- GENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFДокумент43 страницыGENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFhasib_07Оценок пока нет

- Shaft Analsis Using AnsysДокумент118 страницShaft Analsis Using AnsysDaniel WoldemichealОценок пока нет

- Bro CBV 04 13Документ24 страницыBro CBV 04 13ajaysharma_1009Оценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- RBI-Ramesh J PatelДокумент7 страницRBI-Ramesh J PatelAid Farhan MaarofОценок пока нет

- RBI-Ramesh J PatelДокумент7 страницRBI-Ramesh J PatelAid Farhan MaarofОценок пока нет

- Classes of FireДокумент12 страницClasses of Fireajaysharma_1009Оценок пока нет

- Selection of Material Nace - H2S - Technical Paper PDFДокумент21 страницаSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009Оценок пока нет

- Z 711 (P) Quiksteel FSL Epoxy PuttyДокумент4 страницыZ 711 (P) Quiksteel FSL Epoxy Puttydhanasekaran19731945Оценок пока нет

- Mil STD 721cДокумент18 страницMil STD 721cajaysharma_1009Оценок пока нет

- Orifice Plate Flow MetersДокумент8 страницOrifice Plate Flow MetersGaurav Dhiman100% (1)

- Evaluations of Check ValvesДокумент12 страницEvaluations of Check Valvesajaysharma_1009Оценок пока нет

- Mil STD 721cДокумент18 страницMil STD 721cajaysharma_1009Оценок пока нет

- Paper 3 Acid Dew Point Corrosion in HRSGsДокумент83 страницыPaper 3 Acid Dew Point Corrosion in HRSGsajaysharma_1009Оценок пока нет

- LUBE OIL COOLER Brass Tube Failure - Technical PaperДокумент8 страницLUBE OIL COOLER Brass Tube Failure - Technical Paperajaysharma_1009Оценок пока нет

- EIL PipingДокумент748 страницEIL Pipingajaysharma_100983% (6)

- Acid Dew Point Calculation SpreadsheetДокумент2 страницыAcid Dew Point Calculation Spreadsheetunknown8787100% (1)

- Paper 3 Acid Dew Point Corrosion in HRSGsДокумент83 страницыPaper 3 Acid Dew Point Corrosion in HRSGsajaysharma_1009Оценок пока нет

- 10 Low and High Cycle FatigueДокумент14 страниц10 Low and High Cycle FatiguePRASAD326100% (1)

- Novaphit Professional Technolgy eДокумент8 страницNovaphit Professional Technolgy eajaysharma_1009Оценок пока нет

- BlowerДокумент32 страницыBlowerajaysharma_1009Оценок пока нет

- Understanding BlowersДокумент11 страницUnderstanding BlowersJam BabОценок пока нет

- Final Quiz - Asme Pcc-2Документ15 страницFinal Quiz - Asme Pcc-2ajaysharma_100975% (4)

- 5 Ways To Foster A Global Mindset in Your CompanyДокумент5 страниц5 Ways To Foster A Global Mindset in Your CompanyGurmeet Singh KapoorОценок пока нет

- Auditing Principles and Practices-IДокумент8 страницAuditing Principles and Practices-IMoti BekeleОценок пока нет

- Less Homework More TroubleДокумент7 страницLess Homework More Troubleg697a0mw100% (1)

- Role of Communication at Mahabharatha WarДокумент19 страницRole of Communication at Mahabharatha WarAmit Kalita50% (2)

- Chemical & Ionic Equilibrium Question PaperДокумент7 страницChemical & Ionic Equilibrium Question PapermisostudyОценок пока нет

- Ethical Hacking IdДокумент24 страницыEthical Hacking IdSilvester Dian Handy PermanaОценок пока нет

- Corelink Mmu600ae TRM 101412 0100 00 enДокумент194 страницыCorelink Mmu600ae TRM 101412 0100 00 enLv DanielОценок пока нет

- Chapter 5 - Principle of Marketing UpdateДокумент58 страницChapter 5 - Principle of Marketing UpdateKhaing HtooОценок пока нет

- Extraction of Mangiferin From Mangifera Indica L. LeavesДокумент7 страницExtraction of Mangiferin From Mangifera Indica L. LeavesDaniel BartoloОценок пока нет

- Employee of The Month.Документ2 страницыEmployee of The Month.munyekiОценок пока нет

- Gobekli TepeДокумент2 страницыGobekli TepeCarl Feagans100% (1)

- City Limits Magazine, December 1981 IssueДокумент28 страницCity Limits Magazine, December 1981 IssueCity Limits (New York)Оценок пока нет

- French Cuisine RecipeДокумент6 страницFrench Cuisine RecipeJimmy AchasОценок пока нет

- Chapter 30 - HypertensionДокумент70 страницChapter 30 - HypertensionSakaC.TanayaОценок пока нет

- QAU TTS Form Annual AssessmentДокумент6 страницQAU TTS Form Annual AssessmentsohaibtarikОценок пока нет

- Pogon Lifta MRL PDFДокумент128 страницPogon Lifta MRL PDFMašinsko ProjektovanjeОценок пока нет

- Fertilisation and PregnancyДокумент24 страницыFertilisation and PregnancyLopak TikeОценок пока нет

- Lab Science of Materis ReportДокумент22 страницыLab Science of Materis ReportKarl ToddОценок пока нет

- 02 CT311 Site WorksДокумент26 страниц02 CT311 Site Worksshaweeeng 101Оценок пока нет

- You Can't Blame A FireДокумент8 страницYou Can't Blame A FireMontana QuarterlyОценок пока нет

- Overlay Control PlansДокумент1 страницаOverlay Control PlansSTS-SPARK GAMINGОценок пока нет

- Eje Delantero Fxl14 (1) .6Документ2 страницыEje Delantero Fxl14 (1) .6Lenny VirgoОценок пока нет

- FluteДокумент13 страницFlutefisher3910% (1)

- Affidavit of Co OwnershipДокумент2 страницыAffidavit of Co OwnershipEmer MartinОценок пока нет

- 2010 Information ExchangeДокумент15 страниц2010 Information ExchangeAnastasia RotareanuОценок пока нет

- The DIRKS Methodology: A User GuideДокумент285 страницThe DIRKS Methodology: A User GuideJesus Frontera100% (2)

- OsciloscopioДокумент103 страницыOsciloscopioFredy Alberto Gómez AlcázarОценок пока нет

- Standard BMW PDFДокумент19 страницStandard BMW PDFIna IoanaОценок пока нет

- Equilibrium of A Rigid BodyДокумент30 страницEquilibrium of A Rigid BodyChristine Torrepenida RasimoОценок пока нет

- Department of Education: Raiseplus Weekly Plan For Blended LearningДокумент3 страницыDepartment of Education: Raiseplus Weekly Plan For Blended LearningMARILYN CONSIGNAОценок пока нет