Академический Документы

Профессиональный Документы

Культура Документы

Check Sheet For In-Situ Reinforced Concrete For Suspended Slab-F08

Загружено:

zawadimranИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Check Sheet For In-Situ Reinforced Concrete For Suspended Slab-F08

Загружено:

zawadimranАвторское право:

Доступные форматы

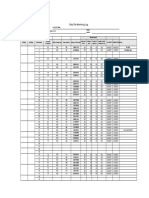

AL HABTOOR ENGINEERING ENTERPRISES CO. (L.L.C.

)

PROJECT : JUMEIRAH BEACH RESIDENCE - JBR 04 CHECK SHEET FOR IN-SITU REINFORCED CONCRETE SHEET No. SITE NO.: 583

SUBCONTRACTOR: SECTION OF Stage FORMWORK (Before Concreting)

H.E.E. LOCATION Item 1 Check falsework design and issue permit to load 2 Check quality of shutter lining for required finish 3 Check formwork ereceted and restrained as per approved drawings Checked Checked by by HEE QC E F GF E F F F E/MEP F E F F P.E./E.R. L F L E F P.E./E.R. F F Date

4 Check dimensions, line and level 5 Check preparation of forms inc. support, tie rods, release agents, cleanliness

6 Check plumbness and spacing props. 7 Check tightness of bolts and wedges 8 Check special built-in items, inserts, mechanical, electrical & plumbing embedments

9 Check stop-ends, waterbar, dowels, flexcell, etc. REINFORCEMENT 10 Check bar placement as per approved bar bending schedule

11 Check tie wires, spacers, cover 12 Clean out loose material (tie-wires, nails etc.) APPROVAL TO POUR PLACING CONCRETE 13 Check correct mix, slump, temp. 14 Check correct placing, compaction, grout loss control

15 Take concrete test cubes and log 16 Recheck line and level 17 Protection against weather condition APPROVAL TO STRIKE STRIKING FORMWORK 18 Check surface for blemishes 19 Check cleanliness of forms after striking

E-ENGINEER, F-FOREMAN, GF-GENERAL FOREMAN, MEP-MEP COORDINATOR, ER-ENGINEER'S REPRESENTATIVE, LLABORATORY TECHNICIAN

c:\mnj\222647875.xlsx.ms_office.xls

Appendix CONC/04/A February 1995

CO. (L.L.C.)

SITE NO.: 583 SHEET No.

Checked by A&BT

Date

GINEER'S REPRESENTATIVE, L-

c:\mnj\222647875.xlsx.ms_office.xls

AL HABTOOR ENGINEERING ENTERPRISES CO. (L.L.C.)

PROJECT : JUMEIRAH BEACH RESIDENCE - JBR 04 CHECK SHEET FOR IN-SITU REINFORCED CONCRETE SHEET No. SITE NO.: 583

SUBCONTRACTOR: SECTION OF Stage FORMWORK (Before Concreting)

H.E.E. LOCATION Item 1 Check falsework design and issue permit to load 2 Check quality of shutter lining for required finish 3 Check formwork ereceted and restrained as per approved drawings Checked Checked by by HEE QC E F GF E F F F E/MEP F E F F P.E./E.R. L F L E F P.E./E.R. F F Date

4 Check dimensions, line and level 5 Check preparation of forms inc. support, tie rods, release agents, cleanliness

6 Check plumbness and spacing props. 7 Check tightness of bolts and wedges 8 Check special built-in items, inserts, mechanical, electrical & plumbing embedments

9 Check stop-ends, waterbar, dowels, flexcell, etc. REINFORCEMENT 10 Check bar placement as per approved bar bending schedule

11 Check tie wires, spacers, cover 12 Clean out loose material (tie-wires, nails etc.) APPROVAL TO POUR PLACING CONCRETE 13 Check correct mix, slump, temp. 14 Check correct placing, compaction, grout loss control

15 Take concrete test cubes and log 16 Recheck line and level 17 Protection against weather condition APPROVAL TO STRIKE STRIKING FORMWORK 18 Check surface for blemishes 19 Check cleanliness of forms after striking

E-ENGINEER, F-FOREMAN, GF-GENERAL FOREMAN, MEP-MEP COORDINATOR, ER-ENGINEER'S REPRESENTATIVE, LLABORATORY TECHNICIAN

c:\mnj\222647875.xlsx.ms_office.xls

Appendix CONC/04/A July 2004

CO. (L.L.C.)

SITE NO.: 583 SHEET No.

Checked by A&BT

Date

GINEER'S REPRESENTATIVE, L-

c:\mnj\222647875.xlsx.ms_office.xls

QC/STR/1-583 Rev.01(Sept.2004)

AL HABTOOR ENGINEERING ENTERPRISES CO. (L.L.C.)

PROJECT : JUMEIRAH BEACH RESIDENCE - JBR 04 CHECK SHEET FOR IN-SITU REINFORCED CONCRETE SHEET No. SITE NO.: 583

SUBCONTRACTOR: SECTION OF Stage FORMWORK (Before Concreting)

H.E.E. LOCATION Item 1 Check falsework design and issue permit to load 2 Check quality of shutter lining for required finish 3 Check formwork ereceted and restrained as per approved drawings Checked by HEE E F GF E F F F E/MEP F E F F E/CR L F L E F E/CR F F Date Checked by A&BT Date

4 Check dimensions, line and level 5 Check preparation of forms inc. support, tie rods, release agents, cleanliness

6 Check plumbness and spacing props. 7 Check tightness of bolts and wedges 8 Check special built-in items, inserts, mechanical, electrical & plumbing embedments

9 Check stop-ends, waterbar, dowels, flexcell, etc. REINFORCEMENT 10 Check bar placement as per approved bar bending schedule

11 Check tie wires, spacers, cover 12 Clean out loose material (tie-wires, nails etc.) APPROVAL TO POUR PLACING CONCRETE 13 Check correct mix, slump, temp. 14 Check correct placing, compaction, grout loss control

15 Take concrete test cubes and log 16 Recheck line and level 17 Protection against weather condition APPROVAL TO STRIKE STRIKING FORMWORK 18 Check surface for blemishes 19 Check cleanliness of forms after striking

E-ENGINEER, F-FOREMAN, GF-GENERAL FOREMAN, MEP-MEP COORDINATOR, CR-CONSULTANT'S REPRESENTATIVE, L-LABORATORY TECHNICIAN

c:\mnj\222647875.xlsx.ms_office.xls

A-Z ENGINEERING & MANAGEMENT SERVICES

PROJECT : SAADIYAT ST. REGIS BEACH RESORT

SITE NO.: HMR - 831 SHEET No.

CHECK SHEET FOR IN-SITU REINFORCED CONCRETE SUSPENDEED SLAB Related I.R. ref.

SECTION OF WORK

LOCATION

CHECKED BY SUBCONTRACTOR / DATE CHECKED BY HMR / DATE CHECKED BY CONSULTANT / DATE

Stage

Item

1. Check falsework design and issue permit to load. Check formwork erected and restrained as per approved drawings. Check construction joints to conform approved shop 3. drawing. 2. 4. Check dimensions, line and level. 5. Check quality of shutter lining for required finish. FORMWORK (Before Concreting) 6. Check preparation of shutters including support, tie rods, release agents, cleanliness.

SE/PE SE/PE SE/PE SUE/PE SE/PE SE/PE SE/PE SE/PE SE/PE MEP / BK Gulf SO/PE SE/PE SE/PE SE/PE SE/PE QCE

LAB. TECH. / QCE LAB. TECH.

SE/PE SE/PE SE/PE SE/PE SE/PE SE/PE SE/PE SE/PE SE/PE

MEP COORD.

7. Check verticality and spacing of props. 8. Check tightness of bolts and wedges. Check end stoppers, waterbars, hyrib, flexcell sheet etc. Check embedded items, inserts and mechanical, 10. electrical and plumbing provisions. 9. 11. Check adequacy of working flatforms. 1. Check bar placement as per approved bar bending schedule.

SO/PE SE/PE SE/PE SE/PE SE/PE QCE

LAB. TECH. / QCE LAB. TECH.

2. Check tie wires, chairs,spacers, cover REINFORCEMENT 3. Check stop-ends, waterbar, dowels, flexcell, etc. 4. Clean out loose material (tie-wires, nails etc.) APPROVAL TO POUR 1. Check concrete mix, temperature and slump. 2. Take concrete test cubes,and log / record. PLACING OF CONCRETE 3. Check proper placing, concrete compaction and grout loose control.

SE/PE SUE/PE SE/PE QCE SE/PE QCE

SE/PE SE/PE SE/PE QCE SE/PE QCE

4. Recheck line and level. 5. Provide protection against weather. APPROVAL TO STRIKE FORMWORK STRIKING OF FORMWORKS 1. Check concrete surface for blemishes. 2. Check cleanliness of forms after striking.

LAB TECH.-LABORATORY TECHNICIAN, SUE-SURVEY ENGINEER, SO-SAFETY OFFICER, SE-SITE ENGINEER, PEPROJECT ENGINEER, MEP COORD.-MEP COORDINATOR, QCE- QUALITY CONTROL ENGINEER

Doc. No.: HMR-831-C-QAC-009-F08

Rev. 01

Вам также может понравиться

- Final Year Project Chapter 2Документ7 страницFinal Year Project Chapter 2MohamadMuqhrisОценок пока нет

- Construction and Design of MultistoreyДокумент37 страницConstruction and Design of MultistoreyFawadОценок пока нет

- Lecture 3 - Soil InvestigationДокумент27 страницLecture 3 - Soil InvestigationLemiОценок пока нет

- Flyover FormworkДокумент13 страницFlyover FormworkvrushankshahОценок пока нет

- Concrete Mix Design FormДокумент1 страницаConcrete Mix Design FormLAYLA SALIKIN CHE ROSMINОценок пока нет

- Mitigating The Effect of Clay Content of Sand On Concrete StrengthДокумент7 страницMitigating The Effect of Clay Content of Sand On Concrete Strengthbpkndl7943Оценок пока нет

- Revised BOQ 24.02.2020 Unique RehabДокумент25 страницRevised BOQ 24.02.2020 Unique RehabSandeep MauryaОценок пока нет

- S/N Requirements Compliance Reason If No Yes No Concrete, Reinforcement and Concrete CoverДокумент3 страницыS/N Requirements Compliance Reason If No Yes No Concrete, Reinforcement and Concrete Coverakash.jainОценок пока нет

- Failure of Pile Foundation & RemediesДокумент4 страницыFailure of Pile Foundation & RemediesJustin MusopoleОценок пока нет

- Caisson Piles Design & ConstructionДокумент57 страницCaisson Piles Design & ConstructionWan50% (2)

- DWall, Capping Beam and Skin Wall Details-Ss PDFДокумент1 страницаDWall, Capping Beam and Skin Wall Details-Ss PDFSanjay Boss100% (1)

- 2 Interpretation SBT Full ColourДокумент36 страниц2 Interpretation SBT Full ColourNaveen SharmaОценок пока нет

- Analysis of Geopolymer Concrete ColumnsДокумент10 страницAnalysis of Geopolymer Concrete ColumnsRodick AndyОценок пока нет

- Cement BaobabДокумент1 страницаCement BaobabYogesh GoburdhunОценок пока нет

- ZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkДокумент1 страницаZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkASAALE GLORIAОценок пока нет

- Application of Braced and Unbraced Frame in Reinforced Concrete StructureДокумент2 страницыApplication of Braced and Unbraced Frame in Reinforced Concrete StructureNazmi DhiyauddinОценок пока нет

- MOS Trial Trench WorkДокумент20 страницMOS Trial Trench Workg.chandra mohanОценок пока нет

- Earthquake Analysis and DesignДокумент11 страницEarthquake Analysis and DesignSharon Shine100% (1)

- Course Syllabus Second Semester FubkДокумент6 страницCourse Syllabus Second Semester FubkAliyu Shehu0% (1)

- 6 Defects in Brickwork Due To Poor WorkmanshipДокумент7 страниц6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- 345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Документ1 страница345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Satya kaliprasad vangaraОценок пока нет

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesДокумент4 страницыPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesRuemu Godwin InikoriОценок пока нет

- RC Hood Details (A) 20181220Документ1 страницаRC Hood Details (A) 20181220Siti Haja's100% (1)

- Specification For Pile EmbankmentДокумент5 страницSpecification For Pile EmbankmentamirriyyahОценок пока нет

- Working of MivanДокумент5 страницWorking of MivanAnuja JadhavОценок пока нет

- 21.stone Pitching & Boundary FenceДокумент1 страница21.stone Pitching & Boundary FenceMian M KhurramОценок пока нет

- Homework #10: Displacement Method of Analysis of Beams and FramesДокумент2 страницыHomework #10: Displacement Method of Analysis of Beams and FrameslkanthkakarlaОценок пока нет

- Verification Manual British CodesДокумент32 страницыVerification Manual British CodeshutuguoОценок пока нет

- Concrete Mix Design Different Grades of ConcreteДокумент1 страницаConcrete Mix Design Different Grades of ConcreteHarshwardhan ShuklaОценок пока нет

- Rheofinish 288FU PDSДокумент2 страницыRheofinish 288FU PDSpn0% (1)

- Characterization and Viability of Clay Soils From Metro Manila As Lanfill Liners - Acebedo, PerdonДокумент5 страницCharacterization and Viability of Clay Soils From Metro Manila As Lanfill Liners - Acebedo, PerdonRalph100% (2)

- Driven Cast in Situ PilesДокумент17 страницDriven Cast in Situ PilesSonu KumawatОценок пока нет

- Smartdek 51Документ12 страницSmartdek 51Fairly InsurgentОценок пока нет

- Crack Width Check BS5400 4Документ5 страницCrack Width Check BS5400 4saravanan4286100% (1)

- BS8110 Span-Depth Ratios PDFДокумент1 страницаBS8110 Span-Depth Ratios PDFRezart PogaceОценок пока нет

- Perimeter WallДокумент1 страницаPerimeter WallBenson Mwathi MungaiОценок пока нет

- D.O. 126, S 2017Документ6 страницD.O. 126, S 2017ZA TarraОценок пока нет

- Nominal Mix Concrete Material CalculationДокумент5 страницNominal Mix Concrete Material CalculationMuhammadIqbalMughalОценок пока нет

- Crack Width by Bs8110Документ2 страницыCrack Width by Bs8110Mohammed100% (1)

- Composite Slab Report For GIS AreaДокумент7 страницComposite Slab Report For GIS AreaMINОценок пока нет

- Core Drilling ProcedureДокумент7 страницCore Drilling ProcedureEngineeri TadiyosОценок пока нет

- Presentation of Our ProductsДокумент18 страницPresentation of Our ProductsBharath Reddy ChinthiReddyОценок пока нет

- Useful Guidelines For Design of RCC Slab Basic Rules For Slab DesignДокумент7 страницUseful Guidelines For Design of RCC Slab Basic Rules For Slab DesignUsman Shahid100% (1)

- Micro Bore Pile Method StatementДокумент8 страницMicro Bore Pile Method Statementnirmal100% (1)

- DCP Manual K100 Models OCT2007Документ36 страницDCP Manual K100 Models OCT2007arypauloОценок пока нет

- Design A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchДокумент1 страницаDesign A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchamitОценок пока нет

- Tunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationДокумент14 страницTunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationfreezefreezeОценок пока нет

- Design of Isolated Footing With Vertical Load Only - According To ACI 318M-99Документ1 страницаDesign of Isolated Footing With Vertical Load Only - According To ACI 318M-99mahmoud IbrahemОценок пока нет

- BB FormworkДокумент66 страницBB Formworkshingkeong100% (1)

- Daily Pile Monitoring Log: Pile Grid ID '' ReinforcementДокумент2 страницыDaily Pile Monitoring Log: Pile Grid ID '' ReinforcementKarl ToddОценок пока нет

- Column Base Design: Default Single Column Example: Working Load Stability ChecksДокумент4 страницыColumn Base Design: Default Single Column Example: Working Load Stability Checkssoly2k12Оценок пока нет

- Minimum Steel Reinforcement in Concrete and Clear Cover RequirementsДокумент3 страницыMinimum Steel Reinforcement in Concrete and Clear Cover RequirementsMuhammadIqbalMughalОценок пока нет

- State DSR 2019-20 PDFДокумент193 страницыState DSR 2019-20 PDFManoj MasutageОценок пока нет

- Work Schedule - FormatДокумент28 страницWork Schedule - FormatZia KhanОценок пока нет

- Project PDFДокумент36 страницProject PDFMable MathewОценок пока нет

- Causes of Deterioration of StructuresДокумент5 страницCauses of Deterioration of StructuresDhruv PatelОценок пока нет

- Diaphragm/slurry Wall SpecificationДокумент27 страницDiaphragm/slurry Wall SpecificationRoy PersonalОценок пока нет

- BOQ Boundary WallДокумент4 страницыBOQ Boundary WallVishal ShrivastavaОценок пока нет

- Beam Column ConnectionДокумент10 страницBeam Column Connectionmaniram7Оценок пока нет

- Productivity RatesДокумент16 страницProductivity Rateszawadimran33% (3)

- Policy StatementДокумент1 страницаPolicy StatementzawadimranОценок пока нет

- Selection of Candidates For The Post of Chief of PartyДокумент6 страницSelection of Candidates For The Post of Chief of PartyzawadimranОценок пока нет

- A-Z Engineering & Management Services: Check Sheet For BlockworksДокумент1 страницаA-Z Engineering & Management Services: Check Sheet For BlockworkszawadimranОценок пока нет

- PlasterДокумент2 страницыPlasterzawadimranОценок пока нет

- Senior Quantity SurveyorДокумент1 страницаSenior Quantity SurveyorzawadimranОценок пока нет

- Anees Ahmad: Career ObjectiveДокумент5 страницAnees Ahmad: Career ObjectivezawadimranОценок пока нет

- Checklist For BrickworkДокумент1 страницаChecklist For BrickworkzawadimranОценок пока нет

- A Full-Day Conference (09:00-18:00 HRS) Date: May 15, 2014 Location: Dubai, UAE Venue: JW Marriott Dubai Address: Abu Baker Al Siddique Road, Hamarain Centre, DeiraДокумент6 страницA Full-Day Conference (09:00-18:00 HRS) Date: May 15, 2014 Location: Dubai, UAE Venue: JW Marriott Dubai Address: Abu Baker Al Siddique Road, Hamarain Centre, DeirazawadimranОценок пока нет

- Checksheet For Concrete Screed Toppings-F05Документ1 страницаChecksheet For Concrete Screed Toppings-F05zawadimranОценок пока нет

- Site Clearance and DemolitionДокумент1 страницаSite Clearance and Demolitionzawadimran100% (1)

- DewateringДокумент2 страницыDewateringzawadimran0% (1)

- Precast Prestressed ConcreteДокумент3 страницыPrecast Prestressed ConcretezawadimranОценок пока нет

- Blinding ConcreteДокумент2 страницыBlinding ConcretezawadimranОценок пока нет

- Construction Quality PlanДокумент85 страницConstruction Quality Plandep_vinОценок пока нет

- Construction Camp & Housing FacilitiesДокумент3 страницыConstruction Camp & Housing Facilitieszawadimran100% (1)

- Mobilization ProgramДокумент5 страницMobilization ProgramzawadimranОценок пока нет

- To Be Attached To Work PermitДокумент1 страницаTo Be Attached To Work PermitzawadimranОценок пока нет

- Surety Bond Claims: A Construction Project Owner's Guide ToДокумент9 страницSurety Bond Claims: A Construction Project Owner's Guide TozawadimranОценок пока нет

- Construction Safety Policy GeneralДокумент58 страницConstruction Safety Policy Generalzawadimran100% (1)

- Omnibus Risk EstimatorДокумент6 страницOmnibus Risk EstimatorConta do CerberusОценок пока нет

- DigiTech Element Element XP Manual-9Документ1 страницаDigiTech Element Element XP Manual-9CaPital100% (1)

- Theories and Methods of Two Way Slab Design-5-8-2017Документ3 страницыTheories and Methods of Two Way Slab Design-5-8-2017amerta 4320Оценок пока нет

- 2020 Specimen Paper 1 Mark SchemeДокумент16 страниц2020 Specimen Paper 1 Mark SchemesarabОценок пока нет

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionДокумент4 страницыDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileОценок пока нет

- HPLC and GC by S NarwadiyaДокумент8 страницHPLC and GC by S Narwadiyasnarwadiya100% (2)

- Final Formula SheetДокумент1 страницаFinal Formula SheetFaryalОценок пока нет

- Unit Iv Ce 6405Документ13 страницUnit Iv Ce 6405HanafiahHamzahОценок пока нет

- Standard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteДокумент4 страницыStandard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteManaswini VadlamaniОценок пока нет

- 1SC0 2PF Exam-Paper 20180616Документ20 страниц1SC0 2PF Exam-Paper 20180616Thasanya AlgamaОценок пока нет

- 3questions Measurements and UncertaintyДокумент2 страницы3questions Measurements and UncertaintyLeanne DerigeОценок пока нет

- Caliper Xy MemoryДокумент6 страницCaliper Xy MemoryA MuОценок пока нет

- Rails BasicsДокумент229 страницRails BasicsachhuОценок пока нет

- CoolebrookДокумент31 страницаCoolebrookloganatahnОценок пока нет

- DPP 01 Periodic Table JH Sir-3576 PDFДокумент5 страницDPP 01 Periodic Table JH Sir-3576 PDFChessОценок пока нет

- Yr 6 Maths G-6 E P-I PDFДокумент168 страницYr 6 Maths G-6 E P-I PDFdina171279Оценок пока нет

- Tugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)Документ4 страницыTugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)fitriani choerunnisaОценок пока нет

- The Mathematical Society of Serbia - 60 YearsДокумент23 страницыThe Mathematical Society of Serbia - 60 YearsBranko Ma Branko TadicОценок пока нет

- Evaluation of Professional Bra Fitting Criteria For Bra Selection and Fitting in The UKДокумент9 страницEvaluation of Professional Bra Fitting Criteria For Bra Selection and Fitting in The UKaqsa imranОценок пока нет

- Question & Answers: Unity Solutions Specialist Exam For Implementation EngineersДокумент6 страницQuestion & Answers: Unity Solutions Specialist Exam For Implementation EngineersAhmad Abd-dayeemОценок пока нет

- Electric Power Applications, Engine & Generator SizingДокумент120 страницElectric Power Applications, Engine & Generator SizingDIPPOSОценок пока нет

- Earthquake EnginneringДокумент11 страницEarthquake EnginneringkkkОценок пока нет

- Efectele Pe Termen Lung Ale Alaptatului OMSДокумент74 страницыEfectele Pe Termen Lung Ale Alaptatului OMSbobocraiОценок пока нет

- Fourier Transform: MATHS (Hons), Second YEARДокумент120 страницFourier Transform: MATHS (Hons), Second YEARmanish chauhanОценок пока нет

- Thermodynamics NotesДокумент2 страницыThermodynamics Notesjpu_48Оценок пока нет

- Net Work Survey VehicleДокумент26 страницNet Work Survey VehiclegurvinderkumarОценок пока нет

- Modern Age Waste Water ProblemsДокумент364 страницыModern Age Waste Water Problemsromaehab201912Оценок пока нет

- System Administration JakartaДокумент347 страницSystem Administration JakartaLorena Castillero80% (10)

- P103154 - 7.00 - Doc - Manual - 8000 WindlassДокумент43 страницыP103154 - 7.00 - Doc - Manual - 8000 WindlassDanОценок пока нет

- Python ProgramДокумент3 страницыPython ProgramGOKUL BОценок пока нет