Академический Документы

Профессиональный Документы

Культура Документы

Electrical Reliability

Загружено:

dediekosАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Electrical Reliability

Загружено:

dediekosАвторское право:

Доступные форматы

Reliability analysis often only implies an assessment of design, but system operations and maintenance typically have a more

significant effect on system reliability

A short outage may not cause much trouble for a refrigerated storage facility, but unplanned shutdowns may cost millions of dollars and cause a drop in share price for data centers, microchip manufacturers, or e-commerce-related companies. In addition, performance appraisals and salaries of facility engineers and plant managers may be negatively influenced by the extent of downtime of

Photo 1. A high-rise was designed with this indoor rated bus duct placed in an area that was washed down periodically. This eventually led to a fault on the system. their electrical systems. In fact, system reliability is often a critical performance measure for facility engineers and plant managers, yet many of them misunderstand important concepts about system reliability and how to improve it. These people, who get paid to know their facilities systems inside and out, often have trouble answering !uestions like, "hat is the total cost of an outage at the facility#, $oes the facility meet %six nines& availability criteria#, or "hat would a probabilistic risk assessment '(RA) of the electrical system tell about downtime# Also, terms like %*+,,& %-T./,& %failure rate,& and %high nines of availability& are often misused or misunderstood. Although (RA techni!ues have been applied for many years and can now be applied using off-the-shelf software, the details of this techni!ue can easily become overwhelming. Reliability through good design. 0ven though system design is typically not the direct cause of e!uipment failure or system shutdown, design will have an effect on system availability and on the length of shutdowns when they do occur. If the system has been designed with multiple redundancies, it can allow for maintenance outages and can ride through e!uipment failures without

resulting in an unplanned shutdown. 1sing common reliability analysis tools, the predicted reliability and availability of your electrical system can be calculated. To provide continuous operation under all foreseeable circumstances, including utility outages and e!uipment breakdown, you must design reliability into an electrical system ' Photo 1). Investigating the number of redundancies designed into the electrical system is one of the common analytical approaches. It identifies the normal source '*) and any redundant circuits2sources or e!uipment that would provide alternate paths for electrical power to flow. A system with one redundant path would be termed an *+3 design. This would allow for one of the paths to be de-energi4ed for maintenance while the other is still energi4ed, allowing maintenance without system shutdown. If the system is designed with a normal path and two alternate paths '*+, design), one path could be down for maintenance, a failure could occur in a second path, and

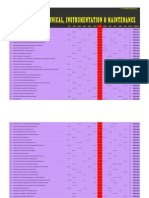

Table 1. A listing of most commonly used reliability terms and e!uations. ideally, the third path would supply power to the load without interruption. An *+3 or *+, assessment of a system can reveal single points of failure within the system. Reliability through probabilistic risk assessment. (erforming a probabilistic risk assessment '(RA) is another way to look at system reliability. Table 1 provides a list of some of the terms and formulae used in analy4ing reliability. $escribing and detailing (RA would take a book s worth of pages to do 5ustice. 6owever, I000 7tandard 89:, Recommended Practice for the Design of Reliable Industrial and Commercial Power Systems 'the ;old .ook) does provide data and describe a process for assessing system performance based on (RA principals. 1sing the typical failure rate for a given type of e!uipment and the mean time necessary to repair it, (RA looks at the probability of failure of each type of electrical power e!uipment and, depending on the number of redundancies built into system design, can be used to predict availability, number of failures per year, and annual downtime. 7oftware is commercially available to perform (RA calculations on electrical distribution systems. .ooks are also available to help explain this concept, such as Probabilistic Risk Assessment and Management for Engineers and Scientists, nd Edition , by 6iromitsu <umamoto and 0rnest =. 6enley 'I7.*> ?-@A?:-B?3@-B). Table 2 'click here) provides a small sample of the type of data available from I000 89:. Cf course, the results of such reliability studies can only predict performance based on available data. And obviously, if the data used for such a study isn t representative, the results will be unreliable. $ata provided by I000 89: is based on failure rates and repair time information gathered from 1.7. industrial plants over the past several years, but it may not be very representative of failure rates and repair times for your facility. As such, you would need to modify this data by including more site-specific information or substituting better data, if such data is available.

Quantifying system reliability. To !uantify system reliability, it s necessary to first define the term %loss of power.& -any utilities don t keep records of service interruptions shorter than one

Table 3. Eisting of respective relationships between downtime and availability. minute. 7ome don t keep records of those interruptions shorter than five minutes. .ut for many critical facilities, even a five- or 3?-second outage would !ualify as loss of power. .efore performing a reliability analysis, you must understand and agree on the circumstances that !ualify as a power failure. Table 3 shows the relationship between downtime and availability. *ote that six nines of availability represents an average annual downtime of more than :? seconds. "hile this may be an acceptable level of availability for many facilities, it would be completely unacceptable for many data centers, intensive care units, and other critical facilities that may expect seven, eight, or nine nines of availability. If the cost of outages and estimated costs of various improvement pro5ects are known, it s possible 'by multiplying the probability of failure and cost of failure, and then subtracting that cost from the cost of each of the improvement pro5ects) to compare the relative merits of the current system and each of the alternatives. Dou can then use this information to evaluate return on investment 'RCI). Reliability through proper maintenance. -aintenance clearly affects reliability. The I000 89: 7tandard provides data showing that failures increase when maintenance is deferred or done poorly. Also, according to */(A 7tandard @?., Recommended Practice for Electrical E!ui"ment Maintenance, %As soon as new e!uipment is installed, a process of normal deterioration begins. 1nchecked, the deterioration process can cause malfunction or an electrical failure.& "ith this in mind, it s important to establish an ongoing program designed to maintain an acceptable level of reliability for the facility. Dou can greatly improve reliability of electrical systems and e!uipment through proper maintenance practices and procedures, starting with effective system startup and acceptance testing.

"hen normal acceptance and start-up testing isn t performed 'usually to save a few dollars), the results can be disastrous. (erfectly good switchgear, transformers, or other e!uipment can be %smoked& due to relatively small installation errors. In other cases, the failures don t occur until months after the facility has gone into operation and the warranties have expired. Eoose connections 'Photo 2) or insulation damage may not show up until more e!uipment comes online and electrical loads increase.

Photo 2. 7imple thermographic scanning of this panel would probably have detected the loose connection and prevented this electrical failure. To implement effective acceptance testing procedures, refer to the recommendations provided by the Inter*ational 0lectrical Testing Association '*0TA) Acceptance Testing 7tandards 'AT7). Acceptance and start-up testing also provides valuable baseline or benchmark information that can be used later. '7ee the comments below about trending of test data.) 7everal good methods exist for establishing maintenance programs designed to maximi4e reliability>

*0TA -aintenance Testing 7tandard '-T7) recommendations *ational /ire (rotection Association '*/(A) @?. 7tandard recommendations A reliability centered maintenance 'RF-) assessment, which rigorously reviews critical system and e!uipment failure effects and establishes appropriate condition assessment tasks and maintenance activities for facilities or systems where reliability is critical

To get the full benefit of condition assessment and maintenance testing, you should trend the results. Trending contact resistance, temperature, insulation resistance, and other indicators will warn of deterioration and often provides an opportunity for a planned shutdown for correction of the problem before failure.

Reliability through proper operations. "hile the relationship between !uality of maintenance and resulting system reliability may be clear, the effect on reliability due to operations and other actions of personnel may be less obvious. This area of human interaction and its effect on the electrical system is considered the main source of unavailability 'Photo 3). It has been estimated that @?G to A?G of all unplanned shutdowns are due to human error, meaning that only ,?G to :?G of unplanned shutdowns are due to e!uipment malfunction or poor design.

Photo 3. -any operational errors cause shutdowns but donHt result in electrical e!uipment failure. This wasnHt the case when a worker shorted two phases while working on an energi4ed switchboard. An extensive shutdown and expensive failure resulted.

The condition and availability of facility records also influences reliability. Cut-of-date or nonexistent drawings and instruction manuals can result in unnecessary shutdowns, e!uipment failures, and even in5uries, yet a surprisingly low number of facilities rigorously maintain these crucial documents in an accurate and up-to-date condition. Recogni4ing that e!uipment may fail or human error may occur, it s important that you have documents and procedures in place to !uickly enable recovery actions and minimi4e the length of the shutdown. 7uch documents should include an up-to-date single-line diagram of the system and a list of emergency contact numbers. 6aving at least a minimal number of spare parts for critical components is also essential to system availability. -aintaining a spare parts inventory for emergencies re!uires the implementation of a program that identifies which e!uipment is critical and which spare parts are needed for emergency conditions. 7uch a program should also involve periodic condition assessment of each of these spare parts and regular updating of the inventory. (ersonnel training and detailed procedures for operation are essential. (rocedures at many data centers and other similar %critical facilities& or facilities with %critical environments& re!uire very detailed work procedures or scripts. These scripts must be written and then reviewed, revised if necessary, and approved by all the appropriate stakeholders, including engineering, maintenance, information technology, construction, and operations and procurement, before any physical work begins. The step-by-step work procedures must be followed without exception. In a typical facility, operations usually have a larger effect on system reliability than maintenance or system design. Table 4 'click here) provides a basic checklist that can help identify areas that need to be evaluated. One step ahead. Dou must design reliability into an electrical system to provide continuous operation under all foreseeable circumstances, including utility outages and e!uipment breakdown. Analy4ing the number of redundancies designed into the electrical system and conducting a (RA are two methods of looking at system reliability. "hen considering the implications of reliability, you must remember that reliability analysis should examine all three pillars of system reliability> design, operations, and maintenance. To effectively examine the overall picture, try using an electrical operations and maintenance checklist like the one shown in Table 8. This checklist serves as a basic blueprint to identify areas in need of evaluation, and when used in an actual working environment it should be written and reviewed by all appropriate personnel in the facility. #ahlstrom is director, technical ser$ices

Electrical Reliability

How reliable is the electrical system in North America? For that matter, how about the rest of the globe? How does the power company define reliability? These are all good questions. Here are three different definitions of electrical reliability from three different utility companies.

The degree to which an electrical system can deliver power to customers at contract specifications, or acceptable regulatory standards. Reliability may be measured by the frequency, duration, and magnitude of adverse effects on the electric supply. It is usually considered for two primary elements: adequacy of supply and security of supply.

The ability of a generation system and of a transmission and distribution system to deliver uninterrupted electricity to customers on demand, and to withstand sudden disturbances such as short circuits or loss of ma or system components. Reliability maybe evaluated by the frequency, duration, and magnitude of any adverse effects on consumer service.

R!"I#$I"IT% is the assurance of a continuous supply of electricity for customers at the proper voltage and frequency.

It s plain to see that power industry itself doesn t agree on a single definition of reliability and that, at best, many of the definitions themsel!es are of limited usefulness.

"eliability is e#pressed in $s. In other words, if something is reliable $$% of the time, the reliability le!el is said to be two $s. Three $s of reliability would indicate a reliability le!el of $$.$%. The electrical system is e#pected to operate &' hours per day, ( days per wee) or *(++ hours per year. The table below illustrates how many hours, minutes, or seconds per year the electrical system will be una!ailable for each le!el of reliability.

9s of Reliability 2 3 4 5 6 7

Outages per Year 876.6 hours 87.66 hours 8.766 hours 5.25 minutes 30 se on!s 3 se on!s

,lectrical reliability is more than -ust power outages. .ecause electricity is used to power some !ery sensiti!e, mission critical technology, the quality of the electrical power is -ust as important as its a!ailability. The ,lectric /ower "esearch Institute 0,/"I1 reported in a

&22& industry paper that, from an a!ailability standpoint, the a!erage 3well managed4 electrical system deli!ered power with a reliability le!el of about three or four $s. Their research went on to say, howe!er, that when 3potentially disrupti!e power quality disturbances4 were factored in, the actual reliability le!el was at least an order of magnitude worse 5 in other words, one $ lower in reliability. And that s true for outside of North America as well. At its 6*th annual congress in &226, The 7orld ,nergy 8ouncil reported similar circumstances in most de!eloped nations throughout the world. 9nde!eloped nations ha!e electrical reliability le!els that are considerably worse.

At four $s of reliability, outages affect the a!erage electrical system about *.* hours per year. :ther in!isible power disturbances, howe!er, reduce the reliability to three $s, which adds appro#imately ($ more hours per year in which the electrical system does not reliably deli!er electrical power that meets the needs of high technology equipment. The power quality picture now loo)s li)e this.

In other words, for a mission critical computer system, power outages are 62% of the problem and other power disturbances are $2% of the problem. ;i)e an iceberg, it s what you don t see that will )ill you. This is the single biggest reason why power conditioning, e!en as part of a 9/< solution is so important. Applied in the right manner, ,TA power conditioners and=or power conditioned 9/< solutions can add much needed $s of reliability to the electrical power deli!ered by the power company.

Вам также может понравиться

- Question Set - Asset IntegrityДокумент5 страницQuestion Set - Asset IntegrityAmal A.Оценок пока нет

- OGP Safety Performance of Helicopters in O & G IndustryДокумент16 страницOGP Safety Performance of Helicopters in O & G IndustrydediekosОценок пока нет

- 291Документ60 страниц291motaz_omar9651Оценок пока нет

- Floating Roof TanksДокумент123 страницыFloating Roof TanksSalman BhattiОценок пока нет

- OGP Human Factors - SafetyДокумент8 страницOGP Human Factors - SafetydediekosОценок пока нет

- OGP Safety Performance of Helicopters in O & G IndustryДокумент16 страницOGP Safety Performance of Helicopters in O & G IndustrydediekosОценок пока нет

- Eaton Aeroquip® Hose Assembly Master CatalogДокумент384 страницыEaton Aeroquip® Hose Assembly Master CatalogcarlosolmoОценок пока нет

- OGP Hra RoadmapДокумент2 страницыOGP Hra RoadmapdediekosОценок пока нет

- OGP Asset Integrity - The Key To Managing Major Incident RisksДокумент20 страницOGP Asset Integrity - The Key To Managing Major Incident Risksdediekos100% (1)

- Spiral Wounds Gasket Dimension ASME B16.20Документ1 страницаSpiral Wounds Gasket Dimension ASME B16.20dediekosОценок пока нет

- OGP Health Performance IndicatorsДокумент20 страницOGP Health Performance IndicatorsdediekosОценок пока нет

- Fire HazardsДокумент16 страницFire HazardsdediekosОценок пока нет

- Diving O&g411Документ52 страницыDiving O&g411phsemОценок пока нет

- LD-36 Armstrong Flange ConnectionДокумент1 страницаLD-36 Armstrong Flange ConnectiondediekosОценок пока нет

- D 200032 X 012Документ6 страницD 200032 X 012dediekosОценок пока нет

- Orifice FlangesДокумент4 страницыOrifice FlangesdediekosОценок пока нет

- Haskel Liquid Pumps v16Документ24 страницыHaskel Liquid Pumps v16Carl Moritz50% (2)

- PCV Fisher 310-AДокумент20 страницPCV Fisher 310-Adediekos100% (1)

- PB154 2nd Gen CH Service 8-1999Документ44 страницыPB154 2nd Gen CH Service 8-1999dediekos100% (1)

- Insulating KitsДокумент4 страницыInsulating KitsdediekosОценок пока нет

- EZ Fisher Data SheetДокумент24 страницыEZ Fisher Data SheetdediekosОценок пока нет

- Cat12 s2Документ38 страницCat12 s2dediekosОценок пока нет

- ED Fisher Data SheetДокумент40 страницED Fisher Data SheetdediekosОценок пока нет

- StrainersCatalogue 2010 SureFlowEquipmentInc YStrainersДокумент16 страницStrainersCatalogue 2010 SureFlowEquipmentInc YStrainersdediekosОценок пока нет

- Lenovo - k900 - Dissambley 2013Документ18 страницLenovo - k900 - Dissambley 2013Ravi VermaОценок пока нет

- 01-Engineering, Technical, Instrumentation & MaintenanceДокумент3 страницы01-Engineering, Technical, Instrumentation & MaintenancedediekosОценок пока нет

- New Sylabus Training TOPДокумент22 страницыNew Sylabus Training TOPdediekosОценок пока нет

- Oil and Gas Training Course Catalog 2014Документ230 страницOil and Gas Training Course Catalog 2014dediekosОценок пока нет

- Eaton Swivel JointДокумент1 страницаEaton Swivel JointdediekosОценок пока нет

- Rhinofitt Bolt Stud Dimensions For Ansi FlangesДокумент1 страницаRhinofitt Bolt Stud Dimensions For Ansi Flangesdediekos100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Com - Upgadata.up7723 LogcatДокумент4 страницыCom - Upgadata.up7723 Logcatxiaowangww0Оценок пока нет

- CF Lecture 06-File System and OSДокумент43 страницыCF Lecture 06-File System and OSFaisal ShahzadОценок пока нет

- Delphi - Technical Reference Card 7.20Документ2 страницыDelphi - Technical Reference Card 7.20Yacine AttouОценок пока нет

- User Manual LOCC-Box-Net - LOCC-Pads: Automation SolutionsДокумент101 страницаUser Manual LOCC-Box-Net - LOCC-Pads: Automation SolutionsThiyaga RajanОценок пока нет

- Embedded CourseДокумент64 страницыEmbedded CourseBogdan CojocaruОценок пока нет

- IBM Lotus Symphony Developer's GuideДокумент150 страницIBM Lotus Symphony Developer's GuideRakesh KumarОценок пока нет

- GEH-6795-EX2100e Excitation Control Engineering Work Station HMI User GuideДокумент32 страницыGEH-6795-EX2100e Excitation Control Engineering Work Station HMI User GuideLê Trung DũngОценок пока нет

- InteliMains NT - Datasheet 2010-03Документ4 страницыInteliMains NT - Datasheet 2010-03Clarice Alves de FreitasОценок пока нет

- Avaya Aura Communication Manager Administrator LoginsДокумент58 страницAvaya Aura Communication Manager Administrator LoginstotinoОценок пока нет

- The Engineering Leader's Guide To PDM & Data ManagementДокумент44 страницыThe Engineering Leader's Guide To PDM & Data ManagementKhor Tze MingОценок пока нет

- Persuasive Technology 8th International Conference PERSUASIVE 2013 Sydney NSW Australia April 3-5-2013 ProceedingsДокумент277 страницPersuasive Technology 8th International Conference PERSUASIVE 2013 Sydney NSW Australia April 3-5-2013 ProceedingsDBICA TUDOR100% (1)

- Eurocircuits-Frontend Data Preparation White PaperДокумент12 страницEurocircuits-Frontend Data Preparation White Paperjagadees21Оценок пока нет

- Mod Cluster UserGuideДокумент94 страницыMod Cluster UserGuideKevin YangОценок пока нет

- Extra Notes DFC3033 - CHAPTER 1Документ17 страницExtra Notes DFC3033 - CHAPTER 1ganeswaranОценок пока нет

- HMC Cabling and FSPДокумент22 страницыHMC Cabling and FSPsatyasrcibОценок пока нет

- Iata Training Online Exam Remote Supervision Student User GuideДокумент38 страницIata Training Online Exam Remote Supervision Student User Guidelorena055Оценок пока нет

- Kia J2534 Reprogramming SystemДокумент1 страницаKia J2534 Reprogramming SystemCristhian HuilcapazОценок пока нет

- PLC Lab ReportДокумент15 страницPLC Lab Reportyeshiwas100% (1)

- Data Lifeguard Diagnostic For DOS: USB Bootable Setup InstructionsДокумент6 страницData Lifeguard Diagnostic For DOS: USB Bootable Setup InstructionsalexannderthegreatОценок пока нет

- Auth API DocumentationДокумент6 страницAuth API DocumentationMarcelo Pereira RodriguesОценок пока нет

- Instruction Manual Inventory ControlДокумент20 страницInstruction Manual Inventory ControlpaulОценок пока нет

- Rain Sensor ModuleДокумент5 страницRain Sensor ModuleBernard BearОценок пока нет

- SD-SDI Quick Start Guide 1.0Документ16 страницSD-SDI Quick Start Guide 1.0Edgar FloresОценок пока нет

- Aut ProcedureДокумент30 страницAut ProcedureAnupam Das100% (4)

- PadWheel Poster V4 HighRezДокумент1 страницаPadWheel Poster V4 HighRezIyMyОценок пока нет

- Huawei AC6605-26-PWR Wireless Access Controller DatasheetДокумент12 страницHuawei AC6605-26-PWR Wireless Access Controller DatasheetGilangОценок пока нет

- 917HITGДокумент50 страниц917HITGLeo QuanОценок пока нет

- HPE ProLiant DL385 Gen11 QuickSpecДокумент51 страницаHPE ProLiant DL385 Gen11 QuickSpecJoe DongОценок пока нет

- Infoblox API Documentation 5Документ1 064 страницыInfoblox API Documentation 5Helios De CreisquerОценок пока нет

- Acyclic Reading and Writing Using The "IO-Link Library": SIMATIC S7-300/400/1200/1500Документ30 страницAcyclic Reading and Writing Using The "IO-Link Library": SIMATIC S7-300/400/1200/1500CesarAugustoОценок пока нет