Академический Документы

Профессиональный Документы

Культура Документы

Mil F 44422

Загружено:

binkyfishОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mil F 44422

Загружено:

binkyfishАвторское право:

Доступные форматы

Downloaded from http://www.everyspec.

com

INCH-POUND

MI L-F-f44422 27 December 1990 SUPERSEDING (See 6.4)

..

141LITARY SPECIFICATION

FIBER ROPE ASSEMBLY, INSERTION/EXTRACTION This specification is approved for use by all Departments and Agencies of the Department of Defense. 1. 1.1 SCOPE q. This specification covers a fiber rope assembly (see 6.1).

1.2 Classification. specified (see 6.2). Type I Type II Type 111 2. 2.1 -

The rope assembly shall be of the following types as

60 feet long (+5X, -O%) 90 feet long (+5%, OX) 120 feet long (+5%, -0%)

APPLICABLE DOCWENTS Government documents.

2.1.1 Specifications, standards, and handbooks. The following sPecif ications, standards, and handbooks form a part of this document to the extent specified herein. Unless otherwise specified, the issues of these documents are those listed in the issue of the Department of Defense Index of Specifications and Standards (DODISS) and supplement thereto, cited in the solicitation (see 6.2).

Benef icial comments (recommendations, additions, deletions) and any pertinent data which may be used in improving this document should be sent to: U.S. Army Natick Research, Development, and Engineering Center. Natick, ~ 017605019 by using the Standardization Document Improvement Proposal (DD Form 1426) appearing at the end of this document or by letter.

AMSC NiA _ DISTRIBUTION STATEMENT A. Approved for public release; distribution

FSC 4020 is unlimited.

--

Downloaded from http://www.everyspec.com

MI L- F- L4422

SPECIFICATIONS FEOERAL UI!-T-81

PPP-6-601

Tag, Shipping

Boxes , Wood,

and Stock Cleated-Plywood

STANDARDS FEDERAL FED-STD-191

FED-STD-595

Textile Test Methods Colors Used in Government Procurement

. MILITARY MI@TD105 sampling Procedures and Tables for Inspection-by. Attributes Marking for Shipment and Storage Pallet ized Unit Loads Quality of Wood Members For Containers and Pallets

MIL-STD-129 MIL-STD-147 MIL-STD-731

(Unless otherwise indicated, copies of federal and military specifications, standards, and handbooks are available from the Standardization Document s.Order Desk. Building 4D, 700Robbins Avenue, Philadelphia, PA 191] 1-S094. ) The following 2. 1.2 Other Government documents, drawings, and publications. otherGovernment documents, drawings, andpublications form a partof this document to the extent specified herein. Unless otherwise specified, the issues are those cited in the solicitation. DRAWINGS

U.S.

APJfY NATICK RESEARCH, DEVELOPMENT, AND ENGINEERING Fiber Rope Assembly, Insertion/Extraction

CENTER

11-1-3957 (Copies of

and Engineering

drawings are available fromthe U.S.

Center, ATTN: STRNC-~, Natick,

Army Research,

MA 01760 -5017.)

Development,

2.2 Non-Government publications . The following documents form a part of this document to the extent specified herein. Unless otherwise specified, the issues of the documents which are DOD adopted are those listed in the issue of the DODISS cited in the solicitation. Unless otherwise specified, the issues of documents not listed in the DODISS are the issues of the documents cited in the solicitation (see 6.2). *.

Downloaded from http://www.everyspec.com

AMERIC.+X SOCIETY FOR TESTING AND NATZii IALS (ASH) D ~76 D 3951

.

{Applications Testing and for tlaterials, ccpiej

Identification of Fibers in Textiles

SLandard be Prac Lice addressed for to Commerc ths ia! Packagin~ Society 12:

should

.Ame rice:.

1916 Race Street. Philadelphia.

PA

19103-1187.)

(Non-Government standards and publications are normally available from organiThese documen Ls a lso may be zations that prepare or distribute the documents. available in or through libraries or other infOrUIa LiOnal service s.) 2.3 Order of precedence. In the even L of a con flicL between the text of this document and the references cited herein. the text of this document Lakes precedence. Nothing in this document, however, supersedes applicable laws and has been obtained. regulations unless a specific exemption 3. RETIREMENTS

3.1 First article. When specified (see 6.2), a sample shall be subjected to first article inspection (see 6.3) in accordance with 4.3. 3.2 Government and contractor purchases. The requirements specified in 3.7 All other and 3.8 apply only to rope purchased directly by the Government. requirements apply both to rope purchased by a contractor as a component for an end item and to rope purchased directly by the Government. 3.3 Material. ,,

3.3.1 Main rope. The Kain rope shall be fabricated from virgin continuous filament, heat and light resistant polyethylene terephthalate type polyester with a staple wrap. The rope shall be dyed green to approximate any color in the range indicated by color chips 34052, 34079, 34086, 34092, 3~096. 34097, Testing shall be as specified in 34098. 34102, 34108, and 34128 of FED-STD-595. 6.4.1.1. 3.3.2 White extraction looPs rope. The extraction loops rope shall be fabricated from bright, virgin, continuous filament, heat and light resistant nylon of at least 6 denier size, having a K inimum tenacity of 8.5 grams per denier. The nylon shall be a long chain polymer made of hexamethylene diamine caproic acid. Mixture and adipic acid, or a long chain polymer of epsilon amino of nylon types shall be prohibited in any one rope. Testing shall be as specified in 4.6.1.1. 3.3.3. Safety line rope. The safety line rope shall be fabricated from continuous filament, U.V. stabilized nylon having a minimum tenacity of 6.5 grams per-denier. Mixture of nylon types shall be prohibited in any one-rope. The rope shall be dyed black to approximate any color in the range indicated by color chips 27040, 37038, and 37056 of FED-STD-595. Testing shall be as specified in 4.4.1.1. 3

Downloaded from http://www.everyspec.com

MIL-F-L4422

3.4

Comoonent

construction.

..

3.4,1 Main rope. The rope shall be constructed of eight strands arranged in four pairs, where one individual strand shall be laid adjacent to the secoad strand in each pair, and shall conform to the requirements specified herein and in-table I. Individual strands shall be made of one size of singles yarn and shall have an.equal number of yarns. The yarn shall be 40000to 50000denier and shall be S and Z twist. The rope shall be constructed without knots or splices in the strands of the rope. However, knots will be permitted in the singles yarn. In preparation of the constituent rope strands, the pattern S2 shall be employed in the twisting of the yarns and the individual strands of the two pairs while the components of the remaining pairs shall be twisted in the 2S pattern. The finished rope shall be so constructed that in the interweaving procedure, pairs of strands of the former structure shall be twisted in the Z direction, while alternating pairs of the latter shall be twisted simultaneously in the S direction. Heat setting of the rope or any portion of its comp~pents shall not be permitted. 3.4.2 White extraction loops rope. The rope shall be constructed of eight strands arranged in four pairs, where one individual strand shall be laid adjacent to the second strand in each pair and shall conform to the requirements specified herein and in table I. Individual strands shall be made of one size The. of balanced 3-ply yarns and shall have equal numbers of plied yarns. singles yarn shall be 4000 to 1000O denier. The rope shall be constructed without knots or splices in the singles yarn, 3-ply yarns, strands, or rope. In the preparation of the Knots in the single filaments are acceptable. constituent rope strands, the pattern S2S twist shall be employed in the twisting of the singles yarns, the 3-ply yarns and the individual strands of two pairs, while the components of the remaining pairs shall be twisted in the 2S2 pattern. The finished rope shall be so constructed that in the interweaving procedure, pairs of strands of the former structure shall be twisted in the Z direction, while alternating pairs of the latter structure shall be th-isted simultaneously in the S direction. The finished rope shall be heat set. Dry heat setting is prohibited. 3.4.3 Safety line rope. The rope shall be constructed of eight strands arranged in four pairs, where one individual strand shall be laid adjacent to the second strand in each pair and shall conform to the requirements specified herein and in table I. Individual strands shall be made of one size of balanced 3-ply yarns and shall have equal numbers of plied yarns. The singles yarn shall be 4000 to 10000 denier. The rope shall be constructed without knots or splices in the singles yarn, 3-ply yarns, strands, or rope. Knots in the single filaments are acceptable. In the preparation of the constituent rope strands, the patter MSZSM twist shall be employed in the twisting Of the Singles Yarns. the 3-ply yarns and the individual strands of two pairs , while the components of the remaining pairs shall be twisted in the 2S2 pattern. The finished rope - shall be%o constructed that in the interweaving procedure, pairs of strands of the former structure shall be twisted in the Z direction, while alternating pairs of the latter structure shall be twisted simultaneously in the S direction. The finished rope shall be heat set. Dry heat setting is prohibited.

,....

..

,.

Downloaded from http://www.everyspec.com

),i~.~-.~~~~ TA6LC I.

Comoonent ohvsica! reauiremen Ls.

Extraction

Cnarac LerisLic

.

Main rope ~,

1000s rope

Safety line rove

::e..ne i?: irs inches

Circumference in

!-31L 5-112~ 1/4

9/!6

9/1.6

inches

at load P

Load Break .P in&

gf

~/ Lh minimum

(pounds) streng

610 35,000

---

(pounds) Hardness minimum/maximum

(po.nds~Feet per pound at load P Elongation maximum (percent) Loss in breaking strength after heat aging, not exceedimz (vercent) floisture content K aximum (percent) Extractable Katter maximum (percent) ~1

3251450 1.23~5% 59%

4fi2 10.79 ~ 5% --

30/60 10.34 : 5% --

1o%

1o%

1o%

5%

5%

5%

4%

4%

included for information only.

4%

if ~/

Not a specification requirement;

The load P (pounds) shall be equal to 200 times the square of the nominal diameter of the rope in inches (P - 200D2).

3.5 Construction of assembly. The fiber rope assembly shall be constructed in accordance with 3.5.1,3.5.2and 3.5.3, and Drawing 11-1-3957. 3.5.1 Main rope. The main rope shall have an eye splice on one end with a minimum of 4 inches and a maximum of 6 inches inside length. The eye splice shall be made using a K inimum of three full tucks and two half tucks. The free end shall be seared and whipped. 3.5.2 White extraction loops rope. The white nylon extraction loops _rope shall be passed through the center of the main rope five picks up from the free end and eye spliced around the outer half of the main rope. At the end of the eye splice, the white rope shall pass through the center of the main rope to form the 5

Downloaded from http://www.everyspec.com

HIL-F-44422 bottom of the first loop, and then enter again through the ceccer of the main rope three picks up from the bottom of Lhe first loop co form the first loop. Each white loop shall consist of 10 inches (~ 1 inch) of exposed rope. After the whi Le rope has been passed through the center Of the main rope forming a loop, it shall be passed back through the center of the main rope one and one-half picks UP,.and then passed through the center of itself where it last entered the main rope. The white rope will then be passed through the center of the main rope two and one-half picks up from the top of the last loop, then passed back through the center of the main rope two picks up from the last exit, then passed back through the center of itself, and passed back through the center of itself and passed back through the center of the main rope one pick up from where it had last passed through iteself, forming the bottom of the second loop. The same procedure shall be followed to make the second and third white loops. After making the third loop, the white nylon rope shall be passed through the center of the main rope three and one-half picks up from the top of the third loop, and then eye spliced around the outer half of the main rope. Each eye splice in the white nyl~n rope shall consist of four full and two half tucks. Safety line rope. The black nylon safety line rope shall pass through the center of the main rope one and one-half picks above, and on the same side as, the upper eye splice of the extraction loops rope. The black nylon safety Line rope shall then pass through the two securing passes of the extraction loops rope, on the same.side as the main rope, then through the center of the main rope, one pick above the lower eye splice of the extraction loops rope. After passing through the main rope, the safety .line rOpe will then be passed thrOugh then the securing passes on the opposite side of the first fwo, and the rope will be spliced to itself with a short splice between the top eye and the top securing pass. After being spliced together, the safety line rope shall extend out as far as the extraction loops, and shall not interfere with the extraction loops.

3.5.3

3.6

Physical requirements.

3.6.1 Finished assembly. The finished fiber rope assembly, consisting of the main rope, extraction loops rope, and safety line rope shall conform to the physical properties listed in table II when tested as specified in 4.4.6. TABLE II. End item physical requirements.

Breaking Extraction loops (each) strength, minimum 9,000

(pounds)

Safety line rope

9,000

3.7 Identification. Each rope assembly shall have a ticket (identification tag) attacked for identification purposes. The ticket shall conform to the requirements for type B, class 1, size 4 Or 5 Of W-T-81. The ticket shall be made of not less than 15-point paper stock and have a minimum tearing resistance

.-

. . .. . -A.-

=. ., .-

.+.

Downloaded from http://www.everyspec.com

MI L-F-4L622

(total) of 850 grams when tested as specified in W-T-81. All in both directions ticket entries shall be legibly printed. scamped, or Lyped with water insoluble ink. .The ticket shall contain the following information:

..

National stock number Nomenclature Specification number Length and weight Contract number and date Contractor s name Date of manufacture (month and year) 3.8 Workmanship. The end item shal 1 conform to the qual ity of product estabIished by this specification and the occurrence of defects shall not exceed the applicable acceptable quality levels. 4. QUA&~TY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. Unless otherwise specified in the contract or purchase order, the contractor is responsible for the performance of all Except as inspection requirements (examinations and tests) as specified herein. otherwise specified in the contract or purchase order, the contractor may use his own or any other facilities suitable for the performance of the inspection requirements specified herei,n, unless disapproved by the GOver~ent. The Government reserves the right to perform any of the inspections set forth in this specification where such inspections are deemed necessary to ensure supplies and services conform to prescribed requirements. 4.1.1 Responsibility for ~ompliance. All items shall meet all requirements of sections 3 and 5. The inspection set forth in this specification shall become a part of the contractors overall inspection system or quality progrsm. The absence of any inspection requirements in the specification shall not relieve the contractor of the responsibility of ensuring that all products or supplies submitted to the Government for acceptance comply with all requirements of the contract. Sampling inspection, as part of manufacturing operations, is an acceptable practice to ascertain conformance to requirements, however, this does not authorize submission of known defective material, either indicated or actual, nor does it commit the Government to accept defective material.

4. 1.2 Responsibility for dimensional requirements. Unless otherwise specified in the contract or purchase order, the contractor is responsible for ensuring cannotbe examined that all specified dimensions have beenmet. Whendimensions on the end item, inspection shall be Kade at any point, or at all points in the compliance with all dimensional manufacturing process necessary to ensure requirements.

4.1.3 Certificates of compliance. When certificates of compliance ar~ submitted, the Government reserves the right to inspect such items to determine the validity of the certification.

7

Downloaded from http://www.everyspec.com

MI LF-44422 4.2 Classification of inspec~ions. herein are classified as follows: The inspection requirements specified

a.

b.

.

First article inspection (see 4.3). Quality conformance inspection (see 4.4).

4.3 First article inspection. When a first article is required (see 3.1 and 6.2), it shall be examined for the defects specified in 4.4.2 through 4.4.5, and tested as specified in 4.4.6. 4.4 Quality conformance inspection. Unless otherwise specified, sampling for inspection shall be performed in accordance with MI L-STD-105. In accordance with 4.1, components 4.4.1 Component and material inspection. and materials shall be inspected in accordance with all the requirements of referenced documents unless otherwise excluded, amended, modified, or qualified in this s~-edification or applicable purchase document. 4.4.1.1 Component testing. The main rope, extraction loops rope, and safety line rope components shall each be tested for the characteristics listed in table IV. The lot size shall be expressed in units of yards of rope. The sample unit shall be 12 yards of rope for the main rope, and 14 yards each for both the extraction loops rope and safety line rope. The inspection level shall be S-1. The lot shall be unacceptable if one or more of the samPle units fails tO.meet any requirement. TABLE III . Characteristic Material Main rope Extraction loops rope Safety line rope Color Hardness

Moisture content

Component tests. Test method

Requirement paragraph

3.3.1 3.3.2

D 276 ~1 ~1 D 276 ~/ ~1

3.3.3 3.3.1and

Table I

Table I 3.3.3

D 276 Al ~1 9010y

6020 ~1 ~1

2600 ~/

Extractable matter Circumference Length per pound

Table I Table I Table I

2611~/

~1 6004 ~/

~/

ASTM test method.

.. . . . . . . .

,.,

. .

Downloaded from http://www.everyspec.com

HIL-F-L4422 A certificate of compliance shall be submitted. Tes L method in FED-STD-191 The length of the rope previously used in the weight determination taped off at eachend and usedas thetest sample. The circumference shall be measured at Lhe beginning of the breaking

test shall with be

shall be

strength

length main rope and to the nearest 1/8 inch for the extraction loops rope and safety line rope. This determination shall be repeated at least three times in different positions not less than LSO turns of rope apart. The average of these determinations shall be the circumference of the rope. 4.2 Cnd item critical defect examination. Every end item, prior to the visual and dimensional examinations in 4.4.3 and 4.4.4, shall be examined for the critical defects listed in table V. Any end item found to contain one or nmre critical defects shall be rejected. 4.4.3 End item visual examination. The finished fiber rope assemblies shall be examined for the defects listed in table V. The lot size shall be expressed in units of finished rope assemblies. The sample unit shall be one finished rope assembly. The inspection level shall be S-4, and the acceptable quality level (AQL), expressed in terms of defects per hundred units, shall be 1.5 for major Any critical defects and 4.0 for total (major and K inor combined) defects. defect found during sampling shall be cause for rejection of the lot represented by the sample. TABLE IV. End item visual defects. Classification Hajor

A hard fiber the speciman under the load P specified in table I. The cut snugly around the rope and cut where it overlaps. passed shall be straightened and measured to the nearest 1/4 inch for the

Examine Appearance and workmanship

.Defect Not constructed as specified Any cut Chafed or damaged

Kink Knot (singles, loose ply, strand, or rope Broken or

Critical 1 2 3

4 5

Minor

ends (singles, ply, strand, or rope) Bulged strand Ends not securely whipped, taped, or heat sealed to prevent fraying or untwisting

6 7

201

Downloaded from http://www.everyspec.com

xILF64422 TABLE IV. End item visual defects. (centd) Classification Major 101 202 203

1/ 204

Examine

.

Defect Other than specified Resists and/or spotty dyeing Uneven

Spot or stain, clearly visible

Critical

Minor

Color

Cleanness

Identification . ~j

Omitted, incorrect, illegible, or not as specified

205

At normal inspection distance (approximately

..

3 feet).

4.4.4 End item dimensional examination. The fiber rope assemblies shall be examined for the dimensions specified in the applicable drawing. Any dimension not within the specified tolerance shall be classified as a defect. The lot size shall be expressed in units of fiber rope assemblies. The sample unit shall be one fiber rope assembly. The inspection level shall be S-3, and the AQL, expressed in terms of defects per hundred units, shall be 2.5. 4.4.5 End item testing. The end items shall be tested as specified in 4.4.5.1. The - lot size shall be expressed in units of fiber rope assemblies. The sample unit shall be one fiber rope assembly. The inspection level shall be s-1. Any test failure shall be cause for rejection of the lot. 4.4.5.1 End item breaking strength and elongation testing. The main rope, extraction loops rope, and safety line ropes of the finished fiber rope assembly shall be tested for breaking strength in accordance with Method 6015 of FED-STD-191, except that the load P, as determined in table I, shall be used in lieu of 1 percent of the breaking strength for measurement of O in the elongation calculation and the extraction loops rope and safety line rope specimans shall be prepared as follows: The main rope of the fiber rope assembly shall be cut so that at least 3 feet the top extraction loop. AS specified in of clear main rope remains above Method 6015, the cut end shall be eye spliced, and the round metal pins or posts from the testing machine shall hold the speciman at the main rope eye splice and at the loop being tested. No more than one extraction loops rope rope shall be tested per each fiber rope assembly. Any and one safety line failure to meet the requirements in 3.6.1 shall be classified as a test failure.

10

Downloaded from http://www.everyspec.com

i+ IL-F-f+4622 4.4.6 Packaging examination. The fully packaged end items shall be examined fOr the de fecLs listed below. The loL.size shall be expressed in units of shipping containers. The sample unit shall be one shipping con Lainer fully packaged. The inspection level shall be S-2 and the AQL, expressed in terms of defecLs per hundred uni Ls, shall be 2.5.

-

Examine

Defect Cmitted: incorrect; illegible; of improper size, location, sequence, or method of application Any component missing, damaged. or not as specified

Inadequate incomplete application sealing or of components, of flap, such as

Marking (exterior and interior) Materials

Workmanship

closure

improper

-Contents

strapping, or inadequate stapling taping, loose Bulged or distorted container Number per container is more or Iess than required

4.4,7 Pallet ization examination. The fully packaged and palletized end items The Iot size shall be expressed shall be examined for the defects listed be Iow. in units of palletized unit loads. The sample unit shall be one palletized unit load, fully packaged. The inspection level shall be S-1 and the AQL, expressed in terms of defects per hundred units, shall be 6.5.

Examine Defect

Finished dimensions

Length, width, or height exceeds specified maximum requirement Pallet pattern not as specified Load not bonded as specified Exceeds maximum load limits Dmitted; incorrect; illegible; of iqroper location, sequence, or Kethod of application size,

Pallet ization

Weight Marking

5.

PACKAGING Preservation shall be level A or Commercial, as specified

5.1 Preservation. (see 6.2).

.-

5.1.1. Level A preservation. Each fiber rope assembly shal I be coiled and secured wjth at least two equally spaced ties of cord or rope passing through the center of the coil to the outside, and knotted.

11

Downloaded from http://www.everyspec.com

?fIL F44422 5 .1.2 Commercial preservation. accordance with ASTM D 3951. Each fiber rope assembly shall be preserved in

5.2

6.2).

Packing.

Packing shail be level A, B or Commercial, as specified (.see

5.2.1 Level A packing. Each fiber rope assembly, preserved as specified in 5.1, shall be packed in a shipping container conforming to overseas type, style A, type II load of PPP-B-601. Inside dimensions of the shipping container shail be a~proximately 19 inches in length, 19 inches i width, ad 17 inches in dept,h for types I and 11, and 19 inches in length, 19 inches in width and 22 inches in depth for the type III. The shipping container shall be closed and strapped as specified in the appendix of PPP-B-601. 5.2.2 Level B packin~. Each fiber rope assembly, preserved as specified in 5.1, shall be packed as specified in 5.2.1, except that the shipping container shal 1 be_domestic type. 5.2.3 Commercial packin~. Each fiber rope assembly, preserved 5.1, shall be packed in accordance with ASTM D 3951. as specified in

5.3 Pallet ization. When specified (see 6.2), fiber rope assemblies packed as specified in 5.2, shall be pallet ized on a 4-way entry pallet in accordance with load type I of MI L-STD-147. Pallet types shall be type I (4-way entry), type IV or tyoe V in accordance with MI L-sTD-147. Pallets shall be fabricated from wood groups I, II, III or IV of MIL-STD-731 . Each prepared load shall be bonded with straps in accordance with bonding means C and D or film bonding means F or G. Pallet pattern shall be number 90 in accordance with the appendix of MIL-STD-147. 5.4 Markin&. In addition to any special marking required by the contract or purchase order, shipping containers and unit loads shall be marked in accordance with MI L-STD-129 or ASl14 D 3951, as applicable. 6. NOTES nature that

(This section contains information of a general or explanatory may be helpful, but is not mandatory. )

6.1 Intended use. The fiber rope assembly is intended for use during both infiltration and exfiltration of military personnel from rotary &-ing aircraft at elevations up to 120 feet above ground level . 6.2 Acquisition requirements. following: a. b. c. Title, number, and Type required (see Issue of DODISS to specific issue of Acquisition documents must specify the

date of this specification. 1.2). be cited in the solicitation, and if required, the individual documents referenced (see 2.1.1, and 2.2).

12

Downloaded from http://www.everyspec.com

NIL-F-46422

d. e. f..

When a first article is required (see 3.1, 4.3, and Levels of preservation and packing (see 5.1 and 5.2).

When pallet ization is required (see 5.3).

6.3).

6.3 First article. When a first article is required, iL shall be inspected and approved under the appropriate provisions of FAR 52.209. The first article specify the should be a preproduction sample. The contracting officer should The appropriate type of firSt article and the number of units to be furnished. contracting officer should also include specific instructions in acquisition documents regarding arrangements for selection, inspection, and approval of the first article.

6.4 Supersession data. This specification supersedes Limited Production Purchase Description No. 1087 (CL), Rope Assembly, Infiltration, Exfiltration. 6.5 Subject term (key word) Iistins. -. Aircraft Cordage Equipment, aircraft Exf iltration Helicopter Infiltration

Custodians: Aruy - GL Navy - SH Air Force - 99 Review activities : DLA - IS Air Force - 82 User activity: Navy - MC

Preparing Activity: Army - GL (Project 4020-0324)

13

Downloaded from http://www.everyspec.com

STANDARDIZATION

DOCUMENT

lNSTRU~ONS

IMPROVEMENT

PROPOSAL

1.

The preparing

a~ivity

mUSt complete

blocks

1, 2, 3, and 8.

In block

1, both

the document

number

and revision

Iecter should be given.

2. The submitter of this form must complete 3. The preparing

activity must provide

blocks 4,

a reply within

5.6, and 7, 30 days from receipt ofthe form.

of to

NOTE: This form may not be used to request copies of documents, nor to request waivers. or clarification . ~e_quirements on current contracts. Comments wbmitted on this form do not constitute or imply authorization waive any portion of the referenced document(s) or to amend contractual requirements.

I RECOfvlMENDA CHANGE:

3. OOCUMEN1 TITLE FIBER

0M;,#;~j~422

OOCUMINT 1. 1990

DATE fWhfMDCS) Oecember 27

ROPE ASSHBLY , INSEP.TIOfl/EXTRXTION nd hrlude proposrd rewrite, if JmnWe. 4. NATURE OF CHAr4G[ (Menti& wragraph number G

A!wch

G nra

sheen

needed)

..

S. REASONFOR RECOMMENDATION

6 suEoAfTTEa

a. NAME

fzarz m.AfiL&

fn/L@

h-

oRGAMzATro?i

-. . .

--)

a. NAME

U.S. Army Natick R06E Center

8.

(2) AU70VON fv appfkabk)

b. TELEPHONE(fncbda -a (1) Commercial C@)

PREPARING ACNWTY

I

(2) AUTOVON

508-651-4532

ROSE Center

256-4532

c. AOORESS(~

Zip Code) Commander, U.S. Army ATTN : STRNC- IRT Natick, M 1426, ~ 01760-s01 Form

Natick 9 OP.

4S OAYS. CONTAfX IF YOU 00 NOT RECEIVEA REPt.v WE7141N nd standardization Office Oefema ouatky G 5203 LeeIbuq Pike. Suite 1403. hlh Church, VA 22041-3466 TeleDhOne f703) 7s&z3ao AUTOVON 209-2340

G le

on

89 NATICK

APR

90

$Yeviws cddaa

_*m.

,91.I

Вам также может понравиться

- TPR CombinedArmsCWMD TacticalPlanningConsiderations (U) AWG 20160625 PDFДокумент2 страницыTPR CombinedArmsCWMD TacticalPlanningConsiderations (U) AWG 20160625 PDFJoe BennettОценок пока нет

- OSHP Use of Force PolicyДокумент7 страницOSHP Use of Force PolicyReba ChenowethОценок пока нет

- Push or Hold 8july09Документ12 страницPush or Hold 8july09Michael McQueenОценок пока нет

- Fm-Field Manuals Us-Army IndexДокумент17 страницFm-Field Manuals Us-Army Indexdnchrist1Оценок пока нет

- Introduccion A Las Tacticas de SWATДокумент3 страницыIntroduccion A Las Tacticas de SWATHa AgОценок пока нет

- Lecture - Barricaded IncidentДокумент15 страницLecture - Barricaded IncidentReynaldo Gacus YantoОценок пока нет

- Close Quarters Marksmanship/Battle (CQM/CQB) : August 2006Документ27 страницClose Quarters Marksmanship/Battle (CQM/CQB) : August 2006Jefferson SanchezОценок пока нет

- Doctrine Overview - Why FM 3-0? - FM 3-0 Big Ideas - Chapter Overview - Warfighting Function ImpactsДокумент38 страницDoctrine Overview - Why FM 3-0? - FM 3-0 Big Ideas - Chapter Overview - Warfighting Function ImpactsChris WhiteheadОценок пока нет

- Small Unit Tactics: Presented By: 1Lt Edgardo R. Regencia (Res) PA Tactical Officer PUP ROTC UnitДокумент18 страницSmall Unit Tactics: Presented By: 1Lt Edgardo R. Regencia (Res) PA Tactical Officer PUP ROTC UnitJanet Loresto100% (1)

- Swat Poi-Pcinsp DagoonДокумент23 страницыSwat Poi-Pcinsp DagoonSalvador Dagoon JrОценок пока нет

- swat-power-point-AU 4Документ15 страницswat-power-point-AU 4Rham HiroОценок пока нет

- RD Classifier Course Workbook v-1.1 2013-08-11Документ413 страницRD Classifier Course Workbook v-1.1 2013-08-11ryand11Оценок пока нет

- Tower Company Trooper HandbookДокумент22 страницыTower Company Trooper HandbookMichael FrantzОценок пока нет

- CRT35b - CQB Hallways and Stairwells - PG - V3.00Документ24 страницыCRT35b - CQB Hallways and Stairwells - PG - V3.00marvic mapacpacОценок пока нет

- Target Shooting Range ManualДокумент47 страницTarget Shooting Range ManualSanti AmatmontreeОценок пока нет

- Line 1 Line 2 Line 3: 9 Liner Medevac RequestДокумент1 страницаLine 1 Line 2 Line 3: 9 Liner Medevac Requestjack.cullinan2046100% (1)

- GSRP Penal Code Finalised 2021Документ51 страницаGSRP Penal Code Finalised 2021api-555108121Оценок пока нет

- Opord Goforth - Pro 7Документ9 страницOpord Goforth - Pro 7rhasdy AmingОценок пока нет

- Afd-051214-004 Requisitos Oficiales PostulantesДокумент12 страницAfd-051214-004 Requisitos Oficiales PostulantesEmely MilagrosОценок пока нет

- AR 190-58 Personal SecurityДокумент15 страницAR 190-58 Personal SecuritySean HoodhoodОценок пока нет

- Tactical Operations: Marshall A. Mckay Captain, ArmorДокумент49 страницTactical Operations: Marshall A. Mckay Captain, ArmorMark Cheney100% (1)

- HK Tactical Team Instructor DevelopmentДокумент62 страницыHK Tactical Team Instructor DevelopmentMatthew NelsonОценок пока нет

- Man TrackingДокумент3 страницыMan Trackingziko52100% (1)

- Care Under Fire: Tactical Combat Casualty Care For Medical Personnel August 2018Документ84 страницыCare Under Fire: Tactical Combat Casualty Care For Medical Personnel August 2018alyssaОценок пока нет

- COL ERIC C GARCHITORENA Closes The VIP PROTECTION COURSE Class 01-14Документ1 страницаCOL ERIC C GARCHITORENA Closes The VIP PROTECTION COURSE Class 01-14Amanda CookeОценок пока нет

- Interagency Helicopter Rappel Guide 2016Документ30 страницInteragency Helicopter Rappel Guide 2016rpguidoОценок пока нет

- SS 3.11 Section Battle Drill FC BCДокумент6 страницSS 3.11 Section Battle Drill FC BCMTStg InFiNiTy TauqeerОценок пока нет

- Warrior Battle DrillsДокумент42 страницыWarrior Battle DrillsAngus Hiscoe100% (4)

- AmphoraДокумент2 страницыAmphoraPaulo Costa SilvaОценок пока нет

- TC1 400Документ336 страницTC1 400leon_lee100% (1)

- Force Protection - IEDs Article03022004bДокумент26 страницForce Protection - IEDs Article03022004bwarrior_2008100% (1)

- First Aid in BleedingsДокумент15 страницFirst Aid in BleedingsDaniel TrОценок пока нет

- 093-401-5040 (React To Unexploded Ordance)Документ35 страниц093-401-5040 (React To Unexploded Ordance)claudioОценок пока нет

- 5 2 - STP - 19 95B1 SM - 191 376 5115, - 191 376 5116 1 2 3 4 5 6 7Документ10 страниц5 2 - STP - 19 95B1 SM - 191 376 5115, - 191 376 5116 1 2 3 4 5 6 7Jose Ortiz PereaОценок пока нет

- Situation: ST STДокумент17 страницSituation: ST STJerry BiswaneОценок пока нет

- Anatomy of A Hostage Rescue - ADA427693Документ209 страницAnatomy of A Hostage Rescue - ADA427693cliftoncage100% (1)

- SFAS Volunteer Statement EnlistedДокумент2 страницыSFAS Volunteer Statement EnlistedMachel Buchanan100% (1)

- Troop Leading ProceduresДокумент14 страницTroop Leading ProceduresMark Cheney100% (1)

- Rules: Bagged Custom'S Fivem Rules & New Player GuideДокумент25 страницRules: Bagged Custom'S Fivem Rules & New Player GuidekvakzОценок пока нет

- Role of Vehicle ArmorДокумент6 страницRole of Vehicle Armortom_taylor_17Оценок пока нет

- CAT Tourniquet Application GuideДокумент2 страницыCAT Tourniquet Application GuidekevinОценок пока нет

- M14 Rifle Marksmanship TrainingДокумент3 страницыM14 Rifle Marksmanship Trainingarmz121Оценок пока нет

- Execution ParagraphДокумент3 страницыExecution ParagraphdcОценок пока нет

- React To ContactДокумент29 страницReact To Contactapi-282851844Оценок пока нет

- fm24 33Документ78 страницfm24 33Alex Alcol100% (1)

- 2nd C-IED Technology Workshop Final Reportc Compressed PDFДокумент44 страницы2nd C-IED Technology Workshop Final Reportc Compressed PDFsenolОценок пока нет

- MK19 Range Brief ExampleДокумент33 страницыMK19 Range Brief ExamplePowerpoint Ranger100% (1)

- Op Boredom Lash - Orders: - ConfidentialДокумент7 страницOp Boredom Lash - Orders: - Confidentialdavid.baileff5748Оценок пока нет

- My CVДокумент2 страницыMy CVBhojmagarОценок пока нет

- TLPДокумент43 страницыTLPAllyssa JhaneОценок пока нет

- GTA Catalog 2Документ36 страницGTA Catalog 2Chris WhiteheadОценок пока нет

- 3 Leadership Card Pg1Документ1 страница3 Leadership Card Pg1joel marinayjr100% (2)

- Islamic Terrorist Bomb Attack RefuseingДокумент159 страницIslamic Terrorist Bomb Attack Refuseingares100% (1)

- HVT S.O.PДокумент5 страницHVT S.O.PAnonymous 7ijQpDОценок пока нет

- Basic VIP Protection - 12 DaysДокумент2 страницыBasic VIP Protection - 12 DaysNisar A.Оценок пока нет

- Receive Mission: Troop Leading ProceduresДокумент36 страницReceive Mission: Troop Leading ProceduresDerrickandShannon KozlowskiОценок пока нет

- How To Become A Successful Bodyguard: Alternative Careers Series, #6От EverandHow To Become A Successful Bodyguard: Alternative Careers Series, #6Оценок пока нет

- Night Vision Enhancement Systems A Clear and Concise ReferenceОт EverandNight Vision Enhancement Systems A Clear and Concise ReferenceОценок пока нет

- Family JewelsДокумент15 страницFamily JewelsbinkyfishОценок пока нет

- Eldritch Horrors: The Modernist Liminality of H.P. Lovecraft's Weird FictionДокумент68 страницEldritch Horrors: The Modernist Liminality of H.P. Lovecraft's Weird FictionbinkyfishОценок пока нет

- T2K4 Character Sheet English Color (Fillable)Документ1 страницаT2K4 Character Sheet English Color (Fillable)binkyfish100% (1)

- Queer Geometry and Higher Dimensions: Mathematics in The Fiction of H.P. LovecraftДокумент18 страницQueer Geometry and Higher Dimensions: Mathematics in The Fiction of H.P. LovecraftbinkyfishОценок пока нет

- H.P. Lovecraft & The French ConnectionДокумент222 страницыH.P. Lovecraft & The French ConnectionbinkyfishОценок пока нет

- The Placid Island of Ignorance: Lovecraft and NatureДокумент10 страницThe Placid Island of Ignorance: Lovecraft and NaturebinkyfishОценок пока нет

- Lovecraft Across Time: Resonation & Adaptation in The Cthulhu MythosДокумент92 страницыLovecraft Across Time: Resonation & Adaptation in The Cthulhu MythosbinkyfishОценок пока нет

- HP Lovecraft Enlightenment and Connection To Cosmicism PDFДокумент31 страницаHP Lovecraft Enlightenment and Connection To Cosmicism PDFbinkyfishОценок пока нет

- Asco Answers Radiation TherapyДокумент2 страницыAsco Answers Radiation TherapybinkyfishОценок пока нет

- Radiation TherapyДокумент44 страницыRadiation TherapybinkyfishОценок пока нет

- Introduction To Radiation Oncology: What Every Medical Student Needs To KnowДокумент49 страницIntroduction To Radiation Oncology: What Every Medical Student Needs To KnowSeni KОценок пока нет

- H.P. Lovecraft and The Modernist GrotesqueДокумент243 страницыH.P. Lovecraft and The Modernist GrotesquebinkyfishОценок пока нет

- Guide To Radiation TherapyДокумент47 страницGuide To Radiation TherapybinkyfishОценок пока нет

- Insides Radiation Therapy and You PDFДокумент64 страницыInsides Radiation Therapy and You PDFbinkyfishОценок пока нет

- MIT22 S902IAP15 GC InstructДокумент23 страницыMIT22 S902IAP15 GC InstructJitendra GurjarОценок пока нет

- Hospital Disaster Management TrainingДокумент6 страницHospital Disaster Management TrainingbinkyfishОценок пока нет

- Operating Characteristics of The Geiger CounterДокумент10 страницOperating Characteristics of The Geiger CounterbinkyfishОценок пока нет

- What Is A Geiger Counter?Документ2 страницыWhat Is A Geiger Counter?binkyfishОценок пока нет

- Geiger Counter: DefinitionsДокумент7 страницGeiger Counter: DefinitionskamaldeepОценок пока нет

- Radiation Safety TrainingДокумент3 страницыRadiation Safety TrainingbinkyfishОценок пока нет

- Star Trek Writers GuideДокумент34 страницыStar Trek Writers GuideBrainiac007Оценок пока нет

- The Role of The Geiger Counter in A Medical InstitutionДокумент3 страницыThe Role of The Geiger Counter in A Medical InstitutionbinkyfishОценок пока нет

- How To Buy A Geiger CounterДокумент18 страницHow To Buy A Geiger CounterbinkyfishОценок пока нет

- DG33BU Product Guide 01 EnglishДокумент75 страницDG33BU Product Guide 01 EnglishAllain Garcia RiveraОценок пока нет

- Battlefleet1900 RulesДокумент22 страницыBattlefleet1900 RulesbinkyfishОценок пока нет

- GM Counter PDFДокумент14 страницGM Counter PDFabahyn100% (1)

- Battlefleet1900 ScalesДокумент3 страницыBattlefleet1900 ScalesbinkyfishОценок пока нет

- Electronic Combat Over The Third ReichДокумент51 страницаElectronic Combat Over The Third Reichbinkyfish100% (1)

- 1484-C Kaypro Technical Manual Aug84Документ154 страницы1484-C Kaypro Technical Manual Aug84binkyfishОценок пока нет

- Archimedes & Water DisplacementДокумент2 страницыArchimedes & Water DisplacementbinkyfishОценок пока нет

- Fortune 2010Документ14 страницFortune 2010Stefan JenkinsОценок пока нет

- Nin/Pmjay Id Name of The Vaccination Site Category Type District BlockДокумент2 страницыNin/Pmjay Id Name of The Vaccination Site Category Type District BlockNikunja PadhanОценок пока нет

- Parwati DeviДокумент25 страницParwati DevikvntpcsktprОценок пока нет

- J of Cosmetic Dermatology - 2019 - Zhang - A Cream of Herbal Mixture To Improve MelasmaДокумент8 страницJ of Cosmetic Dermatology - 2019 - Zhang - A Cream of Herbal Mixture To Improve Melasmaemily emiОценок пока нет

- TLS FinalДокумент69 страницTLS FinalGrace Arthur100% (1)

- Got GottmanДокумент3 страницыGot GottmanaalcantaraОценок пока нет

- AmplifierДокумент20 страницAmplifierValerie StraussОценок пока нет

- History of The UST School of Fine Arts, Chapter 4Документ27 страницHistory of The UST School of Fine Arts, Chapter 4Hannibal F. CaradoОценок пока нет

- Resume Testing6+ SaptagireswarДокумент5 страницResume Testing6+ SaptagireswarSuresh RamasamyОценок пока нет

- Registration - No Candidate Gender Category Rank/Percentage Allotment - Seat Base - Seat Course CollegeДокумент166 страницRegistration - No Candidate Gender Category Rank/Percentage Allotment - Seat Base - Seat Course CollegeCyber ParkОценок пока нет

- Sample Internship PPTДокумент19 страницSample Internship PPTSangeeta JamadarОценок пока нет

- Rizal ExaminationДокумент3 страницыRizal ExaminationBea ChristineОценок пока нет

- Ylarde vs. Aquino, GR 33722 (DIGEST)Документ1 страницаYlarde vs. Aquino, GR 33722 (DIGEST)Lourdes Loren Cruz67% (3)

- Drug Distribution MethodsДокумент40 страницDrug Distribution MethodsMuhammad Masoom Akhtar100% (1)

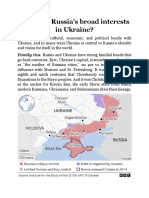

- What Are RussiaДокумент3 страницыWhat Are RussiaMuhammad SufyanОценок пока нет

- Corporation Law Case Digests Philippines Merger and ConsolidationДокумент7 страницCorporation Law Case Digests Philippines Merger and ConsolidationAlpha BetaОценок пока нет

- The Role of Personalization, Engagement and Trust in Online CommunitiesДокумент17 страницThe Role of Personalization, Engagement and Trust in Online CommunitiesAbiОценок пока нет

- Bsed FilipinoДокумент18 страницBsed FilipinoJ.PОценок пока нет

- Introduction To The Field of Organizational BehaviorДокумент22 страницыIntroduction To The Field of Organizational BehaviorSayyid Al ArizieОценок пока нет

- Darkness Points Reminder 2Документ2 страницыDarkness Points Reminder 2Tata YoyoОценок пока нет

- Number SystemsДокумент165 страницNumber SystemsapamanОценок пока нет

- Articles 62 & 63: Presented By: Muhammad Saad Umar FROM: BS (ACF) - B 2K20Документ10 страницArticles 62 & 63: Presented By: Muhammad Saad Umar FROM: BS (ACF) - B 2K20Muhammad Saad UmarОценок пока нет

- Measure For Measure AngeloДокумент1 страницаMeasure For Measure AngeloRoger Knight100% (1)

- Csm6 Ext1y11 BookДокумент955 страницCsm6 Ext1y11 BookJesse Davis100% (12)

- CURRICULUM VITAE Kham Khan Suan Hausing, PHDДокумент8 страницCURRICULUM VITAE Kham Khan Suan Hausing, PHDCinpu ZomiОценок пока нет

- Nurse-Patient Trust RelationshipДокумент12 страницNurse-Patient Trust RelationshipMarina Costa100% (1)

- Chan Sophia ResumeДокумент1 страницаChan Sophia Resumeapi-568119902Оценок пока нет

- GST 101 Exam Past QuestionsДокумент6 страницGST 101 Exam Past QuestionsBenjamin Favour100% (2)

- I Wonder Lonely As A Cloud by W. Words WorthДокумент6 страницI Wonder Lonely As A Cloud by W. Words WorthGreen Bergen100% (1)

- American RunwayДокумент26 страницAmerican RunwayGayathri SuriyaОценок пока нет