Академический Документы

Профессиональный Документы

Культура Документы

Minimum clearances and voltage levels for substation equipment

Загружено:

Víctor RojasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Minimum clearances and voltage levels for substation equipment

Загружено:

Víctor RojasАвторское право:

Доступные форматы

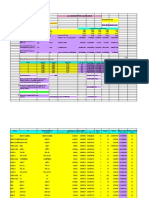

Following minimum clearances shall be maintained :

System operating voltage kV

RMS

400 220 132

Lightning Impulse Withstand Level (LIWL) kV

PEAK

1550 1050 650

Switching Impulse Withstand Level (SIWL) kV

PEAK

1050

Power frequency voltage kV

RMS

630 460 275

Minimum phase to earth clearance mm 3500 2100 1300

Minimum phase to phase clearance mm 4000 2100 1300

Minimum sectional clearance mm 6500 5000 4000

Phase to phase distance between flexible conductor

Levels in the switchyard (Height from Plinth)

System operating voltage kV

RMS

400 220 132

Plinth Level m

First Level - Equipment Connection m

Second Level - Strung Bus - Busbar m

Third Level - Strung Bus - Jack Bus m

Fourth Level - Shield wire m

CASE 1

Voltage kV

RMS

420

Minimum Phase to phase clearance = m 4

Centre-line distance between main conductor mid points m 7

Span length m 100.00

Height of conductor above ground m 15.3

Conductor Type TARANTULLA

No. of sub-conductor of a main conductor Nos. 2

Current Carrying capacity A 2570

Suitability to carry Short Circuit Current Suitable

Effective distance between Sub-conductor = Center line

distance between Sub-conductor

m 0.45

Spacer Span = Centeline distance between connecting pieces or

between one connecting piece and the adjacent support

m 6.00

Static Tensile force per (sub)conductor in flexible conductor

per phase under minimum temperature and maximum wind

condition

kg 1000

No. of Disc Insulator Strings Nos. 4

No. of disc in one string Nos. 30

Static Tensile force PER CONDUCTOR in flexible conductor

per phase under minimum temperature and NO wind condition

(CIVIL INPUT)

kg 467.9

SAG

Net Current Carrying Capacity of the BUNDLE = A 2570

Annexure 1

Sag-Tension Calculation, Sag Tension Chart and

Short Circuit Forces For Structure and Foundation Design

The above levels in switchyard will ensure adequate phase to phase, phase to earth

clearances for maximum sag & swing, short circuit forces and wind forces.

Annexure 1

Sag-Tension Calculation, Sag Tension Chart and

Short Circuit Forces For Structure and Foundation Design

Suitability to carry Short Circuit Current Suitable

Annexure 1

Sag-Tension Calculation, Sag Tension Chart and

Short Circuit Forces For Structure and Foundation Design

SAG

Total maximum sag = m 2.053

Sag due to conductor m 1.296

Sag due to Insulator m 0.757

Height of jack bus/equipment below conductor m 8.3

Therefore, available margin calculated between centre lines

(excluding sub-conductor spacing, conductor width,

equipment clamps etc) =

m 0.947

SWING

Total maximum swing of conductor = m 0.581

Available margin = m 1.969

Phase to phase spacing required = m 5.031

SHORT CIRCUIT

Static Tensile force in flexible conductor per phase under

minimum temperature and maximum wind condition

kg 2000

Therefore design short circuit force

Maximum of following :

kg 5514.9

Tensile force during short circuit kg 2772.2

Tensile force caused by Pinch effect kg 5514.9

Tensile force after short circuit (drop force) kg NA

j 1.1

33

170

80

320

320

3000

33

Annexure-1

System Parameters

Voltage = 420 kV

Current Rating = 3000 A

Three phase Initial symmetrical short-circuit current (r.m.s) = 40,000 A

Duration of the first short circuit current flow = 1 Sec

System frequency = 50 Hz

Wind Parameters

Basic Wind Speed = = 47.00 m/s

Risk Coefficient as per Table 2 of IS: 802, Part 1, Sec 1

{For all Zones & for Reliability level 1(Voltage level upto 400kV)}

= 1.07

Terrain Category = 2

Factor to convert 3 second peak gust speed into

average speed of wind during 10 minutes period =

= 1.3750

Height of conductor above ground = 15.3000

Spacer, additional concentrated mass

Spacer Span = Centeline distance between connecting pieces or

between one connecting piece and the adjacent support

= 6.00 m

Spacer weight = 3 kg

No. of spacers in span = 14 nos.

Additional concentrated mass (other than spacer) representing the

connections of pentagraph isolator ( Mass of one connection)

= 0.00 kg

Nos. of Trapzee Connection of pentagraph isolator in one span = 0 nos.

Conductor Parameters

Conductor Type = TARANTULLA

Type = AAC

Al Strands = 37

Steel Strands = 0

Al Strand Dia = 0.00523

St strand dia = 0

Cross sec. = 0.000794868 sq.m

Diameter = 0.0366 m

Weight = 2.91 kg/m

Young's Mod. Kg./Cm

2

= 608200

Kg./Cm

2

10

6

Young's Modulus (N/sq.m) = 61997961264 N/sq.m.

Drag Coefficient = 1

DC Resistance = 0.0363 Ohm/km

Resulting Mass Per Unit length of one sub-conductor = 3.1452 kg/m

Coefficient of Linear Expansion = 0.000023

/

o

C

length of compensating spring in case of pentograph Isolator = 0.00

No. of Disc Insulator Strings = 4.00

No. of disc in one string = 30.00

Weight of hardware = 60 kg

Length of Hardware before disc = 0.25 m

Disc Insulator Type = 120 kN

x = 0

Creepage = 440 mm.

Diameter of Disc = 0.28 m

Weight of Disc = 8.3 kg

Length of Disc = 0.145 m

CALCULATION FOR FLEXIBLE CONDUCTORS

Page 7 of 32

Annexure-1

Total consolidated length of disc Insulator & Hardware in one side

of Span

= 4.600 m

Total consolidated weight of disc Insulator & Hardware in one side

of Span

1056.000

Layout Parameters

No. of sub-conductor of a main conductor = 2 nos.

Static Tensile force PER CONDUCTOR in flexible conductor per

phase under minimum temperature and maximum wind condition

1 T

Static Tensile force in flexible conductor per phase under minimum

temperature and maximum wind condition

= 2 T

Span length = 100.00 m

Beam width 1.5 m

Length of conductor carrying short circuit current (Chord length of

main conductor in the span)

= 89.3 m

Maximum Ambient Temperature at site = 50.0000

o

C

Minimum Ambient Temperature at site = 0.0000

o

C

Rise in temperature = 35.0000

o

C

Final Temperature after Short Circuit = 200.0000

o

C

Radial Thickness of ICE over the conductor Th

ice

= 0.0000 cm

Phase to phase spacing provided between phases = 7.0000 m

Effective distance between Sub-conductor = Center line distance

between Sub-conductor

= 0.45 m

Minimum Phase to phase clearance = 4 m

Height of jack bus/equipment below conductor 8.3 m

Resultant Spring constant of both support of one Span N/m 100000

( ) l l a I F c k = 2 "3 0 ' 75 . 0 2t n sc g m n F r = ' ' r 1 1 tan = o st n sc c F l g m n b 8 2 ' = n c gb T 8 . 0 2t = ((( (( + = 2 0 1 2 4 2 90 64 1 1 o t r T Tres s s A nE Sl N 1 1 + = >s ((( ||.| \| + = fin s st fin s st fin s st s nA F for E nA F for nAF E E oo o 0 90 sin 7 . 0 3 . 0 ( ) N F l m ng stsc n 3 2 ' 24 = , >s s (( ||.| \| = 5 . 0 2 5 . 0 0 360 cos 1 1 1 1 0 1 1 res kres k res k k TT for TT for TT o o o > s s = 90 1 90 0 sin 1 k k k f or r f or r oo o _ << s + s s = 985 . 0 180 766 . 0 985 . 0 arccos 10 1 766 . 0 arccos 25 . 1 0 __ _ _ _ o f or f or f or m ( ) ( ) < + > + = 4 1 cos sin 3 4 1 1 3 1 1 2 res k k k res k T T f or r T T f or r o o ( ) ( ) ( ) 1 0 0 2 2 1 2 2 3 2 s s = + + + + + , , , 0 0 70 6 . 0 180 8 1 2 . 1 > > + = m m st f r for F F o o , ( ) ( ) 44 70 5 . 2 / 43 50 0 . 2 / s s s s s s s s a l and d a a l and d a > s > s ( ) s k sc s s a n n I m d a n f v 1 2 180 sin 1 2 "3 0 ' 0 1 ||.| \| = t ( ) 3 0 3 3 180 sin 375 . 0 ||.| \| = n d a N l F n s s s v pi c ( ) 2 0 2 2 180 sin 5 . 1 ||.| \| = n d a N l F s s s st st c st pi j c c + = 1 ( ) 3 2 2 "3 0 2 1 v v al n I n F s s k v ||.| \| = t ( ) 2 / 1 4 4 4 4 0 4 2 2 3 0 4 1 arctan 1 180 sin " 2 1 89 2 1 (((((( )` ||.| \| ||.| \| |.| \| + = v v n d a l Nv n I n n v s s k e q t ||.| \| + = 2 1 q cst e st pi v F F ( ) s s s s s d a a d a v = q q 4 q st c ||.| \| + = cst e st pi v F F 1 0 2 3 = + pi st c c ( ) 2 / 1 4 4 3 4 0 4 2 2 3 0 4 1 arctan 1 180 sin . " 2 1 89 2 1 (((((( )` ||.| \| ||.| \| |.| \| + = v v n d a l v N n I n n v s s s k e t s s s d d a v = 4 ( ) st t ela F F N = c < (( > (( = 4 / 4 / 4 / 1 1 2 "3 1 2 "3 res k k s k th res k res s k th th T T f or T nA I c T T f or T nA I c c ( ) th ela c D bl C c c + (( + = 2 83 1 > < < + s = 8 . 1 15 . 1 8 . 1 8 . 0 1 . 0 97 . 0 8 . 0 05 . 1 r f or r f or r r f or CF < > = 1 1 1 sin sin o o o o o o m m c D F m c D F h for b C C for b C C b h b a a 2 min = ( ) ( ) > + = + = conductor bundle for n for F conductor Single for n for F F st st t 2 1 1 . 1 1 1 1 arctan 1 180 sin 3 |.| \| |.| \| = s s s s s s d a d a n a d V

Page 8 of 32

CASE 1.

CALCULATION FOR BUSBAR SIZING

Bundle Conductor Considered AAC TARANTULLA

No. of sub-conductor in a BUNDLE 2

1 Check for continuous thermal withstand capacity of the conductor

The current which a conductor can carry for a given temperature rise depends

upon the rate at which the produced heat is dissipated. In case of an overhead

conductor, the dissipation will be effected by radiation and by convection.

Required Current Carrying Capacity of the BUNDLED conductor 3000 Amps

Hence as given in Heat balance equation : (1)

P

j

+ P

sol

= P

rad

+ P

conv

where,

P

j

= R

T

I, Heat generated by Joule effect (2)

P

sol

= D S

i,

Solar Heat Gain (3)

P

rad

= s D K

e

(T

2

4

T

1

4

), Radiation Heat Loss (4)

P

conv

= Nu (T

2

T

1

) , Convection Heat Loss (5)

where,

I = the conductor current (A)

R

dc(20C)

DC resistance of conductor at 20C 0.0363 /km

R

T

= the electrical resistance of conductor at a temperature T (/m)

= the solar radiation absorption co-efficient Refer IEC 61597 0.50

S

i

= the intensity of solar radiation (W/m), Refer IEC 61597 900.00 W/m

2

D = the conductor diameter (m) 0.0366 m

s = the Stefan Boltzmann constant (5.6710

8

W.m

2

K

4

) Refer IEC 61597 5.67E-08 W.m

2

K

4

K

e

= the emmisivity co-efficient in respect to black body Refer IEC 61597 0.60

Ambient Temperature in (C) 50 C

Final Equilibrium Temperature (C) 85 C

T

1

= Ambient Temperature in (K) 323 K

T

2

= Final Equilibrium Temperature (K) 358 K

= the thermal conductivity of air film in contact with the conductor Refer IEC 61597 0.02585 W m

1

K

1

Nu = the Nusselt number = 0.65 R

e

0.2

+ 0.23R

e

0.61

Refer IEC 61597 25.7

R

e

= the Reynolds number = 1.64410

9

v D[(T

1

+ 0.5(T

2

T

1

)]

1.78

Refer IEC 61597 1871.6

v = wind speed in m/s Refer IEC 61597 1 m/s

f = System frequency 50 Hz

= Thermal Coefficient of Resistivity Refer IEC 61597 4.03E-03 /C

= permeability (= 1, for non magmnatic material) 1

now,

R

T

= R

dc

x K

where,

R

dc

DC resistance of the conductor at operating temperature 85 deg C

K Skin effect coefficient

again,

R

dc(85C)

= R

dc(20C)

(1+(T

2

-20))

R

dc(20degC)

= 0.0363 /km

0.058419 /miles

=> R

dc(85C)

0.073722 /miles

Next for calculation of skin effect coefficient, a factor X [reference (2)]

=> X = 1.65603

For this value of X, the skin effect coefficient K is obtained from Table 4.1.1 of "Power Engineers Handbook"

K = 1.03512

=> R

T

= 0.076311 /miles

4.74E-05 /m

P

sol

= D S

i

16.47

P

rad

= s D Ke (T

2

4

T

1

4

) 21.68

P

conv

= Nu (T

2

T

1

) 73.12

from heat balance equation - 2 we derive,

equation-3

From equation - 3, we obtain

=> Current Carrying Capacity of the CONDUCTOR = 1285 Amps

Net Current Carrying Capacity of the BUNDLE = 2570 Amps

T

sol conv rad

R

P P P

I

) (

max

+

=

) 85 (

0

063598 . 0

C dc

R

f

X

=

Check for Short Circuit Current carring capacity of the incoming line conductor

I"

k3

System short circuit current for System 40,000 A

t Duration of short circuit current 1 sec

Min. reqd. area of cross-section of conductor for short time rating Reference: (2)-(c)

Clause 5.2.2 Eq (3)

in

2

(A

min

) =

where,

T

i

Initial temp. of conductor before short ckt 85

0

C

T

f

Final temp of conductor after short ckt 200

0

C

G Conductivity of conductor Reference: (2)-(c ) 40 %

Clause 5.2.2

0.878063 in

2

Minimum required cross-sectional area 566.49 mm

2

Cross-section of each CONDUCTOR 794.87 mm

2

Overall Cross-section of BUNDLE 1589.74 mm

2

Suitability to carry Short Circuit Current Suitable

3

6

"

( 20 (15150 / ))

0.144 10 log

( 20 (15150 / ))

k

f

i

I X t

T G

X

T G

+

+

3

6

"

( 20 (15150 / ))

0.144 10 log

( 20 (15150 / ))

k

f

i

I X t

T G

X

T G

+

+

Annexure-1

CASE 3.

= Static Tensile force in flexible conductor per phase under minimum

temperature and maximum wind condition

= 2 T

= 19620 N

= Three phase Initial symmetrical short-circuit (r.m.s) = 40000 A

= No. of sub-conductor of a main conductor = 2 nos.

= Subconductor mass per unit length = 2.91 kg/m

= Diameter of flexible conductor = 3.660E-02 m

= Cross Section of one sub-conductor = 7.949E-04

m

2

= Spacer Span = Centeline distance between connecting pieces or between

one connecting piece and the adjacent support

= 6 m

Additional Concerated mass (other than spacer) representing the

connections of pentagraph isolator ( Mass of one connection)

= 0 kg

Nos. of Trapzee Connection of pentagraph isolator in one span = 0 nos.

= Spacer weight = 3 kg

No. of spacers in span = 14 nos.

m

sc

' = Resulting Mass Per Unit length of one sub-conductor

= 3.145 kg/m

= Span length = 100 m

length of compensating spring in case of pentograph of Isolator = 0

= Total consolidated length of disk Insulator & Hardware in one side of

Span

= 4.6 m

= Effective distance between Sub-conductor = Center line distance between

Sub-conductor

= 0.45 m

= Centre-line distance between main conductor mid points = 7 m

Beam Width

1.5 m

= Length of conductor carrying short circuit current (Chord length of main

conductor in the span)

= 89.3 m

S = Resultant Spring constant of both support of one Span N/m = 100000 N/m

= Young's modulus = 61997961264 N/m2

= Duration of the first short circuit current flow = 1 Sec

= Gravitational Constant = 9.81

m/s

2

= Constant = 5.00E+07

N/m

2

f = System frequency = 50 Hz

C

th

= Material Constant = 2.70E-19

m

4

/(A

2

s)

o

= Magnatic Constant, permeability of Vacuum =

410

7

H/m

Short Circuit Force Calculations

Calculation are based on IEC 865-1 (1993)

FOR FLEXIBLE CONDUCTORS

fin

o

l

cl

d

c

l

a

s

A

'

s

m

s

d

s

m

s

l

s

a

st

F

E

"

3 k

I

n

1 k

T

n

g

c

s s

c

c c

s sc

nl

m n

nl

m n

m m + + = ' '

=

c

n

=

c

m

=

s

n

=

sp

l

Page 11 of 32

Annexure-1

CASE 3.

Short Circuit Force Calculations

= 30.62 N/m

= 0.4962

= 26.3888 Deg

= 3.9315 m

= 3.5577 Sec.

= 3.4125 Sec.

= 1.18E-07

= 3.50E+10

N/m

2

From eqn. 22, Equivalent Static Conductor Sag at mid span,

From eqn. 23, Period of Conductor oscillation,

From eqn. 21, Angular direction of the force,

From eqn.19, Characteristic electromagnetic force per unit length on flexible main conductors,

From eqn. 20, the ratio of electromechanical force on a conductor under short circuit condition to gravity,

From eqn. 24, Resulting period of the conductor oscillation during the short circuit current flow,

From eqn. 25, The stiffness norm

Where the actual Young's modulus is given by

( )

l

l

a

I

F

c k

=

2

"

3 0 '

75 . 0

2t

n sc

g m n

F

r

=

'

'

r

1

1

tan

= o

st

n sc

c

F

l g m n

b

8

2 '

=

n

c

g

b

T 8 . 0 2t =

(

(

+

=

2

0

1

2

4 2

90 64

1 1

o t

r

T

T

res

s s

A nE Sl

N

1 1

+ =

>

s

(

(

|

|

.

|

\

|

+

=

fin

s

st

fin

s

st

fin s

st

s

nA

F

for E

nA

F

for

nA

F

E

E

o

o

o

0

90 sin 7 . 0 3 . 0

Page 12 of 32

Annexure-1

CASE 3.

Short Circuit Force Calculations

= 1.78E+00

= 33.4389 Deg

= 0.7266

= 53.3986 Deg

= 0.3490

0.00

= 0.7453

= 2772.1832 Kg

From eqn. 29, Swing out angle at the end of the short-circuit current flow

From eqn. 30, factor

From eqn.28,The stress factor of the main conductor is given by :

From eqn. 31, Maximun swing out angle

From eqn. 32, Load Parameter

From eqn. 33, The factor , can be calculated as a real solution of the equation,

From eqn. 34, the tensile force is given by,

>

s

(

(

|

|

.

|

\

|

+

=

fin

s

st

fin

s

st

fin s

st

s

nA

F

for E

nA

F

for

nA

F

E

E

o

o

o

0

90 sin 7 . 0 3 . 0

( )

N F

l m ng

st

sc n

3

2

'

24

= ,

>

s s

(

|

|

.

|

\

|

=

5 . 0 2

5 . 0 0 360 cos 1

1

1

1 0 1

1

res

k

res

k

res

k

k

T

T

for

T

T

for

T

T

o

o

o

>

s s

=

90 1

90 0 sin 1

k

k k

f or r

f or r

o

o o

_

<

< s +

s s

=

985 . 0 180

766 . 0 985 . 0 arccos 10

1 766 . 0 arccos 25 . 1

0

_

_ _

_ _

o

f or

f or

f or

m

( )

( )

< +

> +

=

4

1 cos sin 3

4

1 1 3

1

1

2

res

k k k

res

k

T

T f or r

T

T f or r

o o

( ) ( ) ( ) 1 0 0 2 2 1 2

2 3 2

s s = + + + + + , , ,

( )

( )

> +

= +

=

conductor bundle for n for F

conductor Single for n for F

F

st

st

t

2 1 1 . 1

1 1

Page 13 of 32

Annexure-1

CASE 3.

Short Circuit Force Calculations

= NA

Kg

= 8.9363E-04

=

1.45828E-04

=

1.1190E+00

=

1.05

=

2.0531

=

2.8938E+00

From eqn. 35, the tensile force after short circuit caused by drop (drop force)

Horizontal Span Displacement b

h

and Min. air clearance a

min

From Eqn. 36, The elastic expansion is given by,

From Eqn. 37, The thermal expansion is given by,

From Eqn. 38, Factor C

D

is given by,

From Eqn. 39, Factor C

F

is given by,

From Eqn. 41, Maximum Horizontal Displacement within a span with strained conductors is given by,

From Eqn. 42, the distance between the mid points of the two main conductors during a line-to-line two-phase

short circuit,

0

0

70 6 . 0

180

8 1 2 . 1 > > + =

m

m

st f

r for F F o

o

,

( )

st t ela

F F N = c

<

(

>

(

=

4 /

4 / 4 /

1 1

2

"

3

1

2

"

3

res k k

s

k

th

res k res

s

k

th

th

T T f or T

nA

I

c

T T f or T

nA

I

c

c

( )

th ela

c

D

b

l

C c c +

(

+ =

2

8

3

1

>

< < +

s

=

8 . 1 15 . 1

8 . 1 8 . 0 1 . 0 97 . 0

8 . 0 05 . 1

r f or

r f or r

r f or

C

F

<

>

=

1

1 1

sin

sin

o o o

o o o

m m c D F

m c D F

h

for b C C

for b C C

b

h

b a a 2

min

=

Page 14 of 32

Annexure-1

CASE 3.

Short Circuit Force Calculations

= 4.2760

= 12.2951

V

2

= 1.5721

=

0.2133

= 7862.0971

Kg

= 0.7313

= 2.1267

= 1.1083

Sub-conductor are considered to clash effectively if the clearence a

s

between the mid -points of adjacent sub-

conductors, as well as the distance l

s

between 2 adjacent spacers fulfil either equation (43) or (44)

SUBCONDUCTORS ARE NOT EFFECTIVELY CLASHING

From equation 46, the factor v

1

is given by,

The factor a

s

/d

s

is equal to

Factor V

2

can be given by fig. 8 as function of V

1

From eqn. 45, Short circuit current force

Factor V

3

can be given by

From eqn. 47 & 48, Strain factor characterizing the contraction of bundle condoctor

If j > 1 : The sub-conductor clash

If j < 1 : The sub-conductors reduce their distances but do not clash

( )

( ) 44 70 5 . 2 /

43 50 0 . 2 /

s s s s

s s s s

a l and d a

a l and d a

> s

> s

( )

s

k

sc s s

a

n

n

I

m d a

n

f v

1

2

180

sin

1

2

"

3 0

'

0

1

|

|

.

|

\

|

=

t

( )

3

0

3

3

180

sin 375 . 0

|

|

.

|

\

|

=

n d a

N l F

n

s s

s v

pi

c

( )

2

0

2

2

180

sin 5 . 1

|

|

.

|

\

|

=

n d a

N l F

s s

s st

st

c

st

pi

j

c

c

+

=

1

( )

3

2

2

"

3 0

2

1

v

v

a

l

n

I

n F

s

s k

v

|

|

.

|

\

|

=

t

1 arctan

1

180

sin

3

|

.

|

\

|

|

.

|

\

|

=

s

s

s

s

s

s

d

a

d

a

n

a

d

V

Page 15 of 32

Annexure-1

CASE 3.

Short Circuit Force Calculations

= 5514.861767 Kg

0.00

. = 1.082580058

= 1.1872

= 1.13E+01

= 5514.861767 Kg

TENSILE FORCE IN CASE OF CLASHING SUB-CUNDUCTORS

From equation (51), is given by the real solution of

SUBCONDUCTORS ARE CLASHING

If j 1, From eqn. 50, the tensile force is given by

Therefore design force in kg (Maximum of F

t

, F

f

& F

pi

)

From eqn. 52,

From eqn. 53,

( )

s s s

s s

d a a

d a

v

=

q

q

4

|

|

.

|

\

|

+ =

c

st

e

st pi

v

F F 1

0

2 3

= +

pi st

c c

( )

2 / 1

4

4

3

4

0

4

2

2

3 0

4

1 arctan

1

180

sin

.

"

2

1

8

9

2

1

(

(

(

(

(

|

|

.

|

\

|

|

|

.

|

\

|

|

.

|

\

|

+ =

v

v n

d a

l

v N

n

I

n n v

s s

s k

e

t

s

s s

d

d a

v

=

4

Page 16 of 32

Annexure-2 CASE 1.

System Voltage V = 420 kV

1 Basic Wind Speed = V

b

= 47.00 m/s

As per IS 802: 1995, basic wind speed is based on gust velocity averaged over a short time interval of 3s.

Wind Zone as per IS: 802, Part 1, Sec 1 4

Risk Coefficient as per Table 2 of IS: 802, Part 1, Sec 1

{For all Zones & for Reliability level 1(Voltage level upto 400kV)} =

K

1

= 1.07

Terrain Category 2

Terrain roughness coeficient (For different Terrain Category) = K

2

= 1.0000

Factor to convert 3 second peak gust speed into

average speed of wind during 10 minutes period =

K

0

= 1.3750

Meteorological reference wind speed = V

b

/K

0

V

R

= 34.1818 m/s

Design wind speed = V

R

x K

1

x K

2

V

d

= 36.5745 m/s

Height of conductor above ground 15.3000 metre

Gust Response Factor for conductor Gc = 1.9837

2 Design Wind Pressure =0.6 x V

d

2

/g Pc = 81.8164 kgf/m

2

Weight of individual spacer = WSP = 3.0000 kgf

Separation between two spacers = SSP = 6.0000 metre

Weight of sub-conductor per metre= W1 = 2.9100 kgf/m

No. of subconductors - single/twin/tri/quad = r = 2

Diameter of sub-conductor = d = 3.6600 cm

Cross Sectional Area of sub-conductor = A = 7.9487 cm

2

Modulus of Elasticity of sub-conductor = ey = 608200.0000 Kg/cm

2

Coefficient of Linear Expansion = a = 2.3000E-05 /

o

C

Maximum Ambient Temperature at site = t1 = 50.0000

o

C

Minimum Ambient Temperature at site = t2 = 0.0000

o

C

Rise in temperature = t3 = 35.0000

o

C

Distance between centre line of beams (for conductor span) = la = 100.0000 m

DIameter of disc = di = 0.2800

Nos. of Insulator Strings in one side of conductor span (Single /Double) Ni = 4

Weight of complete string insulator including hardware W

iT

= 1056.0000

Weight of single string insulator including hardware Wi= 264.0000

Length of insulator string = li = 4.6000 m

Width of beam on which conductor is strung = Bw = 1.5000 m

Tension per SUB-CONDUCTOR under max. wind and min. temp. conditions = Ten1= 1000.0000 Kg

Drag Coefficient C

dc

= 1.0000

3 Effect of Ice formation

Radial Thickness of ICE over the conductor Th

ice

= 0.0000 cm

Effective dia of the conductor considering ICE effect = d+2*Th

ice

D1= 3.6600 cm

Increase in Conducter weight due to effect of Ice formation w3= 0.0000 kg/m

4 Total weight of sub-conductor per phase = Wc = W1+WSP/(r*SSP)+w3 = 3.1452 Kg/m

5 Wind Load on conductor as per IS 802 & IS 5613 = Pcc =

Pc * (d/100) * C

dc

* G

c

= 5.9401 Kg/m

CALCULATIONS FOR SAG AND SWING OF STRUNG CONDUCTOR

Page 17 of 32

Annexure-2 CASE 1.

6 Clear span of conductor = L = la-(2*li)-lt-Bw = 89.3000 m

7 Loading factor during max wind condition = Q1= (1+(Pcc/Wc)

2

) = 2.1371

Loading factor during no wind condition = Q2 = 1.0000

8 SAG CALCULATIONS DUE TO CONDUCTOR

8.1

Under minimum temperature and maximum wind condition condition, the sub-

conductor experiences a stress of f1

f1 = Ten1/A = 125.8071 Kg/cm

2

Weight of sub conductor per m per cm

2

= S = Wc/A = 0.3957

GB = (S * L * Q2)

2

* ey/24 = 3.1640E+07

F = f1 - GB * (Q1/(f1*Q2))

2

- a * ey * (t1+t3-t2) = -10192.9819

To solve the following equation:

The working stress F at tempature t1+t3, is given by the cubic equation

f2

2 *

(f2 - F) - GB = 940491268.11

we get f2 = 304.3152 Kg/cm

2

8.2 Tension in conductor at maximum temperature and no wind

condition = Ten2 = f2*A = 2418.9041 Kg

Max sag due to conductor = Wc*L / (8*Ten2) Sc= 1.2961

9 SAG DUE TO INSULATOR

From Fig 1, we get

Tension per insulator string = Ten2* r / Ni Teni1= 1209.4521

Weight of conductor per String Insulator = Wc*r/Ni Wci= 1.5726

U1 = (li

2

+ (di/2)

2

) = 4.6021 m

U2 = ((li/2) + (di/2)) = 2.3043 m

= Tan

-1

[(di/2)/li] = 0.0304

= Tan

-1

[di/li] = 0.0608

Taking moments at 'P'

Teni1 * U1 *Sin( + ) = (Wci * L/2) * U1 * Cos( + ) + Wi * U2 *Cos( + )

Simplifying :

TP1 = (Wci*L/2) * U1 * Cos + Wi*U2*Cos - Teni1*U1*Sin = 760.8692

TP2 = Teni1*U1*Cos + Wci*(L/2)*U1*Sin + Wi*U2*Sin = 5610.2697

= Tan

-1

(TP1/TP2) = 0.1348

Sag due to Insulator = Si = U1*Sin( + d) = 0.7569 m

Page 18 of 32

Annexure-2 CASE 1.

10 Total maximum sag of moose conductor = Sc+Si = Stot = 2.0530 m

11 Height of conductor above ground 15.3000 m

Height of jack bus/equipment below conductor 8.3000 m

Minimum Phase to phase clearance = 4.0000 m

Total maximum sag of moose conductor = Sc+Si = Stot = 2.0530 m

Therefore, available margin excluding sub-conductor spacing = 0.9470 m

SWING CALCULATIONS

1 SAG DUE TO CONDUCTOR

(under maximum temperature rise in temperature and maximum wind conditions):

SGB = (Q1 * S *L)

2

* ey/24 = 1.4450E+08

SF = (f1-SGB/f1

2

) - a*ey*(t1+t3-t2) = -1.0193E+04

To solve the following equation:

f21

2 *

(f21 - SF) - SGB = 1.11E+10

we get f21 = 1002.7182 Kg/cm

2

Tension in conductor at maximum temperature and maximum wind

condition = Ten21 = f21*A= 7970.2854 Kg

SAG due to conductor = Sc1 = Wc*L

2

/(8*Ten21) = 0.3934 m

2 SAG DUE TO INSULATOR

From Fig 1, we get

Teni2 = Ten21*r/Ni 3985.1427

U1 = (li2 + (di/2)2) = 4.6021 m

U2 = ((li/2)2 + (di/2)2) = 2.3043 m

= Tan

-1

[(di/2)/li] = 0.0304

= Tan

-1

[di/li] = 0.0608

Taking moments at 'P'

TenI2 * U1 * Sin( + ) = (WcI*L/2) * U1 * Cos(+ ) + Wi * U2 *Cos(+ )

Simplifying :

TP1 = (WcI*L/2) * U1 * Cos + Wi*U2*Cos - TenI2*U1*Sin = 372.2725

TP2 = TenI2*U1*Cos + Wc*(L/2)*U1*Sin + Wi*U2*Sin = 18378.4466

= Tan

-1

(TP1/TP2) = 0.0203

SAG due to Insulator = Si1 = U1*Sin( + ) = 0.2331

Page 19 of 32

Annexure-2 CASE 1.

3 SWING DUE TO CONDUCTOR (SWC)

Wind load acting on span = Pcc * L*r = 1060.9103 Kg

Weight of conductor = Wc * L *r= 561.7260 Kg

From Fig 3:

Tan Y1 = (r*Pcc * L/r*Wc * L) = 1.8887

Y1 = Tan

-1

(Pcc/Wc) = 1.0838

SWC = Sc1* Sin Y1 = 0.3476 m

4 SWING DUE TO INSULATOR (SWI)

Wind load on insulator = Wpi = (Pc/2)*di*li *Gc*C

dc

= 100.1105 kg

Y2 = Tan

-1

(Ni*Wpi/Ni*Wi) = 1.5708

SWI = Si1 * Sin Y2 = 0.2331 m

5 Total Swing = Swtot = SWC + SWI = 0.5808

6 Phase to phase spacing provided between phases = 7.0000 m

Subconductor spacing = 0.4500 m

Minimum Phase to phase clearance = 4.0000 m

Phase to phase spacing required = 5.0308 m

Therefore, available margin = 1.9692 m

Page 20 of 32

CASE - 2 ANNEXURE - 2

CASE 2.

NAME OF PROJECT:

CONDUCTOR TYPE: TARANTULLA

NAME OF BAY: 0.35

SPAN LENGTH (Centre Lime distance between beams): 100.00 m

MINIMUM STRINGING TEMPERATURE: 10.00 Deg C

TEMPERATURE RANGE FOR DRAWING STRINGING CHART:

MINIMUM: 0.00 C MAXIMUM: 50.00 C

WIND PRESSURE ON CONDUCTOR PER M RUN: 0.00 kg/m

OVERALL DIA OF THE CONDUCTOR: 3.660 cm

CROSS SECTIONAL AREA OF CONDUCTOR: 7.949 cm

WEIGHT OF CONDUCTOR PER METER: 2.910 kgf/m

COEFFICIENT OF LINEAR EXPANSION: 0.00002300 per C

NO. OF CONDUCTORS PER PHASE: 2

TENSION PER CONDUCTOR UNDER MIN TEMP & MAX WIND CONDITION: 1000.00 kg

MODULUS OF ELASTICITY: 608200.00 kg/cm2

NUMBER OF INSULATOR STRING(S): 4.00

LENGTH OF INSULATOR: 4.600 m

DIAMETER OF INSULATOR: 0.280 m

WEIGHT OF INSULATOR: 264.000 kg

INSULATOR AND TURNBUCKLE DATA

SAG TENSION CHART

GENERAL DATA

CONDUCTOR DATA

Page 21 of 32

CASE - 2 ANNEXURE - 2

MAXIMUM CLEAR SPAN OF CONDUCTOR: 89.30 m

S.NO. TEMPERATURE

TENSION PER

CONDUCTOR

CONDUCTOR

SAG

INSLULATOR

SAG

TOTAL SAG

1 42 587.17 3.8 1.68 5.48

2 12 624.61 3.57 1.59 5.16

3 14 621.89 3.59 1.6 5.19

4 16 619.21 3.6 1.61 5.21

5 18 616.56 3.62 1.61 5.23

6 20 613.94 3.63 1.62 5.25

7 22 611.36 3.65 1.62 5.27

8 24 608.81 3.66 1.63 5.29

9 26 606.28 3.68 1.64 5.31

10 28 603.79 3.69 1.64 5.33

11 30 601.33 3.71 1.65 5.36

12 32 598.9 3.72 1.65 5.38

13 34 596.5 3.74 1.66 5.4

14 36 594.13 3.75 1.66 5.42

15 38 591.78 3.77 1.67 5.44

16 40 589.46 3.78 1.68 5.46

RESULTS

Page 22 of 32

Type Al Strands Steel Strands Al Strand Dia St strand dia Cross sec. Diameter Weight Young's Mod.

Kg./Cm

2

Young's

Modulus

(N/sq.m)

Drag

Coefficient

DC

Resistance

Coefficient of

Linear

Expansion

sq.m m kg/km Kg./Cm

2

BEAR ACSR 30 7 3.350E-03 3.350E-03 3.2612E-04 2.3450E-02 1.229 7.870E+05 8.02E+10 1 0.1093 0.00001843

BEAVER ACSR 6 1 3.990E-03 3.990E-03 8.7525E-05 1.1970E-02 0.303 8.090E+05 8.25E+10 1 0.3825 0.00001931

BUX ACSR 30 7 4.500E-03 4.500E-03 5.8846E-04 3.1500E-02 2.196 7.870E+05 8.02E+10 1 0.0569 0.00001843

CAT ACSR 6 1 4.500E-03 4.500E-03 1.1133E-04 1.3500E-02 0.385 7.350E+05 7.49E+10 1 0.3007 0.00001931

COYOTO ACSR 26 7 2.540E-03 1.900E-03 1.5159E-04 1.5860E-02 0.521 7.870E+05 8.02E+10 1 0.3035 0.00001954

DEER ACSR 30 7 4.270E-03 4.270E-03 5.2984E-04 2.9890E-02 1.977 7.870E+05 8.02E+10 1 0.0673 0.00001843

DOG ACSR 6 7 4.720E-03 1.570E-03 1.1854E-04 1.4150E-02 0.394 7.350E+05 7.49E+10 1 0.2733 0.00001992

FERRET ACSR 6 1 3.000E-03 3.000E-03 4.9480E-05 9.0000E-03 0.171 8.090E+05 8.25E+10 1 0.6766 0.00001931

FOX ACSR 6 1 2.790E-03 2.790E-03 4.2795E-05 8.3700E-03 0.1489 8.090E+05 8.25E+10 1 0.7822 0.00001931

GOAT ACSR 30 7 3.710E-03 3.710E-03 3.9998E-04 2.5970E-02 1.492 7.870E+05 8.02E+10 1 0.0891 0.00001843

GOPHER ACSR 6 1 2.360E-03 2.360E-03 3.0620E-05 7.0800E-03 0.106 8.090E+05 8.25E+10 1 1.0933 0.00001931

GUINEA ACSR 12 7 2.920E-03 2.920E-03 1.2724E-04 1.4600E-02 0.59 1.055E+06 1.08E+11 1 0.2630 0.00001584

LARK ACSR 30 7 2.920E-03 2.920E-03 2.4777E-04 2.0440E-02 0.922 7.870E+05 8.02E+10 1 0.1350 0.00001843

LEOPARD ACSR 6 7 5.280E-03 1.760E-03 1.4840E-04 1.5840E-02 0.493 7.730E+05 7.88E+10 1 0.2184 0.00001954

LION ACSR 30 7 3.180E-03 3.180E-03 2.9386E-04 2.2260E-02 1.097 7.870E+05 8.02E+10 1 0.1213 0.00001843

LYNX ACSR 30 7 2.790E-03 2.790E-03 2.2620E-04 1.9530E-02 0.844 7.870E+05 8.02E+10 1 0.1576 0.00001843

MINK ACSR 6 1 3.660E-03 3.660E-03 7.3646E-05 1.0980E-02 0.255 8.090E+05 8.25E+10 1 0.4546 0.00001931

MOOSE ACSR 54 7 3.530E-03 3.530E-03 5.9699E-04 3.1770E-02 2.002 6.860E+05 6.99E+10 1 0.0547 0.00001991

OTTER ACSR 6 1 4.220E-03 4.220E-03 9.7907E-05 1.2660E-02 0.339 8.090E+05 8.25E+10 1 0.3419 0.00001931

PANTHER ACSR 30 7 3.000E-03 3.000E-03 2.6154E-04 2.1000E-02 0.976 7.870E+05 8.02E+10 1 0.1363 0.00001843

RABBIT ACSR 6 1 3.350E-03 3.350E-03 6.1699E-05 1.0050E-02 0.214 8.090E+05 8.25E+10 1 0.5426 0.00001931

RACCOON ACSR 6 1 4.090E-03 4.090E-03 9.1968E-05 1.2270E-02 0.318 8.090E+05 8.25E+10 1 0.3640 0.00001931

SHEEP ACSR 30 7 3.990E-03 3.990E-03 4.6263E-04 2.7930E-02 1.726 7.870E+05 8.02E+10 1 0.0770 0.00001843

SPARROW ACSR 6 1 2.670E-03 2.670E-03 3.9193E-05 8.0100E-03 0.135 8.090E+05 8.25E+10 1 0.8540 0.00001931

SQUIRREL ACSR 6 1 2.110E-03 2.110E-03 2.4477E-05 6.3300E-03 0.085 8.090E+05 8.25E+10 1 1.3677 0.00001931

TIGER ACSR 30 7 2.360E-03 2.360E-03 1.6185E-04 1.6520E-02 0.604 7.870E+05 8.02E+10 1 0.2202 0.00001843

WEASSEL ACSR 6 1 2.590E-03 2.590E-03 3.6880E-05 7.7700E-03 0.128 8.090E+05 8.25E+10 1 0.9077 0.00001931

WOLF ACSR 30 7 2.590E-03 2.590E-03 1.9494E-04 1.8130E-02 0.727 7.870E+05 8.02E+10 1 0.1828 0.00001843

ZEBRA ACSR 54 7 3.180E-03 3.180E-03 4.8448E-04 2.8620E-02 1.623 6.860E+05 6.99E+10 1 0.0674 0.00001991

ANT AAC 7 3.100E-03 5.2834E-05 9.3000E-03 0.144 6.187E+05 6.31E+10 1 0.5419 0.000023

BLUE BOTTLE AAC 7 3.660E-03 7.3646E-05 1.0950E-02 0.201 6.187E+05 6.31E+10 1 0.3887 0.000023

BUTTERFLY AAC 19 4.650E-03 3.2266E-04 2.3250E-02 0.886 6.082E+05 6.20E+10 1 0.0892 0.000023

CATTER-PILLAR AAC 19 3.530E-03 1.8595E-04 1.0590E-02 0.511 6.187E+05 6.31E+10 1 0.1547 0.000023

CHAFER AAC 19 3.780E-03 2.1322E-04 1.8900E-02 0.586 6.082E+05 6.20E+10 1 0.1349 0.000023

CLEGG AAC 7 4.170E-03 9.5600E-05 1.2510E-02 0.261 6.187E+05 6.31E+10 1 0.2995 0.000023

COCKROACH AAC 19 4.220E-03 2.6575E-04 2.1100E-02 0.73 6.082E+05 6.20E+10 1 0.1083 0.000023

EARWIG AAC 7 3.780E-03 7.8555E-05 1.1340E-02 0.215 6.187E+05 6.31E+10 1 0.3644 0.000023

FLY AAC 7 3.400E-03 6.3554E-05 1.0200E-02 0.174 6.187E+05 6.31E+10 1 0.4505 0.000023

GRASS HOPPER AAC 7 3.910E-03 8.4051E-05 1.1730E-02 0.23 6.187E+05 6.31E+10 1 0.3406 0.000023

IRIS AAC 7 2.480E-03 3.3814E-05 7.4400E-03 0.092 6.187E+05 6.31E+10 1 0.8467 0.000023

LADY BIRD AAC 7 2.790E-03 4.2795E-05 8.3700E-03 0.117 6.187E+05 6.31E+10 1 0.669 0.000023

LOCUST AAC 19 5.360E-03 4.2872E-04 2.6800E-02 1.176 6.082E+05 6.20E+10 1 0.0671 0.000023

MAYBUG AAC 37 4.090E-03 4.8611E-04 2.8630E-02 1.343 5.976E+05 6.09E+10 1 0.0593 0.000023

MOTH AAC 19 5.000E-03 3.7306E-04 2.5000E-02 1.025 6.082E+05 6.20E+10 1 0.0771 0.000023

PANSY AAC 7 2.780E-03 4.2489E-05 8.3400E-03 0.116 6.187E+05 6.31E+10 1 0.6738 0.000023

ROSE AAC 7 1.960E-03 2.1120E-05 5.8800E-03 0.058 6.187E+05 6.31E+10 1 1.3556 0.000023

SCORPION AAC 37 4.270E-03 5.2984E-04 2.9890E-02 1.464 5.976E+05 6.09E+10 1 0.0544 0.000023

SPIDER AAC 19 3.990E-03 2.3757E-04 1.9950E-02 0.652 6.082E+05 6.20E+10 1 0.1205 0.000023

TARANTULLA AAC 37 5.230E-03 7.9487E-04 3.6600E-02 2.91 6.082E+05 6.20E+10 1 0.0363 0.000023

WASP AAC 7 4.390E-03 1.0595E-04 1.3170E-02 0.29 6.187E+05 6.31E+10 1 0.2702 0.000023

SHIELD WIRE 7/9 SW 7 3.660E-03 7.3646E-05 1.2180E-02 0.583 1933000 1.97E+11 1.2 0.000012

SHIELD WIRE 7/8 SW 7 9.0500E-05 1.2180E-02 0.706 1933000 1.97E+11 1.2 0.000012

BLANK SW

disc insulator x

Creepage Diameter of

Disc

Weight of Disc Length of

Disc

120 440 0.28 8.3 0.145

xx

SKIN EFFECT TABLE

Sl No. X K

1 0.00 1.00000

2 0.10 1.00000

3 0.20 1.00001

4 0.30 1.00004

5 0.40 1.00013

6 0.50 1.00032

7 0.60 1.00067

8 0.70 1.00124

9 0.80 1.00212

10 0.90 1.00340

11 1.00 1.00519

12 1.10 1.00758

13 1.20 1.01071

14 1.30 1.01470

15 1.40 1.01969

16 1.50 1.02582

17 1.60 1.03323

18 1.70 1.04205

19 1.80 1.05240

20 1.90 1.06440

21 2.00 1.07816

22 2.10 1.09375

23 2.20 1.11126

24 2.30 1.13069

25 2.40 1.15207

26 2.50 1.17538

27 2.60 1.20056

28 2.70 1.22753

29 2.80 1.25620

30 2.90 1.28644

31 3.00 1.31809

32 3.10 1.35102

33 3.20 1.38504

34 3.30 1.41999

35 3.40 1.45570

36 3.50 1.49202

37 3.60 1.52879

38 3.70 1.56587

39 3.80 1.60314

40 3.90 1.64051

Source : Electrical Transmission & Distribution Reference book by Central Station Engineers of Westinghouse Electric Corporation

Source : Bureau of Standards Bulletin No. 169 on pages 226-8

Source : TNEB HANDBOOK

Source : Electrical Transmission & Distribution Reference book by Central Station Engineers of Westinghouse Electric Corporation

Doc. No. : YN1H300126-403, Rev. A

n

f 50 Hz as

k 1.81 As per IEC-909 ds

k 1.81 as/ds

1/t 22.55772088 ds/as

t 0.04433072

1.499079658 Sqrt((as/ds)-1)

fT

pi

3.410369262 v

3

2tfT

pi

21.41711897

ft 2.216535982 q

c st

c pi

v

1

4.276003 y

a

v

2

1.572075 a

s

v

3

2*y

a

/a

s

A 0.023040059

sqrt[(1-2*ya/as)/2*ya/as]

B 0.616802478 a

sw

C 0.285149187 fq

D 0.312916328

E 0.040923867

F 0.214715018

G 6.22057E-17

V2 1 - A + B - C*[( D + E)*F + G ]

1.572098266

-0.00002

223839692.xls.ms_office Page 27 of 32

Doc. No. : YN1H300126-403, Rev. A

2

0.45

3.66E-02

12.29508197

0.081333333

3.36081567

0.213286608

0.629148847

7.31E-01

2.13E+00

9.50E-02

0.095978973

0.422021926

1.170275665

0.287831932

0.333454919

-6.49E-06

223839692.xls.ms_office Page 28 of 32

Annexure-2 CASE

System Voltage V = 420 kV

1 Basic Wind Speed = V

b

= 0.00 m/s

As per IS 802: 1995, basic wind speed is based on gust velocity averaged over a short time interval of 3s.

Wind Zone as per IS: 802, Part 1, Sec 1 1

Risk Coefficient as per Table 2 of IS: 802, Part 1, Sec 1

{For all Zones & for Reliability level 1(Voltage level upto 400kV)} =

K

1

= 1.07

Terrain Category 2

Terrain roughness coeficient (For different Terrain Category) = K

2

= 1.0000

Factor to convert 3 second peak gust speed into

average speed of wind during 10 minutes period =

K

0

= 1.3750

Meteorological reference wind speed = V

b

/K

0

V

R

= 0.0000 m/s

Design wind speed = V

R

x K

1

x K

2

V

d

= 0.0000 m/s

Height of conductor above ground 15.3000 metre

Gust Response Factor for conductor Gc = 1.9837

2 Design Wind Pressure =0.6 x V

d

2

/g Pc = 0.0000 kgf/m

2

Weight of individual spacer = WSP = 3.0000 kgf

Separation between two spacers = SSP = 6.0000 metre

Weight of sub-conductor per metre= W1 = 2.9100 kgf/m

No. of subconductors - single/twin/tri/quad = r = 2

Diameter of sub-conductor = d = 3.6600 cm

Cross Sectional Area of sub-conductor = A = 7.9487 cm

2

Modulus of Elasticity of sub-conductor = ey = 608200.0000 Kg/cm

2

Coefficient of Linear Expansion = a = 2.3000E-05 /

o

C

Maximum Ambient Temperature at site = t1 = 40.0000

o

C

Minimum Ambient Temperature at site = t2 = 0.0000

o

C

Rise in temperature = t3 = 0.0000

o

C

Distance between centre line of beams (for conductor span) = la = 100.0000 m

DIameter of disc = di = 0.2800

Nos. of Insulator Strings in one side of conductor span (Single /Double) Ni = 4

Weight of complete string insulator including hardware W

iT

= 1056.0000

Weight of single string insulator including hardware Wi= 264.0000

Length of insulator string = li = 4.6000 m

Width of beam on which conductor is strung = Bw = 1.5000 m

Tension per SUB-CONDUCTOR under max. wind and min. temp. conditions = Ten1= 1000.0000 Kg

Drag Coefficient C

dc

= 1.0000

3 Effect of Ice formation

Radial Thickness of ICE over the conductor Th

ice

= 0.0000 cm

Effective dia of the conductor considering ICE effect = d+2*Th

ice

D1= 3.6600 cm

Increase in Conducter weight due to effect of Ice formation w3= 0.0000 kg/m

4 Total weight of sub-conductor per phase = Wc = W1+WSP/(r*SSP)+w3 = 3.1452 Kg/m

5 Wind Load on conductor as per IS 802 & IS 5613 = Pcc =

Pc * (d/100) * C

dc

* G

c

= 0.0000 Kg/m

CALCULATIONS FOR SAG AND SWING OF STRUNG CONDUCTOR

Page 29 of 32

Annexure-2 CASE

6 Clear span of conductor = L = la-(2*li)-lt-Bw = 89.3000 m

7 Loading factor during max wind condition = Q1= (1+(Pcc/Wc)

2

) = 1.0000

Loading factor during no wind condition = Q2 = 1.0000

8 SAG CALCULATIONS DUE TO CONDUCTOR

8.1

Under minimum temperature and maximum wind condition condition, the sub-

conductor experiences a stress of f1

f1 = Ten1/A = 125.8071 Kg/cm

2

Weight of sub conductor per m per cm

2

= S = Wc/A = 0.3957

GB = (S * L * Q2)

2

* ey/24 = 3.1640E+07

F = f1 - GB * (Q1/(f1*Q2))

2

- a * ey * (t1+t3-t2) = -2432.7896

To solve the following equation:

The working stress F at tempature t1+t3, is given by the cubic equation

f2

2 *

(f2 - F) - GB = 6319246.35

we get f2 = 121.8959 Kg/cm

2

8.2 Tension in conductor at maximum temperature and no wind

condition = Ten2 = f2*A = 968.9115 Kg

Max sag due to conductor = Wc*L / (8*Ten2) Sc= 3.2357

9 SAG DUE TO INSULATOR

From Fig 1, we get

Tension per insulator string = Ten2* r / Ni Teni1= 484.4558

Weight of conductor per String Insulator = Wc*r/Ni Wci= 1.5726

U1 = (li

2

+ (di/2)

2

) = 4.6021 m

U2 = ((li/2) + (di/2)) = 2.3043 m

= Tan

-1

[(di/2)/li] = 0.0304

= Tan

-1

[di/li] = 0.0608

Taking moments at 'P'

Teni1 * U1 *Sin( + ) = (Wci * L/2) * U1 * Cos( + ) + Wi * U2 *Cos( + )

Simplifying :

TP1 = (Wci*L/2) * U1 * Cos + Wi*U2*Cos - Teni1*U1*Sin = 862.3686

TP2 = Teni1*U1*Cos + Wci*(L/2)*U1*Sin + Wi*U2*Sin = 2275.2868

= Tan

-1

(TP1/TP2) = 0.3623

Sag due to Insulator = Si = U1*Sin( + d) = 1.7612 m

10 Total maximum sag of moose conductor = Sc+Si = Stot = 4.9969 m

11 Height of conductor above ground 15.3000 m

Height of jack bus/equipment below conductor 8.3000 m

Minimum Phase to phase clearance = 4.0000 m

Total maximum sag of moose conductor = Sc+Si = Stot = 4.9969 m

Therefore, available margin excluding sub-conductor spacing = -1.9969 m

SWING CALCULATIONS

Page 30 of 32

Annexure-2 CASE

1 SAG DUE TO CONDUCTOR

(under maximum temperature rise in temperature and maximum wind conditions):

SGB = (Q1 * S *L)

2

* ey/24 = 3.1640E+07

################

SF = (f1-SGB/f1

2

) - a*ey*(t1+t3-t2) = -2432.7896

To solve the following equation:

f21

2 *

(f21 - SF) - SGB = 93728283.38

we get f21 = 217.4941 Kg/cm

2

Tension in conductor at maximum temperature and maximum wind

condition = Ten21 = f21*A= 1728.7905 Kg

SAG due to conductor = Sc1 = Wc*L

2

/(8*Ten21) = 1.8135 m

2 SAG DUE TO INSULATOR

Page 31 of 32

Annexure-2 CASE

From Fig 1, we get

Teni2 = Ten21*r/Ni 864.3952

U1 = (li2 + (di/2)2) = 4.6021 m

U2 = ((li/2)2 + (di/2)2) = 2.3043 m

= Tan

-1

[(di/2)/li] = 0.0304

= Tan

-1

[di/li] = 0.0608

Taking moments at 'P'

TenI2 * U1 * Sin( + ) = (WcI*L/2) * U1 * Cos(+ ) + Wi * U2 *Cos(+ )

Simplifying :

TP1 = (WcI*L/2) * U1 * Cos + Wi*U2*Cos - TenI2*U1*Sin = 809.1771

TP2 = TenI2*U1*Cos + Wc*(L/2)*U1*Sin + Wi*U2*Sin = 4023.0083

= Tan

-1

(TP1/TP2) = 0.1985

SAG due to Insulator = Si1 = U1*Sin( + ) = 1.0443

3 SWING DUE TO CONDUCTOR (SWC)

Wind load acting on span = Pcc * L*r = 0.0000 Kg

Weight of conductor = Wc * L *r= 561.7260 Kg

From Fig 3:

Tan Y1 = (r*Pcc * L/r*Wc * L) = 0.0000

Y1 = Tan

-1

(Pcc/Wc) = 0.0000

Page 32 of 32

Вам также может понравиться

- 123Документ29 страниц123Pravin Narkhede100% (1)

- Design Calculation: Larsen & Toubro LimitedДокумент72 страницыDesign Calculation: Larsen & Toubro Limitedjm.mankavil6230Оценок пока нет

- 220KV NAGARAM LINE DISTANCE PROTECTION SETTINGДокумент42 страницы220KV NAGARAM LINE DISTANCE PROTECTION SETTING1453h100% (2)

- DSLP Calculation 66kV Grid SubstationДокумент8 страницDSLP Calculation 66kV Grid SubstationanilmarturiОценок пока нет

- Zebra Current Capacity Calculation SheetДокумент1 страницаZebra Current Capacity Calculation SheetbinodeОценок пока нет

- 1.0.0 Symbols & Units: PN SN R SC B BДокумент34 страницы1.0.0 Symbols & Units: PN SN R SC B BVelu SamyОценок пока нет

- Short Circuit Current CalculationДокумент3 страницыShort Circuit Current CalculationDHAMIM ANSARI0% (1)

- DG Fault Current & Earth Flat SizingДокумент2 страницыDG Fault Current & Earth Flat SizingPalani100% (1)

- Short Circuit Force Calculation For 132 KV Substation at Noida-Sector 62Документ7 страницShort Circuit Force Calculation For 132 KV Substation at Noida-Sector 62raghvendraОценок пока нет

- DSLP (11 3m)Документ7 страницDSLP (11 3m)Ashutosh MishraОценок пока нет

- Busbar Sizing For SubstationДокумент22 страницыBusbar Sizing For Substationdundi_kumarОценок пока нет

- MV Cable Sizing CalculationДокумент1 страницаMV Cable Sizing Calculationsureshbabum85Оценок пока нет

- MV Capacitor CalculationДокумент1 страницаMV Capacitor CalculationPramod B.WankhadeОценок пока нет

- Zebra Current Capacity Calculation SheetДокумент1 страницаZebra Current Capacity Calculation Sheetbinode100% (1)

- Sag 340Документ15 страницSag 340tanujaayerОценок пока нет

- 500SQMM-Buried Cable Current Carrying Capacity - RevisedДокумент2 страницы500SQMM-Buried Cable Current Carrying Capacity - RevisedBijaya Kumar MohantyОценок пока нет

- Short-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Документ10 страницShort-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Hassan Bagheri100% (1)

- Short Current Calculation For Derba SubstationДокумент9 страницShort Current Calculation For Derba Substationjie zhang100% (1)

- Technical - Tables Siemens CablesДокумент9 страницTechnical - Tables Siemens CablesIon Logofătu AlbertОценок пока нет

- Cal-Mn Dastur T2117 Rev 2Документ4 страницыCal-Mn Dastur T2117 Rev 2Shubham BaderiyaОценок пока нет

- SLD 02 03 17Документ1 страницаSLD 02 03 17Hari HaranОценок пока нет

- Calculation for busbar & conductor sizing in 400/132 kV switchyardДокумент4 страницыCalculation for busbar & conductor sizing in 400/132 kV switchyardPrashant TrivediОценок пока нет

- Cable Loss CalculationДокумент2 страницыCable Loss CalculationYrty KdfgОценок пока нет

- DSLP Dirct Srole Lightning ProtectionДокумент7 страницDSLP Dirct Srole Lightning Protectiongsaiswaroopg100% (2)

- Aluminium Conductor Sizing - 275kVДокумент10 страницAluminium Conductor Sizing - 275kVsitifarhaniОценок пока нет

- Lightning Protection Calculations for 400/220/33kV Indrapuram SubstationДокумент10 страницLightning Protection Calculations for 400/220/33kV Indrapuram SubstationJay Rameshbhai ParikhОценок пока нет

- Sag Tension 765kVДокумент11 страницSag Tension 765kVvikasrajput1989100% (1)

- 110V DC - Battery and Battery ChargerДокумент4 страницы110V DC - Battery and Battery ChargerSathish100% (1)

- CALCULATIONS FOR BUSBAR & CONDUCTOR SIZINGДокумент6 страницCALCULATIONS FOR BUSBAR & CONDUCTOR SIZINGRavindra GoyalОценок пока нет

- Design of Insulator - 07.11.11Документ1 страницаDesign of Insulator - 07.11.11Natarajan RamakrishnanОценок пока нет

- Dokumen - Tips - 132kv Sag CalculationДокумент14 страницDokumen - Tips - 132kv Sag CalculationKunal AwaghadeОценок пока нет

- IEC1597 and IEC865 equations to calculate current capacity and short circuit withstand capability of 33kV Panther conductorДокумент2 страницыIEC1597 and IEC865 equations to calculate current capacity and short circuit withstand capability of 33kV Panther conductornb nbОценок пока нет

- D.S.L.P Calculation For 100Kv Switchyard For Centur Rayon by Rolling Sphere Method, As Per IEEE-std 998-1996Документ36 страницD.S.L.P Calculation For 100Kv Switchyard For Centur Rayon by Rolling Sphere Method, As Per IEEE-std 998-1996prabhaamj muraliОценок пока нет

- ACSR Conductor SizingДокумент13 страницACSR Conductor SizingraghuvarmaОценок пока нет

- Ieee 80 Tiuch and Step Volt - Full CalcДокумент22 страницыIeee 80 Tiuch and Step Volt - Full CalcVasu Iyer100% (1)

- CT Calculation MFAC14Документ10 страницCT Calculation MFAC14Jay WinОценок пока нет

- Pathlaiya SS 132kV Busbar DesignДокумент9 страницPathlaiya SS 132kV Busbar DesignSantosh GairheОценок пока нет

- Acdb MCCB Setting Calculation - DH BSP - DH BSP - 30.05.17Документ6 страницAcdb MCCB Setting Calculation - DH BSP - DH BSP - 30.05.17Sathiya SeelanОценок пока нет

- Lightning Rolling Sphere 2016-02-04Документ1 страницаLightning Rolling Sphere 2016-02-04Brandon ChoateОценок пока нет

- Short Circuit Value CalculationДокумент1 страницаShort Circuit Value CalculationSmit KadamОценок пока нет

- 33 SCF Tower Span 18mДокумент25 страниц33 SCF Tower Span 18mamrit90320Оценок пока нет

- Equipment Interconnection SCF & Cantilever Strength Analysis For Rigid BusДокумент16 страницEquipment Interconnection SCF & Cantilever Strength Analysis For Rigid BusSamant SauravОценок пока нет

- Siemens - CCДокумент11 страницSiemens - CCtrymskvedaОценок пока нет

- 110/11kV Substation Grid Design CalculationДокумент5 страниц110/11kV Substation Grid Design CalculationPrasadОценок пока нет

- CT SizingДокумент34 страницыCT Sizingrajinipre-1Оценок пока нет

- Calculation of Short CircuitДокумент1 страницаCalculation of Short CircuitramkumartanwarОценок пока нет

- Fault Level CalДокумент2 страницыFault Level Calaviral mishraОценок пока нет

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОт EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsОценок пока нет

- Forces On Gantry-34Документ5 страницForces On Gantry-34vkjainabc100% (1)

- Psme QuizДокумент9 страницPsme QuizJerico LlovidoОценок пока нет

- Short Circuit Force CalculationДокумент11 страницShort Circuit Force CalculationAchint Kumar100% (2)

- Earthing CalculationДокумент14 страницEarthing CalculationNatarajan Ramakrishnan100% (18)

- Mathcad - Central BeamДокумент4 страницыMathcad - Central BeamRudrabir GhantiОценок пока нет

- Torsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionДокумент26 страницTorsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionHafiezul HassanОценок пока нет

- Pyrhonen Squirrel Cage Motor Calculation Mathcad13Документ35 страницPyrhonen Squirrel Cage Motor Calculation Mathcad13Mutee Ullah KhanОценок пока нет

- Solutions HW 7Документ5 страницSolutions HW 7sam9montgomeryОценок пока нет

- Final Design of Angle Members For 4leged Single Angle TowersДокумент65 страницFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerОценок пока нет

- Formula Sheet For DoДокумент6 страницFormula Sheet For DoMirza Waqar BaigОценок пока нет

- Busbar Current Rating and BPI Cantilever Calculation(Equation No. 30, IEEE 605Документ45 страницBusbar Current Rating and BPI Cantilever Calculation(Equation No. 30, IEEE 605annuvyas100% (1)

- Resistivity of Wire Electricity Conductor - Dana Santika - Physics - Ganesha University of EducationДокумент16 страницResistivity of Wire Electricity Conductor - Dana Santika - Physics - Ganesha University of EducationI Gede Dana SantikaОценок пока нет

- Rtaa Svx01a en - 09012005Документ178 страницRtaa Svx01a en - 09012005jars03180950100% (1)

- Rtaa IomДокумент140 страницRtaa IomFabian Lopez100% (1)

- IBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECДокумент10 страницIBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECVíctor RojasОценок пока нет

- Electrical Standard Products: Switchgear Training Centre, CoonoorДокумент20 страницElectrical Standard Products: Switchgear Training Centre, CoonoorVíctor RojasОценок пока нет

- Selective Coordination EATONДокумент22 страницыSelective Coordination EATONBrenda Naranjo MorenoОценок пока нет

- Bussman - How To Size A FuseДокумент15 страницBussman - How To Size A FuseSJS68Оценок пока нет

- 3 CH 2Документ20 страниц3 CH 2Mary HarrisonОценок пока нет

- 4 1 PDFДокумент28 страниц4 1 PDFVíctor RojasОценок пока нет

- HVAC & Refrigeration SystemДокумент22 страницыHVAC & Refrigeration SystemSivakumar NadarajaОценок пока нет

- Bureau of Energy EfficiencyДокумент23 страницыBureau of Energy Efficiencypbs0707Оценок пока нет

- 4 4Документ34 страницы4 4Samir Ranjan ParidaОценок пока нет

- Calculate Fault LevelsДокумент46 страницCalculate Fault LevelsPichumani100% (4)

- Parcial 1 Distribuciones Abril-Jul 2010Документ12 страницParcial 1 Distribuciones Abril-Jul 2010Víctor RojasОценок пока нет

- Case Studies On Paralleling of TransformersДокумент7 страницCase Studies On Paralleling of Transformersmuaz_aminu1422Оценок пока нет

- Wiring Diagram-Split System Air ConditionerДокумент1 страницаWiring Diagram-Split System Air ConditionerSohail Ejaz Mirza83% (12)

- LT Cable Sizing Calculation SheetДокумент12 страницLT Cable Sizing Calculation Sheet2003vinay100% (5)

- UPSДокумент63 страницыUPSgavinilaa100% (1)

- MCC & ContactorsДокумент9 страницMCC & ContactorsbimboawotikuОценок пока нет

- Temp CalculationДокумент1 страницаTemp CalculationVíctor RojasОценок пока нет

- Constr Esb750Документ127 страницConstr Esb750Erica MosesОценок пока нет

- Setting Calulation For Gen Tms TRF and BusbarДокумент10 страницSetting Calulation For Gen Tms TRF and BusbarVíctor Rojas100% (1)

- MCC 15B CalculationV3Документ2 страницыMCC 15B CalculationV3Wimalasiri DissanayakeОценок пока нет

- AP01200003E - Fault Current - Coordination CalculatorДокумент13 страницAP01200003E - Fault Current - Coordination CalculatorVíctor RojasОценок пока нет

- 11 KV transformer and power system analysisДокумент18 страниц11 KV transformer and power system analysisAbdulyunus Amir100% (1)

- Assignment SUBJECT: Industrial Power System Analysis and DesignДокумент1 страницаAssignment SUBJECT: Industrial Power System Analysis and DesignthavaselvanОценок пока нет

- Cable CalcДокумент7 страницCable CalcVíctor RojasОценок пока нет

- Short Circuit HayabusaДокумент3 страницыShort Circuit Hayabusameeng2014Оценок пока нет

- 4.Ht Short Circuir CalculationДокумент11 страниц4.Ht Short Circuir CalculationPrabhash VermaОценок пока нет

- Cable size calculation chart for electrical installationsДокумент6 страницCable size calculation chart for electrical installationsnicrajesh90% (10)

- Relay Setting CoordinationДокумент8 страницRelay Setting Coordinationsmepp100% (2)

- Chapter 6 PDFДокумент56 страницChapter 6 PDFhamza abbasОценок пока нет

- Radioisotopes in Smoke AlarmsДокумент12 страницRadioisotopes in Smoke AlarmsTravleIceОценок пока нет

- Introduction to MEMS Etching TechniquesДокумент16 страницIntroduction to MEMS Etching TechniquesArjit GoswamiОценок пока нет

- Batch ReactorДокумент4 страницыBatch ReactorHarini BugattiveyronОценок пока нет

- Sri Vijay Vidyalaya College of Arts and Science, Bargur Book ListДокумент4 страницыSri Vijay Vidyalaya College of Arts and Science, Bargur Book ListVelu SamyОценок пока нет

- 01 StudyGuide (2021) ChemДокумент157 страниц01 StudyGuide (2021) ChemYzakRVОценок пока нет

- An Ancient Life Crystal TechnologyДокумент2 страницыAn Ancient Life Crystal TechnologyVladan BajicОценок пока нет

- Approximate Design of Multiple Feed Side Stream Distillation Systems 1987 Industrial and Engineering Chemistry ResearchДокумент7 страницApproximate Design of Multiple Feed Side Stream Distillation Systems 1987 Industrial and Engineering Chemistry ResearchDevaucayОценок пока нет

- Synthesis of Biodiesel Via Acid CatalysisДокумент11 страницSynthesis of Biodiesel Via Acid CatalysisMạnh BùiОценок пока нет

- Enzymes 2Документ5 страницEnzymes 2Ema Arroyo LopezОценок пока нет

- Mas and e PDFДокумент5 страницMas and e PDFtulasi saladiОценок пока нет

- Water Purification Experiment Dissolved OxygenДокумент2 страницыWater Purification Experiment Dissolved OxygenJunОценок пока нет

- RonNielsen NuclearReactionsДокумент471 страницаRonNielsen NuclearReactionsr_nielsenОценок пока нет

- Colorimetry 1Документ23 страницыColorimetry 1Denise CssОценок пока нет

- Cementation in Fixed Partial Denture - 01Документ28 страницCementation in Fixed Partial Denture - 01Akshay GajakoshОценок пока нет

- Electronic Expansion Valve ElectronicДокумент2 страницыElectronic Expansion Valve ElectronicIEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPОценок пока нет

- TEST-1 Liquid Solution 06.04.2020Документ4 страницыTEST-1 Liquid Solution 06.04.2020tarunОценок пока нет

- Stereo ChemistryДокумент135 страницStereo ChemistryAntoni Budhi PrasetyoОценок пока нет

- Scheme of Study BS 2013 (120613) - LastДокумент31 страницаScheme of Study BS 2013 (120613) - LastRameezAliОценок пока нет

- Reactor Design Sample ExamДокумент7 страницReactor Design Sample ExamAugustine BrockОценок пока нет

- Metals: Recovery of Valuable Metals From Lithium-Ion Batteries NMC Cathode Waste Materials by Hydrometallurgical MethodsДокумент16 страницMetals: Recovery of Valuable Metals From Lithium-Ion Batteries NMC Cathode Waste Materials by Hydrometallurgical MethodsTahir NizamОценок пока нет

- Charge 4Документ24 страницыCharge 4Than Chet Balck CatОценок пока нет

- ISO 29541-2010 Solid Mineral Fuels - Determination Total Carbon Hydrogen NitrogДокумент18 страницISO 29541-2010 Solid Mineral Fuels - Determination Total Carbon Hydrogen NitrogWinnjone YinОценок пока нет

- Weathering of RocksДокумент2 страницыWeathering of Rocksvee propagandaОценок пока нет

- Exercise: PlaceДокумент1 страницаExercise: PlaceaslamОценок пока нет

- Moving Charges and Magnetism Notes and AssignmentДокумент141 страницаMoving Charges and Magnetism Notes and Assignmenthireng1858Оценок пока нет

- Light PPT 120108205852 Phpapp01Документ13 страницLight PPT 120108205852 Phpapp01padmja4purohit100% (1)

- Creep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HoursДокумент4 страницыCreep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HourssuiafwgehjdfОценок пока нет

- Extended Impregnation Kraft Cooking of SoftwoodДокумент50 страницExtended Impregnation Kraft Cooking of SoftwoodMoksadur RahmanОценок пока нет

- Arlamol PS15E - 0314 PCDS256v2 PDFДокумент2 страницыArlamol PS15E - 0314 PCDS256v2 PDFsimmiОценок пока нет