Академический Документы

Профессиональный Документы

Культура Документы

Transformerfactory

Загружено:

glenysya0 оценок0% нашли этот документ полезным (0 голосов)

129 просмотров13 страницASC has risen from its humble beginning more than 25 years ago of a sole factory for LV boards, to an organisation boasting of 11 factories managing LV and HV switchgear, Transformers and Package Sub-stations. Over time, ASC products have attained a reputation for quality, reliability as well as sustainability which gained recognition in the industrial sector in the region. All products have been developed inside the walls of the factory and will continue to improve, because progress stops once the spirit of pioneering is lost

Исходное описание:

Оригинальное название

Transformerfactory[1]

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документASC has risen from its humble beginning more than 25 years ago of a sole factory for LV boards, to an organisation boasting of 11 factories managing LV and HV switchgear, Transformers and Package Sub-stations. Over time, ASC products have attained a reputation for quality, reliability as well as sustainability which gained recognition in the industrial sector in the region. All products have been developed inside the walls of the factory and will continue to improve, because progress stops once the spirit of pioneering is lost

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

129 просмотров13 страницTransformerfactory

Загружено:

glenysyaASC has risen from its humble beginning more than 25 years ago of a sole factory for LV boards, to an organisation boasting of 11 factories managing LV and HV switchgear, Transformers and Package Sub-stations. Over time, ASC products have attained a reputation for quality, reliability as well as sustainability which gained recognition in the industrial sector in the region. All products have been developed inside the walls of the factory and will continue to improve, because progress stops once the spirit of pioneering is lost

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 13

Transformers

AL-AHLEIA SWITCHGEAR CO.

K.S.C.C.

Kuwait

3

CONTENTS

I PRODUCT RANGE & STANDARDS 4

II TRANSFORMER MANUFACTURING 5

III WEIGHTS & DIMENSIONS 14

IV TRANSFORMER DATA 18

V TYPICAL FITTINGS 20

VI TESTING 21

VII SAFETY 22

VIII ERECTION OF TRANSFORMERS 22

IX QUALITY & EXTERNAL CERTIFICATIONS 22

Driven by a vision to pioneer, ASC has risen

from its humble beginning more than 25

years ago of a sole factory for LV boards,

to an organisation boasting of 11 factories

managing LV & HV Switchgear, Transformers

and Package Sub-stations, establishing itself as

the largest power equipment manufacturer in

the region.

ASC takes pride for being the leading local

manufacturer of HV products, transformers and

package S/S. Over time, ASC products have

attained a reputation for quality, reliability as

well as sustainability which gained recognition

in the industrial sector in the Middle East.

All products have been developed inside

the walls of the factory and will continue to

improve, because progress stops once the spirit

of pioneering is lost.

ion to pioneer, ASC has risen on to pioneer, ASC has risen

le beginning more than 25 e beginning mo

sole factory for LV boards, sole factory for

ion boasting of 11 factories on boasting of 11 factorie

HV Switchgear, Transformers HV Switchgear, Transformer

b-stations, establishing itself as -stations, establishing itself a

er equipment manufacturer in r equipment manufacturer i

e for being the leading local for being the leadi

HV products, transformers and HV products, t

ver time, ASC products have er time ASC produ

ation for quality, reliability as tion fo quality reliability a

bility which gained recognition ility which gained recognitio

sector in the Middle East. sector in the Middle East.

have been developed inside ave been developed insid

factory and will continue to factory and will continue to

e progress stops once the spirit e progress stops once the spiri

lost. ost.

4 5

II. TRANSFORMER MANUFACTURING I. PRODUCT RANGE & STANDARDS

A) PRODUCT RANGE

Oil Filled Transformers up to 50MvA & 132Kv

Cast Pesin Transformers up to 10MvA & 36Kv

"AI-AhIeia" design and manufacture the following types of transformers:

POWEP TPANSFOPMEPS

DlSTPlBUTlON TPANSFOPMEPS (Single & Dual Patio)

TPANSFOPMEPS FOP PETPOLEUM PEFlNEPlES FOP HAZAPDOUS

APEA/ZONES AS SPEClFlED BY CUSTOMEP

HEPMETlCALLY SEALED TPANSFOPMEPS

EAPTHlNG TPANSFOPMEPS

PEGULATlNG TPANSFOPMEPS

AUTO TPANSFOPMEPS

CONvEPTEP TPANSFOPMEPS

FUPNACE TPANSFOPMEPS (lnduction & Arc)

B) STANDARDS

{a) OiI FiIIed Transformers: "AI-AhIeia" make transformers conform to lEC / BSEN 60076

standards. However, "AI-AhIeia" provide transformers conforming to other standards as

per requirement of customers.

{b) Cast Resin Transformers: "AI-AhIeia" make transformers conform to lEC / BSEN 60076,

Part:11. However, "AI-AhIeia" provide transformers conforming to other standards as per

requirement of customer.

LAMlNATlON STACKlNG MACHlNE LAMlNATlON STACKS

LAMlNATlON CUTTlNG MACHlNE

LAMINATION CUTTING

6 7

WlPE WlNDlNG MACHlNE

FOlL WlNDlNG MACHlNE

WINDING MACHINES

vACUUM OvEN CHAMBEP vACUUM CASTlNG PLANT

DEDICATED PLANTS

FOlL WlNDlNG MACHlNE

WlPE WlNDlNG MACHlNE

ASSEMBLY LAMlNATlON (CAST PESlN) COPE & COlL FULLY ASSEMBLED

MOvlNG lNTO DPYlNG OvEN (OlL)

LAMINATION ASSEMBLY

Hv COlLS FOP DlSTPlBUTlON

TPANSFOPMEPS

Lv COlLS FOP DlSTPlBUTlON

TPANSFOPMEPS

COILS {OiI)

Hv SlDE vlEW FOP 1000KvA, 11/0.433Kv, OlL FlLLED TPANSFOPMEP vlEW FOP 1000KvA 11/0 433Kv OlL FlLLED TPANSFO TPANSFO

8 9

Lv COlLS

COILS {CAST RESIN)

COMPLETE COPE COlL ASSEMBLY

WlTH CONNECTlONS

Hv COlLS

TANK FABPlCATlON OF 30MvA TPANSFOPMEP

FABRICATION OF TANK & ROBOT WELDING

FABPlCATlON OF METAL PAPTS OF

TPANSFOPMEP

vAPlOUS TYPES OF CASTlNG

3D VIEW OF LAMINATION & COIL ASSEMBLY

20 MVA, 33/11.5 KV TRANSFORMER

CORE END STUDS LV BUSHING

LV CONNECTION BUSBAR

YOKE STUDS

HV BUSHING

LAMINATION

FLITCH PLATE

PRESSURE SCREW

ASSEMBLY

COIL PRESSING RING

HV TAPPING WINDING

HV MAIN LEADS

HV TAPPING LEADS

LEAD SUPPORT CLEATS

10 11

3D VIEW OF 30 MVA

132/11.5 KV, TRANSFORMER

SECTIONAL VIEW OF LAMINATION & COIL ASSEMBLY

30 MVA , 132/11.5 KV TRANSFORMER

12 13

14 15

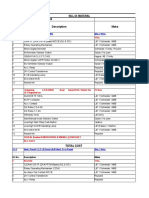

III. WEIGHTS & DIMENSIONS

OIL FILLED TRANSFORMERS

Rating Ratio

Vector

Group

Reference

Length

{mm)

Width

{mm)

Height

{mm)

TotaI

Weight

{Kg)

TotaI

OiI

Weight

{Kg)

AA) Pad mounted, with conservator and breather

1000KvA 11/0.433Kv Dyn11 2050 1470 2000 3450 696

1250KvA 11/0.433Kv Dyn11 2080 1660 2360 4000 830

1600KvA 11/0.433Kv Dyn11 2190 1850 2430 4800 950

7500KvA 11/6.6Kv Dyn11 3395 3200 3800 14595 3025

BB) Hermetically sealed with welded cover

1000KVA 6.6/0.46KV Dyn11 2300 1850 1745 3570 714

1500KVA 11/0.460KV Dyn11 2400 1920 2000 5020 1045

2000KVA 3.45/0.460KV Dyn11 2750 2550 2050 6065 1255

CC) Pad mounted, hermeticaIIy seaIed with boIted cover

400KvA 11/0.4Kv Dyn11 1790 1163 1413 2050 435

630KvA 11/0.4Kv Dyn11 1830 1340 1613 2650 565

1000KvA 11/0.4Kv Dy n11 1830 1612 1633 3275 610

2000KvA 6.6/0.4Kv Dyn11 2430 2195 2085 5650 1070

2000KvA 11/0.4Kv Dyn11 2430 2195 2085 5650 1100

12.5MvA 11/3.45Kv Dyn11 4550 3150 4400 21650 4750

DD) 33kV CIass oiI hIIed, power transformers

7500KvA 33/6.6Kv Dyn11 3700 3275 3750 16528 3633

7500KvA 33/11Kv Dyn11 3700 3275 3750 16240 3633

10MvA 33/6.6Kv Dyn11 4010 3450 4170 19480 4060

20MvA 33/11.5Kv Dyn11 5700 4000 4300 48000 11600

25MvA 33/6.6Kv Dyn11 5600 4050 4770 35974 6845

EE) 132kV Class oil lled, power transformer

20/30MVA 132/11.5KV Dyn11 6725 5450 5550 77000 26000

Weight and dimension of transformers other then the above will be provided on demand.

CAST RESIN TRANSFORMERS

Weight and dimensions of cast resin pad mounted transformer of ratings 250KVA,

1000KVA, 1250KVA & 1600KVA, AN cooIed.

Rating Ratio

Vector

Group

Reference

Length

{mm)

Width

{mm)

Height

{mm)

TotaI Weight

{Kg)

250KvA 11/0.433Kv Dyn11 1860 1550 1550 1600

750KvA 11/0.433Kv Dyn11 2300 1770 2300 3900

1000KvA 11/0.433Kv Dyn11 2300 1770 2300 3900

1250KvA 11/0.433Kv Dyn11 2300 1770 2430 4680

1600KvA 11/0.433Kv Dyn11 2450 1900 2590 5855

Weight and dimension of transformers above 1600KvA rating will be provided on

demand.

CAST RESIN TRANSFORMER

TYPE ATC12

16 17

11/0.433 kV TRANSFORMER

TYPE ATO12

11/0.433 KV TRANSFORMER

TYPE ATO12

COPE COlL ASSEMBLY OF

30MvA POWEP TPANSFOPMEPS

30MvA TANK

30MvA POWEP TPANSFOPMEP

UNDEP TANKlNG

30MVA POWER TRANSFORMER

19 18

IV. TRANSFORMER DATA

DESIGN FEATURES

Transformer designs are developed using CAD (Computer Aided Design), which in turn, are well

connected to CNC and other most modern machines to manufacture the right component.

STEPS IN MANUFACTURING OIL FILLED TRANSFORMERS

Core Construction

The core is constructed from lamination of Cold Polled Grain Oriented, Electrical Sheet, featuring

excellent magnetic properties. lt is cut on most modern CNC core cutting machines for step-lap

construction.

Windings

Al-Ahleia make oil flled transformer windings for distribution transformers uses Copper foil for

Lv winding and paper insulated rectangular/round wire for Hv winding. Sometimes enamelled

conductors are also used. State-of-the-art layer winding machines for winding Hv coils are

used maintaining accuracy of dimensions. For power transformer windings, Lv coils are made

either spiral or helical type. Specialized disc windings and inter-leaved disc windings will be used

having very high series of capacitance giving a very good lmpulse voltage performance.

Core & CoiI AssembIy

Core & Coil assembly for distribution transformers uses special insulating material like crepe

paper tube and are very strong and robust in construction to withstand short-circuit forces. They

are adequately clamped with the tank so that no movement is possible within the tank because

of transport jerks or short-circuit forces.

Fabrication

Transformer tanks are manufactured in the most modern plant having facility of automatic

component manufacturing using CNC machines which reads the component drawing directly

issued by Design department. Welding is done by welding robot ensuring very consistent and

leak proof welds. Tanks are leak tested after fabrication and shot blasted in our shot blasting

plant. After shot blasting and thorough cleaning, they are powder coated in our powder coating

plant, or if required, painted in our liquid paint plant, as the case may be. Al-Ahleia can produce

transformer tanks of the required ratings in their production range.

Vacuum/Vapour Phase Drying Process & Tanking

The core and coil assembly is dried in an oven to improve insulation resistance and remove

ingress of moisture in the insulation materials.

The dried core coil assembly is boxed up in a pre-fabricated M.S. Tank, and vacuum/vapour

phase process is applied for flling oil in the transformer tanks.

Testing

All Poutine/Type tests as per the relevant standard / customer specifcations are conducted.

Every oil transformer is pressure tested, and then fnished, including all fttings and kept ready

for despatch.

STEPS IN MANUFACTURING CAST RESIN TRANSFORMERS

Core Construction

The core is constructed from lamination of Cold Polled Grain Oriented, Electrical Sheet, featuring

excellent magnetic properties. lt is cut on most modern CNC core cutting machines for step-lap

construction.

Windings

Al-Ahleia cast resin transformers are wound with Lv foil winding and Hv sectionalized coil winding.

There is a uniform distribution of ampere turns, throughout the length, resulting in very less

short-circuit axial forces. State-of-the-art winding machines enable insulation and conductor

materials to be wound simultaneously, resulting in a very good compact winding, capable of

resisting short circuit forces. Hv coils are made from suitably insulated copper conductors.

Core & CoiI AssembIy

Core and Coil assembly for cast resin transformers uses Class `F` insulation for 155C. The clamp

plates and the clamping frames are insulated with core using fbre glass sheets. Anti-vibration

pads are provided at the feet to isolate any vibration from the transformers to be transmitted to

the enclosure. High strength coil support blocks are used to keep the resin cast coils in position

on the core.

The core is painted with epoxy resin so that atmospheric pollution will not affect the core steel

surface. Also, it will have dampening effect on the noise produced if any.

EncIosures

Enclosures are generally manufactured from zinc coated steel sheet. The standard fnish is

a polyester based powder coat. The protection categories as per relevant lP number can be

provided based on customer requirement. Enclosures are made on most modern computerized

metal sheet working machines.

Casting

Cast resin transformer coils, both Hv and Lv, are casted with epoxy resin, in the most modern

fully automatic casting plant. The casting plant is state of the art one having thin flm degassing

mixers. The resin mixtures are prepared by automatic weighing and loading of epoxy, resin and

fller components and thereafter loading them into the mixers before casting. Pre-heating of the

coils is done after casting while post-curing is done in the post curing ovens resulting in void free

coils.

Testing

All Poutine/Type tests as per the relevant standard / customer specifcations are conducted.

20 21

V. TYPICAL FITTINGS

BUSHINGS HV & LV:

Bushings/Monoblock is used to take out Hv/Lv terminals out of the transformer for terminations.

voltage/Current Pating is selected according to the system voltage requirement.

GASKETS:

Gaskets are used in transformers for oil sealing. They are made of rubber bonded cork as per

requitements.

AH-CISD - Common lntegrated Safety Device

Al-Ahleia make AH-ClSD is used for transformer protection by detecting oil level,

discharge of gas, tank pressure, and temperature.

HlGH vOLTAGE TEST SET 500Kv AND lMPULSE TEST UP TO 1000 KvA

VI. TESTING

Following test facilities are available at Al-Ahleia works

for transformers up to 50MvA, 132Kv class. Tests are as per lEC-60076.

ROUTINE TESTS

(1) Measurement of Winding Pesistance

(2) Measurement of voltage Patio and Check of Phase Displacement

(3) Dielectric Test

(a) Power Frequency Separate Source High voltage Test

(b) lnduced Over voltage Test

(4) No Load Loss and Exciting Current

(5) Load Loss and lmpedance voltage

(6) Partial Discharge Test - For 132Kv Oil Type Transformers & 11Kv Cast Pesin Transformers

22 23

VII. SAFETY

1. Pead and understand the entire instruction bulletin supplied along with the transformer before

installing, operating or maintaining "AI-AhIeia" transformers. Follow all applicable local and

national codes.

2. Many parts of the transformer operate at high voltages. DO NOT TOUCH. Use only

electrically insulated tools and clothing, and protective gear when working around electrical

equipment.

3. Do not rely on visual indications such as switch position or fuse removal for determining a

de-energized condition. Always assume that a terminal is energized unless it is checked with

a properly rated meter to ensure the terminal is de-energized and grounded.

4. After doing the electrical tests, and before touching the transformer, ensure all static charge

has been discharged by grounding the coils with an appropriate grounding device.

5. This equipment must be installed and serviced only by qualifed electrical personnel.

6. Turn off all power supplying this equipment before working on or inside the equipment.

7. Always use a properly rated voltage sensing device to confrm power is OFF.

8. Peplace all devices, covers etc., before turning on power to this equipment.

FAILURE TO FOLLOW ANY OF THESE PRECAUTIONS WILL RESULT IN DEATH OR SERIOUS

INJURY.

VIII. ERECTION OF TRANSFORMERS

"AI-AhIeia" is in the feld of lnstallation and maintenance of electrical equipments for the past two

decades.

Dedicated and specialized team for lnstallation, Commissioning, Maintenance and after Sale

support for all type of Transformers is available.

IX. QUALITY & EXTERNAL CERTIFICATIONS

"AI-AhIeia" quality assurance system conforms to lSO 9001:2008, 29001:2007, 14001:2004

systems certifed by DNv.

"AI-AhIeia" transformers are tested as per latest lEC and customer specifcations.

SOME OF OUR VALUED CLIENTS

Government Sector OiI Sector Companies

Ministry Of Electricity & Water

Ministry of Defense

Ministry of Health

Ministry of lnformation

Ministry of Public Work

Kuwait Oil Company

Kuwait National Petroleum Company

Petrochemical lndustries

Kuwait Aviation Fuelling Company

KGOC (JO Wafra / JO Khafji)

Chevron

PubIic Sector PMC

Kuwait Port Authority

Director General of Civil Aviation

Public Authority of Housing Welfare

Kuwait University

Fluor

Amec

Worley Parsons

EPC Contractors

Hyundai Heavy lndustries

Hyundai Engineering & Contracting Co.

Daelim

SK Engineering & Contracting Co.

Snamprogetti / Saipem SpA.

National Contracting Co.

Petrofac

Tecnicas Peunidas S.A - Group TP

Technip

Mitsubishi

Ganz

Areva

Siemens

ABB

Ansaldo

Export {PubIic & Private)

South Oil Company (Basrah, lraq)

Qatar General Electricity & Water Corporation

Kahramaa , Qatar

EDD - Bahrain

UNEECO - Bahrain

lTTC, Qatar

voltage Engineering Ltd., Qatar

Al-Bakali General Trading Co., Bahrain

Omar Zawawi Establishment, Oman

Private Sector

Heavy Engineering lndustries &

Shipbuilding Company (HElSCO)

Kharaf National

lntegral Services Company W.L.L. (lSCO)

Mishrif lnternational For Trading &

Contracting Co.

lnstruments lnstallation & Maintenance Co.

(lMCO)

Almeer Technical Services Company

Combined Group Co. For Contracting

K.S.C.C.

Maschinenfabrik Peinhausen (MP)

JAN 2010 9089 / 06

Copy Rights 2010 - AI-AhIeia Switchgear Co.

AII Rights Reserved

GPS Location

29 13' 59.40" N - 48 00' 59.76" E

Вам также может понравиться

- Electrical Boq for Sulphuric Handling at EnclosureДокумент2 страницыElectrical Boq for Sulphuric Handling at EnclosureKrishОценок пока нет

- Interposing Current Transformers: For Use in Conjunction With Type MBCH Transformer Differential ProtectionДокумент12 страницInterposing Current Transformers: For Use in Conjunction With Type MBCH Transformer Differential ProtectionChristopher Mouly100% (1)

- SME APFC Panel CatalogueДокумент6 страницSME APFC Panel CatalogueRam SankarОценок пока нет

- The Art & Science of Protective Relaying - C. Russell Mason - GEДокумент357 страницThe Art & Science of Protective Relaying - C. Russell Mason - GEAasim MallickОценок пока нет

- Electrical Control Panel Design Project ReportДокумент30 страницElectrical Control Panel Design Project ReportRakesh YadavОценок пока нет

- Condenser Bushings GuideДокумент8 страницCondenser Bushings Guidesarkar1981Оценок пока нет

- Moulded Case Circuit Breakers Product HighlightsДокумент56 страницMoulded Case Circuit Breakers Product HighlightsAmit NagОценок пока нет

- ANGEN - EN006 Current Transformer Selection For VAMP Series Overcurrent and Differential Relays PDFДокумент8 страницANGEN - EN006 Current Transformer Selection For VAMP Series Overcurrent and Differential Relays PDFRicardo BozoОценок пока нет

- Modeling and Analysis of System Transients Using Digital Programs Part 2 PREPARED by TheДокумент87 страницModeling and Analysis of System Transients Using Digital Programs Part 2 PREPARED by TheglenysyaОценок пока нет

- Ug Zs1 Iom Man Rev.h 2012 06Документ110 страницUg Zs1 Iom Man Rev.h 2012 06yulizard100% (1)

- Busway SiemensДокумент72 страницыBusway SiemenssnakelostОценок пока нет

- A Novel Scheme To Eliminate Common Mode Voltage in Multilevel InvertersДокумент4 страницыA Novel Scheme To Eliminate Common Mode Voltage in Multilevel InvertersJavier MaldonadoОценок пока нет

- Generator PresentationДокумент20 страницGenerator PresentationAbhishek SinhaОценок пока нет

- Motor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE MultilinДокумент35 страницMotor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE Multilinvaradarajanrengasamy100% (1)

- LV Relay SettingДокумент12 страницLV Relay SettingRatheesh KumarОценок пока нет

- Vs1 en 150dpiДокумент13 страницVs1 en 150dpiPatrik PulungОценок пока нет

- Presentation On Electrical System Stage 2Документ34 страницыPresentation On Electrical System Stage 2Sam100% (1)

- Electrical Load Calculation and Energy Consumption 22 8 12Документ6 страницElectrical Load Calculation and Energy Consumption 22 8 12Mohd Husain ZaidiОценок пока нет

- Record PlusДокумент250 страницRecord PlusDixie VictoriaОценок пока нет

- eVD4 - Breaker Integrated Protection RBX615 - Engineering Manual PDFДокумент100 страницeVD4 - Breaker Integrated Protection RBX615 - Engineering Manual PDFHans MortenОценок пока нет

- Functional Testing of G60 A Test Results Engro PDFДокумент14 страницFunctional Testing of G60 A Test Results Engro PDFunab84Оценок пока нет

- DOE Guidelines On Energy Conserving Design of Buildings v2020Документ74 страницыDOE Guidelines On Energy Conserving Design of Buildings v2020Dominic Vincent Ver100% (1)

- Chapter 7 ConnectionДокумент140 страницChapter 7 Connectionalafkhair tradingОценок пока нет

- Indoor Floor Mounted PLC Panel BOMДокумент10 страницIndoor Floor Mounted PLC Panel BOMPranshu DevganОценок пока нет

- 11 KV Bay EquipmentДокумент22 страницы11 KV Bay EquipmentSudhir ShindeОценок пока нет

- Technical Offer For 11kv Sm6 SwitchgearДокумент6 страницTechnical Offer For 11kv Sm6 SwitchgeardmugalloyОценок пока нет

- VCB 5678 CatalogueДокумент20 страницVCB 5678 CataloguemuraliОценок пока нет

- Cost-Efficient Solution for Power DistributionДокумент8 страницCost-Efficient Solution for Power DistributionaayushОценок пока нет

- Dry Type Transformer: Single-Phase, Three-Single, Three-Two and Three-Phase Transformers 1.1 KV To 7.2 KV ClassesДокумент8 страницDry Type Transformer: Single-Phase, Three-Single, Three-Two and Three-Phase Transformers 1.1 KV To 7.2 KV ClassesJeison Osmar Altamirano SoriaОценок пока нет

- NGR Technical InformationДокумент6 страницNGR Technical InformationPrabakar PОценок пока нет

- Nrjed111211en WebДокумент60 страницNrjed111211en Webjobpei2Оценок пока нет

- Professional Competence and ExperienceДокумент4 страницыProfessional Competence and ExperienceAbdul jaffarОценок пока нет

- Air Insulated Indoor SwitchgearДокумент6 страницAir Insulated Indoor SwitchgearvurumuuОценок пока нет

- ABB Padmount Switchgear Brochure Rev BДокумент12 страницABB Padmount Switchgear Brochure Rev BbertovalenОценок пока нет

- Abb ArrestersДокумент132 страницыAbb ArrestersCesar Becerra P.Оценок пока нет

- A Method of A Lightning Surge Analysis Recommended in Japan Using EMTPДокумент9 страницA Method of A Lightning Surge Analysis Recommended in Japan Using EMTPwhitedaisyvenusОценок пока нет

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityДокумент10 страницTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliОценок пока нет

- A. Wound Type:: 1. What Are The Types of CT? Example?Документ8 страницA. Wound Type:: 1. What Are The Types of CT? Example?deltavijayakumarОценок пока нет

- Substation ReferencesДокумент14 страницSubstation Referencesdeepak jainОценок пока нет

- IEM's History of Manufacturing Power Transformers Since 1948Документ7 страницIEM's History of Manufacturing Power Transformers Since 1948Anonymous sAmJfcVОценок пока нет

- 2.package-20 Vol - 2 of 2Документ302 страницы2.package-20 Vol - 2 of 2Wahed ImtiazОценок пока нет

- Katalog RKS LAST 12 02 2019 ONEPAGE PDFДокумент18 страницKatalog RKS LAST 12 02 2019 ONEPAGE PDFivicaОценок пока нет

- LTB E CB BrochureДокумент6 страницLTB E CB BrochureMidhun VargheseОценок пока нет

- FCMA Soft Starters for MotorsДокумент4 страницыFCMA Soft Starters for Motors4usangeetОценок пока нет

- Topic6 TransfomerДокумент40 страницTopic6 TransfomerLucas GabrielОценок пока нет

- Diesel Generator SetДокумент3 страницыDiesel Generator SetVishal SabaleОценок пока нет

- 600Volt to 69KV Cable Bus Systems for Industrial Commercial Utility ApplicationsДокумент16 страниц600Volt to 69KV Cable Bus Systems for Industrial Commercial Utility ApplicationsUdhay Shankar100% (1)

- Bus Bar Size CalculatorДокумент9 страницBus Bar Size CalculatorAbdul HafeezОценок пока нет

- Evolis Circuit Breaker CatalogueДокумент21 страницаEvolis Circuit Breaker Cataloguepb21Оценок пока нет

- Power Consumption Type A1 RM1448Документ1 страницаPower Consumption Type A1 RM1448Widda ArifaОценок пока нет

- Electromech BOQДокумент3 страницыElectromech BOQCoreg ToОценок пока нет

- Crompton Greaves/ Kirloskar Milestone/As Sociated Switcgears Siemens/L& ToreqДокумент2 страницыCrompton Greaves/ Kirloskar Milestone/As Sociated Switcgears Siemens/L& Torequche ekeОценок пока нет

- Cat C80Документ2 страницыCat C80Imola MovidaОценок пока нет

- Technical Complementary Guide 2013Документ256 страницTechnical Complementary Guide 2013brightstardustОценок пока нет

- ACTOM Outdoor MV Switchgear - SingleДокумент8 страницACTOM Outdoor MV Switchgear - SingleKhashane Willy MohaleОценок пока нет

- VCB BROCHUREДокумент8 страницVCB BROCHUREE.ANANDANОценок пока нет

- Inversor PVS800-MWS 1 - 2.4 MWДокумент4 страницыInversor PVS800-MWS 1 - 2.4 MWandres gascaОценок пока нет

- Bab III.2.1. Generator Sinkron (Lanjutan)Документ28 страницBab III.2.1. Generator Sinkron (Lanjutan)Hariz AudirahmawanОценок пока нет

- 22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & CoДокумент13 страниц22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & Coshan shanzОценок пока нет

- AMF Controler FeaturesДокумент21 страницаAMF Controler FeaturesgvkОценок пока нет

- Lecture 56 - Components of LT SwitchgearДокумент18 страницLecture 56 - Components of LT SwitchgearSahil Dhapola100% (1)

- Simoprime Catalog English Aug2010Документ16 страницSimoprime Catalog English Aug2010muktivarОценок пока нет

- VLT SoftStarter Selection Guide - MCD600 SeriesДокумент28 страницVLT SoftStarter Selection Guide - MCD600 SeriesLim VincentОценок пока нет

- 220kv Line MaterialДокумент2 страницы220kv Line MaterialVasu BagganОценок пока нет

- An ISO 9001:2000 CompanyДокумент6 страницAn ISO 9001:2000 Companyzabiruddin786Оценок пока нет

- Actom DTRДокумент8 страницActom DTRVikram BorawakeОценок пока нет

- 0 - AlkargoPoTrans (Referencia)Документ12 страниц0 - AlkargoPoTrans (Referencia)glenysyaОценок пока нет

- 5417 05Документ6 страниц5417 05glenysyaОценок пока нет

- Catalogo Sediver Hvac 17 32Документ16 страницCatalogo Sediver Hvac 17 32glenysyaОценок пока нет

- CRSM Cable Repair Sleeve Installation GuideДокумент10 страницCRSM Cable Repair Sleeve Installation GuideglenysyaОценок пока нет

- 10 Aeron - Fiberglass CrossarmДокумент3 страницы10 Aeron - Fiberglass CrossarmglenysyaОценок пока нет

- Catalogo Sediver Hvac 1 16Документ16 страницCatalogo Sediver Hvac 1 16glenysyaОценок пока нет

- Minera MP 123kV FTR TechnicalLeaflet enДокумент2 страницыMinera MP 123kV FTR TechnicalLeaflet englenysyaОценок пока нет

- Guia Audible-Visible NotificacionДокумент16 страницGuia Audible-Visible NotificacionglenysyaОценок пока нет

- Aisladores de Suspension Hasta 34.5kvДокумент0 страницAisladores de Suspension Hasta 34.5kvglenysyaОценок пока нет

- List Cab Let I Pic Power EnglishДокумент14 страницList Cab Let I Pic Power EnglishglenysyaОценок пока нет

- NEMA c29.4Документ15 страницNEMA c29.4glenysyaОценок пока нет

- 4007ES and 4007ES Hybrid Fire Alarm Systems: Installation Manual 579-1102 Rev. EДокумент44 страницы4007ES and 4007ES Hybrid Fire Alarm Systems: Installation Manual 579-1102 Rev. ELuis Walter LeoneОценок пока нет

- 3CHEB PS4 Group12-4Документ11 страниц3CHEB PS4 Group12-4Vicente JonathanОценок пока нет

- Deye 16KW Hybrid InverterДокумент2 страницыDeye 16KW Hybrid InverterkresennnОценок пока нет

- Data Sheet RFQ - Modec - 1415Документ1 страницаData Sheet RFQ - Modec - 1415mauricio carvalhoОценок пока нет

- Earth Science Theories and Planetary ClassificationДокумент28 страницEarth Science Theories and Planetary ClassificationJovi VillanuevaОценок пока нет

- NEA Short & Long Questions on Power Systems TopicsДокумент1 страницаNEA Short & Long Questions on Power Systems TopicsPhool Mohammad RayeenОценок пока нет

- Touhou - A Scientific InterpretationДокумент14 страницTouhou - A Scientific InterpretationDylanWalsh100% (1)

- 04.integration of 2D Analog and 3D High Resolution Seismic Data For Regional Shallow Overburden Description in Tangguh Field, IndonesiaДокумент17 страниц04.integration of 2D Analog and 3D High Resolution Seismic Data For Regional Shallow Overburden Description in Tangguh Field, IndonesiaHerry SuhartomoОценок пока нет

- Integers Math ConceptsДокумент25 страницIntegers Math ConceptssomedayОценок пока нет

- Desempeño Sísmico de La Construcción de Acero Modular de Altura Media A AltaДокумент20 страницDesempeño Sísmico de La Construcción de Acero Modular de Altura Media A AltaDaniel Sunico LewinОценок пока нет

- ASTM D5454-11e1Документ3 страницыASTM D5454-11e1Angel MurilloОценок пока нет

- Frederick Terry's Lab Report Fluid Dynamics - AsdДокумент19 страницFrederick Terry's Lab Report Fluid Dynamics - AsdFreddie TerryОценок пока нет

- Modeling in Respiratory Movement Using Labview and SimulinkДокумент27 страницModeling in Respiratory Movement Using Labview and SimulinkNashitah AlwazОценок пока нет

- Physics Formula Sheet PDFДокумент4 страницыPhysics Formula Sheet PDFDirty PiloОценок пока нет

- Section-GTR, Revision-14 - TS of RTV Coating - Annexure H - Rev 1Документ5 страницSection-GTR, Revision-14 - TS of RTV Coating - Annexure H - Rev 1shaswatОценок пока нет

- CHAPTER 10.5-Distance Time Graphs2Документ13 страницCHAPTER 10.5-Distance Time Graphs2Shweta BharrgavОценок пока нет

- Các Phương Pháp Phân Tích Hiện ĐạiДокумент7 страницCác Phương Pháp Phân Tích Hiện ĐạiTrần Thuý QuỳnhОценок пока нет

- Macedonia1Документ94 страницыMacedonia1Rodney FloresОценок пока нет

- Dhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Документ8 страницDhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Kalai ArasanОценок пока нет

- OceanEng ResumesДокумент84 страницыOceanEng ResumesChristoper NavaОценок пока нет

- Altistart 01 - ATS01N232QNДокумент6 страницAltistart 01 - ATS01N232QNEm GomezОценок пока нет

- Spec Sheet MX-4 ENДокумент1 страницаSpec Sheet MX-4 ENFresh FindingsОценок пока нет

- 3RT1024-1B Siemens Manual DatasheetДокумент7 страниц3RT1024-1B Siemens Manual Datasheetdisanty94Оценок пока нет

- What Are Valence Electrons?: Oxidation StateДокумент3 страницыWhat Are Valence Electrons?: Oxidation StateexoisnineОценок пока нет

- PN 31274Документ16 страницPN 31274Ivan DОценок пока нет

- Pressure Sensors: Types and Applications (TITLEДокумент44 страницыPressure Sensors: Types and Applications (TITLEIroshiniОценок пока нет

- Instrument SAssessment Mthobisi Malunga.Документ4 страницыInstrument SAssessment Mthobisi Malunga.MthobisiОценок пока нет

- 3.1 Light (1) (1) - 2Документ10 страниц3.1 Light (1) (1) - 2Dark VariantОценок пока нет