Академический Документы

Профессиональный Документы

Культура Документы

Experiments in Programmable Logic Controller

Загружено:

sivaeeinfoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Experiments in Programmable Logic Controller

Загружено:

sivaeeinfoАвторское право:

Доступные форматы

Experiment 8 Programmable Logic Controller

8.0 Objective

This experiment aims to: Present the background for Programmable Logic Controllers (PLCs). Build a PLC application.

8.1 Relays and Ladder Diagrams

8.1.1 Relays

A relay (also known as contactor) is a switch, where a high power signal or supply to a load is controlled by small signal (see figure 8-1). The small control signal (5 or 12V for example) is applied to a coil thus magnetizing it. The magnetized coil attracts the common (C) contact of the switch from the normally closed (NC) contact to the normally open (NO) contact. This connects the supply (220V for example) to the load which could be a large motor.

Figure 8-1. Structure of a relay diagram (shaded) with external connections.

8.1.2 Ladder Diagrams

An industrial process, such as an assembly line, uses many relays to control the various motors, heaters, spray painters, presses, etc Each relay is enabled or disabled according to input conditions such as temperature, pressure, etc As industrial processes grew in size and complexity the number of relays used grew to large numbers. The need for a clear and easy to

1

understand schematics for such systems arose. The solution developed and adopted by the industry was the ladder diagram. Figure 8-2 shows a simple ladder diagram.

Figure 8-2. Simple ladder diagram. A ladder diagram consists of two vertical rails that represent the power lines. The left rail is the live (L) line and the right rail is the neutral (N) line. Each rung (step) in the ladder represents an action. The left side of the rung contains the input conditions that activate a single output placed on the right side of the rung. When all conditions are closed the power is applied to the output element. In figure 8-2, when the operator presses the momentary normally open pushbutton PB1 the coil of the relay CR1, represented by a circle, on the right side of rung 1 is activated. This will close the normally open contacts of CR1 represented by two small vertical lines. The closure of CR1 contacts in rung 1 lower branch will latch its coil. Thus CR1 will remain energized indefinitely. Also the contact of CR1 in rung 2 will close thus switching on the red lamp. To switch off the system the normally closed momentary switch PB2 is activated by the operator thus de-energizing the coil of the relay CR1. Standard symbols exist for many hardware components used in industrial processes. The symbols for the relay are shown in the following table. Table 8-1. Some standard symbols for ladder diagrams.

Control Relay

NO Control Relay Contacts

NC Control Relay Contacts

8.1.3 Time Delay Relays (Timers)

Three types of timers are available for use in the lab. Each timer is different in contacts start and stop times and their relation to the trigger signal. Timers are best understood by their timing diagrams. Table 8-2 shows the different timers and their timing diagrams. Table 8-2. PLC delay timers. Timer Type Trainer Symbol Timing Diagram

OnDelay

OffDelay

Pulse

8.2

PLCs

A PLC is a computer (see figure 8-3) used for automation of electromechanical processes, such as control of machinery in a factory assembly line. A PLC is designed for multiple inputs and outputs. Since a PLC controls a process by coded software it is easy to implement many functions such as timers, counters, mathematical formulas etc

Figure 8-3. Basic structure of a PLC. The input modules of a PLC are designed in a variety of forms such as analog voltage, analog current, bipolar inputs (0/24V or 0/12V, etc), and some have serial or parallel inputs. In a similar fashion, output modules could be analog voltage and current or bipolar outputs of various levels. The PLC to be used in this lab is a Colter FMT-200J specially setup for training (see figure 8-4). The PLC has the following modules: 32 0/24V bipolar inputs, addresses I0000-I0031. o 8 of the bipolar inputs have sockets, addresses I0000-I0007. o 8 of the bipolar inputs have switches, addresses I0008-I0015. 8 analog inputs (set to 0/10V, 0/24V or 0/20mA), addresses AI0000-AI0007. o 2 of the analog inputs are sockets, addresses AI0000 & AI0001. o 2 of the analog inputs are potentiometers, addresses AI0002 & AI0003. 24 0/24V bipolar outputs, addresses Q0000-Q0023. o 8 of the bipolar outputs are relays, addresses Q0000-Q0007. 4 0/24V analog outputs, addresses AQ0000-AQ0003. o 2 of the analog outputs are sockets, addresses AQ0000 & AQ0001.

Figure 8-4. PLC training module. This PLC can be programmed using the Flex-32 software provided by the manufacturer. The software enables the user to design his process control program and download it to the PLC either using a graphical ladder diagram or by writing a code somewhat similar to C.

8.3

Practice

A simple project will be prepared and downloaded to the PLC in this session (see figure 8-5). The project toggles an output relay for 1 or 4 seconds depending on the state of a digital input. The overall system is switched on or off by the state of another digital input. Figure 8-6 shows the ladder diagram to be implemented.

8.4

Procedure

123456-

789-

Make sure the serial cable between Port 0 of the controller and the PC is connected. Start the computer and switch on the trainer. Start Flex 32 software. Start a new project: File New Project. Set the Project Name : dayGrroupnumber. Set FMT Type: FMT 200J. Set Programming Station Number: 0. Accept the directory suggested by the software. From the Project Configuration window select: Create new module (See fig. 8-5 below).

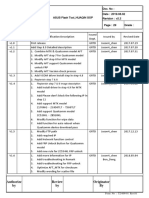

Figure 8-5. Project Configuration window. 10- Enter the ladder steps as in figure 8-6.

Figure 8-6. Simple ladder diagram. 11- Save your ladder: Save As: Example1, make sure you are saving in your project folder (step 5). 12- Compile and download your ladder to the PLC by pressing: Run. See figure 8-7.

Figure 8-7. Compile and download of ladder. 13- Press OK when download finishes and the PLC starts to beep. 14- Connect the 0V COM socket in the DIGITAL INPUTS panel to the 0V OUT socket in the AUXILIARY 24Vdc OUTPUT SUPPLY panel. 15- Place the COM switch in the DIGITAL INPUTS panel to the 0V position. 16- Close switch I8 in the DIGITAL INPUTS panel to switch on the system. 17- Toggle switch I9 to energize the relay for 1 or 4 seconds. 18- Try to modify the ladder and see what happens. 19- Add the timers in table 8-2 to your ladder and test how they work. 20- Use the help to read about the Counter Function. 21- Implement the counter application shown in figure 8-8 on your PLC.

Figure 8-8. Counter Implementation

22- What is the count stored in the counter at start of run? Is the output on or off? 23- Load the counter. 24- Test how the output can be switched on after loading. 25- What is the effect of switch I11.

8.5 Hand in

Hand in a complete report, and describe your observations about the functioning of your ladder diagram and PLC. You must include clearly all your results.

7

Вам также может понравиться

- Department of Electronics and Instrumentation Engineering Unit IIIДокумент3 страницыDepartment of Electronics and Instrumentation Engineering Unit IIIsivaeeinfoОценок пока нет

- Academic Year 2020-2021 ODD SEM Department of Electronics and Instrumentation Engineering Unit IIДокумент3 страницыAcademic Year 2020-2021 ODD SEM Department of Electronics and Instrumentation Engineering Unit IIsivaeeinfoОценок пока нет

- How Does A Microprocessor Work?: Then, We Will See The Terminologies Used in A MicroprocessorДокумент4 страницыHow Does A Microprocessor Work?: Then, We Will See The Terminologies Used in A MicroprocessorsivaeeinfoОценок пока нет

- Regulation: 2018 Formative Assessment I - May 2020 III Semester 18MC302Документ2 страницыRegulation: 2018 Formative Assessment I - May 2020 III Semester 18MC302sivaeeinfoОценок пока нет

- Concepts ElectromagnetismДокумент26 страницConcepts ElectromagnetismsivaeeinfoОценок пока нет

- Industrial Automation Syllabus 3Документ2 страницыIndustrial Automation Syllabus 3sivaeeinfoОценок пока нет

- Industrial Automation Syllabus 2Документ2 страницыIndustrial Automation Syllabus 2sivaeeinfoОценок пока нет

- Department of Electronics and Instrumentation Engineering Unit IVДокумент2 страницыDepartment of Electronics and Instrumentation Engineering Unit IVsivaeeinfoОценок пока нет

- Task 1 - C-Programming Question - 1: OutputДокумент6 страницTask 1 - C-Programming Question - 1: OutputsivaeeinfoОценок пока нет

- Serial Communication 8051 MicrocontrollerДокумент27 страницSerial Communication 8051 Microcontrollersivaeeinfo100% (1)

- ROBOMAZEДокумент6 страницROBOMAZEsivaeeinfoОценок пока нет

- Robogames 2020: EVENT NAME: - RobowarsДокумент6 страницRobogames 2020: EVENT NAME: - RobowarssivaeeinfoОценок пока нет

- Serial Communication 8051 MicrocontrollerДокумент27 страницSerial Communication 8051 Microcontrollersivaeeinfo100% (1)

- SIA203 - Vision System and Manipulator Control in ROS Advanced Vision System and Manipulator Control in ROS AdvancedДокумент2 страницыSIA203 - Vision System and Manipulator Control in ROS Advanced Vision System and Manipulator Control in ROS AdvancedsivaeeinfoОценок пока нет

- SIA203 - Vision System and Manipulator Control in ROS Advanced Vision System and Manipulator Control in ROS AdvancedДокумент2 страницыSIA203 - Vision System and Manipulator Control in ROS Advanced Vision System and Manipulator Control in ROS AdvancedsivaeeinfoОценок пока нет

- One Mark Robotic QuestionДокумент108 страницOne Mark Robotic Questionmahantesh1844% (9)

- BOM RevisedДокумент1 страницаBOM RevisedsivaeeinfoОценок пока нет

- One Mark Robotic QuestionДокумент108 страницOne Mark Robotic Questionmahantesh1844% (9)

- Cost EstimationДокумент1 страницаCost EstimationsivaeeinfoОценок пока нет

- Control System Assignment II III & IVДокумент4 страницыControl System Assignment II III & IVsivaeeinfoОценок пока нет

- BH1750 Humidity DatasheetДокумент21 страницаBH1750 Humidity DatasheetsivaeeinfoОценок пока нет

- Model Test Questions - 1Документ3 страницыModel Test Questions - 1sivaeeinfoОценок пока нет

- 15MC405 Control System Assignment 1Документ3 страницы15MC405 Control System Assignment 1sivaeeinfoОценок пока нет

- Fabrication Spec DetailsДокумент1 страницаFabrication Spec DetailssivaeeinfoОценок пока нет

- Robotics and Machine: Page 1 of 1Документ1 страницаRobotics and Machine: Page 1 of 1sivaeeinfoОценок пока нет

- Q Bank UNIT - 5Документ6 страницQ Bank UNIT - 5sivaeeinfoОценок пока нет

- Part - A: Q. No. Marks Thinking Skill (Bloom's Taxonomy)Документ7 страницPart - A: Q. No. Marks Thinking Skill (Bloom's Taxonomy)sivaeeinfoОценок пока нет

- Instrumentation Amplifier FeaturesДокумент7 страницInstrumentation Amplifier FeaturessivaeeinfoОценок пока нет

- NXP CUP 2019 RulesДокумент18 страницNXP CUP 2019 RulessivaeeinfoОценок пока нет

- Journallist 1 PDFДокумент400 страницJournallist 1 PDFRajasekar PichaimuthuОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Chat Bot SynopsisДокумент4 страницыChat Bot SynopsisShubham JaiswalОценок пока нет

- Jamil2017 PDFДокумент3 страницыJamil2017 PDFRENE FABIAN ZUNIGA MUNOZОценок пока нет

- Patran 2010 Training 301 Coursenotes PDFДокумент865 страницPatran 2010 Training 301 Coursenotes PDFUmit AytarОценок пока нет

- IBM - Mail File Is Slow To ..Документ3 страницыIBM - Mail File Is Slow To ..Saravana Kumar100% (1)

- Free PDF Version of Undocumented Windows 2000 SecretsДокумент2 страницыFree PDF Version of Undocumented Windows 2000 SecretsTonyaОценок пока нет

- User's Guide: Dell™ Cost Effective RAID ControllerДокумент154 страницыUser's Guide: Dell™ Cost Effective RAID ControllerLarry CastroОценок пока нет

- Video Intercom Firmware V1.5.1 Release Notes - 5Документ6 страницVideo Intercom Firmware V1.5.1 Release Notes - 5LAILA IDRISSIОценок пока нет

- Opti-6100 Provision - 61184500L1-6JДокумент340 страницOpti-6100 Provision - 61184500L1-6JRobert Freeman100% (1)

- CR8F6122 STMicroelectronicsДокумент89 страницCR8F6122 STMicroelectronicsspotОценок пока нет

- Global NetAcad Instance - Keamanan Informasi UTM Kelas C - Networking Academy-1Документ2 страницыGlobal NetAcad Instance - Keamanan Informasi UTM Kelas C - Networking Academy-1ATIKHA PAROLINAОценок пока нет

- N13DCP Mb-Grundig GNB 1335 A1 I5-1a5-Gbl PDFДокумент53 страницыN13DCP Mb-Grundig GNB 1335 A1 I5-1a5-Gbl PDFJokoKiyerОценок пока нет

- Ether CATДокумент12 страницEther CATRoshan RajuОценок пока нет

- SpeederXPДокумент10 страницSpeederXPaksandani100% (1)

- AFT HuaQin SOP v2.2 K0802Документ30 страницAFT HuaQin SOP v2.2 K0802Faisal RizaОценок пока нет

- CNS - 2 MarksДокумент28 страницCNS - 2 Markssweetsundari1710Оценок пока нет

- An A-Z Index of The Database: SQL Server 2005Документ4 страницыAn A-Z Index of The Database: SQL Server 2005Madhu PriyaОценок пока нет

- AnsibleTowerInstallationandReferenceGuide PDFДокумент37 страницAnsibleTowerInstallationandReferenceGuide PDFsavsabien972Оценок пока нет

- Analysis of Algorithm Chapter 1Документ35 страницAnalysis of Algorithm Chapter 1aklilu YebuzeyeОценок пока нет

- IntelliSteer Operating Guide PDFДокумент240 страницIntelliSteer Operating Guide PDFCristian MancholaОценок пока нет

- IMS Call FlowsДокумент40 страницIMS Call FlowsVivek Nagal100% (1)

- Dit 1Документ12 страницDit 1rahimshahpk4200Оценок пока нет

- Assessment 2 - Report RevisedДокумент11 страницAssessment 2 - Report RevisedDanОценок пока нет

- Excel Dashboard Using Power Query and Power Pivot: Related TrainingДокумент29 страницExcel Dashboard Using Power Query and Power Pivot: Related TrainingLe Bacha Bacha100% (1)

- AlalaДокумент28 страницAlalaJuan Pablo AndresОценок пока нет

- Overview - Modbus PLC SimulatorДокумент3 страницыOverview - Modbus PLC SimulatorAnhVũОценок пока нет

- How To Use ChatGPT To Be More Productive & CreativeДокумент15 страницHow To Use ChatGPT To Be More Productive & CreativerolfОценок пока нет

- Multimedia & Animation-CCS352 - CAT-1 Questions With Answer KeysДокумент12 страницMultimedia & Animation-CCS352 - CAT-1 Questions With Answer Keysragavaharish463100% (1)

- Rave Dev Guide 5Документ320 страницRave Dev Guide 5sandrolp_15Оценок пока нет

- STM 32 WL 55 JCДокумент147 страницSTM 32 WL 55 JCDaniel Gustavo Martinez MartinezОценок пока нет