Академический Документы

Профессиональный Документы

Культура Документы

Cutting Gears With Form Tools

Загружено:

sonytechoИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cutting Gears With Form Tools

Загружено:

sonytechoАвторское право:

Доступные форматы

CUTTING INVOLUTE GEARS WITH FORM TOOLS

by John Stevenson I am proposing to write two articles about gear cutting, this the first will be about making and using form tools and the second will be about making and using hobs. Firstly a few notes about tools required. As I realise that not everybody has a well-equipped workshop so these notes will be written with a lathe and milling machine in mind, however a miller is not completely necessary and with a little forethought all the work can be done on a lathe with a vertical slide fitted. Secondly a note on the contents of these articles. As I lot of this material has been collected over the years from a lot of sources I am bound to be repeating pieces that have been published before. I make no claim that all of this is my own work only that I have pieced together the relevant details from many sources. Some of this work is what I would state was mine but when like minds ponder on a problem there is often duplication of ideas, all that matters is the information is readily available to others. Enough drivel, now to work!

A lot of books have been written on gears and gear cutting and it will serve the reader good to read up on the overall principles before getting stuck in to practical work. The involute form is now the presently accepted form of gear tooth is general use. The shape of the tooth form can be best described as the path taken by a point on a piece of string, as it is unwound of the circumference of a circle. The geometrical build up of the involute is quite complex but for our use it can be simplified into a single radius. Most of the early work on form tools was done by Brown and Sharp where a lot of this information has come from. If one looks at a gear with 12 teeth and two others with say 25 and 60 teeth it will be obvious that the shape of the involute changes from a small radius on smaller gears up to straight sides on a rack. To cut gears with different number of teeth a different cutter is required for each gear. As this is undesirable a standard was introduced using a series of eight cutters to cover the range. These are listed in Table 1.

Number of Cutter 1 2 3 4

Will cut Gears from 135 to a Rack 55 to 134 35 to 54 26 to 34

Number of Cutter 5 6 7 8

Will cut Gears from 21 to 25 17 to 20 14 to16 12 to 13

Table 1

Because of the differences in shape the lower number in the range is correct for that gear, the other numbers are a compromise i.e. Number 5 cutter 21 to 25 teeth is only accurate for 21 teeth.

The main principle behind the form tool is to adapt the radius of the involute to the form tool. Looking at one tooth on a gear it is obvious that it has the same radius both sides to form the tooth. So if we take two disks of known radius and present them to the tooth so that they fit snug all we need to know is the distance apart and the distance fed in to duplicate the tooth. All this information is in Table 2.

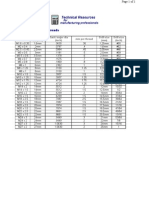

Involute Cutter Proportions 20 deg. Pressure Angle For 1 DP or 1 Module Cutter No. Range of Teeth Pin Dia. D 46.17 18.81 11.97 8.89 7.18 5.81 4.788 4.10 Pin Centres C 44.80 19.07 12.64 9.75 8.147 6.864 5.905 5.267 Feed in F 3.934 3.415 3.098 2.875 2.710 2.543 2.387 2.251 Blank Width W 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0

1 2 3 4 5 6 7 8

135 - Rack 55 - 134 35 - 54 26 - 34 21 - 25 17 - 20 14 - 16 12 -13

Some Useful Formulae

TO FIND METRIC IMPERIAL PCD Number of teeth x Mod No of teeth / DP O/D [No of teeth + 2] x Mod [No of teeth + 2] / DP DP 25.4 / Mod Pi [3.1416] / CP MODULE mm CP / Pi 25.4 / CP NO TEETH PCD [mm] - Mod PCD x DP CP Mod x Pi Pi / DP Pi can be taken as 3.1412. A quick note here on the difference between DP CP and module. DP which stands for Diametrical pitch is the number of teeth per inch measured on the pitch diameter. CP which stands for Circular Pitch is the distance measured between two teeth measured on the pitch diameter. The module is the metric equivalent of the circular pitch and is the distance between two teeth measured on the pitch diameter in millimeters. DP gear data is found by dividing the figures in Table 2 by the DP and the results will be in inches. Module gear data is found by multiplying the figures by the module and the results will be in millimeters. Using the diagram in Figure 1 and Table 2 we will lay out an example for a 24 DP gear with 20 teeth.

From the table we need to make a No 6 cutter to cover 17 - 20 teeth, the diameter of the pins [D] needs to be 5.81 divided by 24 =0.242" dia. The distance apart [C] will be 6.864 / 24 = 0.286". The infeed distance [F] will be 2.543 / 24 =0.106" given that the blank [W] is 4.0 / 24 = 0.167". To make the cutter first of all decide what bore size you will need to fit your machine. To economise on material if you select a bore size of 3/4" then the cutters can be made out of 1 1/2" silver steel or drill rod. Sizes above this are hard to find. To make these cutters you will need an arbor. Make up an arbor that can be used in the lathe as well as the miller. To make the form tool turn up two pins in drill rod or silver steel as shown in Figure 2 and mount them in a holder to fit your lathe toolpost.

These pins must be hardened and tempered after turning. The top face then needs grinding flat to give a cutting edge. The distance apart [C] is critical and is best don with the holder mounted in the toolpost at an angle of 5 degrees and the distance measured using the crossslide dial. The cutter is the next job. Turn up a blank of drill rod with a bore of 3/4" and a width of 0.167" [W]. Mount this on the arbor and present the form tool to it as laid out in Fig1. Using a slow speed and lots of coolant wind the form tool in to 0.106" [F]. this will then give you a disk cutter with the right shape but no cutting edges or clearance, also called form relief. Remove the cutter from the arbor and mark eight equal radial lines on it, mark four lines 'A' and the other four lines 'B'. Refit the cutter to the arbor and mount in four jaw chuck and set to run 1/4" offset. Set the cutter so that one radial line, A, is on the centre at the point where the eccentric is nearest the tool, See Fig3.

Bring the cutter in and clean up the form until the cut extends between one pair of 'B' lines. Note the crosslide reading. Rotate the blank to the next 'A' line and repeat. Do this four times and you will have a blank with four equal lobes. Remove from the arbor and mill the four spaces out between 'A' and 'B'. mark the cutter details on one side. You will need the cutter number , the DP and the depth to cut. This is not the feed in depth from table 2 but the full depth plus clearance. This will have to be obtained either from a hand book or from the formulae 2.25 divided by the DP. Harden and temper the cutter to light straw. To harden tools made in silver steel or drill rod, heat up evenly to a cherry red and quench in water vertically. Clean one face and put it on a steel plate with the clean face up. Heat the plate from underneath and watch the colour of the cutter, when it reaches light stray colour remove and requench as quickly as possible. Clean up and grind the four cutting faces taking care to keep the faces radial. Provided that the cutter is reground equally and radially it can be reused until it is worn away. To make a cutter for a one off job or to make a quick job, the cutter blank can be mounted on the arbor and offset an 1/8" as described above and the form turned on in one go. Instead of rotating round and repeating the process, remove from the arbor and cut one gash in at the point of maximum eccentricity. Harden and temper as above and this will give you a serviceable fly cutter that is able to be reground many times. The set out for a module gear is exactly the same the only difference is the working out of the form tool sizes. As an example we will take a 1.5Mod pitch gear with 13 Teeth. From table 2 we need a number 8 cutter. The pin diameter [D] is 4.100 x 1.5 = 6.15mm. The distance [C] is 5.267 x 1.5 = 7.90mm. The feed in [F] is 2.251 x 1.5 = 3.37mm and the blank width is 6.0mm. The cutting depth to be marked on the cutter is worked out from the formulae 2.25 x mod which in this case is 2.25 x 1.5 = 3.38 mm.

Email: John Stevenson Return to Home Page Rev: 03/17/97

Вам также может понравиться

- Making A Wooden Clockworks 2Документ8 страницMaking A Wooden Clockworks 2MiguelDelBarrioIglesisasОценок пока нет

- Manual Pulidora RaytechДокумент37 страницManual Pulidora RaytechWarner BenavidesОценок пока нет

- Gear Cutters 01Документ4 страницыGear Cutters 01Raúl MuñizОценок пока нет

- Gear Cutters 01 PDFДокумент4 страницыGear Cutters 01 PDFFabio Gilii100% (1)

- Gear CuttingДокумент9 страницGear CuttingRodolfo Sepúlveda100% (1)

- Broaches - Basic CharacteristicДокумент5 страницBroaches - Basic CharacteristicDhan CОценок пока нет

- Ar Cutting OperationДокумент7 страницAr Cutting OperationNandakrishnan S LОценок пока нет

- The Involute Curve, Drafting A Gear in CAD and Applications by Nick CarterДокумент12 страницThe Involute Curve, Drafting A Gear in CAD and Applications by Nick Carterseis11Оценок пока нет

- Departmental of Mechanical Engineering Me 213: Manufacturing Practicle Lab Notes On Gears and Gear CuttingДокумент7 страницDepartmental of Mechanical Engineering Me 213: Manufacturing Practicle Lab Notes On Gears and Gear Cuttingnisteelroy100% (1)

- Building: LatheДокумент60 страницBuilding: LathePierre799es86% (7)

- MCTD LabДокумент38 страницMCTD LabnidhidarklordОценок пока нет

- Machining FixedДокумент512 страницMachining FixedstephendixОценок пока нет

- Drawing A Spur Gear Profile in AUTOCAD: D N / P N Module 40 0.2mm 8mmДокумент7 страницDrawing A Spur Gear Profile in AUTOCAD: D N / P N Module 40 0.2mm 8mmbatra1985Оценок пока нет

- BHManual Fuselage46 79rev1Документ34 страницыBHManual Fuselage46 79rev1viorelu99Оценок пока нет

- (L) Examples of Machine Shop Practice (1910)Документ54 страницы(L) Examples of Machine Shop Practice (1910)Ismael 8877100% (1)

- Mitec1 03 2005Документ21 страницаMitec1 03 2005Sunilkumar ReddyОценок пока нет

- Simple and Inexpensive Hobbing For The General Shop: Robert H. Sturges, JRДокумент9 страницSimple and Inexpensive Hobbing For The General Shop: Robert H. Sturges, JRInternational Journal of Engineering Inventions (IJEI)Оценок пока нет

- Woodworking For Am 00 Gri FialaДокумент136 страницWoodworking For Am 00 Gri FialaIvan BaićОценок пока нет

- Mapúa University: Shop Practice No. 8Документ10 страницMapúa University: Shop Practice No. 8marisonОценок пока нет

- Dibujos de Fresass!!!!Документ19 страницDibujos de Fresass!!!!Humberto AnguloОценок пока нет

- Worm Wheel HobsДокумент7 страницWorm Wheel HobsRaul PerezОценок пока нет

- Department of Mechanical Engineering Answer Key - Iat-I Subject Name: Manufacturing Technology Year/Sem: II/III Subject Code: 17MECC04 Part-A Answer All The Questions (7x2 14 Marks)Документ7 страницDepartment of Mechanical Engineering Answer Key - Iat-I Subject Name: Manufacturing Technology Year/Sem: II/III Subject Code: 17MECC04 Part-A Answer All The Questions (7x2 14 Marks)karthik jОценок пока нет

- Threads Design in SolidWorksДокумент12 страницThreads Design in SolidWorksRicky TerryОценок пока нет

- Tools Required: Boring BitsДокумент10 страницTools Required: Boring BitsSai SudheerОценок пока нет

- Lathe MachineДокумент20 страницLathe MachineNor Faizal Nuroddin100% (2)

- Making Toggle ClampsДокумент7 страницMaking Toggle ClampsGermanHund100% (2)

- Chapter 05Документ15 страницChapter 05Muhammad Nur IkhwanОценок пока нет

- Exp No 10 DrillingДокумент11 страницExp No 10 DrillingM IRFANОценок пока нет

- 2 Gear BasicsДокумент6 страниц2 Gear BasicsMohamed Adel RizkОценок пока нет

- TheoryДокумент4 страницыTheoryDavid DjОценок пока нет

- Bonelle GrinderДокумент11 страницBonelle Grinderjohnjohn520% (1)

- How To Measure The Pressure Angle of A Physical Spur GearДокумент16 страницHow To Measure The Pressure Angle of A Physical Spur Gearian_new100% (2)

- End Mill GrindingДокумент4 страницыEnd Mill GrindingtakudomeОценок пока нет

- Shaper Gear CuttingДокумент4 страницыShaper Gear Cuttingnevadablue100% (4)

- Guia VeritasДокумент10 страницGuia VeritasNatalia DiazОценок пока нет

- Shaving PDFДокумент8 страницShaving PDFd_a0nОценок пока нет

- Making A T-NutДокумент8 страницMaking A T-NutkokiskoОценок пока нет

- The Involute Curve, Drafting A Gear in CAD and ApplicationsДокумент15 страницThe Involute Curve, Drafting A Gear in CAD and ApplicationsPepe Garcia CruzОценок пока нет

- Gear MillingДокумент54 страницыGear MillingMichael Castro AbuduОценок пока нет

- Elementary Machine Shop PracticeДокумент136 страницElementary Machine Shop PracticeTaliaNara88% (8)

- Drill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderДокумент14 страницDrill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderAndy L100% (1)

- Drawing An Approximate Representation of An Involute Spur Gear ToothДокумент4 страницыDrawing An Approximate Representation of An Involute Spur Gear Toothramchandra rao deshpandeОценок пока нет

- Home Shop Machinist's Gears GuideДокумент8 страницHome Shop Machinist's Gears Guidegaragepunkfan100% (1)

- Power SkivingДокумент11 страницPower SkivingahemerlyОценок пока нет

- Chapter 10 - Cabinetmaking Textbook PDFДокумент11 страницChapter 10 - Cabinetmaking Textbook PDFsubhan sibghatОценок пока нет

- Cove Cutting Jigs For The BT3000 by Jim FryeДокумент8 страницCove Cutting Jigs For The BT3000 by Jim FryeozilogОценок пока нет

- Ez Engine Build InstructionsДокумент24 страницыEz Engine Build InstructionsAnonymous T7zEN6iLHОценок пока нет

- Fraesen eДокумент172 страницыFraesen eMarin Ionut-EduardОценок пока нет

- Quorn: Tool and Cutter GrinderДокумент5 страницQuorn: Tool and Cutter GrinderDan HendersonОценок пока нет

- (Metalworking) Welding and MachiningДокумент1 767 страниц(Metalworking) Welding and MachiningEugeneОценок пока нет

- Milling Tool DesignДокумент18 страницMilling Tool DesignSiddharth DubeyОценок пока нет

- Milling: Prepared By: Dinbandhu Singh 1Документ23 страницыMilling: Prepared By: Dinbandhu Singh 1Dino SinghОценок пока нет

- Elementary Course in Woodwork: Designed for use in high and technical schools, with one hundred and thirty-four illustrations: First EditionОт EverandElementary Course in Woodwork: Designed for use in high and technical schools, with one hundred and thirty-four illustrations: First EditionОценок пока нет

- Elementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsОт EverandElementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsОценок пока нет

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsОт EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsРейтинг: 5 из 5 звезд5/5 (1)

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsОт EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsОценок пока нет

- Presspower 2 WebДокумент3 страницыPresspower 2 WebsonytechoОценок пока нет

- Focus ChartДокумент2 страницыFocus ChartAleksandar ObradovicОценок пока нет

- Tap Chart - Metric ThreadsДокумент1 страницаTap Chart - Metric ThreadssonytechoОценок пока нет

- Infineon ICE3BR0665J DS v02 - 03 en PDFДокумент31 страницаInfineon ICE3BR0665J DS v02 - 03 en PDFsonytechoОценок пока нет

- ChartДокумент1 страницаChartsonytechoОценок пока нет

- ClaritiДокумент1 страницаClaritisonytechoОценок пока нет

- What Is The Fuss Over Total Dissolved SolidsДокумент2 страницыWhat Is The Fuss Over Total Dissolved SolidssonytechoОценок пока нет

- Sony Userguide EN MN800 1245-8216.2Документ27 страницSony Userguide EN MN800 1245-8216.2sonytechoОценок пока нет

- Sony NW-ZB133 Operation ManualДокумент38 страницSony NW-ZB133 Operation ManualsonytechoОценок пока нет

- Sony DSR-300A Operation ManualДокумент136 страницSony DSR-300A Operation ManualsonytechoОценок пока нет

- Sony Userguide en MW1 1250-7843.1Документ21 страницаSony Userguide en MW1 1250-7843.1sonytechoОценок пока нет

- Sony NW-A605 Operation ManualДокумент92 страницыSony NW-A605 Operation ManualsonytechoОценок пока нет

- Sony Userguide en MN2 1258-0295.3Документ19 страницSony Userguide en MN2 1258-0295.3sonytechoОценок пока нет

- Sony DSR500WSP Operation ManualДокумент144 страницыSony DSR500WSP Operation ManualsonytechoОценок пока нет

- The Video Connection Book - PanasonicДокумент75 страницThe Video Connection Book - PanasonicsonytechoОценок пока нет

- Sony DSR450 Operation ManualДокумент140 страницSony DSR450 Operation Manualsonytecho50% (2)

- Sony DSR2000P Operation ManualДокумент2 страницыSony DSR2000P Operation ManualsonytechoОценок пока нет

- Sony DSR40P Operation ManualДокумент2 страницыSony DSR40P Operation ManualsonytechoОценок пока нет

- 2SJ412Документ6 страниц2SJ412sonytechoОценок пока нет

- Sony DSR1500AP Operation ManualДокумент2 страницыSony DSR1500AP Operation ManualsonytechoОценок пока нет

- Sony DSR1P Operation ManualДокумент2 страницыSony DSR1P Operation ManualsonytechoОценок пока нет

- AJ - D250E Operation ManualДокумент80 страницAJ - D250E Operation ManualsonytechoОценок пока нет

- Sony HVR-Z5P BrochureДокумент12 страницSony HVR-Z5P BrochuresonytechoОценок пока нет

- Sony Semiconductor LibraryДокумент1 страницаSony Semiconductor LibrarysonytechoОценок пока нет

- Diodes Ap1538sg-13Документ14 страницDiodes Ap1538sg-13sonytechoОценок пока нет

- Radar DetectorДокумент2 страницыRadar DetectorsonytechoОценок пока нет

- 2SB1132Документ4 страницы2SB1132sonytechoОценок пока нет

- 2SB1132Документ4 страницы2SB1132sonytechoОценок пока нет

- New Product BulletinДокумент2 страницыNew Product BulletinsonytechoОценок пока нет

- Cisco CRSДокумент988 страницCisco CRSSon PhamОценок пока нет

- Feasibility Study ChecklistДокумент6 страницFeasibility Study Checklistzaq rewОценок пока нет

- Reflection Paper 1Документ2 страницыReflection Paper 1Dela Peña, Rey Igino K.Оценок пока нет

- l200 PDFДокумент369 страницl200 PDFMohammad Abu Al-ToyourОценок пока нет

- SeeGull EX Hardware Reference Manual PDFДокумент32 страницыSeeGull EX Hardware Reference Manual PDFOsmar Santinato de OliveiraОценок пока нет

- NC Perfect Part Brochure 2011 WebДокумент12 страницNC Perfect Part Brochure 2011 WebMetrology Software Products Ltd (MSP)Оценок пока нет

- Password Recovery Procedure For The Cisco 3600 and 3800 Series Routers - CiscoДокумент9 страницPassword Recovery Procedure For The Cisco 3600 and 3800 Series Routers - CiscoDani Kirky YlaganОценок пока нет

- Supplier Quality Assurance ManualДокумент48 страницSupplier Quality Assurance ManualRamón G. PachecoОценок пока нет

- 151SGДокумент2 страницы151SGdcsamaraweeraОценок пока нет

- Method Statement and Risk Assessment For Scaffold ErectionДокумент24 страницыMethod Statement and Risk Assessment For Scaffold ErectionBarry Hart50% (2)

- Manual Denon DVD Player AVR-3805Документ2 страницыManual Denon DVD Player AVR-3805romanbunОценок пока нет

- Catalog 1 PDFДокумент19 страницCatalog 1 PDFtoto-gmbhОценок пока нет

- What Is QualityДокумент7 страницWhat Is QualityRoubina NuckcheddyОценок пока нет

- 1.2 Project Management FundamentsДокумент43 страницы1.2 Project Management FundamentsVishwas JОценок пока нет

- Accident Blackspot Investigation HandbookДокумент37 страницAccident Blackspot Investigation HandbookMichael DixonОценок пока нет

- D07be8 Com It Msys3Документ1 страницаD07be8 Com It Msys3Harsh MehtaОценок пока нет

- Current Internet Limitations v9Документ16 страницCurrent Internet Limitations v9MadagunduОценок пока нет

- Template - Phase Review Form - PlanningДокумент4 страницыTemplate - Phase Review Form - PlanningGryswolfОценок пока нет

- Oracle® Application Express: Accessibility GuideДокумент49 страницOracle® Application Express: Accessibility GuideKrunal MakwanaОценок пока нет

- Technical Specification For FlangesДокумент13 страницTechnical Specification For FlangesRahul GangulyОценок пока нет

- REC 210 AE-US Watt Solar Panel 210WPДокумент3 страницыREC 210 AE-US Watt Solar Panel 210WPJignesh ChaudharyОценок пока нет

- EcoStruxure™ Link150 - EGX150Документ3 страницыEcoStruxure™ Link150 - EGX150Mehak FatimaОценок пока нет

- ELTR 353 Power Electronics - 5Документ1 страницаELTR 353 Power Electronics - 5Engr Shehzad HaneefОценок пока нет

- Spe 77-101 Steel Gate Globe and Check Valves To Iso 15761Документ13 страницSpe 77-101 Steel Gate Globe and Check Valves To Iso 15761zeke2611100% (1)

- Scotch Marine Boiler Design: Wetback Vs DrybackДокумент24 страницыScotch Marine Boiler Design: Wetback Vs DrybackGopal RamalingamОценок пока нет

- Max-3 Ehf CatalogДокумент2 страницыMax-3 Ehf Catalogಶ್ರೀಕಾಂತ್ ತಿಪ್ಪೇರುದ್ರಪ್ಪОценок пока нет

- LTEДокумент32 страницыLTEJESUS MARIA GONZALEZ GUARDOОценок пока нет

- Dry Van ManualДокумент234 страницыDry Van ManualMichael Yoanito Oliviano100% (1)

- CCIE Security Advanced Lab Workbook Version 3.0 PDFДокумент1 067 страницCCIE Security Advanced Lab Workbook Version 3.0 PDFSandeepChodhury100% (1)

- IATF 16949-2016 Requirements.Документ24 страницыIATF 16949-2016 Requirements.Gaurav Kansara100% (1)