Академический Документы

Профессиональный Документы

Культура Документы

Modeling 6.1 Development of Non-Linear Model: Tuning of Injection Molding Machine

Загружено:

goldy243usОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Modeling 6.1 Development of Non-Linear Model: Tuning of Injection Molding Machine

Загружено:

goldy243usАвторское право:

Доступные форматы

TUNING OF INJECTION MOLDING MACHINE

CHAPTER 6

MODELING 6.1 Development of Non-linear Mo el

The injection molding process can be divided up into at least 4 different parts: the plastification phase, the injection phase, the packing phase, and the cooling phase. The goal of this work was to simulate injection and packing phases of the injection molding cycle. Models of the machine's response in both injection and packing phases were developed to be used for controller simulation. Modeling of the injection molding process has been done in the past, but none of the models dealt with all of the non linearities associated with a hydraulically driven injection molding machine. The models developed here are found using the nonlinear e!uations governing the systems, so the final system is a set of non linear state e!uations which

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

include such difficulties as a time delay "e ts#, saturation and valve dead $one. %ecause of the difficulty involved in solving general non linear e!uations, the e!uations were put into block diagram form and then modeled using Matlab&s 'imulink program. (sing 'imulink, the simulated response of the injection molding model could be compared with the actual response of the injection molding machine.

6.1.! H" ra#li$ %"&tem

)or both the packing and the injection phases of the process, much of the hydraulic system remains the same, the difference between the two is the valve in the pump being used for control. *n the injection phase, velocity is the primary parameter being controlled, therefore the proportional servo flow valve is used to control the output from the pump. +owever, for the packing phase, the pressure e,erted by the ram is the controlled parameter, so the proportional servo pressure relief valve was used to control the output from the pump. 'ince controlling hydraulic systems is the main thrust of this thesis, the majority of the time spent on developing the *M model was spent on understanding the hydraulics system. The hydraulic components were divided into 4 sections which were looked at separately: valve, line pressure, orifice, and actuator. These components were then analy$ed for both the injection and the packing phase, and models were developed for each and then put in Matlab&s 'imulink blocks for the purpose of simulaton.

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

6.1.' In(e$tion P)a&e

The injection phase was developed to model the injection of the polymer into open air, or a completely empty mold, where the outside pressure remains at atmospheric pressure.

6.1.'.1 Proportional *lo+ ,alve

*n general, valves of this type can be appro,imated by using %ernoulli e!uation: P V2 + + Z = -onstant g 2g )ollowing form can be appro,imated:

P C

Q= Cq

../ 0here - is a coefficient which includes the fluid mass density and the area of the restrictor as such: -1/a2. P is the pressure differential between the inlet and the outlet of the valve. *n the case of the pump flow valve, P1"3sup 3line#. *t is assumed that the supply pressure from the pump, 3 sup, is constant, The final term, -! is a flow coefficient which accounts for valve specific losses, and must be found e,perimentally for each valve design. +ere in this work e,perimental data from the valve manufacturer was used to find a

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

piece wise continuous function which described the response of the valve to input voltage. The term -! is taken as 4nom for simulink modeling where 4nom accounts for valve losses and should be found for each valve design from manufacturer data. 5s per manufacture manual the valve has been designed so that when it is operated for 67879, the response of the valve is relatively linear, when operation outside of this range, the values become very non linear. )or input voltages less than /.:/ volts there is no flow through the valve, causing a dead $one effect to occur, and for voltages greater than ;./ volts, the valve is wide open, and there is no change in the output of the valve. 5 plot of for which, is in )igure ../.

)ig. ../ 3roportional flow valve response

The final e!uation for the flow valve "not including the transmission lines# becomes:

Q1= Q nom P sup P1 C

..2

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

6.'.! Line D"nami$& - Tran&mi&&ion D"nami$&

%etween the pump and the hydraulic cylinder for the ram there are about /< feet of hydraulic line of various si$e and material. There are a number of connections and other restrictions "such as a filter in the line#. )low is diverted to both the injection manifold and the clamping manifold "which is not operating while the polymer is being injected.#. *t was decided that the dynamics would be small enough, and die out fast enough that they could be neglected in this model. To account for the effects of the length of the lines a time delay, , was added into the e!uation of the line pressure and the volume of the lines, 8l was used in the calculation of the total volume, 8 t. The time delay between the pump and the actuator could be found by sending a step input to the flow valve, and the noting the time between the step input, and when the pressure began to increase could be considered the time delay caused by the transmission lines. =ue to nonavailability of facility and as e,perienced by some researchers. *t was assumed that the flow valve dynamics themselves are fast enough to be neglected. )inally, the e!uation for the flow from the pump, including the time delay due to the transmission lines is:

Q1= Q nom ( ) t

P P sup 1 C

..6 *n addition to the time delay due to the hydraulic lines, the appro,imate volume of the lines was also found inductively by measuring the length and outside diameter of the lines, an appro,imation of the *.=. was

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

made from the measured >.=. )or fi,tures other than straight pipe, the appro,imate total length of the piece was used as the length. (sing these appro,imated length and diameter values, the estimated volume of the hydraulic lines was calculated. Table / 'hows all of these calculations.

6.'.' line pre&&#re

The pressure in the line is found by summing the flow through a control volume. The control volume is the hydraulic line and its associated components discussed in the previous section. *t has an estimated volume 8/. The sum of the flows is simply the flow into the hydraulic line from the pump and out of the line into the actuator. The total sum of the flow is e!ual to the change in volume of the control volume, plus the fluid capacitance times the change in pressure.

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

dV1 V dP Q1 Q2 = + l dt dt

..4 0here is %ulk Modulus Term specified by the volume of the fluid divide by its bulk modulus,

, measures the compressibility of the fluid.

*t was assumed that the volume of the lines remained constant, so d8l?dt1@. Thus the e!uation becomes:

V Q Q2 = l 1 dP dt

..< Vl and integrating, the e!uation for the pressure in the

%y dividing by line is found to be:

P= Vl

(Q Q )

1 2

... There is a pressure relief valve installed in the pump which is discussed in section <.2.2. This valve is modeled in flow model as a saturation of the pressure in the line. The saturation is designed so that pressures below $ero are e!ual to $ero, and any pressure above the ma,imum pressure set by the relief valve remains at the ma,imum pressure.

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

*ncluding the pressure relief valve, the final e!uation used to model the pressure in the lines is:

P= (Q1 Q2 ) saturation Vl

..:

6.'.. Orifi$e

The hydraulic fluid flows from the hydraulic lines into the cylinders, but what is physically happening in that connection is unknown. %etween the hydraulic line and the actuator there is a small connector restriction that causes a pressure drop between the line pressure and pressure in the actuator. This unknown pressure drop or restrictor is modeled as an orifice. The e!uation for an orifice comes from %ernoulli's e!uation for steady, incompressible pipe flow:

P

..9

v2 ++ gz = const 2

0hen the energy on both sides of the orifice are e!uated, the e!uation for the orifice becomes:

2 2 P P v v2 2 1 +1 + g z + + g 2 z2 1 1 2 2

= headloss

...

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

-anceling the appropriate terms, the e!uation is simplified to:

P P 1 2

v2 v 21 = 2

../@

(sing the minor head loss due to a change in area, with flow substituted for velocity to give:

P P 1 2 Q2 2 A2

= K

..// 0here, A is the loss coefficient, 4 is the flow through the orifice, and 5 is the area of the orifice. 'olving this for 4, the e!uation for the flow through the orifice becomes:

A 2 Q= P P 1 2 K

../2 A 2 Beplacing K by -v e!uation becomes:

Q= Cv P P 1 2

../6 0here, -v, the orifice coefficient, was appro,imated.

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

6.'./ A$t#ator

5 schematic of the actuator can be seen in )igure <.. located in section <.../. There are two cylinders, which work together to transfer the hydraulic pressure into injection ram motion. )rom the figure, it can be seen that as volume 5 is filled, the ram moves forward, injecting polymer into the mold. 0hen this is reversed and pressure is placed on side %, and side 5 is released to the Tank, the ram moves backwards. *n addition to this mechanism for moving the ram, there was also a hydraulic motor "not shown here# which rotated the auger when the polymer is being plasticised. This work did not involve the plasticising of the polymer to be injected, the hydraulic motor will not be analy$ed here. To determine the pressure which was created in the actuator, a balance of flow in the front cylinder was done. The total flow into the cylinder, 42, would have to e!ual the sum of the change in volume, the change in pressure and the flow leaking past the seals as such:

dV (x ) Va (x ) dP a Q2 = a + + C1 P a dt dt

or

V ( x )dP a Q2 =Aa vram + a + C1 P a dt

../4

0here 5a is the area of the actuator cylinder, vram is the velocity of the ram, 0here 8a is the volume of the actuator cylinder "this term is a function of the ram position#. 5lso is the bulk modulus and - / is the leakage

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

coefficient, which is modeled as constant. 'olving this e!uation for the derivative of the pressure in the actuator, 3a, gives:

dP dVa ( x ) a =Q2 C 1 P a dt dt Va ( x )

or

../<

dP a (Q2 = Aa vram C1 P a ) dt Va (x )

*ntegrating the entire e!uation leads to an e!uation for the pressure in the actuator:

P a =

dVa ( x ) C 1 P Q2 a Va ( x ) dt

or

../.

P a =

Va ( x )

(Q2 Aa vram C 1 Pa )

as

dVa ( x ) is change in volume dt

6.'.6 Ram Po&ition

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

The ram position during the injection phase of the molding cycle is found using a force balance e!uation: F1ma. *n this case, the sum of the forces is F1)actuator )friction, which results in:

P A Ff dV = a a dt m

../:

0here the friction term ) f and is: F f = f stick + f viscous + Fc

incorporates a number of non linearities

of which two were identified and modeled in the simulation were: /. The directional nature of coulomb friction poses a problem because, depending on the direction of the movement of the ram, the coulomb friction acting on it will be of a constant amplitude, but opposite sign, causing a discontinuity at $ero velocity. The nonlinear 'imulink models accounts for this by taking the force calculated for the friction and multiplying it by the sign of the velocity. 2. 5t very low velocities the force needed to overcome the static friction is higher than the kinetic frictional force, stick slip frictional behavior can cause problems such as chattering or speed hunting. =.,Cheng. 0!1 Modeled this stick slip type friction. +is model implies that for small velocities "less than =v# the system can be assumed to have no movement. The velocity re!uired for the object to begin moving is called the breakaway velocity "=v#, and once that is reached, the friction force is reduced, as static friction is no longer acting. The 'imulink model incorporates this idea by

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

having a function which inputs the current velocity, and the breakaway velocity, if the velocity is less than = v, the output velocity is $ero, otherwise, it is the same as the input velocity. The friction function uses the input velocity to determine if the frictional force should include both the static and kinetic friction terms, or just the kinetic friction term. 6. 5nother part of the friction in a fluid system is the viscous friction. 'ince the velocities are rather low, and polymers heated to their proper temperatures are much less viscous than cool polymers, it was decided that viscous friction should be neglected in the model. The final model for friction was: F f 1 signum"8ram#D)c 0here 8ram is $ero for values less than =v. 3utting this into the e!uation ../::

dx 2 = P signum (vram ) Fc a A a dt 2

../9

../; %y integrating this e!uation "adding an additional pole at $ero in the Eaplace domain transfer function# the e!uation for the ram position was found to be:

x=

..2@

Pa Aa ( signum ( vram ) Fc ) ms 2

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

6.'.2 Com3ination of All Component&

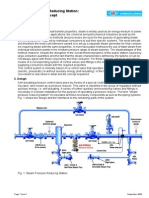

3utting these < components together resulted in the Matlab 'imulink block diagram shown in )igure /..

%im#lin4 mo el

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

6.1.. Pa$4in5 P)a&e

The packing phase was developed to model the situation were the machine is packing against an already solid mold. *n this case the major source of compliance is the compressibility of the hydraulic fluid. The following alterations were made to the injection phase model for the packing phase: the pressure relief valve was added, the ram was fi,ed, and the orifice coefficient was changed.

6.1...1 Pre&&#re Relief ,alve

The pressure relief valve is a feedback compensated solenoid proportional relief valve which can be controlled by sending a @ to /@ 8 input signal to an amplifier card. This amplifier converts the signal into a pulsewidth modulated signal which is sent to the valve, much like in the proportional flow valve. )or modeling purpose a relationship between voltage input and pressure is re!uired as the proportional relief valve is operated by sending an input signal to an amplifier card which modulates the signal and passes it to the valve for appropriate functioning where there may be some caliberation error. )or which pressure reading of relief valve set at constant voltages of both 28 and <8 flow rates "corresponding to a flow of @.@@@@< l?sec and @.@@@. l?sec respectively#. Becorded over the range of @.9448 to ;.;/8 are taken from manufacturer manual. he calibration between the inp t !i"nal to the a#pli$ier car%& an% the re! ltin" !tea%' !tate h'%ra lic pre!! re wa! %eter#ine% e(peri#entall' a! ! ch) *+ The $low ,al,e wa! !et to a con!tant $low b' !en%in" it a con!tant ,olta"e $ro# the co#p ter+ Te!t! were r n with ,olta"e! o$ both - . an% / . 0corre!pon%in" to a $low o$ 1+1111/ l2!ec an% 1+1113 l2!ec re!pecti,el'4+

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

-+ The ,olta"e to the relie$ ,al,e wa! !et at a con!tant ,olta"e& the !tea%' !tate ,olta"e rea%in" $ro# the pre!! re tran!% cer wa! then recor%e%+ In "eneral the tran!ient re!pon!e o$ the pre!! re loo5e% li5e an n%er6%a#pe% -n% or%er !'!te#& with a ti#e %ela'+ 7+ The pre!! re wa! then increa!e% in incre#ent! which loo!el' corre!pon%e% to a pre!! re increa!e o$ *11 p!i 0a! %eter#ine% b' the #icroproce!!or8! open loop ,olta"e co##an%! to the a#pli$ier4& an% !tea%' !tate ,olta"e wa! recor%e% a"ain+ 9+ Thi! proce!! wa! %one $or both -. an% /. $low rate!& o,er the ran"e o$ 1+:99. to ;+;* .& corre!pon%in" to a pre!! re ran"e o$ *+1<e3 to *+</e< Pa+ The re! lt! o$ the!e te!t! can be !een in Table -+ (sing the results, a plot of the pressure response of the valve from @ ;.; 8 was created. This function was then simplified into two linear continuous functions which were used as the calibration between voltage input and steady state pressure in both the modeling and the e,perimental controller as well. The functions used are as follows:

3lots of the e,perimental results and the lineari$ed functions are found in )igure /:.

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

)rom the tests run, it was clear that the pressure could be controlled more accurately at low pressures when the flow rate was lower "the lower flow rate in the tests was around @.@@@@< l?sec which corresponded to a 2 8 input#, however, the machine is unable to create pressures above 6.4e. 3a with this low flow rate. 'ince the cavity pressure of the packing phase is normally around 9e. 3a for this si$e mold, the machine could not be operated at such

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

a low flow rate. *n order to be able to generate higher pressures, the flow rate had to be set higher, such as the @.@@@. l?sec corresponding to a < 8 input. 5t this higher flow rate, the machine was able to generate pressures as high as those generated with the flow valve completely open "/@ 8 output#, and still have acceptable control of low pressures.

The transient response of the pressure valve was modeled by a second order transfer function, the coefficients of the transfer function were determined empirically using plots of the e,perimental pressure response. The damping coefficient and natural fre!uency chosen from the e,perimental results were tweaked using the final model to make the simulated pressure react in the same way that the e,perimental pressure did.

DEPARTMENT OF MACHANICAL ENGINEERING

TUNING OF INJECTION MOLDING MACHINE

..1...! Ram Po&ition - Orifi$e Coeffi$ient

%y fi,ing the ram position, the assumption is made that there is no flow of hydraulic fluid in to the cylinders any longer. The affect of the orifice will change as the flow goes to $ero. To model this, the orifice coefficient was reduced until it was nearly $ero "ie. there was not flow through the orifice# this gave the results closest to the e,perimental pressure trace.

..1...' Com3ination of All Component&

Making the appropriate changes to the injection phase block diagram resulted in the following packing phase Matlab 'imulink block diagram ")igure /9#.

Simulink model

DEPARTMENT OF MACHANICAL ENGINEERING

Вам также может понравиться

- Some Aspects of Numerical Simulation of Control Valves For Steam TurbinesДокумент1 страницаSome Aspects of Numerical Simulation of Control Valves For Steam TurbinesSharat ChandraОценок пока нет

- REPORTpp 1Документ16 страницREPORTpp 1gajulavamshikrishna02Оценок пока нет

- Lab Manuals Fluid Mechanics-IIДокумент30 страницLab Manuals Fluid Mechanics-IISri E.Maheswar Reddy Assistant ProfessorОценок пока нет

- Energy Losses in BendsДокумент8 страницEnergy Losses in BendsVikramSingh0% (3)

- Control Valves - Modeling and Simulation: Cpatrascioiu@upg-Ploiesti - Ro C.panaitescu@gmail - Ro Nparaschiv@upg-PloiestiДокумент6 страницControl Valves - Modeling and Simulation: Cpatrascioiu@upg-Ploiesti - Ro C.panaitescu@gmail - Ro Nparaschiv@upg-PloiestiTimothy FieldsОценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Fluid Mechanics-II Lab Manual: University College of Engineering and TechnologyДокумент27 страницFluid Mechanics-II Lab Manual: University College of Engineering and Technologyzia malikОценок пока нет

- 2011 - Modeling and Simulation of Flow Field of Main Spool in Servo Valve - HaoДокумент4 страницы2011 - Modeling and Simulation of Flow Field of Main Spool in Servo Valve - Haoarm coreОценок пока нет

- TEP4195 TURBOMACHINERY VALVE CONTROLLED SYSTEMSДокумент15 страницTEP4195 TURBOMACHINERY VALVE CONTROLLED SYSTEMSCatalin PruncuОценок пока нет

- SS 09Документ3 страницыSS 09Ajaykumar TiwariОценок пока нет

- 20 - Pumps PDFДокумент6 страниц20 - Pumps PDFEmmanuel EvangelistaОценок пока нет

- Lab 5 - Operating Characteristics of A Centrifugal PumpДокумент9 страницLab 5 - Operating Characteristics of A Centrifugal PumpGianne Nigelle DoriaОценок пока нет

- Control Valve OcrДокумент14 страницControl Valve OcrpathakshashankОценок пока нет

- Volume (10) Issue (2) 160-173Документ14 страницVolume (10) Issue (2) 160-173abhisek haldarОценок пока нет

- chp 3& 6 ihp msdteДокумент10 страницchp 3& 6 ihp msdteRocky JОценок пока нет

- Coin Box Based Automatic WheelДокумент52 страницыCoin Box Based Automatic WheelAakash DindigulОценок пока нет

- Measure Minor Losses in Pipe FittingsДокумент26 страницMeasure Minor Losses in Pipe Fittingsdainer08Оценок пока нет

- PCV SizingДокумент8 страницPCV SizingKhanh PhamОценок пока нет

- Comsol Report FinalДокумент12 страницComsol Report FinalEsraaОценок пока нет

- PT18PCMTL5 - Applied Hydraulics & Pneumatics LabДокумент37 страницPT18PCMTL5 - Applied Hydraulics & Pneumatics LabvamshimohanОценок пока нет

- BMT7L1-Fluid Power Automation LabДокумент37 страницBMT7L1-Fluid Power Automation LabvamshimohanОценок пока нет

- Flow Analysis of Butterfly Valve Using CFDДокумент7 страницFlow Analysis of Butterfly Valve Using CFDIJMERОценок пока нет

- PumpДокумент25 страницPump최승원100% (1)

- CASE STUDY- SURGE ANALYSIS OF METHANOL PIPELINEДокумент12 страницCASE STUDY- SURGE ANALYSIS OF METHANOL PIPELINEchen junwenОценок пока нет

- Handout Water PumpДокумент7 страницHandout Water PumpGarrett KnappОценок пока нет

- Dinamica de Fluido Sucker Rod PumpДокумент26 страницDinamica de Fluido Sucker Rod PumpyeralhОценок пока нет

- Pneumatic Paper Cutting Machine CountingДокумент23 страницыPneumatic Paper Cutting Machine CountingManish Shetty100% (2)

- Flow Measurement in Closed ConduitДокумент65 страницFlow Measurement in Closed ConduitjohnmayardОценок пока нет

- Pressure Pulsation in Reciprocating Pump - Part 1Документ9 страницPressure Pulsation in Reciprocating Pump - Part 1Jose PradoОценок пока нет

- Ipr TPRДокумент6 страницIpr TPRsisiminkinОценок пока нет

- Total Head CalculationДокумент16 страницTotal Head CalculationZaid Al RayesОценок пока нет

- Hydraulic Study of GRE Piping Using Pipenet SimulationДокумент5 страницHydraulic Study of GRE Piping Using Pipenet SimulationpsycopaulОценок пока нет

- PrdsДокумент0 страницPrdssandi1111Оценок пока нет

- Numerical Flow Analysis of An Axial Flow PumpДокумент6 страницNumerical Flow Analysis of An Axial Flow Pumpbinho58Оценок пока нет

- HydraulicsДокумент65 страницHydraulicsMohsin EhsanОценок пока нет

- CE Hydraulics Laboratory Experiments and Computational LabsДокумент12 страницCE Hydraulics Laboratory Experiments and Computational LabsArman OlaОценок пока нет

- Dynamic Analysis of Proportional Solenoid Controlled Piloted Relief Valve by BondgraphДокумент18 страницDynamic Analysis of Proportional Solenoid Controlled Piloted Relief Valve by BondgraphmilligatorОценок пока нет

- Boiler Water LVL DP CellДокумент10 страницBoiler Water LVL DP CellParthiban Nagarajan100% (1)

- MIT-EL-80-017-09574615 Steam Bubble Collapse Water Hammer and Piping Network Response Volume 1 PDFДокумент51 страницаMIT-EL-80-017-09574615 Steam Bubble Collapse Water Hammer and Piping Network Response Volume 1 PDFhamadaniОценок пока нет

- ME Sessional ThermofluidДокумент9 страницME Sessional Thermofluidnadimduet1Оценок пока нет

- Centrifugal Pump Performance TestДокумент10 страницCentrifugal Pump Performance TestAnurag KashyapОценок пока нет

- International Journal of Pressure Vessels and Piping: ArticleinfoДокумент10 страницInternational Journal of Pressure Vessels and Piping: ArticleinfoMahdiОценок пока нет

- Aerodynamics Lab Manual III Year B.Tech (Aeronautical EngineeringДокумент50 страницAerodynamics Lab Manual III Year B.Tech (Aeronautical Engineeringshibin874141Оценок пока нет

- Fluid Flow Measurement and Analysis ExperimentДокумент11 страницFluid Flow Measurement and Analysis ExperimentJohn TomlinsonОценок пока нет

- SECTION 07 Hydraulics2 9020-9030Документ16 страницSECTION 07 Hydraulics2 9020-9030Vjz10997100% (2)

- Control Valves - Modeling and SimulationДокумент7 страницControl Valves - Modeling and SimulationErick Renzo Hidalgo OrtegaОценок пока нет

- Fluid Power Data BookДокумент64 страницыFluid Power Data BookAnand Gopinath25% (4)

- Need For Balancing ValvesДокумент12 страницNeed For Balancing ValvesBubai111Оценок пока нет

- EXAMPLE 5.2-1: Filling A Watering Tank: Table 1: Data From The Manufacturer's Pump CurveДокумент4 страницыEXAMPLE 5.2-1: Filling A Watering Tank: Table 1: Data From The Manufacturer's Pump CurveRohit Gadekar100% (1)

- Centrifugal pump lab experimentДокумент17 страницCentrifugal pump lab experimentKarla PerezОценок пока нет

- Objective of Experiment. Equipment Set-Up. Theory of Experiment. Procedure. Results & Calculations. Discussion of The Results. ConclusionДокумент11 страницObjective of Experiment. Equipment Set-Up. Theory of Experiment. Procedure. Results & Calculations. Discussion of The Results. ConclusionAmmar Al-AghbariОценок пока нет

- Piping SystemsДокумент5 страницPiping SystemsDesislavОценок пока нет

- Valve ModelingДокумент10 страницValve ModelingmsОценок пока нет

- Designing Steam Pressure Reducing StationsДокумент7 страницDesigning Steam Pressure Reducing StationsMohammed Hassan B KorainaОценок пока нет

- AMEE 310 LAB: PRESSURE DROP VS FLOW RELATIONSHIPДокумент12 страницAMEE 310 LAB: PRESSURE DROP VS FLOW RELATIONSHIPinfo5280Оценок пока нет

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- The Crystalline and Domain Properties ofДокумент9 страницThe Crystalline and Domain Properties ofgoldy243usОценок пока нет

- Modeling and Simulation of Wear in A Pin On Disc TribometerДокумент10 страницModeling and Simulation of Wear in A Pin On Disc Tribometergoldy243usОценок пока нет

- Operations Research Cutting Plane MethodsДокумент255 страницOperations Research Cutting Plane Methodsgoldy243usОценок пока нет

- The Crystalline and Domain Properties ofДокумент9 страницThe Crystalline and Domain Properties ofgoldy243usОценок пока нет

- Optical Layers Produced by SputteringДокумент12 страницOptical Layers Produced by Sputteringgoldy243usОценок пока нет

- The Thickness Uniformity of Films Deposited by Magnetron SputteringДокумент4 страницыThe Thickness Uniformity of Films Deposited by Magnetron Sputteringgoldy243usОценок пока нет

- Thermal Stability of Platinum Bottom ElectrodeДокумент10 страницThermal Stability of Platinum Bottom Electrodegoldy243usОценок пока нет

- Journal of Theoretical and Applied Mechanics 44Документ35 страницJournal of Theoretical and Applied Mechanics 44krishan_24Оценок пока нет

- The Ferroelectric Properties of (Na0.5K0.5) NbO3Документ7 страницThe Ferroelectric Properties of (Na0.5K0.5) NbO3goldy243usОценок пока нет

- Modeling Magnetron Sputter DepositionДокумент7 страницModeling Magnetron Sputter Depositiongoldy243usОценок пока нет

- PZT Thin-Film Meso - and Micro DevicesДокумент21 страницаPZT Thin-Film Meso - and Micro Devicesgoldy243usОценок пока нет

- United States Patent (191: Tsunekawa Et A1. (45) Date of PatentДокумент10 страницUnited States Patent (191: Tsunekawa Et A1. (45) Date of Patentgoldy243usОценок пока нет

- Journal of Theoretical and Applied Mechanics 44Документ35 страницJournal of Theoretical and Applied Mechanics 44krishan_24Оценок пока нет

- Thin Film Reaction of Transition Metals With GermaniumДокумент13 страницThin Film Reaction of Transition Metals With Germaniumgoldy243usОценок пока нет

- Fabrication and Characterization of Pb-Rich LeadДокумент8 страницFabrication and Characterization of Pb-Rich Leadgoldy243usОценок пока нет

- N Interface Broadening Due To Ion Mixing During Thin Film Growth at The Radio-FrequencybiasedДокумент10 страницN Interface Broadening Due To Ion Mixing During Thin Film Growth at The Radio-Frequencybiasedgoldy243usОценок пока нет

- Sputtering Pressure Effect On The Giant Magnetoresistance of FeCr SuperlatticesДокумент6 страницSputtering Pressure Effect On The Giant Magnetoresistance of FeCr Superlatticesgoldy243usОценок пока нет

- Fabrication of PZT Thin Films With TiOx BufferДокумент9 страницFabrication of PZT Thin Films With TiOx Buffergoldy243usОценок пока нет

- Impact of Tungsten Sputtering Condition On Magnetic andДокумент4 страницыImpact of Tungsten Sputtering Condition On Magnetic andgoldy243usОценок пока нет

- Quantitive Roughness of Sputtered Fe CR SuperlatticesДокумент7 страницQuantitive Roughness of Sputtered Fe CR Superlatticesgoldy243usОценок пока нет

- Synthesis of nanocrystalline δ-MoN by thermal annealing of amorphous thin filmsДокумент16 страницSynthesis of nanocrystalline δ-MoN by thermal annealing of amorphous thin filmsgoldy243usОценок пока нет

- Operations Research Cutting Plane MethodsДокумент255 страницOperations Research Cutting Plane Methodsgoldy243usОценок пока нет

- Spintronics Based Random AccessДокумент19 страницSpintronics Based Random Accessgoldy243usОценок пока нет

- Effect of Low Temperature Baking in Nitrogen On The PerformanceДокумент10 страницEffect of Low Temperature Baking in Nitrogen On The Performancegoldy243usОценок пока нет

- Design and Fabrication of A Lead ZirconateДокумент13 страницDesign and Fabrication of A Lead Zirconategoldy243usОценок пока нет

- Dielectric and Structural Properties of PST FilmsДокумент8 страницDielectric and Structural Properties of PST Filmsgoldy243usОценок пока нет

- Dependence of Ferroelectricity On Film ThicknessДокумент12 страницDependence of Ferroelectricity On Film Thicknessgoldy243usОценок пока нет

- Properties of Micropatterned PDFДокумент11 страницProperties of Micropatterned PDFgoldy243usОценок пока нет

- Ion-Induced Spike Effects On Metal SurfacesДокумент14 страницIon-Induced Spike Effects On Metal Surfacesgoldy243usОценок пока нет

- Pulsed Laser Deposition of PDFДокумент7 страницPulsed Laser Deposition of PDFgoldy243usОценок пока нет

- NX569J User ManualДокумент61 страницаNX569J User ManualHenry Orozco EscobarОценок пока нет

- Energy Efficient Solar-Powered Street Lights Using Sun-Tracking Solar Panel With Traffic Density Monitoring and Wireless Control SystemДокумент9 страницEnergy Efficient Solar-Powered Street Lights Using Sun-Tracking Solar Panel With Traffic Density Monitoring and Wireless Control SystemIJRASETPublicationsОценок пока нет

- STAR Worksheet Interviewing SkillsДокумент1 страницаSTAR Worksheet Interviewing SkillsCharity WacekeОценок пока нет

- Fault Tree AnalysisДокумент5 страницFault Tree AnalysisKrishna Kumar0% (1)

- GR 5 Unit Plan 18-19 Art Warli ArtДокумент4 страницыGR 5 Unit Plan 18-19 Art Warli ArtSanjay RautОценок пока нет

- Solar PV Array Modelling PDFДокумент13 страницSolar PV Array Modelling PDFsunilkumarece100% (1)

- Pedestrian Safety in Road TrafficДокумент9 страницPedestrian Safety in Road TrafficMaxamed YusufОценок пока нет

- Finger Relaxation Technique Reduces Post-Appendectomy PainДокумент13 страницFinger Relaxation Technique Reduces Post-Appendectomy PainIan ClaxОценок пока нет

- Roman Questions II PDFДокумент738 страницRoman Questions II PDFjlinderski100% (3)

- Watershed Management A Case Study of Madgyal Village IJERTV2IS70558Документ5 страницWatershed Management A Case Study of Madgyal Village IJERTV2IS70558SharadОценок пока нет

- Es E100091 Pi PDFДокумент1 страницаEs E100091 Pi PDFCarlos Humbeto Portillo MendezОценок пока нет

- Date ValidationДокумент9 страницDate ValidationAnonymous 9B0VdTWiОценок пока нет

- Advance Control Systems LabДокумент2 страницыAdvance Control Systems Labpadmajasiva100% (1)

- Blank Character StatsДокумент19 страницBlank Character Stats0114paolОценок пока нет

- C code snippets with answersДокумент14 страницC code snippets with answersqwerty6327Оценок пока нет

- CH13 QuestionsДокумент4 страницыCH13 QuestionsAngel Itachi MinjarezОценок пока нет

- Moment Baseplate DesignДокумент10 страницMoment Baseplate DesignNeil JonesОценок пока нет

- 07CRMДокумент81 страница07CRMsangramlifeОценок пока нет

- Finance Process Optimization - Mapping The Journey To High PerformanceДокумент3 страницыFinance Process Optimization - Mapping The Journey To High PerformanceStephen G. LynchОценок пока нет

- Sublime QR CodeДокумент6 страницSublime QR Codejeff_sauserОценок пока нет

- Carnot CycleДокумент3 страницыCarnot CyclealexontingОценок пока нет

- Agricultural Typology Concept and MethodДокумент13 страницAgricultural Typology Concept and MethodAre GalvánОценок пока нет

- COS1512 202 - 2015 - 1 - BДокумент33 страницыCOS1512 202 - 2015 - 1 - BLina Slabbert-van Der Walt100% (1)

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankДокумент15 страницRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- What Is Science Cornell Notes ExampleДокумент3 страницыWhat Is Science Cornell Notes Exampleapi-240096234Оценок пока нет

- Growing Up Psychic by Chip Coffey - ExcerptДокумент48 страницGrowing Up Psychic by Chip Coffey - ExcerptCrown Publishing Group100% (1)

- Worksheet 9-2 - Math 7Документ2 страницыWorksheet 9-2 - Math 7bfbrfvlfrerОценок пока нет

- The God Complex How It Makes The Most Effective LeadersДокумент4 страницыThe God Complex How It Makes The Most Effective Leadersapi-409867539Оценок пока нет

- Clinic Management System (24 PGS)Документ24 страницыClinic Management System (24 PGS)pranithОценок пока нет

- Grillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종Документ8 страницGrillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종tyuОценок пока нет